2 minute read

Fingeriointed studs: efficient use of wood

ar TUI)S 9 ft. long that stay 9 straight under most conditions can be a reality, not a dream. with fi ngerjointed studs manufactured from western woods.

Using multiple pieces of Doug fir, hemfir, Englemann spruce or lodgepole pine, the engineered product has superior dimensional stability because it uses lumber dried to 1906 or less moisture content. This means it will stay straight with no warping, an advantage in hot climates. lt will also yard well.

Since the stud is engineered, it can be manufactured in any trim up to 120". Strength is another benefit. Glued joints are considered to be stronger than the original wood. Accepted by the model building codes and national building standards, fingerjointed studs are recognized as having the same characteristics as full length solid sawn lumber of the same grade and species and are graded accordingly.

Good for any stick construction, fingerjointed studs are gaining popularity in southern California and Texas with some used in Florida, Virginia, the Carolinas and other states with hot climates. Thev are not a new product. Joe llelknap, sales manager at Trumark Industries, Spokane, Wa., says his company was a pioneer in fingerjointing studs l5 years ago. With the present concern for more efficient log utilization they are seen as filling a need. Solid material is not always available to meet special long length requirements.

Retailers and wholesalers who inventory the product say it sells fairly well although there are several negatives to overcome. l"ramers have a reputation ofobjecting to the appearance. However, an informal field study showed most of them like the performance, especially the strength and straightness.

Lonnie Coolsby, president, John E. Quarles Co., a F'ort Worth, Tx., retailer, compared the acceptance of fingerjointed studs to that of OSB. "As the consumer becomes more accustomed to the product, more will be used," he commented.

His company inventories fingerjointed studs in 8,9 and l0 ft. lengths. "We have to have them," Goolsby said. They're not a big profit item, nor a premium item in the present Texas economy, just a close margin with a normal markup, he added.

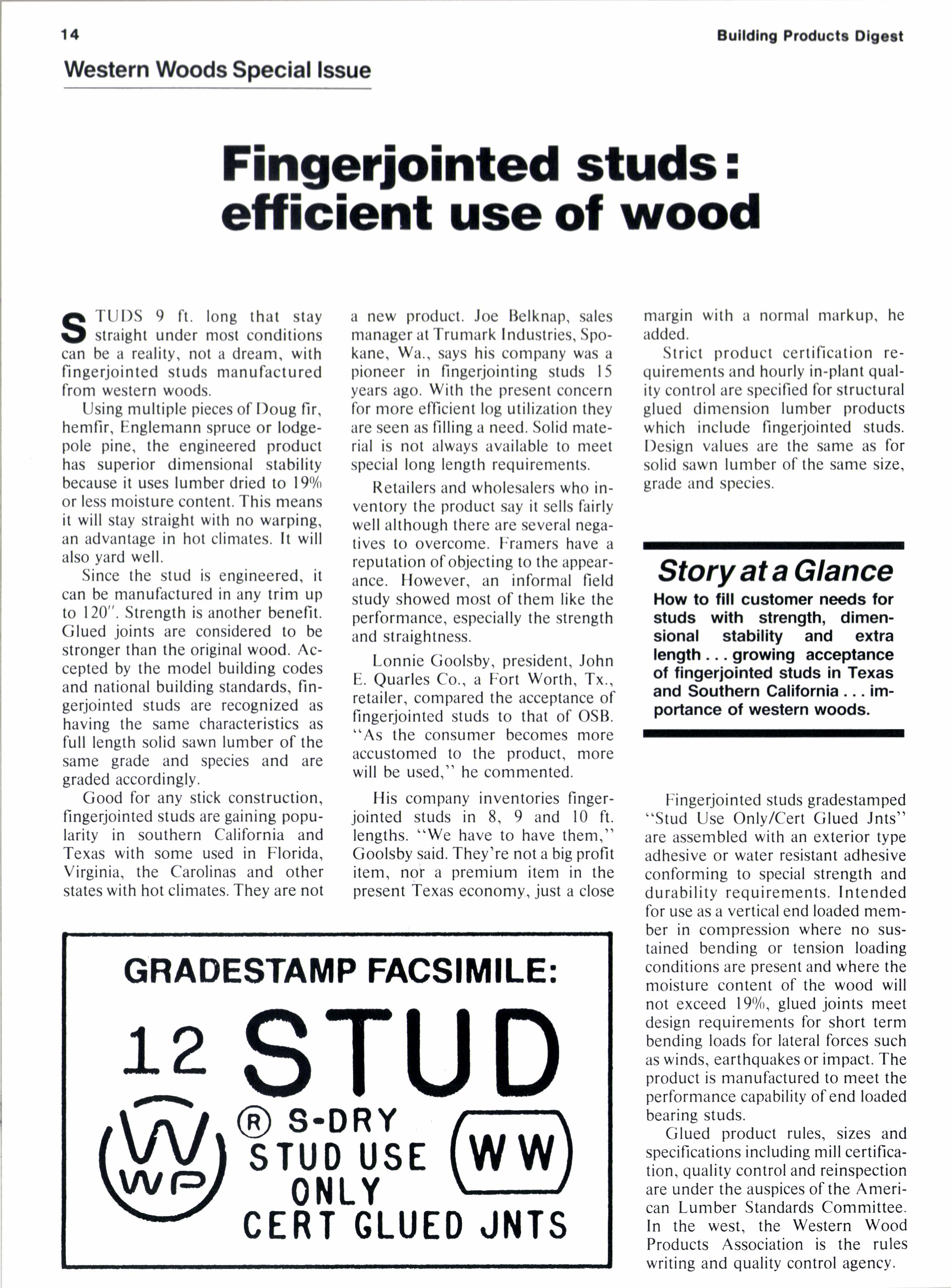

Strict product certification requirements and hourly in-plant quality control are specified for structural glued dimension lumber products which include fingerjointed studs. I)esign values are the same as for solid sawn lumber of the same size, grade and species.

Story at a Glance

How to llll customer needs for studs with strength, dimensional stability and extra length. growing acceptance of fingerjointed studs in Texas and Southern California... importance of western woods.

Fingerjointed studs gradestamped "Stud Use Only/Cert Glued Jnts" are assembled with an exterior type adhesive or water resistant adhesive conforming to special strength and durability requirements. Intended for use as a vertical end loaded member in compression where no sustained bending or tension loading conditions are present and where the moisture content of the wood will not exceed l9%r, glued joints meet design requirements for short term bending loads for lateral forces such as winds, earthquakes or impact. The product is manufactured to meet the performance capability of end loaded bearing studs.

Glued product rules, sizes and specifications including mill certification, quality control and reinspection are under the auspices of the American Lumber Standards Committee" In the west, the Western Wood Products Association is the rules writing and quality control agency.