2 minute read

How a mark certifies pressure treated wood

alf ONFIDENCE is a marketable Ycommodity, especially with the consumer or d-i-y-type customer. You as a retailer can capitalize on this with pressure treated wood that is backed by the quality mark of the American Wood Preservers Bureau.

With the quality mark you can easily identify the preservative used and the specific uses for which the wood has been prepared. Preservatives may color wood showing whether creosote, waterborne or oilborne preservatives have been used, but there is no way the eye can determine the penetration and retention of the pressure injected preservative. Color can not reveal if the wood has been superficially coated, dipped or sprayed.

The mark of the American Wood Preservers Bureau, an independent third-party agency that licenses numerous testing agencies, assures that the product meets specifications. These testing agencies have highly trained inspectors to qualify individual treating plants for participation in the program. They train treating personnel for internal quality-control programs, train internal quality control supervisors, and independently collect statistically random samplesof pressure-treated wood both at the treating plants and at job sites.

After the inspectors measure to determine whether preservative penetration meets the standard, the samples are sent to AWPB's national headquarters in Arlington, Va., to be subjected to rigorous, exacting laboratory analysis to assure that preservative retentions meet or exceed the standards in every aspect. This procedure assures both the seller and the buyer that pressure treated wood meets the specifications indicated on the quality mark.

Interpreting the mark is simple. In addition to bearing the American Wood Preservers Bureau trademark, it tells the year of the treatment, the preservative used, the applicable AWPB standard, the trademark of the inspection agency, the maximum

Story at a Glance

Quality mark in wide spread use . . . helps to identily product . . suppliers meet strict standards.

or worst exposure conditions to which the pressure-treated wood should be subjected (ground contact, for example) and the treating company name and plant location. Standards applied to pressure treated software lumber, timber and plywood indicate suitability for above ground or ground contact. Other standards qualify marine piling and construction poles. Pressuretreated wood to be used in residential and light commercial foundations (All-Weather Wood Foundations) must conform to special code requirements and bear a special quality mark identifying it as acceptable for foundations.

More pressure treated wood is now available with the assurance of the AWPB quality-control mark since they have licensing agreements with over half of the pressure treating plants in the United States.

RY\ llcoD

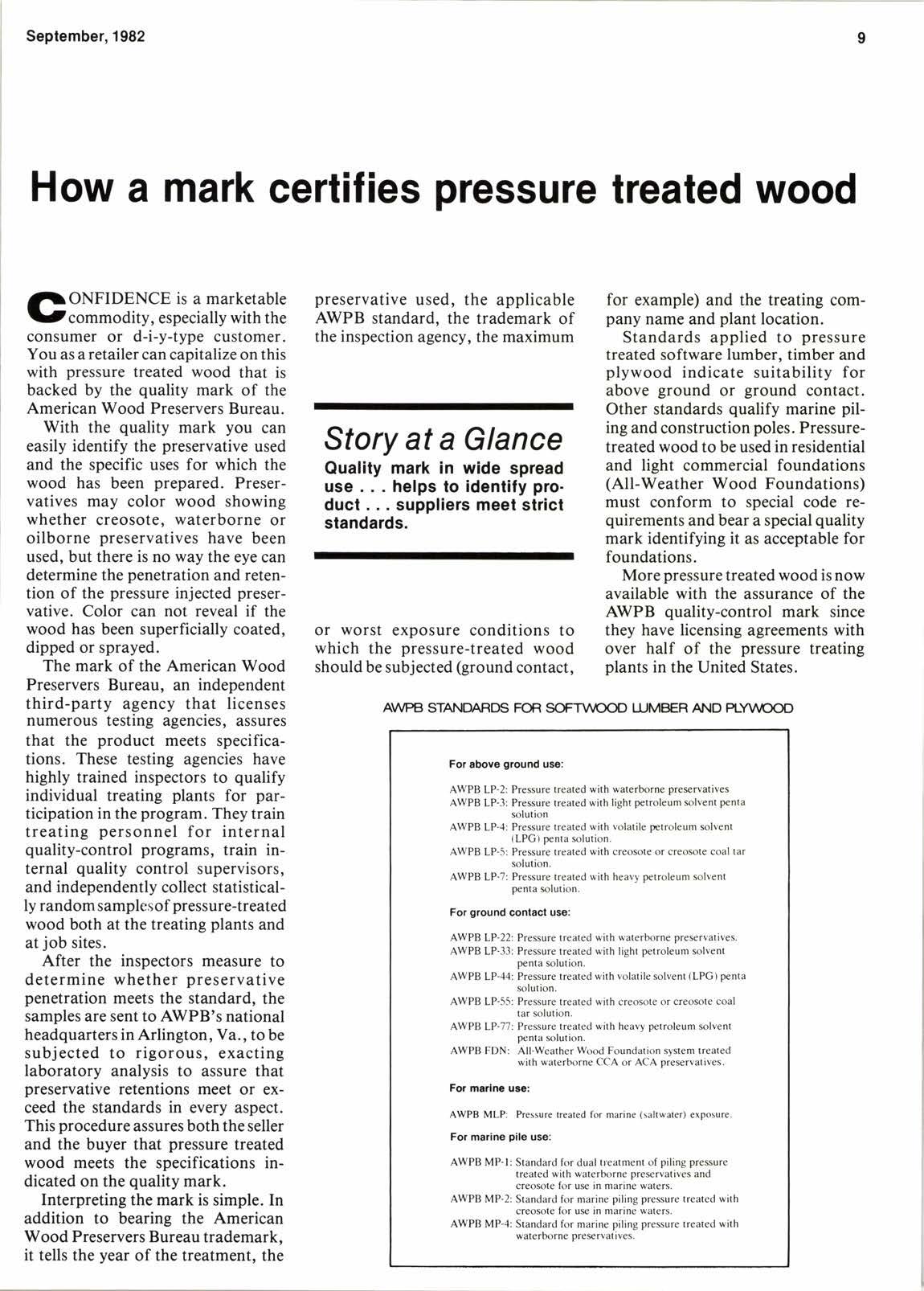

For abov6 ground u3o:

AWPB LP-2: Presure tr€ated with waterborne presrvatives

AWPB LP-3: Pressure tr€ated with light petroleum $lvent penta solution

AWPB LP-4: Presure treated wirh volatile p€troleum solvent (LPG) penta $lution,

AWPB LP-5: Pressure treated with creosote or creomte coal tar solution.

AWPB LP-?: Presure treated with heavv oetroleum solvent penta $lution.

For ground contact use:

AWPB LP-22: Pressure treated with waterborne presrvatives.

AWPB LP-13: Presure treated with light petroleum solvenl penta solution.

AWPB LP-44: Pressure treated with volatile solvent (LPG) penta solution.

AWPB LP-55: Presure treated with creosote or creosote coal tar $lution.

AWPB LP-77: Pressure treated with heavy petroleum solvent penta solution.

AWPB FDN: All-Weather Wood Foundation system treated with waterborne CCA or ACA oresrvatives.

For mrdn€ usc:

AWPB MLP: Pressure treated for marine (saltwater) exposure.

For marine pile uso:

AWPB MP-l: Standard for dual tr€atm€nt of piling presure treated with waterborne presrvatives and creorcte lor ur in marine waten.

AWPB MP-2: Standard for marine piling pressure treated with creosote tor us in marine waters.

AWPB MP-4: Standard for marine piling presure treated with waterborne presrvatives.