3 minute read

$rl $ll Selling the proper nail

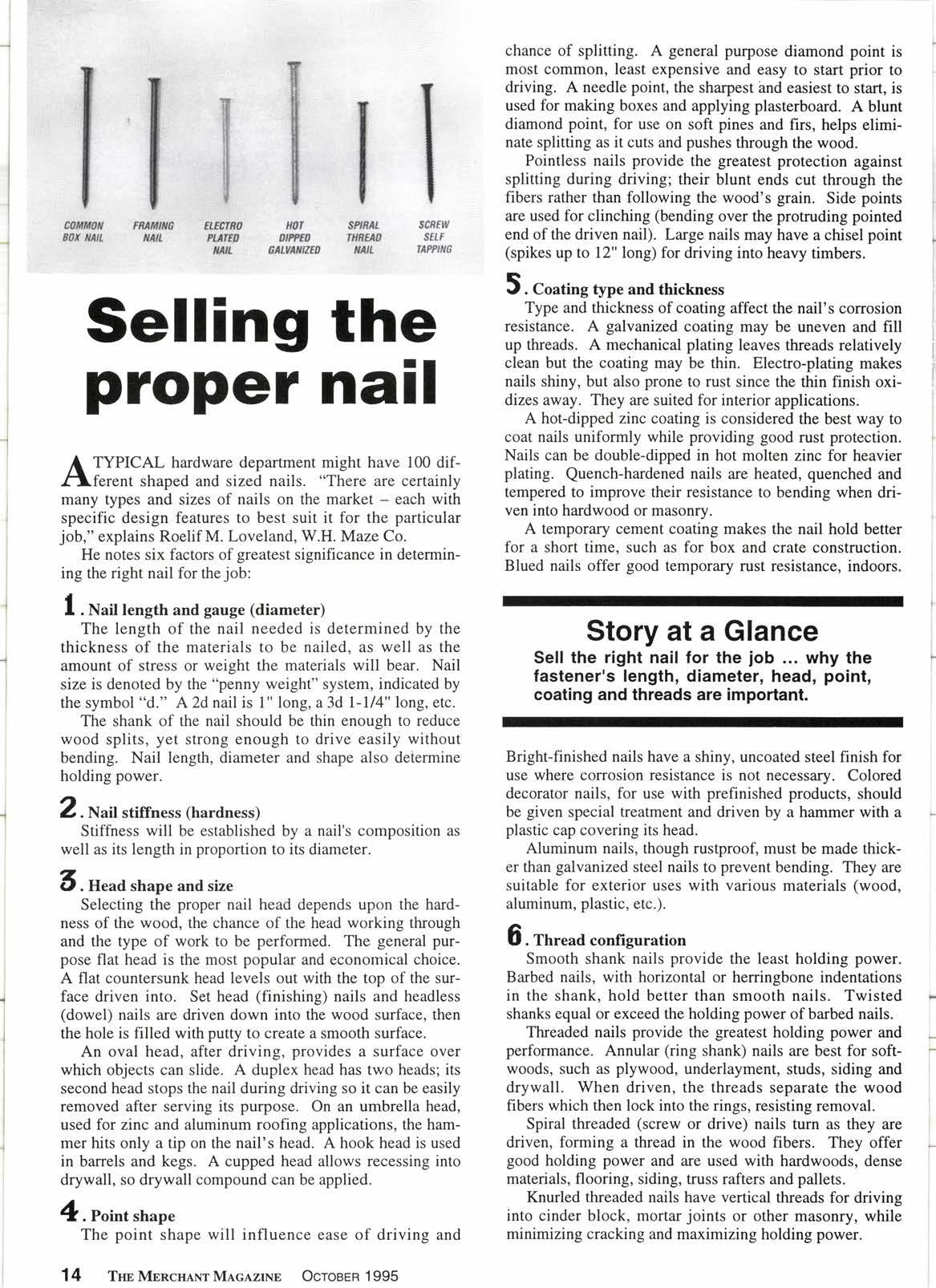

A TYPICAL hardware department might have 100 diflA.ferent shaped and sized nails. "There are certainly many types and sizes of nails on the market - each with specific design features to best suit it for the particular job," explains Roelif M. Loveland, W.H. Maze Co.

He notes six factors of greatest significance in determining the right nail for thejob:

f I Nail length and gauge (diameter)

The length of the nail needed is determined by the thickness of the materials to be nailed, as well as the amount of stress or weight the materials will bear. Nail size is denoted by the "penny weight" system, indicated by the symbol "d." A 2d nail is 1 " long, a 3d 1-l/4" long, etc.

The shank of the nail should be thin enough to reduce wood splits, yet strong enough to drive easily without bending. Nail length, diameter and shape also determine holding power.

2 N^itstiffness (hardness)

Stiffness will be established by a nail's composition as well as its length in proportion to its diameter.

a, O. Head shape and size

Selecting the proper nail head depends upon the hardness of the wood, the chance of the head working through and the type of work to be performed. The general purpose flat head is the most popular and economical choice. A flat countersunk head levels out with the top of the surface driven into. Set head (finishing) nails and headless (dowel) nails are driven down into the wood surface, then the hole is filled with putty to create a smooth surface.

An oval head, after driving, provides a surface over which objects can slide. A duplex head has two heads; its second head stops the nail during driving so it can be easily removed after serving its purpose. On an umbrella head, used for zinc and aluminum roofing applications, the hammer hits only a tip on the nail's head. A hook head is used in barrels and kegs. A cupped head allows recessing into drywall, so drywall compound can be applied.

4. Poior rhup"

The point shape will influence ease of driving and 14

Ocroaen1995 chance of splitting. A general purpose diamond point is most common, least expensive and easy to start prior to driving. A needle point, the sharpest hnd easiest to start, is used for making boxes and applying plasterboard. A blunt diamond point, for use on soft pines and firs, helps eliminate splitting as it cuts and pushes through the wood.

Pointless nails provide the greatest protection against splitting during driving; their blunt ends cut through the fibers rather than following the wood's grain. Side points are used for clinching (bending over the protruding pointed end of the driven nail). Large nails may have a chisel point (spikes up to 12" long) for driving into heavy timbers.

J. Coating type and thickness

Type and thickness ofcoating affect the nail's corrosion resistance. A galvanized coating may be uneven and fill up threads. A mechanical plating leaves threads relatively clean but the coating may be thin. Electro-plating makes nails shiny, but also prone to rust since the thin finish oxidizes away. They are suited for interior applications.

A hot-dipped zinc coating is considered the best way to coat nails uniformly while providing good rust protection. Nails can be double-dipped in hot molten zinc for heavier plating. Quench-hardened nails are heated, quenched and tempered to improve their resistance to bending when dri ven into hardwood or masonry.

A temporary cement coating makes the nail hold better for a short time, such as for box and crate construction. Blued nails offer good temporary rust resistance, indoors.

Story at a Glance

Sell the right nail for the iob ... why the fastener's length, diameter, head, point, coating and threads are important.

Brighrfinished nails have a shiny, uncoated steel finish for use where corrosion resistance is not necessary. Colored decorator nails, for use with prefinished products, should be given special treatment and driven by a hammer with a plastic cap covering its head.

Aluminum nails, though rustproof, must be made thicker than galvanized steel nails to prevent bending. They are suitable for exterior uses with various materials (wood, aluminum, plastic, etc.).

O. Thread configuration

Smooth shank nails provide the least holding power. Barbed nails, with horizontal or herringbone indentations in the shank, hold better than smooth nails. Twisted shanks equal or exceed the holding power of barbed nails.

Threaded nails provide the greatest holding power and performance. Annular (ring shank) nails are best for softwoods, such as plywood, underlayment, studs, siding and drywall. When driven, the threads separate the wood fibers which then lock into the rings, resisting removal.

Spiral threaded (screw or drive) nails turn as they are driven, forming a thread in the wood fibers. They offer good holding power and are used with hardwoods, dense materials, flooring, siding, truss rafters and pallets.

Knurled threaded nails have vertical threads for driving into cinder block, mortar joints or other masonry, while minimizing cracking and maximizing holding power.