3 minute read

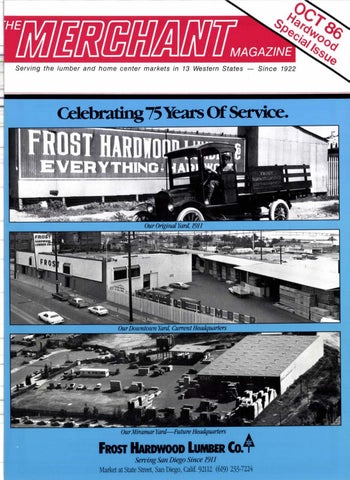

Yellow popl ar battles for market recognition

ATCH OUT, dealers, yellow poplar, the long neglected stepchild of the hardwood industry is ready to tackle the marketplace.

Propelled by the promotion committee of the Appalachian Hardwood Manufacturers, Inc., poplar has been introduced and increasingly accepted by the furniture producers as a major component in solid wood furniture. The committee is now working on acceptance by distribution yards.

" Their customers include important secondary producers in construction and home remodeling industries as well as millwork, door and sash producers and retail yards," according to Emmet Vaughn Jr., co-chairman of the promotion committee. "These wholesale yards share our intense interest in the successful promotion of the more complete utilization of the poplar product."

Vaughn, president of Emmet Vaughn Lumber Co., Knoxville, Tn., and promotion committee co-chairman, Jim C. Hamer of Kenova, WV., have been the driving force behind the well organized and hard hitting movement to find a strong, viable market for PoPlar.

Marketing presentations to furniture manufacturers, distributors, cabinet producers, pallet manufacturers and offshore markets in both Europe and the Pacific Rim nations are a follow up to earlier efforts to establish yellow poplar as a construction dimension material.

Research into poplar utilization was begun by the Appalachian Hardwood Manufacturers several years ago. Their work at that time resulted in the species being approved for construction use by the American Lumber Standards Committee.

Although the construction market was penetrated and poplar's use in studs, beams and other dimension was apprwed by various code people. according to Vaughn, there is a home grown problem in that Appalachian mills are not set up to produce studs and many of the people are not equipped to make a commitment to that market. Although construction is a viable potential market for poplar, the production of material for such use is completely apart from the normal operations of the mills. Few manufacturers have been willing to submit their resources, human and economic, to a market that is even more volatile than the traditional hardwood markets, Vaughn points out.

Story at a Glance

Yellow poplar promotion taryets distribution yads...approved for construction use, but production lags...outstanding working characteristics, abundant resources...ripe for increased acceptance.

The furniture promotion phase of the overall yellow poplar promotion has been highly successful. In comparing it to the oak promotion two decades ago, Vaughn emphasizes that it is "more successful at this stage than we had been with oak."

There are many reasons for yellow poplar (Lirodendron tulipfe ra), also known as the tulip tree or tulip poplar, to be raised from a 'Junk tree" classification. A prolific grower, it accounts for as much as 28% of the toal hardu'ood sand. Foresters project that this figure will reach 30% by the year 2000. Although it grows throughout the eastern hardwood forests, yellow poplar grown in the Appalachian mountain area is often considered to be superior due to ideal growing conditions of rainfall, drainage, seasonal change and rich soil. known as one of the best in the country.

Yellovr poplar is known for its outstanding working characteristics. The Appalachian Hardwood Manufacturers claim that in any application where white pine may be used, poplar has significant advantages in working properties, finishing, drying and cost. It dries with less problems, has no stain problems and less degrade. Knife life is longer with poplar which also takes all tints, stains and coatings as well as any species and better than most, according to the association. Fuzzing problems and color aberrations have been solved. Compared to white pine, yellow poplar is harder, stronger and heavier.

Historically, poplar was used as long as 500 years ago. Federal, Shaker and Early American fumiture still in existence today demonstrates its early use as a furniture wood. Poplar also has been used as core stock in furninrre manufacturing for years and often by millwork houses for mouldings, window casings, doors and decorative architectural woodwork. Ffowever, its use has never come close to equaling its availability.

Given the strong yellow poplar resources, its proven value for use in both construction and furniture and the push to make distribution yards, cabinet producers, pallet manufacturers and offshore markets aware of itsassets,it seems likely that poplar will become a popular commerical species. Vaughn predicts that "Poplar will indeed be a money tree and we will be as happy to have that species in our inventory as we have been with oak."

Andersen'windows are the most popular for one important rqnon: they're made the best way we know how. Only the best materials are used. Onlv the best windows get our label.

No compromises, no seconds. Just top-guality, stateof-theart windows from sash to glass.

Right here in the West, there are 15 distributors and more than 100 salesmen. With

I 15 trucks and an inventory worth nearly $5 million. So when you call in, your order moves out. Fast and efficiently.

If you aren't an Andersen dealer, talk to your nearby

MAPLE BROS..INC.

Brea (2r3t 694-377r

MAPLE BROS., INC.

El Cajon

(6t9t 442-8895

WESTERN D@R & sAsH co.

Oakland (4lt s35-2000

COLORADO

BOISE CASCADE

The beauty of this pole shed we built for Rialto Lumber Co., Rialto, Ca., is that it has gteat practicality. It is as functional as it is straight forward and that's a beautiful situation for any firm that needs a building to store inventory and equipment.

San Antonio Pole Construction has built an unequaled reputation for excellence by building structures that follow a basic concept of beauty: form follows function. Our cus-