2 minute read

3 barriers to selling hardwood millwork

IX/HILE not a huge volume prodY Y uct. hardwood millwork does offer solid margins. Retailers should be able to respond to the three most common hindrances to selling hardwood chair rails, crowns and other decorative mouldings:

"It's where?"

The best advice Jim Pierce, national accounts manager for Ornamental Mouldings, can provide is: "Stock it." Many independent retailers offer the products only by special order, losing many sales to the large warehouse chains that inventory it.

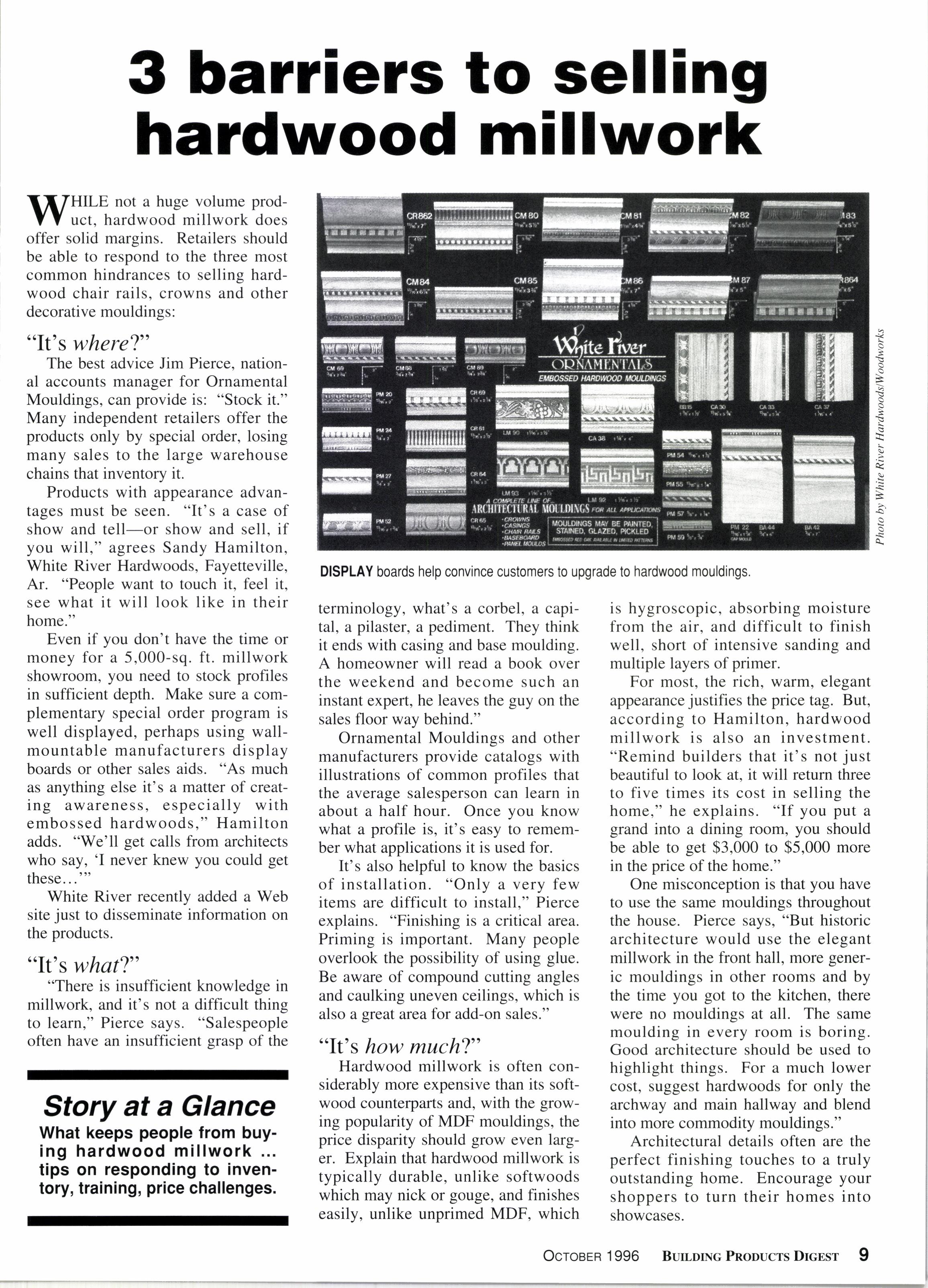

Products with appearance advantages must be seen. "It's a case of show and tell-or show and sell. if you will," agrees Sandy Hamilton, White River Hardwoods, Fayetteville, Ar. "People want to touch it, feel it, see what it will look like in their home."

Even if you don't have the time or money for a 5,000-sq. ft. millwork showroom, you need to stock profiles in sufficient depth. Make sure a complementary special order program is well displayed, perhaps using wallmountable manufacturers display boards or other sales aids. "As much as anything else it's a matter of creating awareness, especially with embossed hardwoods," Hamilton adds. "We'll get calls from architects who say, 'I never knew you could get these.. "'

White River recently added a Web site just to disseminate information on the products.

"It's what?"

"There is insufficient knowledge in millwork, and it's not a difficult thing to learn," Pierce says. "Salespeople often have an insufficient grasp of the

Story at a Glance

What keeps people from buying hardwood millwork ... tips on responding to inventory, training, price challenges.

terminology, what's a corbel, a capital, a pilaster, a pediment. They think it ends with casing and base moulding. A homeowner will read a book over the weekend and become such an instant expert, he leaves the guy on the sales floor way behind."

Ornamental Mouldings and other manufacturers provide catalogs with illustrations of common profiles that the average salesperson can learn in about a half hour. Once you know what a profile is, it's easy to remember what applications it is used for.

It's also helpful to know the basics of installation. "Only a very few items are difficult to install," Pierce explains. "Finishing is a critical area. Priming is important. Many people overlook the possibility of using glue. Be aware of compound cutting angles and caulking uneven ceilings, which is also a great area for add-on sales."

"It's how much?"

Hardwood millwork is often considerably more expensive than its softwood counterparts and, with the growing popularity of MDF mouldings, the price disparity should grow even larger. Explain that hardwood millwork is typically durable, unlike softwoods which may nick or gouge, and finishes easily, unlike unprimed MDF, which is hygroscopic, absorbing moisture from the air. and difficult to finish well, short of intensive sanding and multiple layers of primer.

For most, the rich, warm, elegant appearancejustifies the price tag. But, according to Hamilton, hardwood millwork is also an investment. "Remind builders that it's not just beautiful to look at, it will return three to five times its cost in selling the home," he explains. "If you put a grand into a dining room, you should be able to get $3,000 to $5,000 more in the price of the home "

One misconception is that you have to use the same mouldings throughout the house. Pierce says, "But historic architecture would use the elegant millwork in the front hall, more generic mouldings in other rooms and by the time you got to the kitchen, there were no mouldings at all. The same moulding in every room is boring. Good architecture should be used to highlight things. For a much lower cost, suggest hardwoods for only the archway and main hallway and blend into more commodity mouldings."

Architectural details often are the perfect finishing touches to a truly outstanding home. Encourage your shoppers to turn their homes into showcases.