3 minute read

CPR 122---Ceiling Prices for Western Softwood Plywood and Yeneer

The Office of Price Stabilization today announced dollarsand-cents ceilings on direct mill sales of standard grades and dimensions of softwood plywood and Douglas fir veneer produced west of the 1O5th meridian, and provided means for pricing special items manufactured in that area.

The ceilings are prescribed in Ceiling Price Regulation 122, effective February 4, 1952, and apply only to sales in the continental United States.

The specified production area is roughly that part of the United States west of the Rocky Mountains.

Plywood is widely used in construction, cabinet rvork, mill work and packaging, and is in demand in marine construction, and by electronics industries and other war industries. It is made of three or more plies or laminations of veneer glued together with the grain of alternate plies running at right angles.

The new regulation conforms with the OPS program of issuing tailored dollars-and-cents regulations as expeditiously as possible for all industries where they are appropriate.

Spelled out ceilings are provided for standard grades and dimensions of plywood made of Douglas fir, West Coast hemlock, noble fir, r,vhite fir, ponderosa pine, Idaho pine, sugar pine, u'estern red cedar, redwood, Engelmann spruce and Sitka spruce. Douglas fir is the species predominantly used.

The general level of prices established is approximately equal to the level prevailing during the period from January 25 to February 24,1951.

The plywood industry in the area concerned produces nearly 3,000,000,000 surface feet annually, valued at about $300,000,000. A surface foot is a piece of plvrvood /{ of an inch thick, one foot square, and is a measurement unit for the plywood industry comparable to the board foot measurement in the lumber industry.

The plywood industry employs about 20,000 factory workers r.vhose aggregate pay approximates $100,000,000 annually.

There are about 80 plyrvood mills in the area covered, most of rvhich are integrated, manufacturing both veneer and pl1'wood. The veneers run from l/10 to 1/5th of an inch in thickness, and are rotary-cut, or "peeled" from logs.

Some 16 to 20 "green end" veneer mills only peel, cut and grade green veneer for shipment to plywood mills. A fs11' plywood rnills depend entirely on purchased veneer.

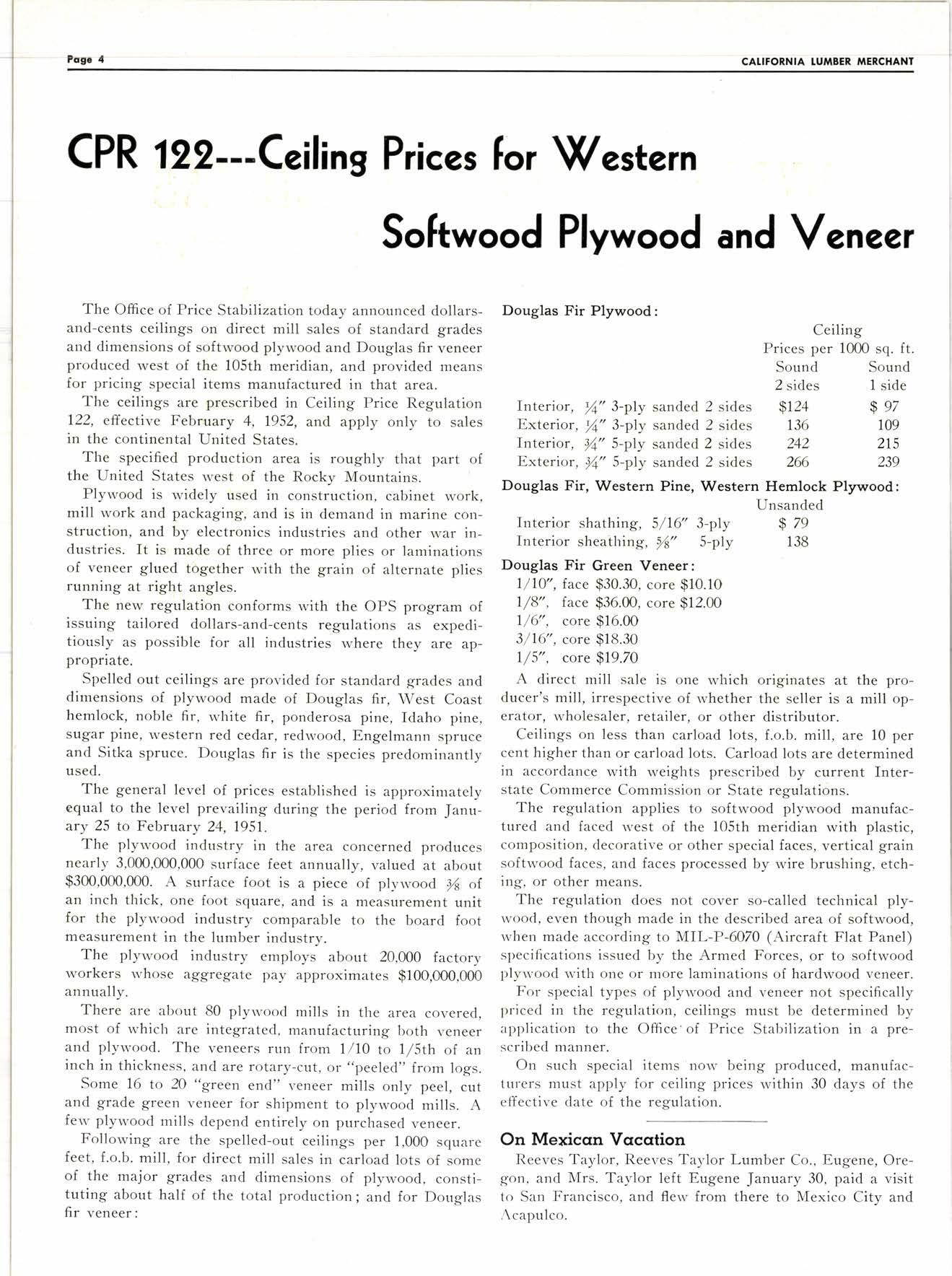

Following are the spelled-out ceilings per 1,000 square feet, f.o.b. mill, for direct mill sales in carload lots of some of the major grades and dimensions of plywood, constituting about half of the total production ; and for Douglas fir veneer:

Douglas Fir Plywood:

Ceiling Prices per 1000 sq. ft. Sound Sound 2 sides I side

Interior, t/q" 3-ply sanded 2 sides $124 $ 97

Exterior, %" 3-ply sanded 2 sides 136 109

Interior, %" S-ply sanded 2 sides 242 215

Exterior, %" S-ply sanded 2 sides 266 239

Douglas Fir, Western Pine, Western Hemlock Plywood: Unsanded

Interior shathing, 5/IA'3-ply $ 79

Interior sheaLhing, sf" 5-ply 138

Douglas Fir Green Veneer: l/10', face $30.30, core 910.10

1/8', face $36.00, core 912.00 l/6,', core $16.0O

3/76", core 918.30

I/5', core $19.70

A direct mill sale is one which originates at the producer's mill, irrespective of rvhether the seller is a mill operator, l'i'holesaler, retailer, or other distributor.

Ceilings on less than carload lots, f.o.b. mill, are 10 per cent higher than or carload lots. Carload lots are determined in accordance with weights prescribed by current Interstate Commerce Commission or State regulations.

The regulation applies to softwood plywood manufactured and faced rvest of the 105th meridian with plastic, composition, decorative or other special faces, vertical grain softwood faces, and faces processed by wire brushing, etching, or other means.

The regulation does not cover so-called technical plywood, even though made in the described area of softwood, when made according to MIL-P-6070 (Aircraft Flat Panel) specifications issued by the Armed Forces, or to softwood plyrvood rvith one or more laminations of hardwood veneer.

For special types of plywood and veneer not specifically priced in the regulation, ceilings must be determined by application to the Offrce'of Price Stabilization in a prescribed manner.

On such special items norv being produced, manufacturers must apply for ceiling prices within 30 days of the effective date of the regulation.

On Mexiccn Vacqtion

Reeves Taylor, Reerres Taylor Lumber Co., Eugene, Oregon, and Mrs. Taylor left Eugene January 30, paid a visit to San Francisco, and fle.lv from there to Mexico City and Acaoulco.