4 minute read

Enginee ture

Glued engineered wood products expected to boom into the 21 st Century

rnHE YEAR 2000 is just three-andI a-half vears away. About 1,265 days and counting. As ttre millennium approaches, construction industry prof'essionals are making plans for the future. The evolution of new buildine

Story at a Glance

Product-by-product f ive-Year forecast for glued engineered wood products big jumPs expected in OSB, glulams, LVL and l-joists.

materials, enhancements of existing materials and changing construction techniques are affecting the way builders and design professionals do business.

Few areas of the building products industry have seen more change or grown faster in recent years than the engineered wood products sector.

Builders, remodelers and design professionals who just a decade ago were wary of these emerging technologies, are now increasingly educated in the potential cost savings and superior strength which these products offer.

Today, more and more building trade professionals view the use of OSB, plywood, glulams, I-joists and LVL as standard building materials. And recently released statistics by APA - The Engineered Wood Association indicate the market for engineered wood products continues to be wide open and growing fast.

APA classifies glued engineered wood products into four general groups: structural wood panels, glued laminated timber (glulam), structural composite lumber (SCL) PrimarilY consisting of laminated veneer lumber (LVL), and wood I-joists. Market studies indicate that the use of some of these products will more than double by the year 2000.

Structural Wood Panels

Structural wood panels, which include plywood, oriented strand board (OSB) and composite panels, are perhaps the most widely used of the glued engineered wood products. From siding and roof sheathing to floor underlayment and concrete forming, structural wood panels are an increasingly growing part of the building materials used by today's contractors. According to APA statistics, North American structural wood panel production has grown from 19.3 billion square feet in 1980 to 32.6 billion square feet in 1994. This 69Vo increase has come from consistent growth in a wide variety of market segments.

While demand for plywood is forecast to level off in the coming years, it is expected that demand for OSB will increase significantly. The construction of 24 new OSB mills combined with plant expansions at several current major OSB producers in North America underscores the industry's response to a changing resource supply base. Total market demand for structural panels is expected to increase as much as 6 billion feet as new APA marketing programs are implemented over the next few years.

Glued Laminated Timber (Glulam)

Glulam is an engineered stress-rated product created by adhesively bonding together individual pieces of lumber having a net thickness of 50 mm (2 in.) or less. It is the most versatile of the engineered wood products as it can be

&

Production - North America

easily shaped into forms ranging from straight beams to complex curved members and is used for a wide variety of structural applications in both residential and non-residential construction. Some of the largest wood structures in the world have been framed using glulam components.

Domestically, a wider range of North American lumber resources are being used to produce glulams thus minimizing the demand on fiber from older growth forests. Internationally, glulam standards are being redefined to allow greater flexibility in manufacturing processes and in the sourcing of the wood laminations used in this product.

In addition. research in the use of synthetics and laminated veneer lumber to improve performance and lower the cost of glulams is under way at a number of university, government and industry laboratories - including APA's Research Center in Tacoma, Wa. These changes, along with the addition of new plants in both the U.S. and Canada and a rapidly growing export market are expected to increase U.S. production of glulam beams to 280 million board feet in 1995 - up from 1994's total of 259 million board feet.

Glulam Demand & Production - U.S.

(LvL)

LVL is the most widely used of the sfiuctural composite lumber products, particularly in header and beam applications. It is produced by adhesively bonding thin wood veneers together in such a manner that the grain of all veneers is approximately parallel to the long direc- parallel to tion of the member.

North American production of LVL is expected to increase from 31 million cubic feet in 1995 to 45 million cubic feet by the year 2000. LVL should continue to be the main flange component for prefabricated wood I-joists and the product of choice for such applications as scaffold planking where a high degree of structural reliability is essential.

Prefabricated Wood I-Joists

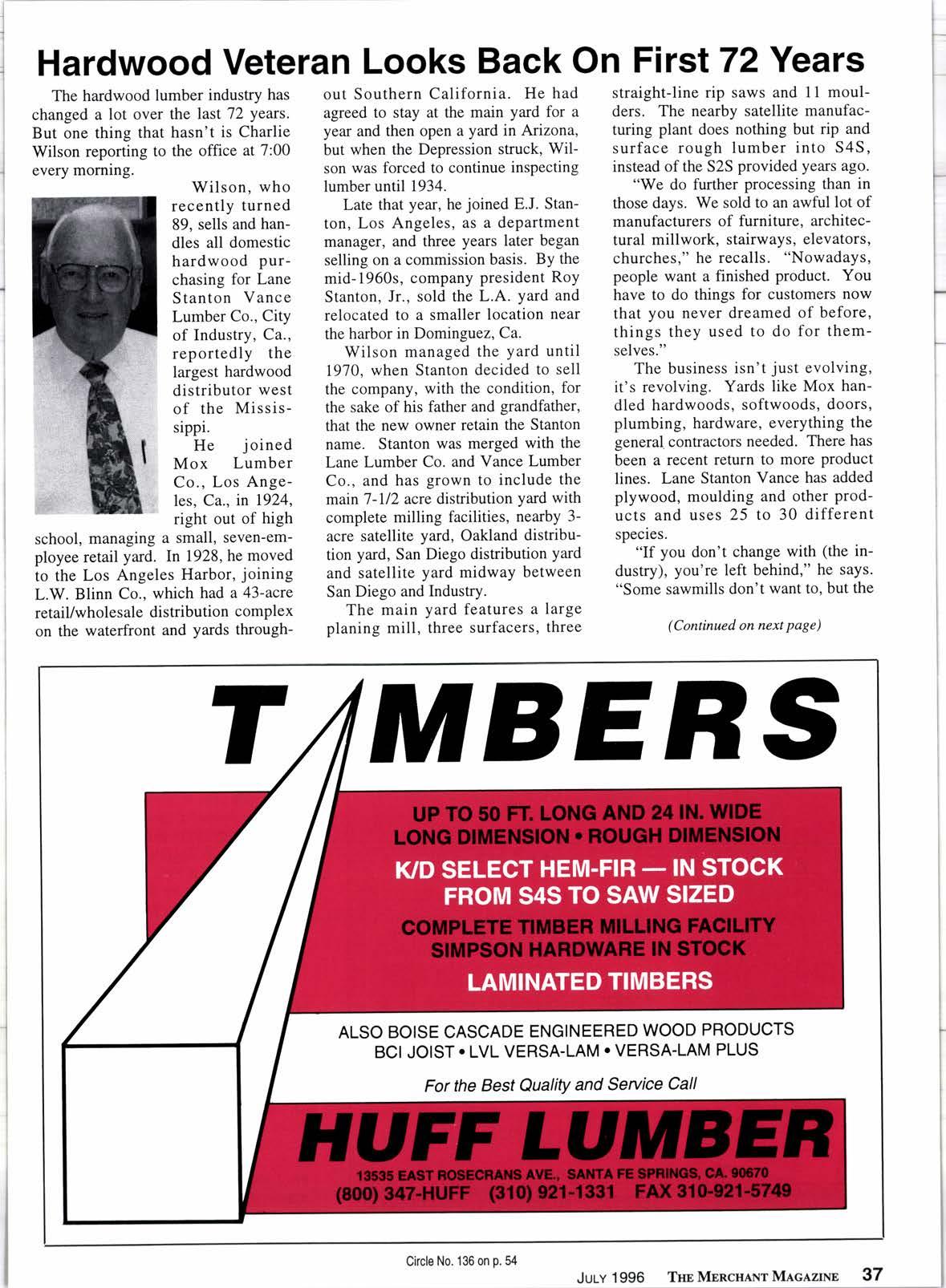

Pre fab ri c ated wood I-joists, used extensively in residential construction, continue to be the fastest growing of the glued engineered wood products. Although these products have been available for more than 25 years, their use has seen significant growth in all 4arkets during the past decade as design professionals and builders have become more familiar with the inherent advantages associated with I-joists. In addition, new manufacturers of these products have entered into the marketplace making them more readily available.

The supply of high quality wide dimension lumber for floor joists is expected to continue its decline, creating a ready market for I-joist growth. It is anticipated that industry performance standards for these products will be developed in the near future, which will result in a market share increase from approximately 2OVo in 1996 for U.S. residential floor construction to as much as 45Vo or more by 2000.

Building Products of Tomorrow

Growth in the use of engineered wood products can be partly attributed to the fact that these products are resource efficient and have fewer environmental conseL quences than other competitive construction materials. Engineered wood products utilize more of our available resources with very little waste.

The environmental benefits of engineered wood products, coupled with their ready availability, high strength, natural aesthetic characteristics and growing cost-effectiveness, make them a viable alternative to most other building products. As a construction material, glued engineered wood has secured a leading place among the building products ofthe future.

Wood l-Joist Production - U.S. & Canada

(Estimates in Million Lineal Feet)