3 minute read

Moulder: friend or foe?

By David Miller Michael Weinig, Inc.

I F YOU are a wholesaler or custom I mill using a moulder to produce wood mouldings, youknowthatyougetpaidby the minute. 45 lineal feet per minute x 60 minutes x 8 cents per foot has the potential of eaming $216 perhow. Most of us could live on that.

But what if your moulder only runs 20minutes perhour? Now we're down to $72 per hour. Does this amount justify the space, cost of the moulder and salary of the operator?

Why does a moulder operate at one third of its capabilities? Some do because oftheir age relative to state ofthe art technology, but most perform poorly due to a lack of proper training. This training deficiency does not always begin with the operator who is accustomed to taking an hour or longer to make a set-up, but with the owner or manager who doesn't know what his machines are capable of producing. for a machine so important to a successful business.

If the set-up man is accustomed to taking an hour or longer to make a setup and running the machine at 20 to 30 feet per minute then why should he do it any differently? Most people produce what is expected of them. If our expectations are low, our results will probably reflect that attitude. On the other hand, operating a machine at its design capabilities is basic good business sense.

Story at a Glance

How to determine if your moulder is operating at top etficiency . suggestionsfor increasing output... a formula for determining capability.

Miller, who grew up inthe lumber business, workedfor some 15 years in Oregon and Northern California as a millwright and was later a production manager for Peternan Lumber and Saroyan Lumber in S outhe rn C alifu rnia.e dito r

Does this mean that owners are going to have to learn how to operate a moulder? No. However, a quickcourse on its capabilities is a small price to pay

Do you,as an owner, know that by using the technology now being built into a modern moulder, set-up times of 20 minutes or less should be the norm? Your operator or mill foreman may not either.

These set-up aids are notexotic com- puters that require an on site programmer, but rather simple procedures and measurements that add no more than five minutes to tooling preparation in the grinding room.

Using a procedure called "axial constant" an operator only need make one adjustment per cutterhead and that adjustment is determined inthe tool room so that the first piece of moulding out of the machine should be the correct size and shape.

What is your moulder capable of producing per day? A simple formula might read as follows:

Non-jointed or single knife production:

7 hours production per day = 420

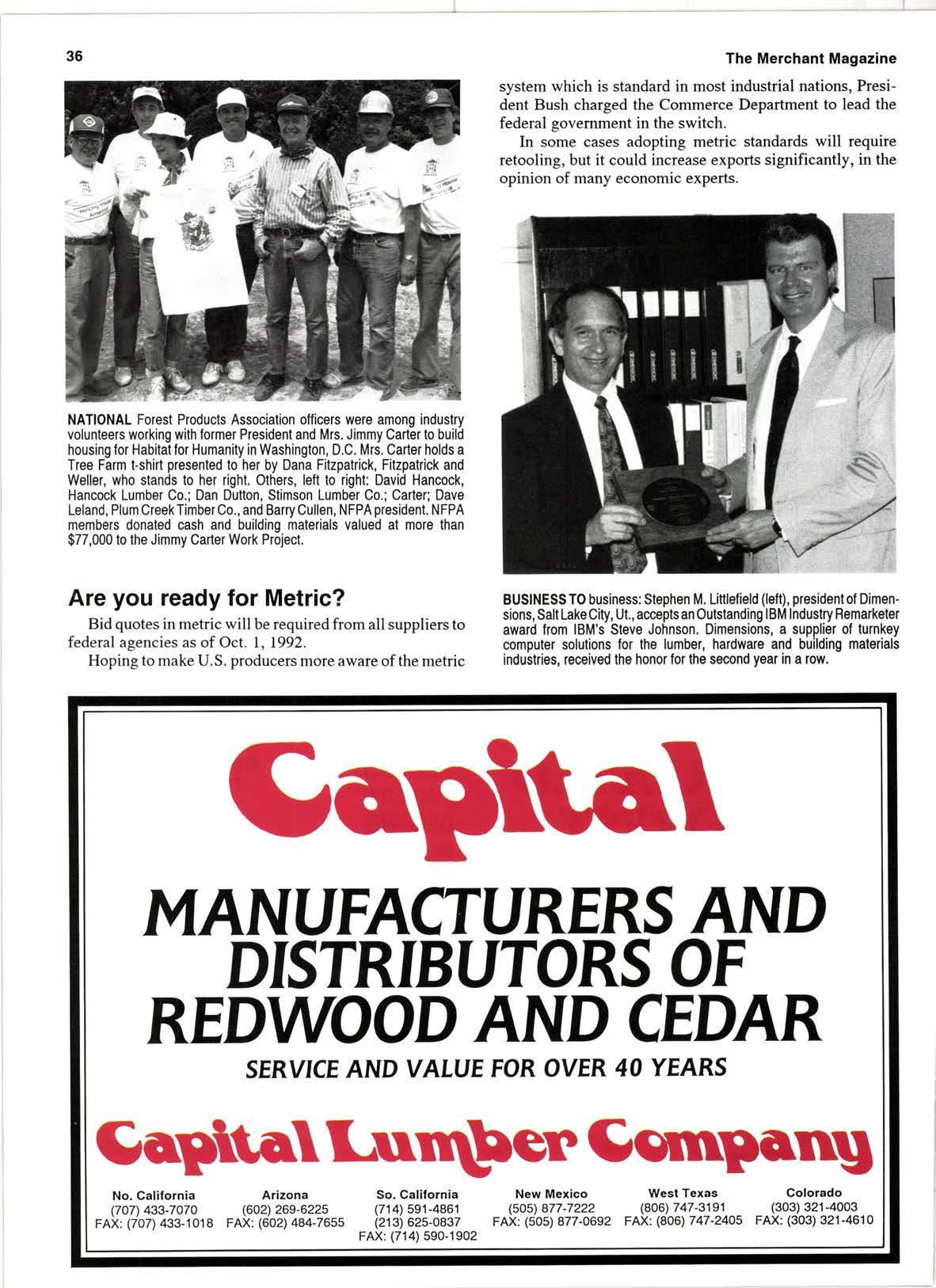

MOULDING ffOBlLE, better known as the Weinig Unimobile, a truck mounted demonstration vehicle, is touring the country demonstrat ing the $74,000 (base price) Unimat 23 moulder. The rig, valued at about $250,000, costs $1,fi)0 a day !o operate, Weinig representatives (top right)Jim Ginley, John Manusharow, Jason Lincoln and Mark Houston display a project completed during a mid-May visit at Custom Mills, City of lndustry, Ga, A select company of wholesalers and custom milling people attended including (lower photos, left to right) Bob Cole, John Hodge, Glenn McNary, Jerry Lapin, Brian Reynolds, John Manusharow, Fred Jones.

45 L.F. per minute x 420 minutes = 18,900 L.F. per day

Less 1000 L.F. per set-up

Jointed or multi-knife production: 7 hours production pet day = 42O minutes production time.

100 L.F. per minute x 420 minutes = 42,000L.F.

Less 3500 L.F. per set-up

Moulder operation in the past was considered a necessary evil to help sell lumber. In these days of thinner profit margins, the economical operation of your moulder is imperative. Is your moulder as productive and profitable as it should be?

Are you ready for Metric?

Bid quotes in metric will be required from all suppliers to federal agencies as ofOct. l,1992.

Hoping to make U.S. producers more aware of the metric system which is standard in most industrial nations, President Bush charged the Commerce Department to lead the federal government in the switch.

In some cases adopting metric standards will require retooling, but it could increase exports significantly, in the opinion of many economic experts.

Blades Of Time

A saw blade clock that looks real enough to cut wood is new from Universal Products Co.