14 minute read

Gomplying with the Lacey Act-or else

IIJsnr Do MERANTI rr-vwooo, ip6

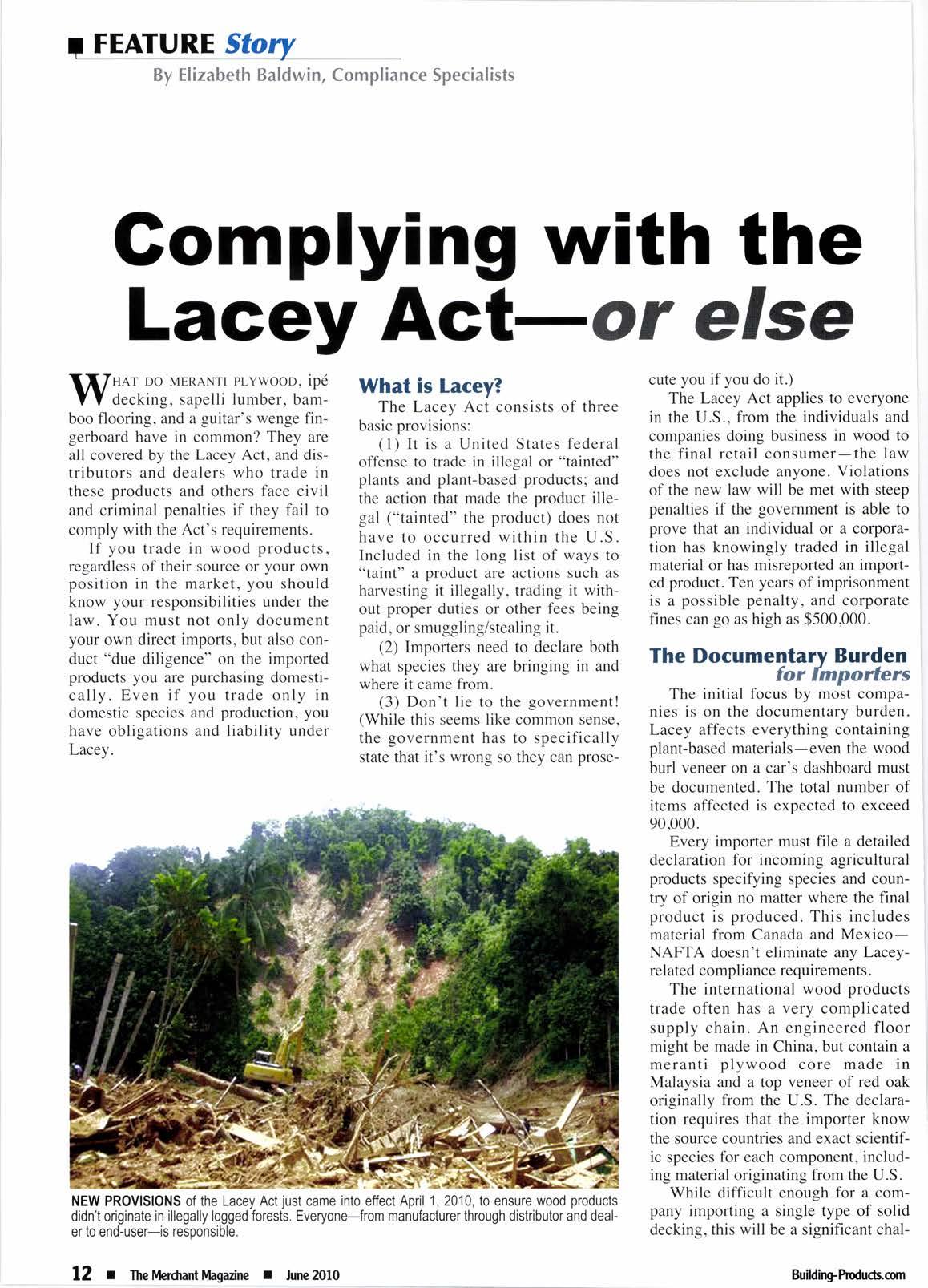

Y V decking, sapelli lumber, bamboo flooring, and a guitar's wenge fingerboard have in common? They are all covered by the Lacey Act, and distributors and dealers who trade in these products and others face civil and criminal penalties if they fail to comply with the Act's requirements.

If you trade in wood products, regardless of their source or your own position in the market, you should know your responsibilities under the law. You must not only document your own direct imports, but also conduct "due diligence" on the imported products you are purchasing domestically. Even if you trade only in domestic species and production, you have obligations and liability under Lacey.

What is Lacey?

The Lacey Act consists of three basic provisions:

(l) It is a United States federal offense to trade in illegal or "tainted" plants and plant-based products; and the action that made the product illegal ("tainted" the product) does not have to occurred within the U.S. Included in the long list of ways to "taint" a product are actions such as harvesting it illegally, trading it without proper duties or other fees being paid, or smuggling/stealing it.

(2) Importers need to declare both what species they are bringing in and where it came from.

(3) Don't lie to the government! (While this seems like common sense, the government has to specifically state that it's wrong so they can prose- cute you if you do it.)

The Lacey Act applies to everyone in the U.S., from the individuals and companies doing business in wood to the final retail consumer-the law does not exclude anyone. Violations of the new law will be met with steep penalties if the government is able to prove that an individual or a corporation has knowingly traded in illegal material or has misreported an imported product. Ten years of imprisonment is a possible penalty, and corporate fines can go as high as $500000.

The Documentarv Burden for fmporters

The initial focus by most companies is on the documentary burden. Lacey affects everything containing plant-based materials-even the wood burl veneer on a car's dashboard must be documented. The total number of items affected is expected to exceed 90,000.

Every importer must file a detailed declaration for incoming agricultural products specifying species and country of origin no matter where the final product is produced. This includes material from Canada and MexicoNAFIA doesn't eliminate any Laceyrelated compliance requirements.

The international wood products trade often has a very complicated supply chain. An engineered floor might be made in China, but contain a meranti plywood core made in Malaysia and a top veneer of red oak originally from the U.S. The declaration requires that the importer know the source countries and exact scientific species for each component, including material originating from the U.S. While difficult enough for a company importing a single type of solid decking, this will be a significant chal-

Hardwood Decking Buyers, Beware -

"What everyone fails to mention is the importance of being Lacey Act safe. Everyone who buys ip6 needs to be comfortable asking their suppliers about the legality of the fiber.

'With the market fluctuations and emerging imports from other countries, especially lndonesia and places other than Brazil with cheaper labor costs, it has become attractive to look to those places from a cost standpoint for alternatives. What many don't realize is that a good majority of this fiber will not pass the litmus test for Lacey compliance. A lot of importers do not have direct ties to the production and many don't care. lt's the guy with the inventory at the end who gets the fine. We ensure that all our wood is Lacey safe because we want to and have to."

- Sean Burch, Redwood Empire, Morgan Hill, Ca,

lenge to companies that import mixed species production, such as furniture or kitchen cabinet companies. Wood is traded under a commercial or trade name, but is rarely purely a single species of tree. A meranti plywood core might require a declaration of over 50 species (out ofover 250 possible). The top veneer might come from several countries and include dozens of species within the one genus. Developing a system to document and track the species is one of the challenges Lacey puts on companies.

In many cases, a freight forwarder or broker will file the declaration, but the company must provide the information for them. U.S. Customs is trying to accept information electronically, but is still receiving the majority of declarations on paper. They have developed a rolling implementation schedule, requiring declarations for different HS Codes to start on different dates. An updated listing of items subject to declaration (listed by HS code) is on the USDA Animal & Plant Health Inspection Service website at www.aphis.usda.gov/plant_health/ lacey_act/index.shtml.

The Lesality Burden for ilsolutely Everyone

The potential for legal liability falls on everyone in the chain. On an absolute level, Lacey allows for the confiscation of goods from anyoneeven to the point of allowing the government to enter a home to pull up a living room floor, rip out the kitchen cabinets, or seize Johnny's new bunk bed. Now, in the real world, that's just not going to happen, but that's the potential extent of liability. Anyone in the chain, from the importer to the retailer to the homeowner. and even the trucking companies, technically share the risk for the legality of their wood in the product.

Most people define Lacey's start date as when their specific import declarations are required. This focus can be dangerous since the legality requirement is already in effect-as of May 22,2008, it is against U.S.law to trade in any illegally harvested agricultural product. Every one of us is currently Lacey liable.

While the greatest burdens and risks will be on the actual importers, distributors and retailers should also be asking some questions of their suppliers, if only to be able to respond to their customers' questions. In some markets. domestic producers are using Lacey as a scare tactic in their marketing to try to pull customers away from imported products.

It's important to note that Lacey does not specifically require importers to document the legality of their material at time of entry and there is no specific burden of documentation or labeling for anyone further down the chain of custody. So, technically, there is no immediate legal obligation to compel a company to ensure the legality of their supply chain. However, forcing companies to trace a product's chain of legality is most definitely the intent and the expectation of the government, and the government can prosecute based on a failure to do so if they determine that you've traded in "tainted" material.

Furthermore, ignorance will not be considered a sufficient defense. Even if a company or an individual had no idea that a product was tainted, they can still face fines or confiscation if the government believes that they should have reasonably known.

The good news is that the U.S. government bears the burden of proof. For criminal charges, they must demonstrate beyond a reasonable doubt that you knowingly committed the crime or knowingly traded in tainted material. To assess civil penalties, they must show, again beyond a reasonable doubt, that you failed in your professional due diligence and truly should have known that a product was tainted.

The greatest challenge is that under Lacey, material can become tainted even if the law being broken is not an American one. The illegal action can occur at any point in the chain. From that point further, the wood is considered tainted, thereby becoming a violation of Lacey to import or sell it within the U.S. So, importers must ensure not only that their immediate purchase is legal but also attempt to trace the origin of the material back to it's original point of harvest, confirming that each step along the way was made in accordance with local and international laws.

Many people assume that FSC certification protects them. It does not. While being certified or carrying/ purchasing a certified product (be it by FSC, SFI, PEFC, MTCC or by any other internationally recognized program) does not specifically protect companies from prosecution under Lacey, it does help show that a company is doing its due diligence. Although it will certainly be considered a sign of good faith, the U.S. government does not accept any third party verification regarding the legality (or illegality) of material.

Finally, it should be noted that foreign companies and individuals can also be prosecuted under Lacey and in past cases (for fish and wildlife, not wood), foreign nationals have been arrested during a visit to the U.S. and subsequently tried and jailed.

Lacey & U.S. Woods

Trade in U.S. woods is also covered by Lacey. For example, if the government can prove that a 1og was taken from the wrong side of a property line, that would be a Lacey violation and the U.S. company would be liable for any applicable penalties. Furthermore, all American domestic woods need to be declared upon their re-entry into the U.S. If a foreign company utilizes American red oak or walnut for a floor, pecan for a kitchen cabinet, or SPF for plywood, those species will be subject to Lacey declaration requirements when the final product is imported into the U.S. So while much less likely to be targeted for investigation, a certain level of due diligence should be done regarding the American supply chain as well.

Many American manufacturers are anticipating an increase in their domestic market share as both downstream producers and retail customers shift from imported species to the "safer" domestic hardwoods. Certainly there is likely to be a change in that area, but U.S. companies should not neglect their opportunity to utilize the Lacey Act to increase their export opportunities as well.

U.S. companies should be offering their overseas customers who intend to export a finished product back to the U.S. documentation to show that their production has an extremely low risk of being considered tainted. Such documentation can include the FSC's own assessment of American hardwoods as "low risk," or copies of reports by the American Hardwood Export Council, Appalachian Hardwood Manufacturers, and other industry organizations. Local universities often have studies (Purdue has an excellent one on Indiana timber) that can be quoted. Companies with good documentation packages should become preferred suppliers to nervous overseas buyers.

The Future of Laceyaround th6 World

Lacey' s goal is to protect the world's forests by encouraging more detailed questioning of supply chains and by providing a means of enforce- ment against egregious offenders. So whether you choose to take action because it's the right thing to do or because you are afraid of potential prosecution, you will be following the spirit of the law, perhaps even more so than the letter.

Finally, the international demand for legality documentation is here to stay, and it's not just for the U.S. Japan began requiring some forms of legality statements more than five years ago, and the United Kingdom is debating the issue. The European Union is currently developing legislation similar to Lacey that will cover international trade with all of the countries in the Euro-zone. (It is rumored that this legislation may require the submission of legality documentation at the point of entry, which Lacey currently does not require).

So the work you do today may help you far beyond just complying with the Lacey Act. The documentary conditions created by Lacey may well become the default condition for the international trade of wood products.

- Elizabeth Baldwin is president of Compliance Specialists, Eugene, Or., and author of Complying with the Lacey Act: A Real World Gride. Reach her at (541) 48409 83 o r e baldw in@ baldw inre so urc e s.c om.

For more on compliance...

A bit of due diligence on your part can reduce or mitigate potential penalties as well as significantly diminish your overall risk of being the target of an investigation.

Revised this spring, Conplying with the Lacey Act: A Real World Guide provides practical instructions to help you organize and manage your species information and legality documentation, and coordinate your internal and external communications.

The printed guide-complete with sample databases and documentationwill assist you in preparing for the import declarations, learning how to document product legality, and edumting yourself, staff, suppliers and customers regarding the potential impact of the Lacey Act.

Also included is a CD-ROM containing assorted templates and documentation with recommendations for use with domestic customers and international partners, and a reference file linking to online resources. Sample purchase order text has also been orovided in muF tiple languages common to many key supplying regions.

Visit www. laceyactresources.com.

Backed by 20 years of proven performance, and a lifetime limited warranty.

Lookinq for a treated wood product to sell and install with confidence? Choose Preservel pressure-treated wood, an environmentally advanced copper-and-quaternary (AC0o) system that provides proven, long-term protection from decav and termites.

AWPA standardized wood preservative and ICC-ES building code approved

. NAHB Research Center Green Approved Product

. US EPA Presidential Green Chemistry Challenge Award

. Lifetime limited warranty

. Proven performance against decay and termites

Above Ground and Ground Contact applications

. Approved for fresh water immersion and salt water splash zone

. For decking, playgrounds, walkways, benches, chairs, fencing and gazebos ll rforsrunE MANAcEMENTt sysIVltems-such as water resistive barriers, housewraps, and rainscreen systems-can be a potent weapon against mold and mildew buildup behind exterior walls. Persuading customers to invest in such protection requires a thorough understanding of the performance characteristics of each product type-and the climate in which it will be used.

Increasingly, building professionals are viewing moisture management solutions not as "nice to have" extras, but as essential elements of exterior wall assemblies. These products are designed to protect against the potential effects of mold damage, especially in areas that experience heavy, winddriven rain, or high temperatures and humidity.

Even in drier climates, professionals looking to preserve the life of exterior cladding are turning to moisture management systems as added insurance against expensive call backs, remediation, and/or litigation.

Building professionals are often confused by the array of moisture management systems available and unsure as to when and where to use each solution. To compound the problem, the building industry uses terms like rainscreen and housewrap interchangeably, when in fact they play distinctly different roles. In addition, housewraps and building papers are available in dozens of varieties.

At present, there are few standardsbased methods to help professionals evaluate these products. The International Residential Code and International Building Code require a means of draining water that enters the assembly to the exterior but does not describe how to achieve drainage. In Canada, on the other hand, the National Building Code requires the use of "a drained and vented air space not less than 1Omm deep behind the cladding over the full height of the wall" in areas that exceed a certain annual rainfall threshold.

A study commissioned by Benjamin Obdyke indicates that a building's location and the choice of exterior cladding are central to the decision of which building envelope solution to use. Here is a basic primer for to select the right system for each job:

Water Resistive Barriers

Water resistive barriers are the part of an exterior wall system designed to prevent air and water from entering the stud wall cavity from the outside. In effect, they perform like a shell for buildings: liquid water that has penetrated the exterior finish does not pass through, yet water vapor from the interior can escape so that the framing and wall cavity can dry, reducing the threat of mold and rot. There are three basic types:

Building Papers and Felt: A paper sheet or felt material coated or impregnated with asphalt to increase its strength and water resistance; primarily used as a drainage barrier.

Housewraps: Engineered plastic sheet membranes wrapped around a house or other low-rise construction, designed to resist the movement of water in the liquid state while allowing the movement of water in the vapor state. Housewraps are not designed to channel the direction of water movement. While helpful when allowing moisture vapor from the inside of the structure to exit, it can also allow moisture vapor to be driven into the wall.

Enhanced Housewraps: Also engineered synthetic membranes, these products offer the features of housewraps or building papers but also include a drainage space to promote bulk water drainage through channels engineered into the sheet.

Rainscreens

The laws of physics state that moisture will always seek a drier plane. Thus, even with a drainable housewrap, water may still seep through crevices in exterior cladding into interior assemblies, especially in regions prone to heavy rainfall, high temperatures, and high humidity-and sometimes even in climates that receive low or average rain. This, in turn, can lead to mold and mildew buildup.

When a more effective water management solution is called for, a rainscreen system should be considered. This system works by creating a pressure-equalized air space immediately behind cladding, in conjunction with a water resistive barrier. The air space helps neutralize the forces that draw water into the assembly. Any water that does enter the wall is managed by allowing it to enter and exit through an opening at the bottom of the wall. Rainscreens provide the additional benefit of providing ventilation drying of any residual moisture from the back side of the cladding.

There are two ways to construct a rainscreen system airspace. The first is nailing wood furring strips over wall studs after applying a building paper or housewrap. The second is using "void space" products that use a threedimensional plastic matrix to create a vented continuous rainscreen. Building professionals can choose from a plastic matrix that can be applied directly over a water resistive barrier or bonded, one-step installation products that combine the plastic matrix with a water resistive barrier.

Selecting the Right Product

Product performance, however, is only one variable in selecting the right moisture management system. According to building experts, rainfall is the single most important factor to consider when designing for wall durability. The main rule of thumb in choosing such a product is to first determine the amount of rain control needed.

For extremely wet and/or humid climates, such as coastal areas and &riHlng-Prcdudsom hilltop exposures receiving high (a0" to 60" annually) or extreme (60" or more annually) rainfall, a rainscreen assembly is generally the best solution. It is also advised for areas that experience high winds in addition to rain, as wind-driven rain frequently manages to penetrate small openings in cladding.

In climates that experience moderate rainfall (20" to 40" annually), protection against rain penetration should include an enhanced housewrap. And in areas of low rainfall (less than 20" annually), a housewrap or building paper should offer sufficient water resi stance.

Gladding Choice a Factor, Too

In selecting a moisture management solution, cladding choice must be considered. Some claddings are more moisture absorbent than others, and therefore could benefit from enhanced housewraps or rainscreen systems.

Wood Cladding: All woods are highly susceptible to moisture penetration and absorption, and require air space protection. The best option is a rainscreen system.

Stucco or Stone Masonry: The porous nature of stucco and stone absorbs water and therefore benefits from air space protection. Drainable housewrap may suffice in certain dry climates. but not all enhanced housewraps optimize drying. Over time, small cracks will appear in stucco.

requiring water drainage behind cladding. A rainscreen or enhanced housewrap is the best choice.

Fiber Cement: This material is less susceptible to moisture infiltration and absorption than wood, but it can trap water like stucco. A rainscreen system or enhanced housewrap will provide optimum protection.

Vinyl Siding: This product is nonabsorbent, does not trap water, and has a low potential for rot. Good-performing building paper or housewrap is recommended to optimize long-term performance.

Brick: The nature of brick construction practice creates sufficient moisture protection and air movement with 1" and 2" air space. However, clear drainage at weep areas must be maintained. Use a "knuckle" space and mortar deflection product.

As the state of building science continues to progress, more standards will be developed to assist building professionals in the decision-making process. But in the meantime, arTned with the knowledge of the roles and performance characteristics of rainscreen systems and the distinct types of water resistive barriers, building professionals are in a better position to make the right choice.

- Michael Coulton is director of product development for Benjamin Obdyke, Horsham, Pa. (www.benjaminobdyke.com), and president of the Building Enclosure Moisture Manapement Institute.