1 minute read

Nailers make it easy

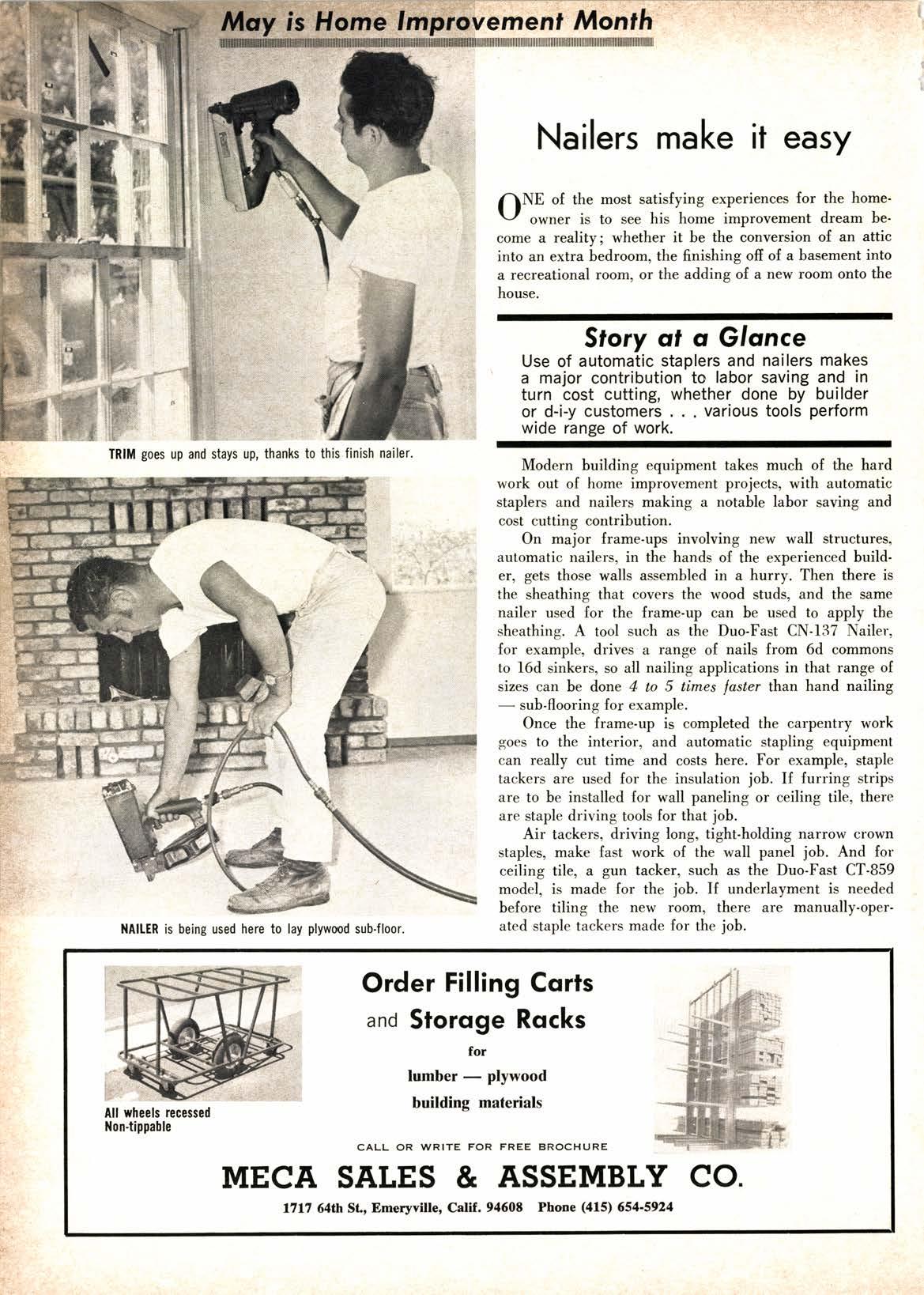

NE of the most satisfying experiences for the home' owner is to see his home improvement dream become a reality; whether it be the conversion of an attic into an extra bedroom, the finishing ofi of a basement into a recreational room, or the adding of a new room onto the house,

Story at d Glqnce

Use of automatic staplers and nailers makes a major contribution to labor saving and in turn cost cutting, whether done by builder or d-i-y customers . various tools perform wide range of work.

Modern building equipment takes much of the hard work out of home improvement projects, with automatic staplers and nailers making a notable labor saving and cost cutting contribution.

On major frame-ups involving new wall structureso automatic nailers, in the hands of the experienced builder, gets those walls assembled in a hurry. Then there is the sheathing that covers the wood studs, and the same nailer used for the frame-up can be used to apply the sheathing. A tool such as the Duo-Fast CN-137 Nailer, for exampleo drives a range of nails from 6d commons to I6d sinkers, so all nailing applications in that range of sizes can be done 4 to 5 times laster than hand nailingsub-flooring for example.

Once the frame-up is completed the carpentry work goes to the interior, and automatic stapling equipment can really cut time and costs here. For example, staple tackers are used for the insulation job. If furring strips are to be installed for wall paneling or ceiling tile, there are staple driving tools for that job.

Air tackers, driving long, tight-holding narrow crown staples, make fast work of the wall panel job. And for ceiling tile, a gun tacker, such as the Duo-Fast CT-859 rnodel, is made for the job. If underlayment is needed before tiling the new room, there are manually-operated staple tackers made for the job.