4 minute read

VTAFERBOARD letween Louisiana-Pacific and herits of the structural panel each 1nd Louisiana-Pacific with its Wafenruood Oriented Strand Board gains industry respect

By H.R. Hutchins Potlatch Corp.

Ai:*xl;{T:J!::n:ffi'i;

structural building panels and three points consistently lead the list: performance, cost savings and minimum claims.

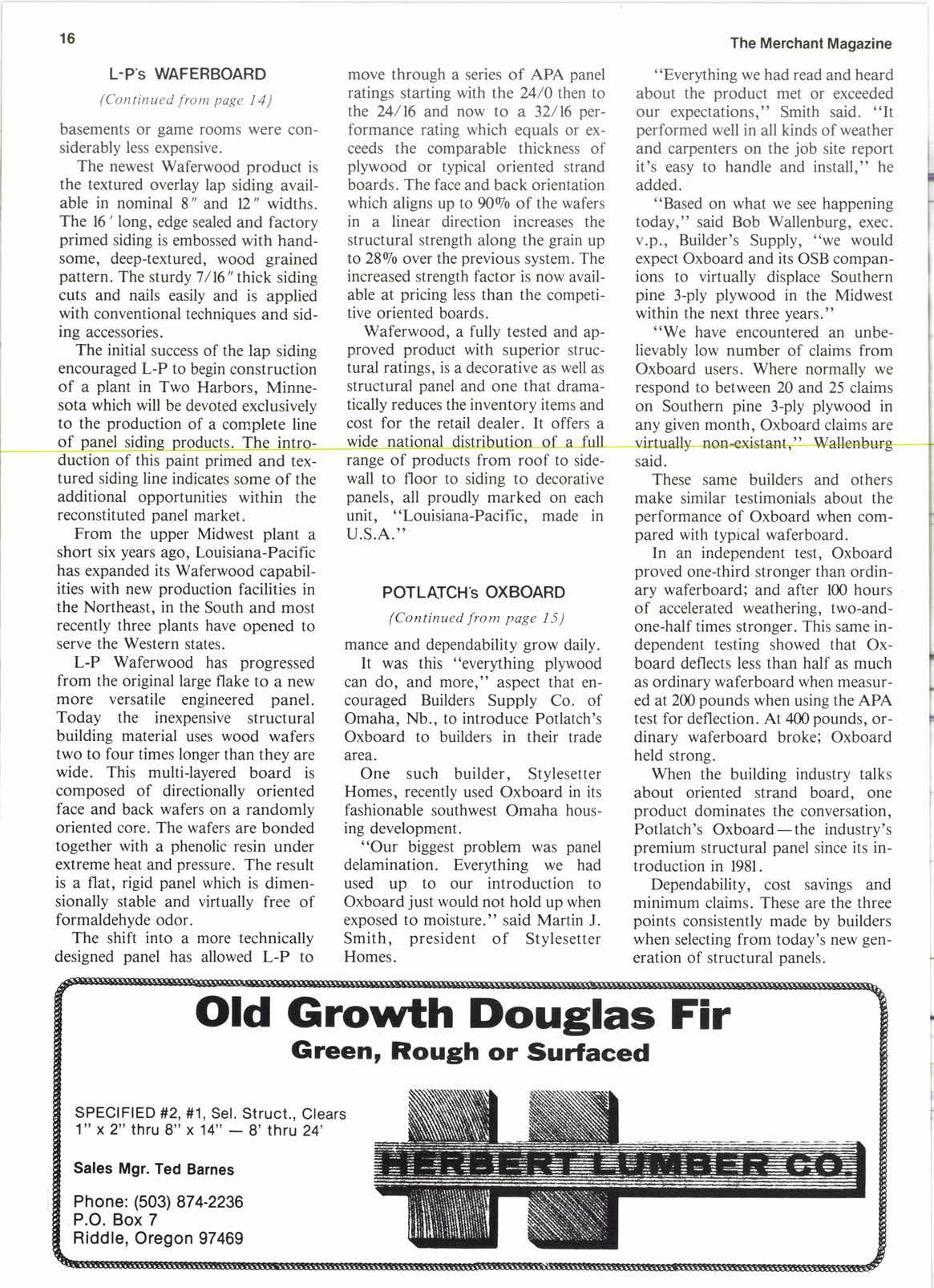

tBuilders nationwide more and more are pointing with growing satisfaction to a new structural panel that delivers on all three points, and more. The product is oriented strand board (OSB), an engineered structural panel designed to perform. Unlike the random wafers in ordinary waferboard, the strands of wood in OSB are oriented at right angles, layer by layer, for greater strength and stiffness.

An industry leader in the introduction of this innovative structural panel is Potlatch, a diversified forest products company with extensive timberlands and manufacturing operations nationwide.

Potlatch was the first major forest products company to bring OSB into the marketplace with the l98l startup of a 150 million-sq. ft. (3/8" basis) production facility at Bemidji, Mn.

Introduced under the imaginative tradename of Oxboard. this new fivelayer, structural panel quickly gained the attention of builders throughout mid-America. Today it is considered the premium OSB on the market.

In 1983, a second Potlatch Oxboard plant began production at Cook, Mn., giving the company annual pro- duction capacity of more than 300 million sq. ft. (3/8 " basis).

Why Oxboard? This new structural panel carries an American Plywood Association performance rating, which means it can replace plywood for sheathing, subfloor and roof decking at a price competitive with plywood. But more important, Oxboard is superior, performance-wise, to plywood and ordinary waferboard. Oxboard doesn't have knotholes or core voids and it never delaminates.

Rudy Trone, a Minneapolis, Mn., builder says it best, "Oxboard does everything plywood can do, and more.tt

"It spans the same distances as plywood. Each panel is uniform, dimensionally stable and without voids. And Sturd-I-Floor rated panels are tongue-and-grooved to eliminate the need for blocking," Trone adds.

The strongest arguments for Oxboard and OSB come from the industry's builders and materials dealers themselves. Testimonials on perfor-

(Please turn to page 16)

Story at a Glance

On this page, Pollatch presents Oxboard's features and benefits, including dependability, cost savings and minimum claims. . .highlights include their feelings as to its "greater strength" in independent tests.

DESIGNED to compete head on with plywood and other structural panels, manufacturer Potlatch claims its panels beat the competition in strength, stiffness, weight and dimensional stabilitv. i{ARR()W strands of wood, seen here in raw form, are aligned in layers during the manufacluring process. Alternate layers of 0SB are perpendicular and bonded with phenolic resin for strength.

L-Ps WAFERBOARD

(Continued from page I4) basements or game rooms were considerably less expensive.

The newest Waferwood product is the textured overlay lap siding available in nominal 8 " and 12 " widths. The 16' long, edge sealed and factory primed siding is embossed with handsome, deep-textured, wood grained pattern. The sturdy 7/16 " thick siding cuts and nails easily and is applied with conventional techniques and siding accessories.

The initial success of the lap siding encouraged L-P to begin construction of a plant in Two Harbors, Minnesota which will be devoted exclusively to the production of a complete line sidi uction of this paint primed and textured siding line indicates some of the additional opportunities within the reconstituted panel market.

From the upper Midwest plant a short six years ago, Louisiana-Pacific has expanded its Waferwood capabilities with new production facilities in the Northeast, in the South and most recently three plants have opened to serve the Western states.

L-P Waferwood has progressed from the original large flake to a new more versatile engineered panel. Today the inexpensive structural building material uses wood wafers two to four times longer than they are wide. This multilayered board is composed of directionally oriented face and back wafers on a randomly oriented core. The wafers are bonded together with a phenolic resin under extreme heat and pressure. The result is a flat, rigid panel which is dimensionally stable and virtually free of formaldehyde odor.

The shift into a more technically designed panel has allowed L-P to move through a series of APA panel ratings starting with the 24/0 then to the 24/16 and now to a 32/16 performance rating which equals or exceeds the comparable thickness of plywood or typical oriented strand boards. The face and back orientation which aligns up to 9090 of the wafers in a linear direction increases the structural strength along the grain up b 28qo over the previous system. The increased strength factor is now available at pricing less than the competitive oriented boards.

Waferwood, a fully tested and approved product with superior structural ratings, is a decorative as well as structural panel and one that dramatically reduces the inventory items and cost for the retail dealer. It offers a range of products from roof to sidewall to floor to siding to decorative panels, all proudly marked on each unit, "Louisiana-Pacific, made in u.s.A."

POTLATCH's OXBOARD

(Continued from page 15) mance and dependability grow daily.

It was this "everything plywood can do, and more," aspect that encouraged Builders Supply Co. of Omaha, Nb., to introduce Potlatch's Oxboard to builders in their trade area,

One such builder, Stylesetter Homes, recently used Oxboard in its fashionable southwest Omaha housing development.

"Our biggest problem was panel delamination. Everything we had used up to our introduction to Oxboard just would not hold up when exposed to moisture." said Martin J. Smith, president of Stylesetter Homes.

"Everlthing we had read and heard about the product met or exceeded our expectations," Smith said. "It performed well in all kinds of weather and carpenters on the job site report it's easy to handle and install," he added.

"Based on what we see happening today," said Bob Wallenburg, exec. v.p., Builder's Supply, "we would expect Oxboard and its OSB companions to virtually displace Southern pine 3-ply plywood in the Midwest within the next three years."

"We have encountered an unbelievably low number of claims from Oxboard users. Where normally we respond to between 20 and 25 claims on Southern pine 3-ply plywood in any given month, Oxboard claims are said.

These same builders and others make similar testimonials about the performance of Oxboard when compared with typical waferboard.

In an independent test, Oxboard proved one-third stronger than ordinary waferboard; and after 100 hours of accelerated weathering, two-andone-half times stronger. This same independent testing showed that Oxboard deflects less than half as much as ordinary waferboard when measured at 200 pounds when using the APA test for deflection. At 400 pounds, ordinary waferboard broke; Oxboard held strong.

When the building industry talks about oriented strand board, one product dominates the conversation, Potlatch's Oxboard-the industry's premium structural panel since its introduction in 1981.

Dependability, cost savings and minimum claims. These are the three points consistently made by builders when selecting from today's new generation of structural panels.