10 minute read

CBAM SO 19 - Cover story

from CBAM SO.19

The Engineering Crafters

The art and science of creating paper structures that save the planet

By Eric Balinski

Throughout history, people have marveled at magnificent man-made structures, from the ancient pyramids, to the Roman aqueducts, the Eiffel Tower, the Brooklyn Bridge, the Dubai’s Palm Islands, the Hoover Dam and New York’s Freedom Tower. Looking at these structures begs the question: “How did they make that?”

Few would suggest the 2,000 year old art of papermaking would draw such awe. Even though its inventor, Cai Lun, was deified as the god of papermakers in the Han Dynasty, creating papermaking as we know it by combining natural materials like tree bark to make a pulp mixture with fibers pressed into paper.

But papermaking is entering a new realm of sophisticated engineering, driven by the technology wizards at Footprint. Its development efforts create engineered paper by formulating fibers, additives and manufacturing to achieve specific paper structures for consumer packaging that is replacing single use plastics.

Footprint is leading the way with disruptive technologies across a wide range of industries too. Its ability to deliver game-changing solutions for its customers is based on the work performed by Footprint’s technology innovation team. Led by Yoke Chung, co-founder and Chief Technology Officer, this team is made of up Ph.Ds., chemists, material scientists, mechanical and process engineers, and designers, all working together to build the formulations, equipment and process controls necessary for Footprint’s success.

As a measurement of their success, the team has enabled 1,124 global inventions to be patented or that are in process of being patented. The team’s success in creating and bringing to market the technologies of the future has been unmatched in the industry.

Craft Brand and Marketing Magazine spoke with Footprint’s SVP Marketing, Jeff Basset, to learn more about their engineering crafters that will make the world’s environment better.

Give us a snapshot of the current environmental/green product market(s). Today’s green product market, especially in packaging, is focused on the easily implemented items such as picnic and to-go containers. The reason the segment is focused in these areas is because of the low technical requirements necessary to deliver product performance. At Footprint, we refer to these solutions as “low hanging fruit.” These are the easy items to replace and have been in the market in one form or another for some time (think back to picnics as a kid using the thin paper plates).

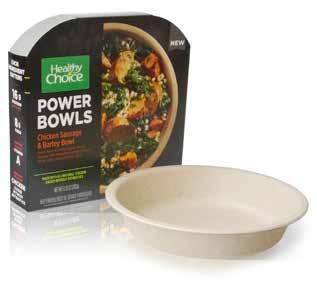

But these items, while great at picnics, are not the items that large consumer brands are being asked to change. Footprint tackles the elimination of plastic from products and packaging in market segments were paper based packaging has typically never been used. From frozen food, to shelf stable cups, and even six-pack rings. Footprint is focused on helping brands solve real world demands from their consumers to eliminate plastic.

What trends are defining the space? People want to buy sustainable products. Consumers pressuring brands to do better by eliminating plastic from their packaging is the defining trend of 2019. You are seeing the results of this as the EU and now Canada have announced significant bans on all single use plastics. There is also some compelling consumer research that proves consumers are not going to allow plastic to exist when there are viable alternatives. The move to eliminate these plastics is coming from rising consumer awareness about how plastic is affecting our environments in the form of pollution, but also how plastics are causing detrimental impacts to our food chain and human health.

Plastic in general are getting negative stories about their environmental impact. What specific environmental issue does Footprint address or solve? Footprint solutions address a wide range of negative environmental impacts, first and foremost

is the elimination of plastic. By eliminating plastic at the source, Footprint is putting a stop to the influx of waste plastic into the ocean which is killing more than 1.1 million sea birds and marine animals each year. Footprint solutions are biodegradable, compostable and recyclable, which offers brands and municipalities several options for how to handle the end of life of a Footprint product. Having multiple end-of-life options is a critical benefit for municipalities as waste infrastructure varies greatly. Flexibility to fit into the waste infrastructure on a national, regional and local level means that our solutions can immediately help address environmental impacts due to plastic waste.

Footprint’s technology innovation team members are:

Yoke Chung, Chief Technology Officer Brandon Moore, SVP Design & Tooling Engineering Mike Lembeck, Director Tooling Engineering Kent Warner, VP, Product Management Jean Pelkey, VP, Product Management Steve Lucero, VP Equipment Development Engineering Todd Biggs, Director Process Development Engineering Winnie Luong, Senior Process Engineer Rick Gonzalez, VP Materials Science & Engineering Yiyun Zhang, Director Materials Development Engineering Austin Gann, Lab Manager Timsy Shukla, Materials Engineering Matt Wang, Materials Engineering Megan Dieu, Materials Engineering

Your website says Footprint is “reinventing sustainable packaging.” What does this mean? Footprint is taking sustainable packaging into the future, essentially reinventing where and how paper-based packaging can be used. As a powerful example, we’ve eliminated the need for plastic sixring beverage packaging with our new molded-fiber alternative. More importantly, as an innovation technology company and as a manufacturer, Footprint is developing solutions to be consistent with current pricing models of materials and components that brands buy today. It is disproving the long-standing belief that sustainable packaging has to be more expensive.

At the heart of reinventing sustain packaging is Footprint’s technology innovation team, which ultimately makes Footprint products work and make a difference to improving our customers businesses. Without this team pioneering the technologies, and then refining the technologies to make sense at mass scale, Footprint would not be where it is today. These are the unsung heroes that are fulfilling Footprint’s vision of eliminating plastic. Our technology innovation team that is creating the solutions to make future grocery stores free of single use plastics.

Most plastics are chemical compounds originating from petroleum. Footprint uses fibers as the basis of its product. What is the fibers source from? Footprint use a range of fibers to produce our products, the majority of which comes from recycled sources. Paper is the number one recycled material in the U.S. (roughly 85% recycling rate), using recycled fibers is an easy win. Footprint has even built closed loop supply chains that take a customer’s waste fibers, such as corrugate boxes, from their factories and turned it back into their packaging. The best part of using fiber sources is their renewability and availability. Unlike petroleum-based plastics which rely on fossil fuels or even bio-based plastics that use food crops as their inputs.

Tell us how Footprint products are more sustainable and beneficial than other consumer package options? Simply put, Footprint solutions are more sustainable due to the renewable nature of their raw materials, the ability to use high percentages of recycled paper content (up to 70%) and most importantly, their non-detrimental impact at the end of life stage. Because our products are paper based, they are generally recognized as recyclable, compostable in industrial composting facilities and if they leak out into the environment, they behave just like any other paper type product (they bio-degrade and quickly break apart). I don’t know about you, but I’ve never heard of a whale that died from swallowing too much paper, or a bird that mistook paper for food and subsequently died. These situations with animals, which have become all too common with plastics, simply don’t happen with fiber-based products.

Is there any environmental impact associated with generating or using these fibers? There are environmental impacts associated with all materials. The best advantage of using fibers vs plastic and petroleum-based solutions, is the renewability of the fiber sources. More plants, more trees, more agricultural by-products are available every year and the fiber sources used to create papers or footprint products are largely bi-products of other industries.

For example, trees are cut down for lumber for buildings and furniture. The left-over bits are used for making paper. The world has a finite amount of petroleum, and while the debate rages as to when it will run out, the real fact is that it will run out. Fiber sources can be regrown.

What are the unique benefits for companies who use Footprint products? Footprint products can be disposed of in any bin—which eliminates confusion for the consumer. Other benefits fall into two primary categories— and are benefits we pass on to consumer brands, the first is consumer recognition. The second is product performance.

The No. 1 way that consumers evaluate a companies’ sustainability position is through their packaging. Consumers immediately and intuitively understand the sustainable characteristics, such as recyclable, compostable and biodegradability, of paper-based packaging. This is vastly different from other packaging solutions that are not immediately recognized by customers.

Examples from the plastic industry, such as light-weighting plastics, (where plastic solutions are made with less plastic) or alternative plastics such as recycled plastics and bioplastics are not noticeable to consumers and can even harm the brand in terms of lower quality perception. The methods used to make plastics “more sustainable” have no immediately discernible differences from regular plastics.

The second way that companies’ benefit is in the packaging performance. Footprint products are engineered to protect the product just as well, and in some cases, even better than plastic. Take our fiber six-pack rings. Our rings pass the same test standards as plastic rings, including jolt testing in high-humidity environments.

What are the benefits for end-use consumers? Consumers want to do the right thing. They want to feel good when they walk away from a typical landfill/recycle/compost bin. But the consumer rarely feels like they get this decision correct. To compound the problem, municipalities are starting to abandon recycling and are taking the recyclables that consumers separate and sending them straight to a landfill.

With Footprint products, consumers can feel confident that even if they get it “wrong” they are doing better by having used a fiber product rather than a plastic product. Footprint solutions have advantages over plastic no matter which bin they go in.

Compared to other bio-degradable single use products, what makes Footprint a superior? Footprint products are superior because they work. Our ability to engineer precise performance standards with a fiber product is unmatched in the industry. From frozen foods, to fiber meat trays, to fiber six-pack rings, our technologies meet customers’ needs, and in some cases, outperform the performance plastic based solutions. Footprint’s product performance paired with our “Any Bin, You Win” material makes our products a formidable force that is driving key market segments to switch to Footprint Fiber.

What’s the biggest issue today related to the marketing/sales side of green products today? Performance and price. Footprint demonstrates that matching the performance requirements of our partners is achievable, but often, the initial perception of what fiber products can do is negative. Footprint is clearly reversing that initial perception but it is still an issue that needs to be overcome. A great example of this is seen in the paper straw market. When the big conversion to paper straws occurred, an influx of substandard straws from other suppliers and countries flooded the market. Now we see a lack of consumer confidence in the category. This has driven several brands to reach out to Footprint to solve the performance issues they are experiencing with other paper straws, which of course is Footprint’s area of expertise; matching sustainable solutions to customers performance requirements.

We believe that a paper straw should outlast your longest party. This means that our straws are engineered to last through multiple drinks and not fall apart in milkshakes and such. Footprint’s paper straws vastly outperform other paper straws by lasting a full 24 hours or more and are, in essence, coming to the rescue of the paper straw segment. Pricing is another issue with marketing green products. Green products have to compete vs. their plastic counterparts on what is essentially an uneven cost playing field. Don’t get me wrong, Footprint is still winning the game, but it does create an uphill battle. The plastic industry has had a 20-50-year head start on green products in general. Essentially, we are a new technology, while plastics have had decades to automate and improve their manufacturing process to lower costs.

Footprint solutions see the same cost reduction curves that the emerging plastic industry experienced decades ago. Give Footprint three years and we see a roadmap to being less expensive than our plastic counterparts. The other thing that the plastic industry has done very well is to externalize their costs. This gives the perception that the products are inexpensive, but the truth is, that the consumers pay for the externalized costs of plastics.

From cleaning plastics out of our oceans and off our streets, to the recycling infrastructure, all of these costs are paid for by us, the consumer, not the plastic manufacturers. In essence, it gets to flood the market with low value waste, that consumers have to foot the bill to pick up. Unlike the paper fiber industry where recycled fiber is valuable which is demonstrated by the high recycling rates.

What do you see as some of your biggest opportunities moving ahead? Our biggest near-term opportunity is launching the Footprint paper cup. Footprint was recently named a winner of the “Nextgen Cup Challenge” for our ability to eliminate plastic liners from typical paper cups. This challenge was a global innovation challenge that received close to 500 entries from 26 countries to solve the problem of plastic liners that are used in paper cups. Beyond our fiber drinking cups, Footprint is also expanding into products that are disposable, such as disposable razors, hotel room keys and even diapers.

While Cai Lun was deified as the god for his invention of papermaking, perhaps one day Footprint’s technology innovation team may be recognized for their role in transforming the landscapes and seascapes littered with single used plastics back to their natural beauty. Surely, if nothing else, traditional papermaking will forever be changed by the know-how being developed at Footprint to engineer paper beyond what most people can imagine paper can do.

Eric Balinski is the owner of Synection, LLC, which is a strategy and growth consultancy firm. For more information, visit: synection.com.