2 minute read

Hardboard looking good for the'80s

By Pete Smart Marketing Mgr. Temple-Eastex, Inc. Diboll, Tx.

lltITH UNSTABLE interest

UU rates, unsteady employment rates and more Americans living in older homes (about 7090) the residential repair and remodeling market should be looking forward to a more positive note in the near future. Of course, a lot depends on the overall economic recovery; however, many experts are predicting a substantial growth for the already multi-billion dollar industry.

As the remodeling and housing repair market grows so will the siding industry. Siding represents a big part

Story at a Glance

Hardboard popular in remod. eling market . . . saves labor available in wide variety of architectural styles . . easy maintenance a sales feature. of residential remodeling. It is virtually a part of every room addition and new garage and is used in various other applications including soffits and exterior ceilings.

Although there are several different kinds of materials used to produce siding, some people have recently discovered the benefits and unique qualities of hardboard. I believe builders, remodeling contractors, architects and home buyers are beginning to recognize the durability, versatility and beauty hardboard offers.

Through the use of modern processes, real wood fibers are fused under heat and pressure to produce a product that handles better than actual wood. Hardboard does not split, crack or warp and resists hammer marks. It can be worked with ordinary carpentry tools which not only makes application easier it makes it quicker. We have had remodeling contractors tell us that the qualities of hardboard speed-up installation, but that the newest designs have really made the difference.

Several firms now offer siding in large 12" x 16' panels. However, some firms manufacture a panel that combines three labor-saving narrow laps to allow application in a single course. Also some hardboard designs offer alignment guides to help the applicator achieve quick, consistent overlapping. These designs offer the traditional beauty of lap siding with the fast application that cuts remodeling costs.

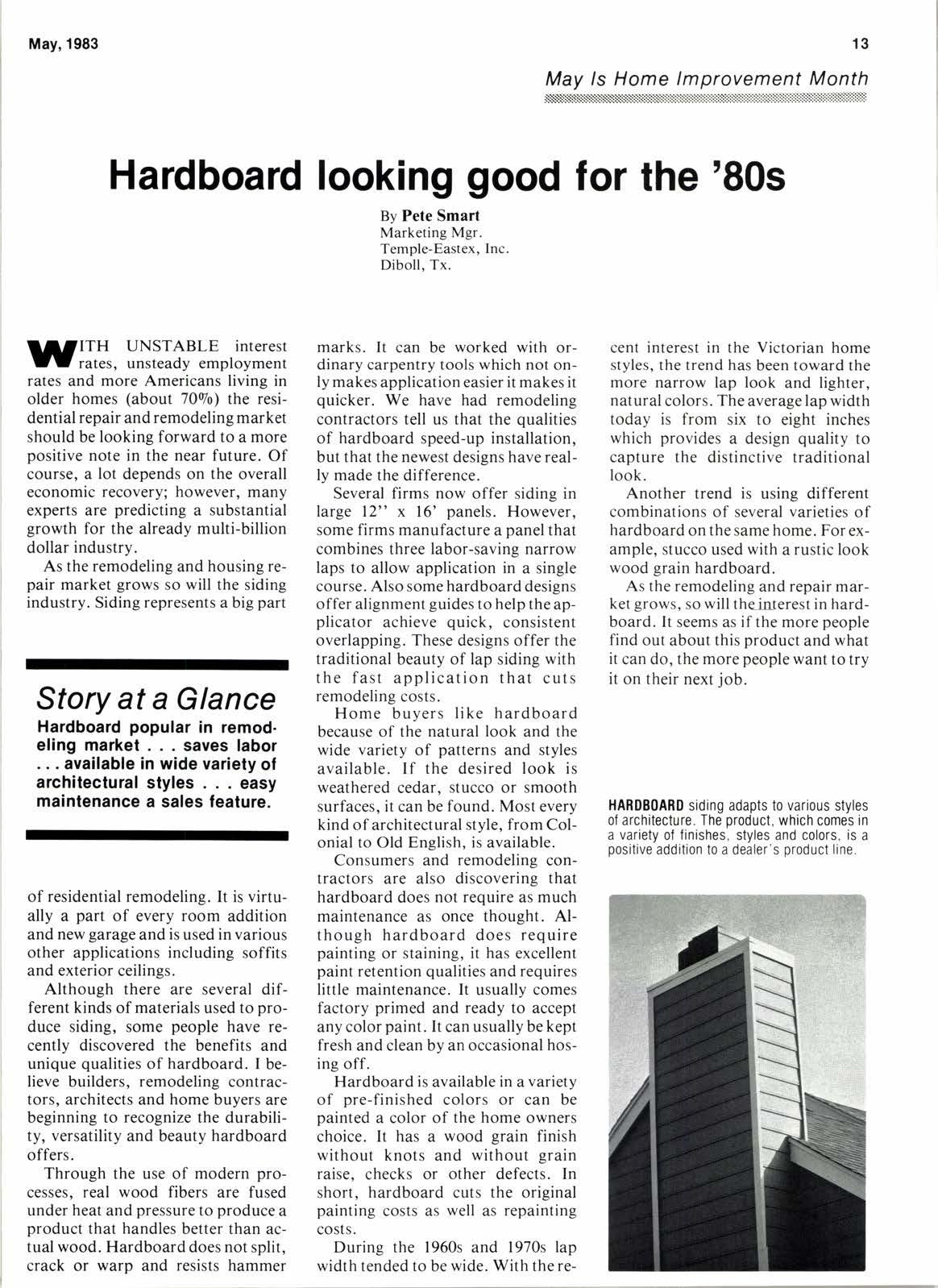

Home buyers like hardboard because of the natural look and the wide variety of patterns and styles available. If the desired look is weathered cedar, stucco or smooth surfaces, it can be found. Most every kind of architectural style, from Colonial to Old English, is available.

Consumers and remodeling contractors are also discovering that hardboard does not require as much maintenance as once thought. Although hardboard does require painting or staining, it has excellent paint retention qualities and requires little maintenance. It usually comes factory primed and ready to accept any color paint. It can usually be kept fresh and clean by an occasional hosing off.

Hardboard is available in a variety of pre-finished colors or can be painted a color of the home owners choice. It has a wood grain finish without knots and without grain raise, checks or other defects. In short, hardboard cuts the original painting costs as well as repainting costs.

During the 1960s and 1970s lap width tended to be wide. With the re- cent interest in the Victorian home styles, the trend has been toward the more narrow lap look and lighter, natural colors. The average lap width today is from six to eight inches which provides a design quality to capture the distinctive traditional look.

Another trend is using different combinations of several varieties of hardboard on the same home. For example, stucco used with a rustic look wood grain hardboard.

As the remodeling and repair market grows, so will thqinterest in hardboard. It seems as if the more people find out about this product and what it can do, the more people want to try it on their next job.

HARDBOARD siding adapts to various styles of architecture. The product, which comes in a variety of finishes, slyles and colors, is a oositive addition to a dealer's oroduct line.