4 minute read

lnnovation at work

an effort to increase the consumer side of the business.

II tHEN Jeff

Swan decided to U U modernize Evergreen Lumber he wisely enough began re-thinking some basics involved in starting from the ground up and with some helP, evolved an ingenious systems ol concrete tees to support both the materials sheds and the new office/showroom building itself. For full details on that part of this story, please see the other page.

Evergreen Lumber was begun bY Jeff's dad in 1939 and operated bY the family for a number of Years. It subsequently passed out of familY control, only to be reacquired bY Jeff and a partner in 1961 In I 972 he bought out his parlner and took over as sole owner and president.

At that time, it was a fairly typical small town lumber Yard in HarPer, seven miles from Port Orchard, Washington, a ferry boat ride and a whole world away from Seattle, just across Puget Sound. It had but two employees, Jeff and LarrY Lund, the current manager.

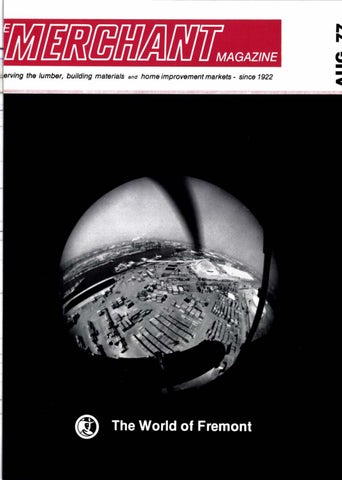

Today, it is quite a different story. Thirteen full-time employees work in all brand new buildings. All the old buildings were cleared when they re- built and totally reorganized the yard.

Surrounded by a fully blacktoPPed yard, much needed in their rainy climate, the new 8000 sq. f1. building houses showlooms downstairs with three offices and an employees lunchroom upstairs, and includes 4,000 sq. ft. of warehouse space.

One thing that is very much unchanged is the traditional dedication to the individual approach in dealing with customers. Good customer service gets a lot more than lip service. Stresses Jeff Swan, "We are f air priced and service oriented."

Traditionally a contractor-oriented business, the new changes are in part

Story at a Glance

Innovative thinking when completely redesigning their lumber yard leads small Washington State retailer to develoP ingenious new concrete tees for both storage sheds and the main office/showroom/warehouse structure.

When rcmodeling, the entrance side of the building was designed with a separate entrance for contractors and the general public. In addition to local contractor and walk-in traffic, Evergreen does a substantial business in selling lumber for comrnercial jobs that are out for bid all over the State of Washington. Their big green and white trucks have even been spotted as far north as Alaska, hauling lumber to a job.

Consumer trade now has a far wider inventory to choose from than in the past. Included are plurnbing, electrical, moulding, paneling, hand and Power tools and hardware. D-l-Y merchandise abounds and they schedule how-to clinics frequently to provide back-up knowledge for customers.

Store hours are M'F 8:00 - 5:30, 8:00 - 5 Saturday.

The new showroom allows Evergreen to serve a far wider range of customers from the vantage point of being a small family-run business.

"We believe in well-informed and courteous sales personnel who can answer the customers' questions and then go out and strap a piece of plYwood to their car."

It may be a small firm, but Evergreen Lumber's commitment to service and innovative thinking is as big as any one else's in the business.

VOU DON'T have to be

I Frank Lloyd Wright to come up with a new design for a building. First you decide what the building has to do, then you figure out how to do it. Sounds simple, but not everyone approaches it that way.

But that is what architect Keith Putnam did, when owner Jeff Swan of Evergreen Lumber first talked to him about a new facility. The two made a list of square footages needed for offices, a lunchroom, main showroom, "rough sales" area, etc. Swan also wanted a plan that would allow for expansion in a few years, and of course, the whole thing had to be economically feasible.

Initial planning for the project included a complete re-design and layout of the yard. Special consideration was given to the placement and accessibility of lumber storage since Evergreen Lumber's current mix of customers is approximately 80Vo contractor sales, 20% consumer walk-in trade. Two-sided, covered lumber trees that could store materials hve to six slings high were a major factor to increase efficiency. Contractors and consumers were each given separate driveways and entrances as traffic patterns were changed.

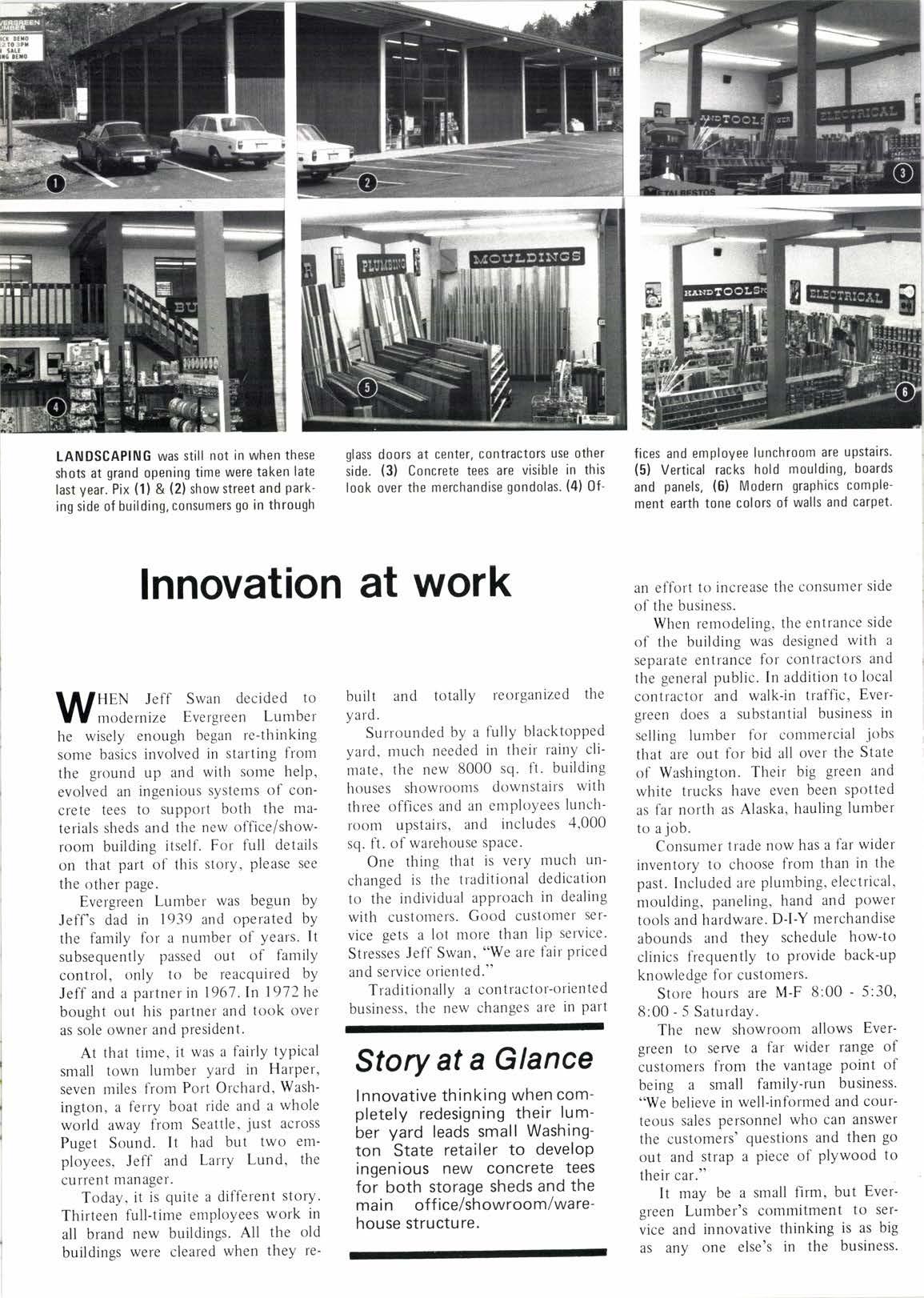

It was established that the lumber trees must be stressed to carry a full load of green lurnber on one side. As Putnam began his search for the kind of structure that could accomplish this goal, he considered a wood tee concept. However, working with structural engineers Kelly, Pittelko, Fritz & Forssen of Seattle, they found that the center section of the wood tee would have been too wide to carry the fully-loaded weight and make best use of the space available. Therefore, they came up with the concrete tee, reinforced with steel re-bar, which could hold the steel arms from the lumber trees, as well as use less space than the wood tee.

Having settled on the concrete tees for the lumber trees, Putnam worked the tees into the main building as well to achieve two goals:

(l) to lower the total overall cost per tee and

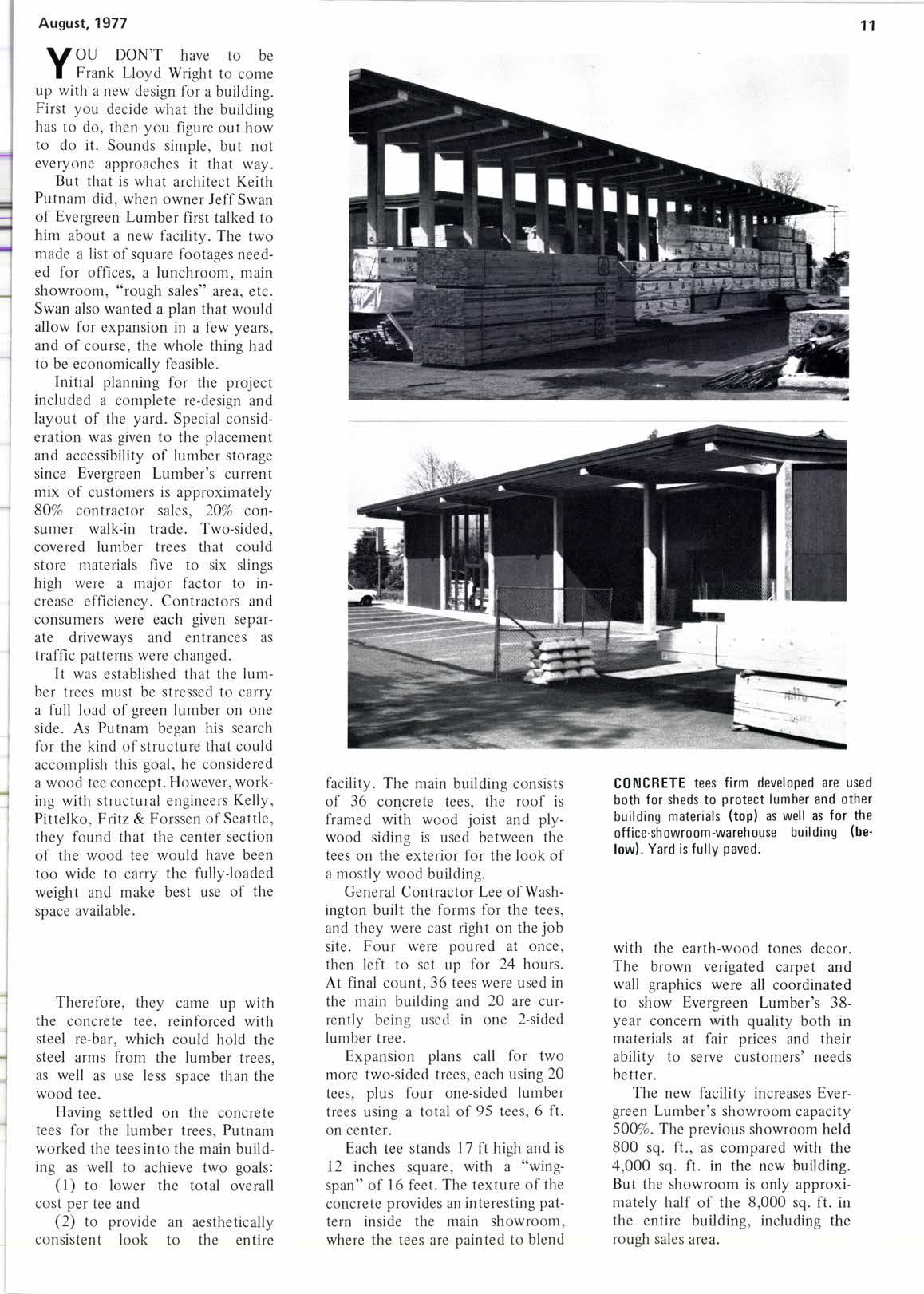

(2) to provide an aesthetically consistent look to the entire facility. The main building consists of 36 concrete tees, the roof is framed with wood joist and plywood siding is used between the tees on the exterior for the look of a mostly wood building.

General Contractor Lee of Washington built the forms for the tees, and they were cast right on the job site. Four were poured at once, then left to set up for 24 hours. At final count, 36 tees were used in the main building and 20 are currently being used in one 2-sided lumber tree.

Expansion plans call for two more two-sided trees, each using 20 tees, plus four one-sided lumber trees using a total of 95 tees, 6 ft. on center.

Each tee stands I 7 ft high and is l2 inches square, with a "wingspan" of l6 feet. The texture ofthe concrete provides an interesting pattern inside the main showroom, where the tees are painted to blend with the earth-wood tones decor. The brown verigated carpet and wall graphics were all coordinated to show Evergreen Lumber's 38year concern with quality both in materials at fair prices and their ability to serve customers' needs better.

CONCRETE tees firm developed are used both for sheds to protect lumber and other building materials (top) as well as for the office-showroom-warehouse building {be' low). Yard is fully paved.

The new facility increases Evergreen Lumber's showroom capacity 5OO%. The previous showroom held 800 sq. ft., as compared with the 4,000 sq. ft. in the new building. But the showroom is only approximately half of the 8,000 sq. ft. in the entire building, including the rough sales area.