3 minute read

DECKIlIG

of our Western red and Pecky-Cedar, construction lumber and cost-saving Hemlock were other reasons why the dealer serving this contactor was able to get a major share of the business. This kind of profitable project is available to you when you call Fountain /irsf. Ed Fountain Lumber Company, 6218 South Hooper Avenue, Los Angeles, California 90001, (213) 583-1381.

DAVID CUTLER editor-publ isher

Editorial

One For Our Side

llt ITH all the pressures for tieing up the lU nation's wood supply by the environmentalists, ecologists and preservationists, it seems at times as if we've all been Sierra Clubbed without telling the forest products industry side of the story.

Happily, this has been less true in recent years as the industry has done a more effective job in getting out the real story. Even more encouraging is the fact that a growing segment of the public is gaining awareness of what forests do, what they can produce and why the country should think more in terms of productivity than preservation.

Recently in Los Angeles, a conservation group called the Tree People, headed by a young man named Andy Lipkis, who has a dream of an urban forest in Los Angeles, staged a l0 kilometer run to raise funds for growing and planting tree seedlings. The group even managed to get part of the freeway system closed for the run, a California first. We don't know how he managed that feat, but we're glad he's on our side.

His dream of an L.A. forest includes the extensive replanting of smog damaged trees in and around the city. Beginning several years ago, the Tree People now have a l0 acre site producing 10,000 seedlings a year. Importantly for our industry, they have added guided tours of the site, along with ecology walks, workshops and seminars to get across the message that we all need trees. And not just to look at, either.

The likelihood of "harvesting" the trees they hope to plant in backyards, vacant lots and open spaces in the city is small, but the potential for the positive education of the public of the real facts of forest products is large. With every tree planted, the chance of correcting the damages done by the ecologists grows.

While the reality of an urban forest in Los Angeles lies off in the future, a more immediate offshoot is the repeated realization that the forest products industry has a strong story to tell. With every communications success, public support is growing. Like those young seedlings, it needs all the nurturing and encouragement Dossible.

. western red cedar

. incense cedar r port orford cedar

. alaska yellow cedar r inland red cedar

. tennessee red cedar

. western cedar

Cedar Forest

PRODUCTS, Box 617 Portland, Or. 97207

Leonard Newman (503) 224-3999

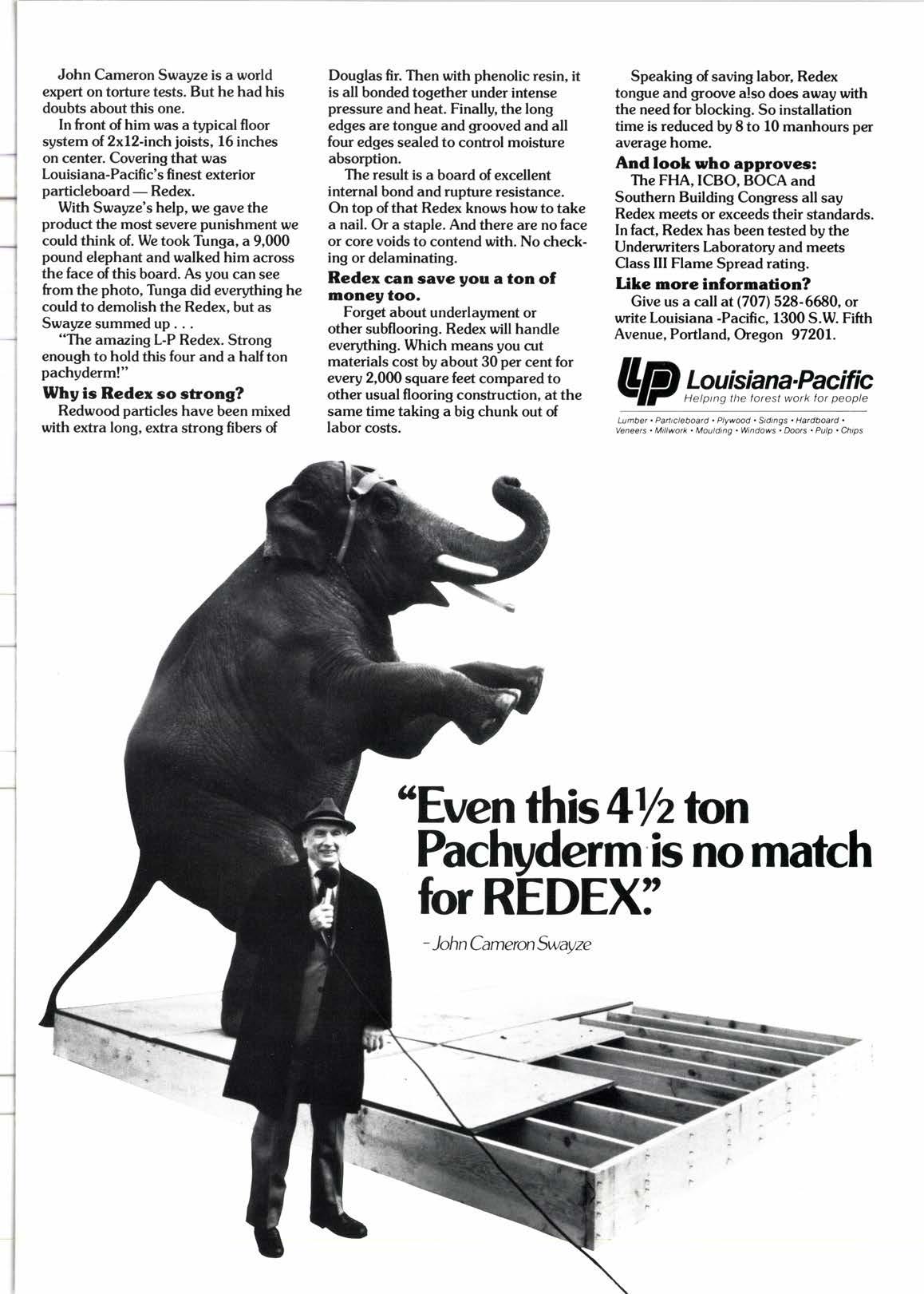

John Cameron Swalze is a world er<pert on torture tests. But he had his doubts about this one.

In front of him was a tgrpical floor system of 2x12-inch joists, 16 inches on center. Covering that was Louisiana-Paciffc's ft nest exterior particleboardRedex.

With Swape's help, we gave the product the most severe punishment we could think of. We took Tunga, a 9,fi)0 pound elephant and walked him across the face of this board. As you can see from the photo, Tunga did everything he could to demolish the Redex, but as Swape summed up.

"The amazing L-P Redex. Strong enough to hold this four and a half ton pachyderm!"

Whyic Rcdcxsoslrong?

Redwood particles have been mixed with extra long, extra strong ffbers of

Douglas ffr. Then with phenolic resin, it is all bonded together under intense pressure and heat. Finally, the long edges are tongue and grooved and all four edges sealed to control moisfure absorption.

The result is a board of excellent internal bond and rupfure resistance. On top ofthat Reden knows how to take a nail. Or a staple. And there ate no face or core voids to contend with. No checking or delaminating. Reder Gan 3avc you a ton of mon€ytoo.

Forget about underlalment or other subflooring. Redex will handle everything. Which means you crrt materials cost by about 30 per cent for every 2,0(X) square feet compared to other usual flooring construction, at the same time taking a big chunk out d labor costs.

Speaking dsaving labor, Reden tongue and groove also does away with the need for blocking. So installation time is reduced by 8 to l0 manhours per average home.

Andlookwho approvcs:

The FHA,ICBO, BOCA and Southern Building Congress all say Redex meets or exceeds their standards. In fact, Redex has been tested by the Underwriters Laboratory and meets Class III Flame Spread rating.

IJLe morelnformation?

Give us a call at (707) 528-6680, or write Louisiana -Paciftc. 1300 S.W. Fifth Avenue, Portland, Oregon 97201.