1 minute read

New drying process improves southem pine quality

HE MARKET is talking and Georgia-Pacific Corporation is listening.

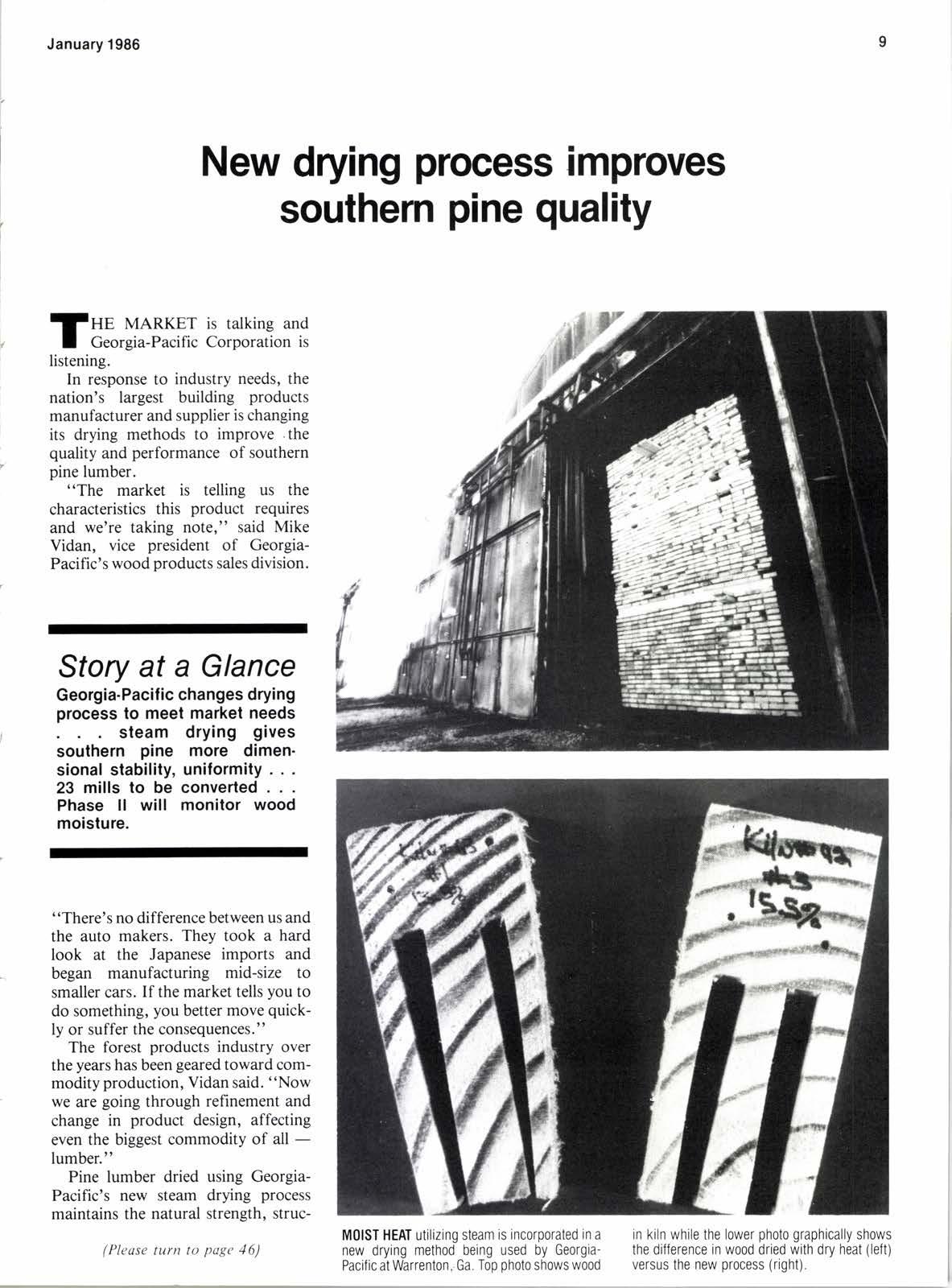

In response to industry needs, the nation's largest building products manufacturer and supplier is changing its drying methods to improve 'the quality and performance of southern pine lumber.

"The market is telling us the characteristics this product requires and we're taking note," said Mike Vidan, vice president of GeorgiaPacific's wood products sales division.

Story at a Glance

Georgia-Pacif ic changes drying process to meet market needs . steam drying gives southern pine more dimensional stability, unilormity . 23 mills to be converted . . Phase ll will monitor wood moisture.

"There's no difference between us and the auto makers. They took a hard look at the Japanese imports and began manufacturing mid-size to smaller cars. If the market tells you to do something, you better move quickly or suffer the consequences."

The forest products industry over the years has been geared toward commodity production, Vidan said. "Now we are going through refinement and change in product design, affecting even the biggest commodity of alllumber."

Pine lumber dried using GeorgiaPacific's new steam drying process maintains the natural strength, struc-

(Please turn to page 46)