4 minute read

Plastic lumber: a serious threat to treated lumber or a p racti cal j okg ?

DEDUCING the use of plastic has l\been a goal of many environmenally-minded consumers an( until recently, the idea of plastic "wood" was considered silly, if considered at all. But now - as a result of new technologies, misperceptions about CCA preservative, higher lumber prices and the enftance of fonnidable producers - plastic lumber has a fufirre that cannot be ignored.

Plastic wood is not a single product. This variation is one of its biggest problems; there are no uniform standards and no consistencies among processors. An article in one trade publication included this precaution: "Order a truckload of 2x4s carrying the grade stamp approved by one of the major lumber associations and you know what you're getting. Order a truckload of plastic lumber and there's no telling what lies beneath the material's smooth, even surface."

Depending on the manufacturer, the raw material may be virgin plastic or recycled plastic or a mixture of plastics in combination with other substances. These feedstocks have different physical properties, such as strength, flexibility and dimensional stability.

The variability has made building codes reluctant to accept recycled plastic products.

Furttrermore, inadequate cleaning of recycled containen may leave contaminants that eat away at reforrred products, and molding equiprnent that fails to eliminate bubbles in the plastic will produce material of inferior strength.

Some fear that the acceptance of recycled plastic products will remove concems about plastics generally and even lead to increased production, which requires nonrenewable and cancer-causing ingredients. And, should recycled plastic be involved in a fire, the resulting byproducb could present problems.

A southeastern resort, which installed boardwalks made of recycled plastic lumber, found that the pieces expanded and contracted so much that nails broke. The plastic boards warped and the surface got painfully hot for barefoot sunbathers. After one year, the plastic lumber was replaced with pressure treated wood.

Virginia Polytechnic Institute shrdied pallets made of recycled plastic lumber. Among other findings, this study indicated that the plastic lumber was 53Vo heavier than wood, creeped (deformed) ftom 15 to 23 times faster, was weaker and much less rigid and absorbed less impact energy.

Today's plastic lumber is not suitable for most sEuctural applications and, on top of all this, it costs about twice as much as wood.

Despite ttrese shortcomings, plastic lumber has auracted noteworthy intoESL

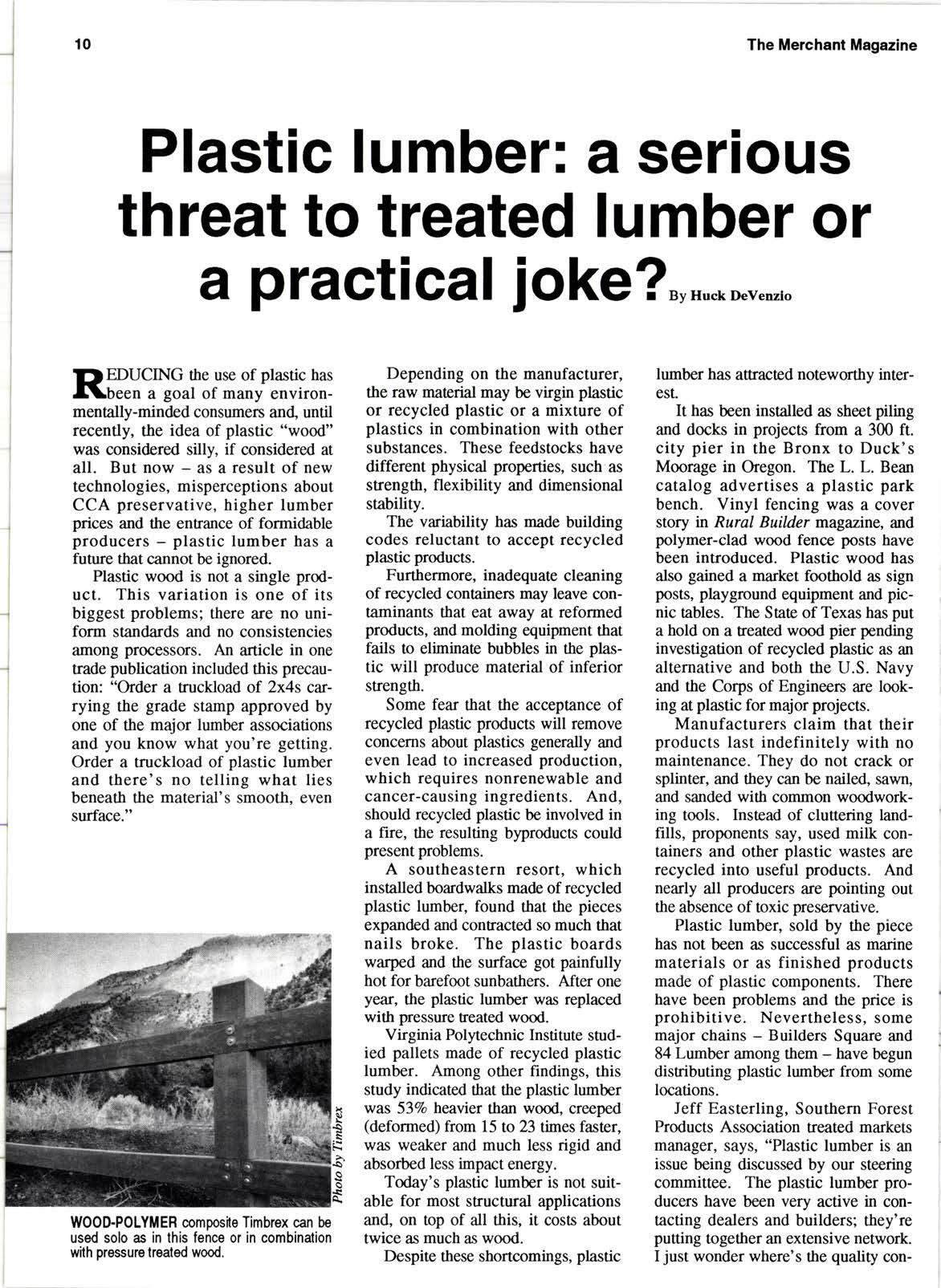

It has been installed as sheet piling and docks in projects from a 300 ft. city pier in the Bronx to Duck's Moorage in Oregon. The L. L. Bean catalog advertises a plastic park bench. Vinyl fencing was a cover story in Rural BuiWer magazing and polymer-clad wood fence posts have been introduced. Plastic wood has also gained a market foothold as sign posts, playground equipment and picnic tables. The State of Texas has put a hold on a treated wood pier pending investigation of recycled plastic as an alternative and both the U.S. Navy and the Corps of Engineen are looking at plastic for major projects.

Manufacturers claim that their products last indefinitely with no maintenance. They do not crack or splinter, and they can be nailed, sawn, and sanded with common woodworking tools. Instead of clunering landfills, proponents say, used milk containers and other plastic wastes are recycled into useful products. And nearly all producers are pointing out the absence of toxic preservative.

Plastic lumber, sold by the piece has not been as successful as marine materials or as finished products made of plastic components. There have been problems and the price is prohibitive. Nevertheless, some major chains - Builders Square and 84 Lumber among them - have begun disfibuting plastic lumber from some locations.

Jeff Easterling, Souttrern Forest Products Association treated markets manager, says, "Plastic lumber is an issue being discussed by our steering comnittee. The plastic lumber producers have been very active in contacting dealers and builders; they're putting together an extensive network. I just wonder where's the quality con- trol for the product."

The prospects for plastic lumber have moved onto a new level, however, with the recent entrance of Mobil Chemical Co. Unlike most previous operations which were founded by inventors or small entrepreneurs, Mobil brings enormous capital and wide-ranging expertise along with its product, an exruded wood-polymer composite called Timbrex.

The impact of Mobil's marketing capability is already noticeable - the

Story at a Glance

What's ahead for plastic lumber ... product problems and shortcomings ... noteworthy uses impact of Mobil's Timbrex ... retaalers and wholesalers testing market effect on traditional materials including pressure treated wood.

Timbrex promotion effort has probably generated more brand awareness than the campaigns for all the other products combined. Among other advertising, Mobil displayed Timbrex at the National Association of Home Builders show.

Some major eastern wholesalers are distributing Timbrex, though not on a big scale. The list includes Logan Lumber, Wholesale Wood Products, Furman Lumber, Snavely Forest Products and PlunkettWebster. For Plunkett-Webster, which supplies home centers with some interior wood products but not beated wood, the addition of Timbrex represents entrance into new outdoor applications. "Initial response has been 1007o positive," said PlunkettWebster's Mike Keadle, though orders were not yet being booked at the time of the interview.

Mobil has a production facility operating in Florida and is reported to have at least one other facility planned. Its plant, enclosed by a Timbrex fence, is only eight miles from the Tampa headquarters of Robbins Manufacturing Co., one of the South's largest producers of pressure treated wood. Dick Gates, sales manager at Robbins, is concerned. "The name of the game anymore is new products, and recycled products are considered very favorably by mnsumers."

Mobil is not the only major corporation becoming involved; the Comingled Plastics Task Group of the American Society of Testing and Materials has had participation from Arco, Occidental Chemical, Conoco, DuPont and Monsano.

In the next year or two, plastic lumber is unlikely to cirpture a significant share of the reated wood market However, plastic products have overmken raditional materials for siding, gutters, pipe, flooring, molding and outdoor furniture; it would be foolish to disregard plastic.

Should the cost of plastic lumber fall, as it probably will, competition with real wood will get tougher. Also, the involvement of major corporations is certain !o have an effect.

Even if treated wood doesn't lose market share to plastic, it may well suffer from declining consumer confi- dence as plastic lumber producers repeat dubious statements questioning the safety of wood impregnated with preservative chemicals Such messages, as misleading and inaccurate as they may be, can only add to public misperceptions about Eeated wood.