7 minute read

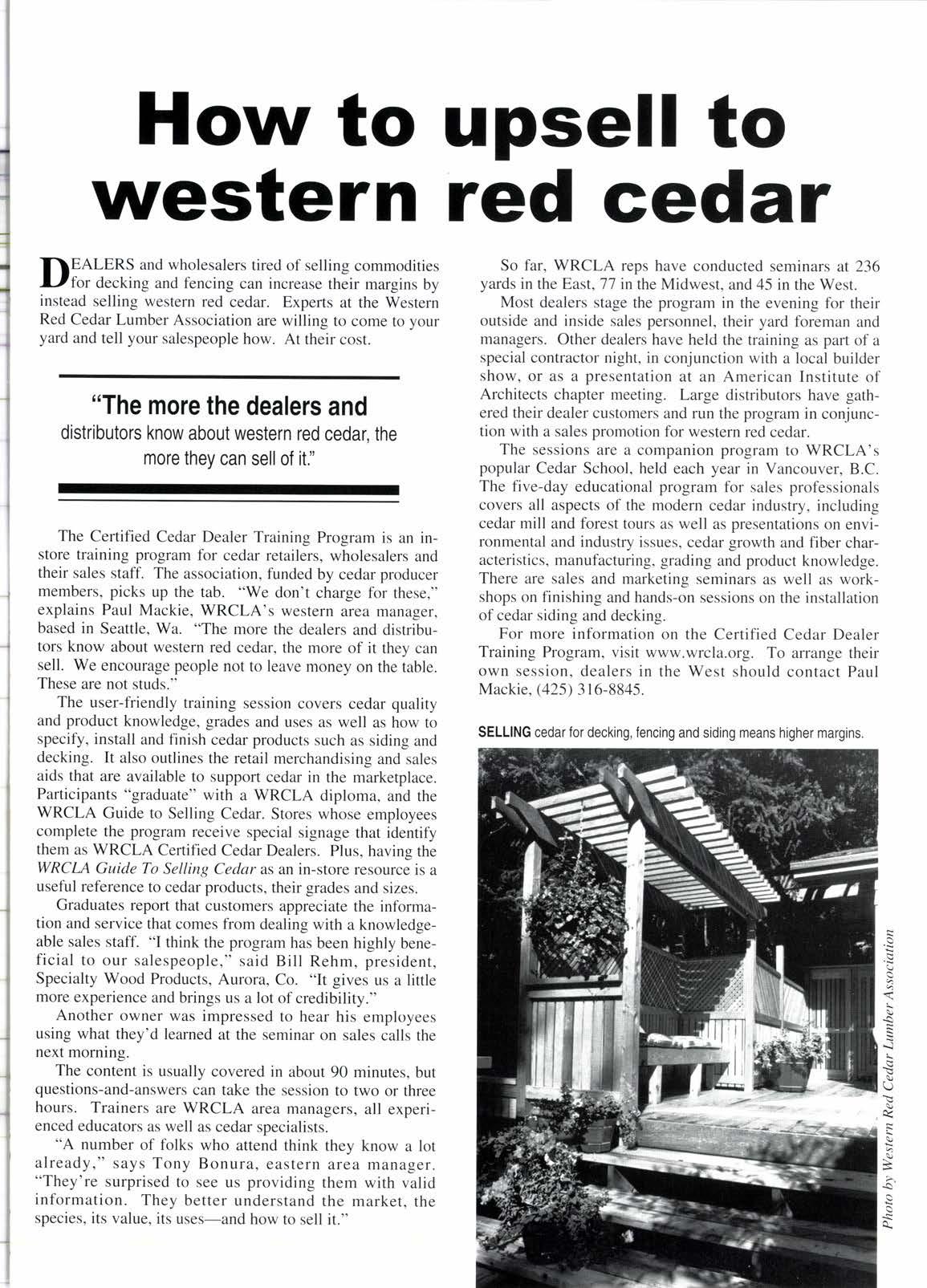

How to upsell to western red cedar

IEALERS and wholesalers tired of selling commodiries

Lf for decking and fencing can increase their margins by instead selling western red cedar. Experts at the Western Red Cedar Lumber Association are willing to come to your yard and tell your salespeople how. At their cost.

The

The Certified Cedar Dealer Training Program is an instore training program for cedar retailers, wholesalers and their sales staff. The association, funded by cedar producer members, picks up the tab. "We don't charge for these," explains Paul Mackie, WRCLA's western area manager, based in Seattle, Wa. "The more the dealers and distributors know about western red cedar, the more of it they can sell. We encourage people not to leave money on the table. These are not studs."

The user-friendly training session covers cedar quality and product knowledge, grades and uses as well as how to specify, install and finish cedar products such as siding and decking. It also outlines the retail merchandising and sales aids that are available to support cedar in the marketplace. Participants "graduate" with a WRCLA diploma, and the WRCLA Guide to Selling Cedar. Stores whose employees complete the program receive special signage that identify them as WRCLA Certified Cedar Dealers. Plus, having the WRCIA Guide To Selling Cedar as an in-store resource is a useful reference to cedar products, their grades and sizes.

Graduates report that customers appreciate the information and service that comes from dealing with a knowledgeable sales staff. "I think the program has been highly beneficial to our salespeople," said Bill Rehm, president, Specialty Wood Products, Aurora, Co. "It gives us a little more experience and brings us a lot of credibility."

Another owner was impressed to hear his employees using what they'd learned at the seminar on sales calls the next morning.

The content is usually covered in about 90 minutes, but questions-and-answers can take the session to two or three hours. Trainers are WRCLA area managers, all experienced educators as well as cedar specialists.

"A number of folks who attend think they know a lot already," says Tony Bonura, eastern area manager. "They're surprised to see us providing them with valid information. They better understand the market, the species, its value, its uses-and how to sell it."

So far, WRCLA reps have conducted seminars at 236 yards in the East, 77 in the Midwest, and 45 in the West.

Most dealers stage the program in the evening for their outside and inside sales personnel, their yard foreman and managers. Other dealers have held the training as part of a special contractor night, in conjunction with a local builder show, or as a presentation at an American Institute of Architects chapter meeting. Large distributors have gathered their dealer customers and run the program in conjunction with a sales promotion for western red cedar.

The sessions are a companion program to WRCLA's popular Cedar School, held each year in Vancouver, B.C. The five-day educational program for sales professionals covers all aspects of the modern cedar industry, including cedar mill and forest tours as well as presentations on environmental and industry issues, cedar growth and fiber characteristics, manufacturing, grading and product knowledge. There are sales and marketing seminars as well as workshops on finishing and hands-on sessions on the installation of cedar siding and decking.

For more information on the Certified Cedar Dealer Training Program, visit www.wrcla.org. To arrange their own session. dealers in the West should contact Paul Mackie. A25l316-8845

solutions for rnanufae&xxrers* distributors, demXers, builders amd Xxwme&wmers

THE lumber industry appears lo I. have a giant. new problem: mold. Yel, mold on lumber is not new; it was just never before viewed as a real problem. It was seen as a surface blemish. since the lumber was not affected structurally and would be used as framing, hidden inside a home's walls.

The difl'erence now are growing concerns that the mold could be "toxic," presenting a health hazard to residents living inside fungi-framed homes. Although little scientific evidence exists to back the claim, the mere possibility that millions of homes could be toxin traps is enough to send trial lawyers salivating. Mold. like all fungi. requires warmth. oxygen and moisture to grow. While it is typically difficult to control temperature and oxygen for wood products, each member of the supply chain should be vigilant in minimizing the moisture.

As provided by the Southern Pine Council. the Western Wood Products Association and APA-The Engineered Wood Association, here are segmentspecific ways for you can do your part-and to pass along to your supoliers and customers:

Proper Storage Prevents Mold

Given the importance of controlling moisture in preventing mold, proper lumber storage is essential. Western Wood Products Association suggests:

For green lumber,

Move inventory quickly using the "first in, first out" rule.

Sticker green lumber to allow air circulation if wood is to be stored for a long period.

. Place cover boards, extending beyond the ends of the stack, on the top package of lumber to protect the wood from the sun.

Do not store lumber near standing water; ensure the storage area has good drainage.

. Raise stacks of lumber at least 1 2" to 18" off the ground to allow cool, moist air to move downward and away from the lumber.

For dry lumber,

Open or closed storage sheds are preferable to outside storage. lf stored outdoors, cover dry lumber with tarpaulins, canvas or paper wrapping.

. Repair any tears in paper wrapping immediately.

Store high-grade dry items, such as shop, moulding and millwork, in a closed, heated shed that has a clean, paved floor.

Solutions For Manufacturers

. Mold requires a moisture content of at least 20Vc to survive on wood. Ensure seasoned dimension lumber is properly dried to a moisture content of l9%o or less and properly grademarked to identify it as such. Building codes require all structural fiaming lumber be dried to a maximum l9o/o MC befbre enclosure.

. Consider kiln drying instead of air drying. ln addition to reducing stain, mold and insects, kiln drying also produces a more quickly, consistently, evenly dried product.

. Correctly bind, handle and store lumber at the mill site. (See tips at lower left)

. If the purchaser will pay for it, properly wrap the lumber and cover the shipment with a tarp during transport.

. Also at the purchaser's request, add a mold inhibitor, particularly for green lumber. Anti-stain treatments include NP- l. Double Diamond and Diamond Brite from Kop-Coat, Britewood from Contechem Inc., and Mycostat from Diacon Technologies. These fungicides are applied by dipping entire bundles of lumber into a treatment solution or by spraying all four surfaces of individual boards. The chemicals are designed to provide a microscopic barrier against fungal attack that lasts for three to six months, depending on the chemical, the concentration used, the wood species and the climatic conditions. They are not designed for long-term protection of the wood.

Solutions For Distributors & Dealers

Wrapping options are chosen at the purchaser's discretion. The purchaser may choose not to wrap the lumber, or may choose what is usually a plastic or paper wrap that either covers the entire lumber pack (six sides) or a "shed" wrap over the top and sides.

. Shipping method is also a purchaser choice. The purchaser may choose to ship the lumber on an open "chain car" flatbed, or request that the load be covered with a tarp.

Check the condition of the lumber immediately upon delivery to the receiving facility.

Correctly handle and store lumber at the distribution site. (See tips on previous page)

. Storage time should be kept to a minimum in order to reduce exposure to moisture and the elements.

Each memberof the

supply chain should be vigilant in minimizing the moisture.

Solutions For Builders

Check the condition of the lumber immediately upon delivery to the job site.

. Once on site, store lumber in an orderly fashion and protect it from moisture. Lumber packs need to be properly bunked underneath (4x4s are recommended) to separate the material from ground contact. Keep lumber covered with a tarp or other vapor-permeable cover.

Practice good housekeeping and segregate scraps from the lumber storage area. Scraps scattered about on moist ground is food for mold.

. Once the builder is sure that all framing lumber is dried to a moisture content of 19Va or less. the structure should be enclosed as soon as possible. Purchase of a moisture meler might be a good investment.

. Use proper construction techniques, including the correct use of flashing and weather-resistive barriers.

Solutions For flomeowners

. Grade and landscane lots and

ELIMINATING through better install downspouts and splash pads so water drains away from the foundation. crawlspace.

. Repair cracks in foundations, flashing around doors and windows, plumbing.

. Do not block vents in a crawlspace fbundation, weep holes in brick veneer walls, attic turbines, or roof vents. Keep roof valleys and rain gutters free of leaves and other debris.

. Install adequate insulation in the exterior walls.

. Take notice of musty odors in the home because they indicate the presence of mold. Look for visible signs of mold and abate the moisture source.

. Watch for condensation and wet spots and eliminate sources of moisture.

. Keep the home's relative humidity low.

Clean and dry any wet or damp areas within 48 hours.

Fix plumbing leaks immediately Mold can surface at any point durand properly insulate pipes and duct- ing dlstribution and construction. work. Protecting lumber from moisture to Vent moisture-laden air from the prevent its growth requires vigilance clothes dryer, bathroom and kitchen to and teamwork by all parties in the the outdoors, never to an attic or chainofcustody.

Blue Stain Is Not Mold

What many people commonly identify on lumber as mold is actually blue stain. Blue stain, or sap stain, is not mold. lt is a bluish or grayish black discoloration of the sapwood caused by lhe growth of certain dark-colored fungi on the surface and interior of the wood. Blue stain can occur under the same conditions that favor the growth of other fungi.

With some molds and lesser fungus stains, there is no clear-cut way to differentiate between the two, In general, however, the difference between molding and staining is made primarily on the basis of the depth of discoloration. Unlike mold fungus, typical sap stain or blue stain fungus penetrates deeply into the sapwood and cannot be removed by surfacing or chemical cleaners.

Stain is an appearance characteristic only and is allowed in varying degrees in all lumber grades, lt does not affect lumber strength or utility, nor does it pose any health risk. Southern Pine Inspection Bureau's grading rules permit stain and discoloration due to exposure to the elements on southern pine lumber.

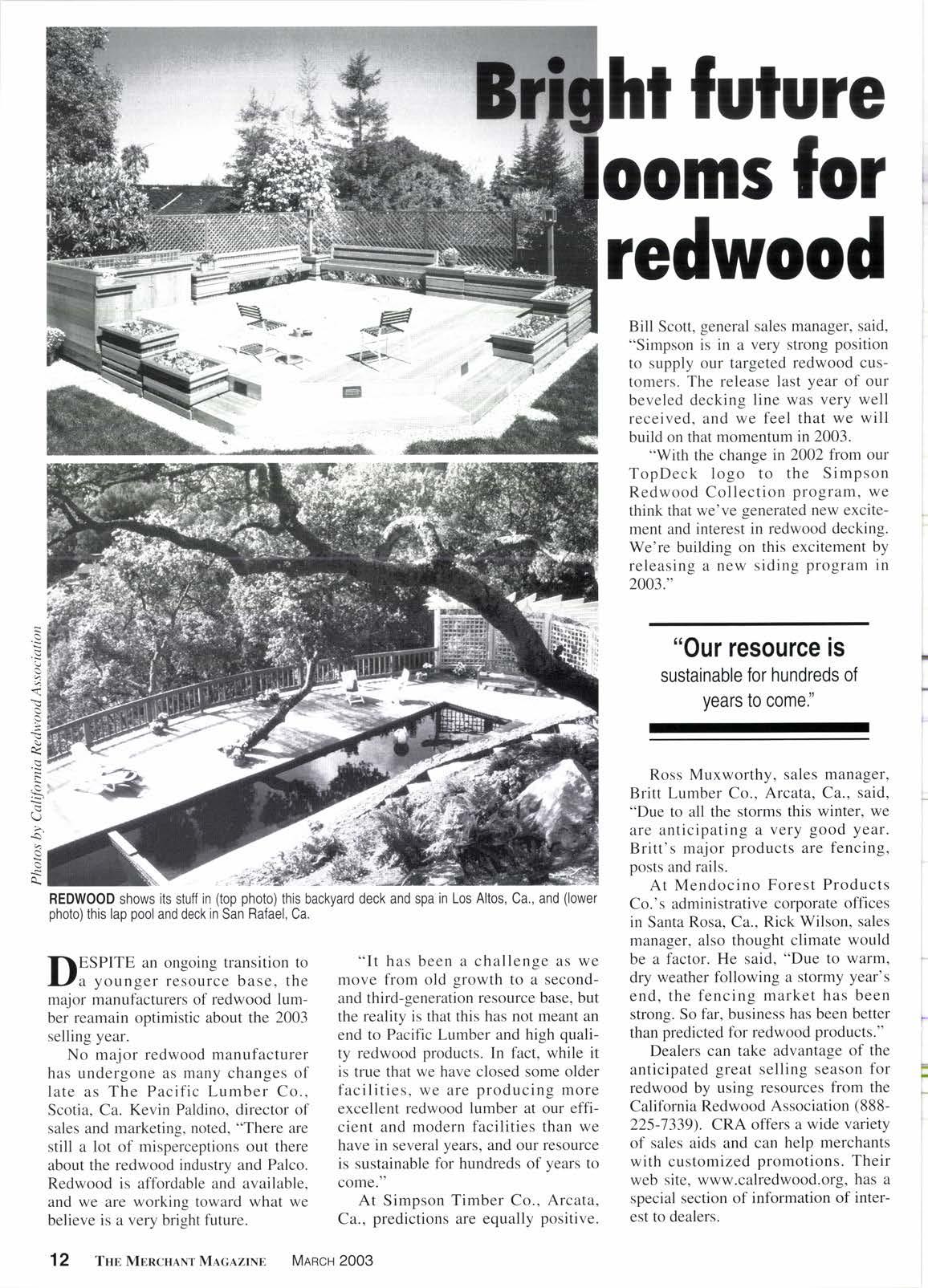

IESPITE an ongoing transition to l-fa younger resource base, the major manufacturers of redwood lumber reamain optimistic about the 2003 selling year.

No major redwood manufacturer has undergone as many changes of late as The Pacific Lumber Co., Scotia, Ca. Kevin Paldino, director of sales and marketing, noted, "There are still a lot of misperceptions out there about the redwood industry and Palco. Redwood is affordable and available. and we are working toward what we believe is a very bright future.