3 minute read

e I ln fl HI gh

SOLID wood flooring is more than IJan attractive covering; it adds strength and stability to the floor sys-

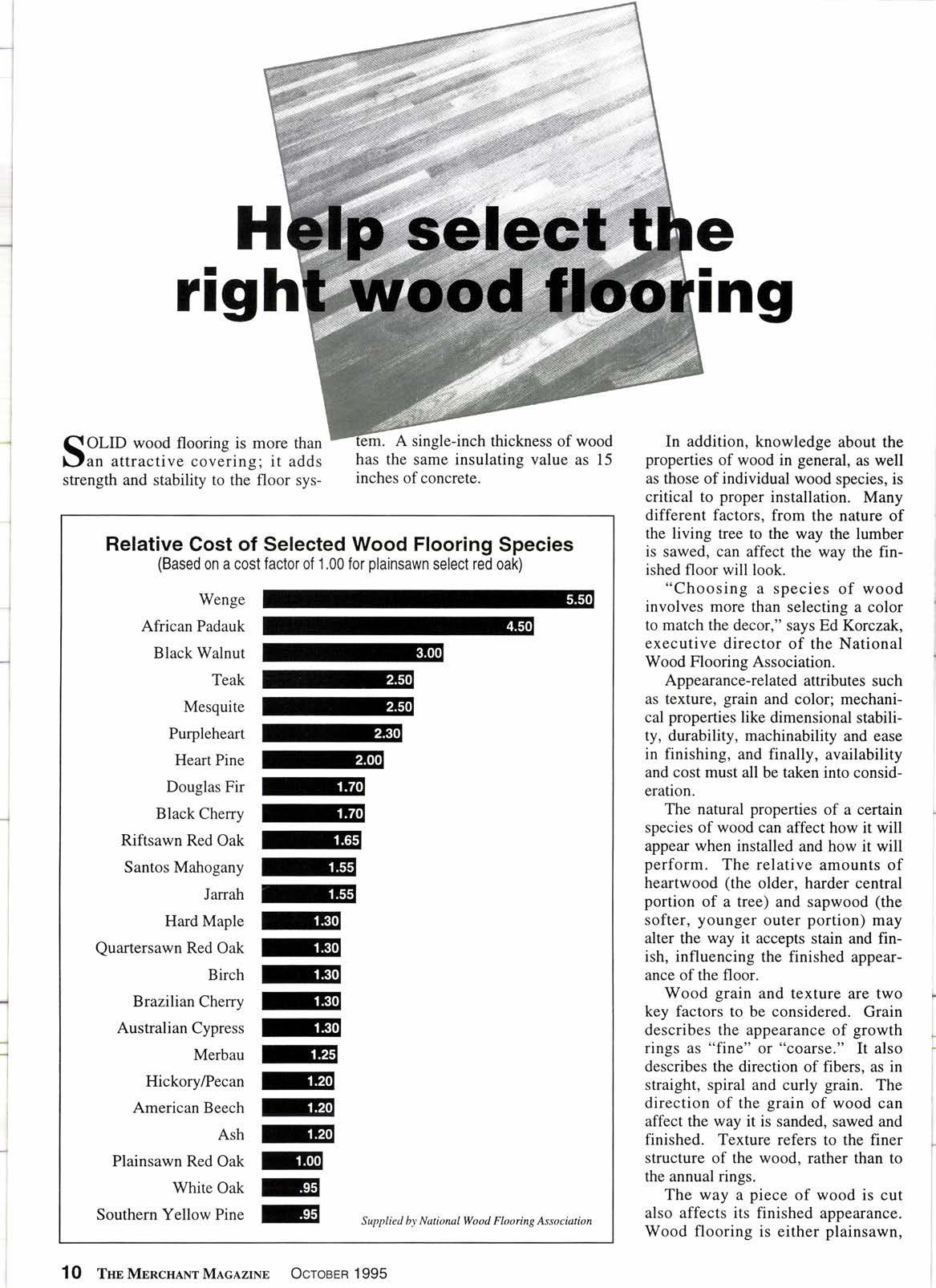

Relative Cost of Selected Wood Flooring Species

Wenge

African Padauk

Black Walnut

Teak

Mesquite

Purpleheart

Heart Pine

Douglas Fir

Black Cherry

Riftsawn Red Oak

Santos Mahogany

Jarrah

Hard Maple

Quartersawn Red Oak

Birch

Brazilian Cherry

Australian Cypress

Merbau

Hickory/Pecan

American Beech Ash

Plainsawn Red Oak

White Oak

Southern Yellow Pine

In addition, knowledge about the properties of wood in general, as well as those ofindividual wood species, is critical to proper installation. Many different factors, from the nature of the living tree to the way the lumber is sawed, can affect the way the finished floor will look.

"Choosing a species of wood involves more than selecting a color to match the decor," says Ed Korczak, executive director of the National Wood Flooring Association.

Appearance-related attributes such as texture, grain and color; mechanical properties like dimensional stability, durability, machinability and ease in finishing, and finally, availability and cost must all be taken into consideration.

The natural properties of a certain species of wood can affect how it will appear when installed and how it will perform. The relative amounts of heartwood (the older, harder central portion of a tree) and sapwood (the softer, younger outer portion) may alter the way it accepts stain and finish, influencing the finished appearance of the floor.

Wood grain and texture are two key factors to be considered. Grain describes the appearance of growth rings as "fine" or "coarse." It also describes the direction of fibers, as in straight, spiral and curly grain. The direction of the grain of wood can affect the way it is sanded, sawed and finished. Texture refers to the finer structure of the wood, rather than to the annual rings.

The way a piece of wood is cut also affects its finished appearance. Wood flooring is either plainsawn, quartersawn or riftsawn. Plainsawn is the most colrunon and least expensive cut; it produces the widest boards and results in the least waste. The board contains more variation than the other cuts because figure patterns resulting from the growth rings are more Pronounced.

Quartersawing produces relatively narrow boards. More waste is left, therefore quartersawn lumber can be more expensive than plainsawn. Quartersawn wood twists and cuPs

Story at a Glance

Assist your customers in choosing the right wood species for their flooring key considerations: aPPearance, mechanical ProPerties, availability, cost.

less, and wears more evenly.

Riftsawing is similar to quartersawing, but at a slightly different angle. Riftsawing creates more waste than quartersawing, making it generally more expensive.

Mechanical properties of wood are other important concerns in selecting wood flooring. Moisture content plays a large part in how wood behaves, both during the machining and after installation. Most solid wood flooring will contract during periods of low humidity, sometimes leaving noticeable cracks between boards.

Probably the most imPortant strength property for wood used in flooring applications is its side hardness, also known as Janka hardness. Side hardness represents the resistance of wood to wear, denting and marring.

There are many factors that affect the installation of wood flooring. The relative density and grain can make a species either easier or more difficult to work with.

Some woods are highly resinous and may clog sandpaper, in which case a different grade or method should be used.

Some woods may split when nailed or not hold certain types of nails securely. The density or grain of some species may make them difficult to cut or shape.

Some woods, especially imports, contain oil and chemical compounds that may adversely react with certain types of finishes to inhibit drying, dramatically change the color of the wood or both. Certain species do not accept stain as readily or evenly as others, such as hard maple, pine and fir.

And just as each individual wood species is dynamic and prone to change in response to its environment, so too is the market for all wood flooring species. Availability, location and time of year may influence the cost of a particular species. Users should also have realistic expectations of how the wood will perform. Most yvood used for flooring is essentially a by-product of more expensive wood-consuming industries (furniture manufacturing, for example), so it is usually not the highest grade of lumber. This does, however, make it quite economical in comparison.

Finally, if shoppers have further questions, refer them to the National Wood Flooring Association's consumer hotline at (900) 646-WOOD, where wood flooring experts reportedly can answer any question from maintenance and finish to installation and repair. The 90P-per-minute charge goes to pay for the service.

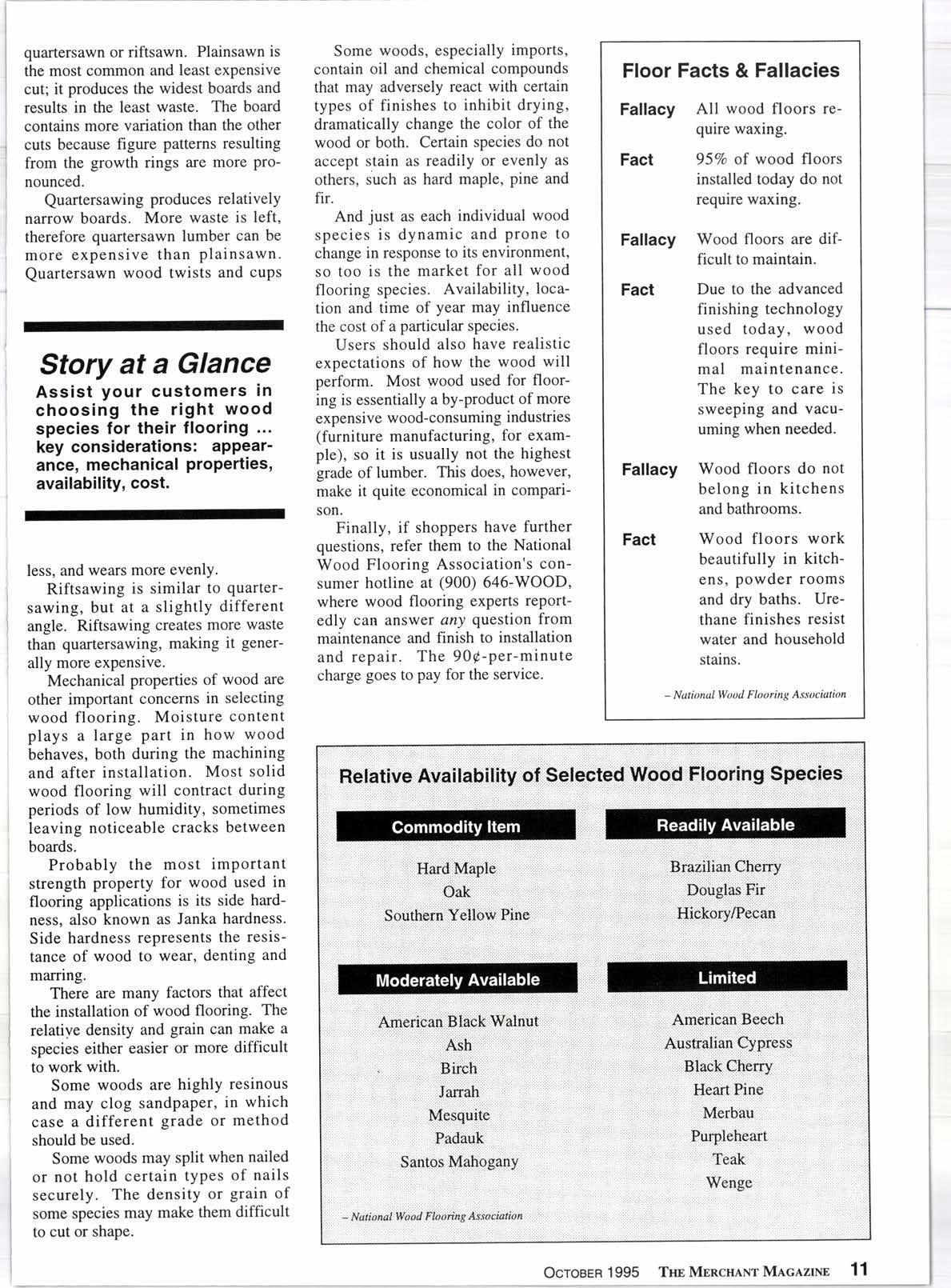

Floor Facts & Fallacies

Fallacy

All wood floors require waxing.

95Vo of wood floors installed today do not require waxing.

Wood floors are difficult to maintain.

Due to the advanced finishing technology used today, wood floors require minimal maintenance. The key to care is sweeping and vacuuming when needed.

Wood floors do not belong in kitchens and bathrooms.

Wood floors work beautifully in kitchens, powder rooms and dry baths. Urethane finishes resist water and household stains.