5 minute read

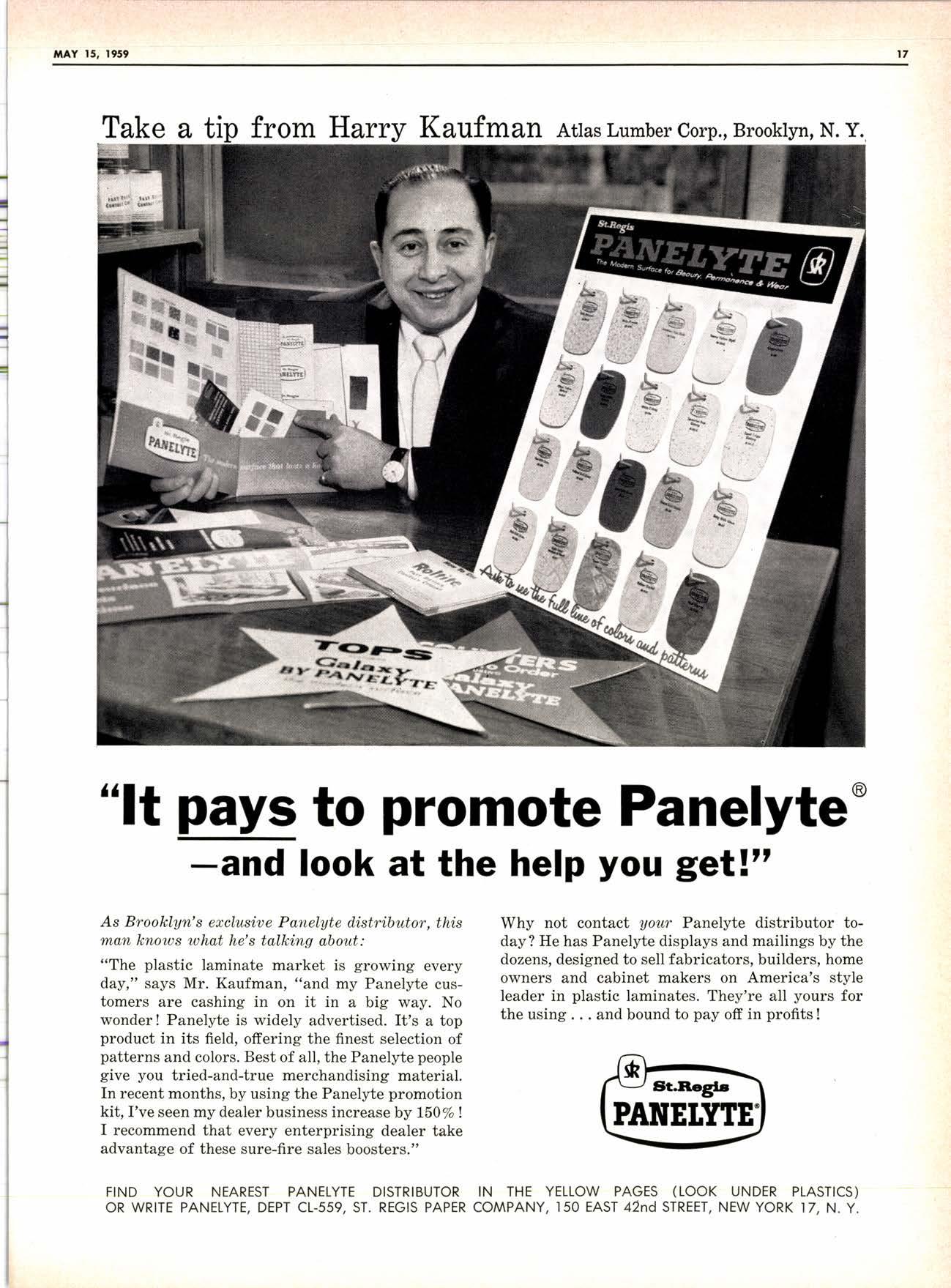

"lt pays to promote Panelyte' -and look at the help you get!"

As Brooklyn's enclusiae Panelyte distributor, this mon knows uhat he's talking about:

"The plastic laminate market is growing every day," says Mr. Kaufman, "and my Panelyte customers are cashing in on it in a big way. No wonder ! Panelyte is widely advertised. It's a top product in its field, offering the finest selection of patterns and colors. Best of all, the Panelyte people give you tried-and-true merchandising material. In recent months, by using the Panelyte promotion kit, I've seen my dealer business increase by L50%t I recommend that every enterprising dealer take advantage of these sure-fire sales boosters."

Why not contact 'your Panelyte distributor today? He has Panelyte displays and mailings by the dozens, designed to sell fabricators, builders, home owners and cabinet makers on America's style leader in plastic laminates. They're all yours for the using. and bound to pay off in profits!

IHPA Stotes lts Cose in Tqriff Gommission Heorings

The Imported Hardwood Plywood Association presented its case before the U.S. Tariff Commission in Washington, D.C., last month, answering charges brought against the association by the Hardwood Plywood Institute. Six directors of IHPA attended the hearing as observers and advisors, and one director, Jack Davidson of Pacific Wood Products Co., testified.

The other IHPA directors present at the hearings were H. Rainer, president IHPA, of East Asiatic Co.; Charlie Schmitt, 2nd vice-president of IHPA, of Atkins, Kroll & Co.; IHPA past president Bob Reid, of Ziel & Co.; past president Grant Hellar, of Heidner & Co., and Tom Parker of Getz Bros.

In addition to Davidson, testifying in behalf of IHPA

Qualily Redwood

were E. M. "Bud" Critchfield, California Wood Products, Inc.; Francis Haley, Haley Bros; Larry Flahive, Plywall Products Co.; Edward Eichler, Eichler Homes, Inc. ; John Mercier, Ray Hill Lumber Co., Jack Carlow, counsel for the Southern California Door Institute; Gerrald Saperstein, Saperstein Plywood Co., Philadelphia; Herbert W. Robinson, C-E-f-R, fnc., Washington, D.C.; Al Theis, Miratile Co., Chicago; Sam David, David Plywood Co., Chicago; Itichard J. Harper, American Wood Products International Corp., Bayside, N. Y.; and Robert Wallace, Wallace Manufacturing Co., Kansas City, Mo.

Washington, D.C., April l4-Hearings on the first major, industry-wide investigation of the injury reportedly done domestic manufacturers by excessive imports to be conducted under the 1958 revision of the Escipe Clause of the Trade Agreements Act opened today before the United States Tariff Commission, it was announced by Robert N. llawes, general counsel of the Hardwood Plywood Institue, petitioners in the case.

Testimony supporting the domestic industry was presented to the Commission by senators and representatives from widespread sections of the country. Congressional witnesses included Senators Thurmond (D-S.C.) and Wiley (R-Wis.) and Representatives Blitch (D-Ga.), Byrnes (R-Wis.), Dorn (D-S.C.), Laird (R-Wis.), and Mack (R-Wash.).

"This is a test case for all American industries suffering from low-wage foreign competition," Hawes pointed out. "It will reveal whether the Escape Clause, as now written, offers a significant avenue of relief to a nation-wide industry group, such as the hardwood plywood industry."

The Institute, representing 48 American manufacturers, l-rad petitioned the Tariff Commission in January to establish a quota on hardwood plywood imports under the terms of the so-called Escape Clause. The Commission ordered an investigation of the problem which was the subject of today's hearing.

. A year-end report of the Forest Products Division, Business and Defense Services Administration. U.S. Deoartment of Commerce, was used to show the domestic industry's plight and predict that the downward trend in American production rvill continue through 1959, HPI disclosed.

The petition filed by HPI traced most of the industry's trouble to imports from Japan, whose share of the American market jumped lrom I.5,4o in 1951 to almost 40/o in 1958. Four-fifths of the hardwood plywood imported into the LTnited States comes from Japan, HPI noted. Imports from Japan alone equal 84/o oI total domestic output.

Total imports in 1958 exceeded 900 million square feet, about 117 million square feet more than American factoriei produced, the Institute reported. It said imports have gained 36/o since 1955, and I,157% since 1951, when Japan began its spectacular climb to become the world's biggest hardwood plywood producer and exporter.

United States consumDtion of hardwood plvwood has

UNLIMITED StlURCE OF

SUPPLY o lmpofied qnd Domestic Hcrdwoods ond Softwoods for Every purpose o All Species of Fine Cobinet Woods o Inferior Poneling-All Species o Old-Growrh Douglos Fir from R.oss lumber Mills, Medford, Oregon

. Door Gosings ond Stops Pockoged in Sets

' Speciol Selection for Speciol Requirements-Widrhs, lengths, Colors o Over Nine Yeqrs' Dependoble Service fo Retoil Lumber Deolers

' Modern New Focilities for F-A-S-T DEUVERy qnd plcK-up

JUST /tfrNUfES lrom rhe SANIA ANA FREEWAYwith FAgr Dt[fvERY to ALL soufhern calilornio cities ondTowns r950

Sreody Growrh Through Speciol Service to Retqil Lumber Deqlers

8725 Cleto Street - DOWNEY, Colifornio; p.O. Box 4g FOR ''ABSOLUTELY NOTH'NG BUT fHE BESr''

CALL: SPruce 3-l9lO nearly doubled since 1952, but the domestic industry's production has decreased, Attorney Hawes pointed out. American producers shipped 792 million square feet in 1958, continuing a decline that began in 1955 ; it was the industry's second worst year since 1951, Hawes observed.

The petition pointed out that profits realized by domestic manufacturers of hardwood plywood have also been hard hit by imports. In 1955, the average profits on sales before taxes for Institute members was 5.77/o.In 1956 this figure declined to 3.35/o in 1957 to 0.44/o; and in 1958 these manufacturers suffered a loss of l.29%o.

Japanese prices, reflecting that country's wage levels, were alleged to have forced cutbacks in imports from other countries. Canada's share of the American hardwood plywood market has dropped 50/o, and imports from countries other than Japan declined 44 million square feet from 1955 to 1957. thev claimed.

In 19'57 the average price per 1,000 square feet of Japanese hardwood plywood was $65.13, HPI said, while the average price of imports from other countries was $110.39. By August 1958, other countries had slashed their average price to $6.76 per 1,000 square feet in efforts to meet TaDanese competition.

Fallacy of Figures Shown

Testifying before the United States Tariff Commission in the hearing instituted by the domestic hardwoo_d plyyqod industiy, Jack Davidson, executive vice-president -of Pacific Wood Products Co. of Los Angeles, said that whatever difficulties the domestic industry was undergoing, they were not caused by imports but by other factors within the United States.

He listed five domestic products which have greatly increased in use during the past few years:

(1) Hardboard consumption in-the United :3t::11; increased from 1951 to 1958 by some 800,000,000 rncreased trom ly5r to ryJ6 Dy 6t J,u\ J'( ^r square feet. This product is used largely for the same purposes as is plywood and by the same three indusiries, namely, the construction industry, the furniture industry and the mobile home industry.

(2) The Chipboard industry had a total production in 1956 of 83.000.000 square feet and in 1958 183,000,000 square feei, an incrdase of approximately 125/o. This pioduct is also replacing plywood in the same fields as hardboard.

(3) Mr. Davidson cited the recent growth of the so-called ' prefinishing business and pointed out that where faneling r.ias done on the job it cost considerable money,-but now when it is merely a question of installing a prefinished panel, this can be done at considerably less expense.

(4) Mr. Davidson said that a whole new industry had ' developed in the United States in the so-called pri-nr ing or^lithographing of hardwood-plywood .and.that this industry is supplyin1 80% of the needs of the mobile home industry for interior decorations.

(5) The fifth development which is affecting the domestic hardwood plywood industry is the great growth of the hardwood plvwood industry in the Pacific Northwest, which-was 417,000,000 square feet in 1958, which on a converted basis as far as Japanese imports of plywood are concerned, is more than the 1958 Japanese imports.

Mr. Davidson paid tribute to the Japanese plywood industrv and the Ta-panese Government for their efforts to put into effect a woikable export quota system. This system has been in effect since April 1 of this year and, Mr. Davidson believes, should solve many of the problems about r,vhich the domestic industry has been complaining.