10 minute read

Exclusive interview: Ainhoa Lete, BuntPlanet

U.S. drought accelerates ‘water reuse revolution’

Exclusive Interview: H2O Global News Editor, Siôn Geschwindt, spoke with Epic Cleantec Co-founder and CEO, Aaron Tartakovsky, about their water reuse solution for buildings and, more broadly, the importance of designing smarter, more resilient cities for the future.

Advertisement

In the heart of Silicon Valley, an innovative building complex is in the works. The proposed ‘Park Habitat’ workspace, in San Jose, California, has a ‘green lung’ 20-storey vertical façade, a rooftop garden, and energy saving and renewable technologies – setting the bar for truly ‘smart’ buildings.

But given the fact that California is beset by severe drought, can we really afford to water all those plants?

The answer to that question lies hidden in the basement.

Park Habitat will be fitted with a state-of-the-art recycling system that takes all the water used in the building, cleans it and reuses it for non-potable purposes like flushing toilets and watering plants.

And the brains behind the operation? San Francisco based startup, Epic Cleantec.

What’s so Epic?

Founded by father and son duo, Igor and Aaron Tartakovsky, Epic Cleantec installs on-site water recycling systems to process black and grey water for reuse within the building.

“The vast majority of water in buildings is used for non-potable purposes such as flushing or irrigation,” said Epic Cleantec Co-Founder and CEO, Aaron Tartakovsky. “Given the droughts and water scarcity we are facing – and will continue to face – it simply doesn’t make sense to use drinking water for these purposes.”

Epic Cleantec look to usher in a ‘water reuse revolution’, where getting the most out of our scarce water resources is the norm, not the exception. Tartakovsky predicts this will change in the near future.

“I think in 10-15 years it’s going to be very common to use recycled water for drinking,” he said. “The technology to bring recycled water to drinking standards is already here, and despite the ‘yuck factor’, I believe water scarcity issues will move us to adopt these technologies more quickly.”

And this is not just about water, it’s about food and energy too.

Epic Cleantec’s system extracts organic material from the building’s waste water to produce a natural soil amendment. They’ve even built a food garden in downtown San Francisco, to showcase the amazing potential of this natural fertiliser Locally-made soil amendments from Epic Cleantec’s system.

Energy can also be extracted from the buildings water: “An incredible amount of energy is used to heat water in buildings,” said Tartakovsky. “We repurpose this energy, for example, to heat the domestic water of the building.”

Epic Cleantec have already installed their technology in two San Francisco high-rises: the 35-storey NEMA building, nestled between the Uber and Twitter headquarters, and the Fifteen Fifty apartments, a few blocks away. These buildings are reusing an average of 5000 gallons (22730.45 liters) a day, or 1.8 million gallons each year.

And the Park Habitat building is next in line.

“We will use our technology [at Park Habitat] to irrigate 20-storeys of living wall,” said Tartakovsky. “We will be tweaking our process to leave some of the organics in the water to give the plants extra nutrients.”

“15-20 years ago, having a green building was a nice-to-have but now it’s a must have; driven by a broader conversation around building smarter, more resilient cities,” he continued. “There is a relative consensus that the main difficulties in increasing water reuse are not technological,” said International Water Association (IWA) Director of Strategic Programmes and Engagement, Daniela Bemfica, in an interview with H2O Global News. “The main barriers are related to policy, regulation and cultural aspects.”

“The drought is accelerating the conversation and our decisionmakers understand the challenge, but there are a lot of stakeholders that you need to bring together,” said Tartakovsky. “That’s why since the beginning we have been working with policymakers and urban leaders to create a conducive regulatory pathway to mainstream water reuse in our cities.”

Smart buildings, smart cities

Buildings are among the top five contributors to global carbon emissions, and office blocks alone make up 10% of annual water use in the U.S.

Yet, as urban populations grow, so must the built environment, which poses the question: how can we design more efficient and sustainable buildings?

Reusing water on-site is one solution that helps buildings cut expenses, reduces overall water use and eases the strain on existing sewage networks, many of which are ageing.

There are also hidden advantages to this decentralised approach.

“About 20% of the state’s energy budget is spent on water, and a big chunk of that is for pumping,” said Tartakovsky. “Decentralising water management will cut energy costs and diversify our water sources so that if one runs dry, we have others to fall back on.”

“In the 21st century we really shouldn’t have to depend on whether it rains or not to ensure that our communities have enough water,” he continued.

Building resilience in our water supply will become increasingly important as climate change causes more frequent and extreme weather events.

Fortunately, most of the solutions to tackle climate change are already here. The big challenge is creating a policy framework that supports the rapid implementation of these solutions.

Building for the future

Building smarter, more resilient cities is a behemoth undertaking that will require targeted investment and political support.

In April of this year, the bipartisan Drinking Water and Wastewater Infrastructure Act of 2021 passed unanimously through the U.S. Senate. The bill allocates over $35bn in funding for drinking water and waste water infrastructure.

“We strongly support this bipartisan bill and applaud those who worked across party lines to negotiate this deal,” said National Association of Clean Water Agencies CEO, Adam Krantz. “However, there is still much work to be done and clean water’s role must be placed on equal footing with other infrastructure sectors such as roads, bridges and broadband.”

The focus on water infrastructure at the national level is a promising sign, but as Krantz underscored, much more investment is needed.

Tartakovsky agrees:

“The bill is a step in the right direction and signifies overwhelming support for modernising our water infrastructure. However, if we are to tackle water scarcity and really build smart cities we will need much more investment and the deployment of all the solutions we have, and rapidly.

By ushering in a water reuse revolution, we at Epic Cleantec hope to be part of the solution – building better cities, not just for this generation, but for those to come.”

The Park Habitat office tower in San Jose, CA. (Credit: Kengo Kuma and Associates / Westbank) Website: epiccleantec.com

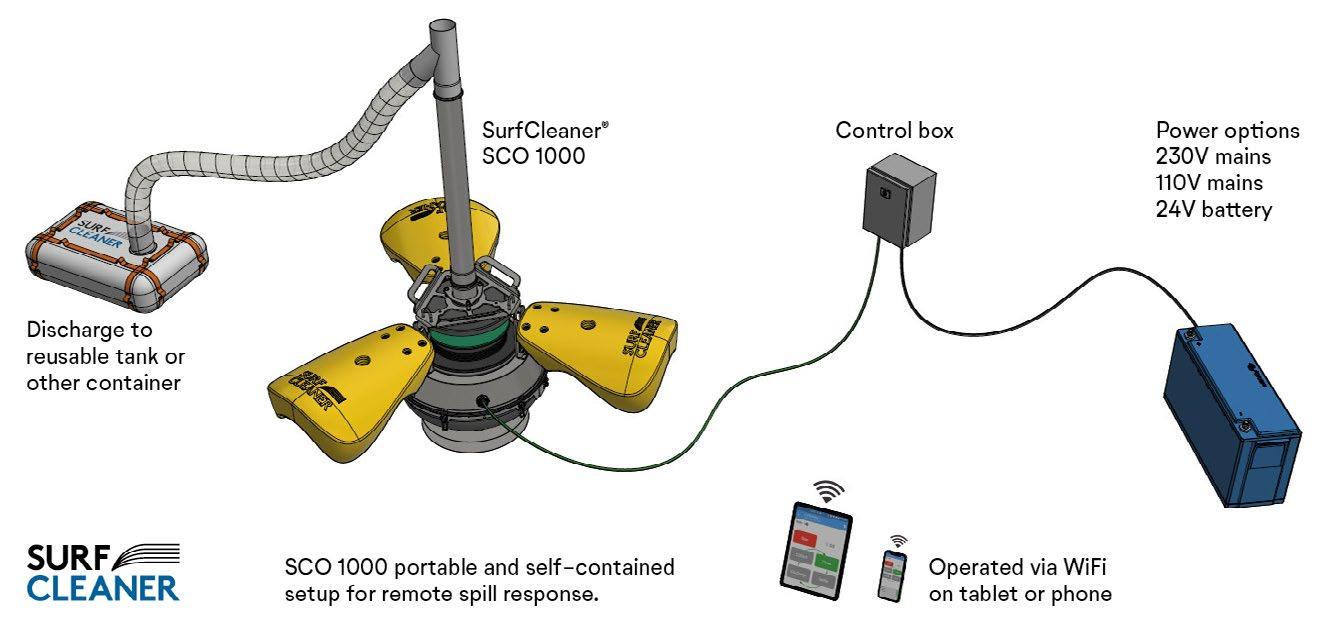

SurfCleaner - On mission to tackle the world’s untreated water

Swedish water treatment specialist and pioneer of the world’s first skimmer separator device is on a mission to make a positive, direct and sustainable impact on the environment.

With over 80% of used water still going untreated globally - the scale of the challenge is colossal. However, SurfCleaner is mobilising fast, rapidly expanding its distributor network across continents and forging new deals in multiple sectors worldwide.

plan, adding to an existing network spanning the UK, United States, Canada, Mexico, Nigeria, Libya and Turkey.

The firm’s technology recovers contaminants from water surfaces including oil, diesel, petrol, plastics, sludge and other pollutants. It has identified huge potential across energy and industrial sectors, including wastewater treatment plants, refineries, process industries, steel mills, tunneling, mining, recycling, waste management and broader infrastructure projects, as well as oil-spill clean-up and recovery projects across harbours, ports and coastlines.

For environmentally conscious operators, the benefits are threefold. While improving water quality by recovering myriad pollutants, it also boosts green credentials by reducing VOC emissions and carbon footprints. Thirdly, it neatly collects by-products including oil which can be re-used and resold contributing to the circular economy while generating new income streams.

Following a recent high-profile deal with Scandinavian environmental services giant Ragn-Sells, SurfCleaner is managing a steep trajectory with strong order volumes in what promises to be its busiest year to date. Having already installed around 40 units across the oil-water separation segment its roster of clients include the Swedish Coast Guard, Preem Refinery, Esso Refinery, Sonatrach Refinery, Exxon Mobil and Ports of Stockholm.

New distributor partnerships in Norway and Italy with Christian Berner and WTE are also part of a broader strategic expansion Led by an experienced team, SurfCleaner remains a passionate family-led firm, with the late inventor, Dr Stig Lundbäck’s daughter, Christina, now at the helm. Driven by a desire to solve environmental problems, Christina is upholding the Lundbäck legacy as an outspoken advocate for sustainable industry.

Aligning with global decarbonisation and net-zero targets, recently set out at COP26, SurfCleaner is also well positioned to help relieve future carbon tax burdens placed on industry – widely recognized as the most cost-effective mechanism to reduce emissions at the scale and speed necessary.

In the meantime, the technology remains at the ‘heart of global water treatment’ in more sense than one, as Stig’s innovative technology - coined DAPP (Dynamic Adaptive Piston Pump) - takes front and central stage, mimicking the pumping principles of the human heart which pulses blood through the body 100,000 times a day.

Website: surfcleaner.com

Combatting Artificial Additive Threats to our Environment and Health

By Atle Mundheim, Chief Technology Officer, M Vest Water

The prevalence of perfluoroalkyl and polyfluoroalkyl substances – often referred to as ‘PFAS’ - in the environment is one of today’s most pressing issues. Norwegian-based M Vest Water is addressing this major global challenge. The company has developed innovative green products that capture PFAS by flocculating these molecules or polymolecules in a manner that enables efficient removal from water and wastewater.

PFAS: the harmful “forever chemicals” that are virtually indestructible. These short or long chain molecules are among the most persistent in the world and are often called “forever chemicals” since they take thousands of years to degrade. Used in industrial activities and to produce consumables, these molecular bonding substances are disposed of in waste and then find their way into and accumulate in ground water and oceans.

Due to their nano sizing, they migrate in the food chain, and finally end up at our table in shellfish, fish, meat, food and water. They are even transported through air and spread over vast areas where they contaminate soil and waterways.

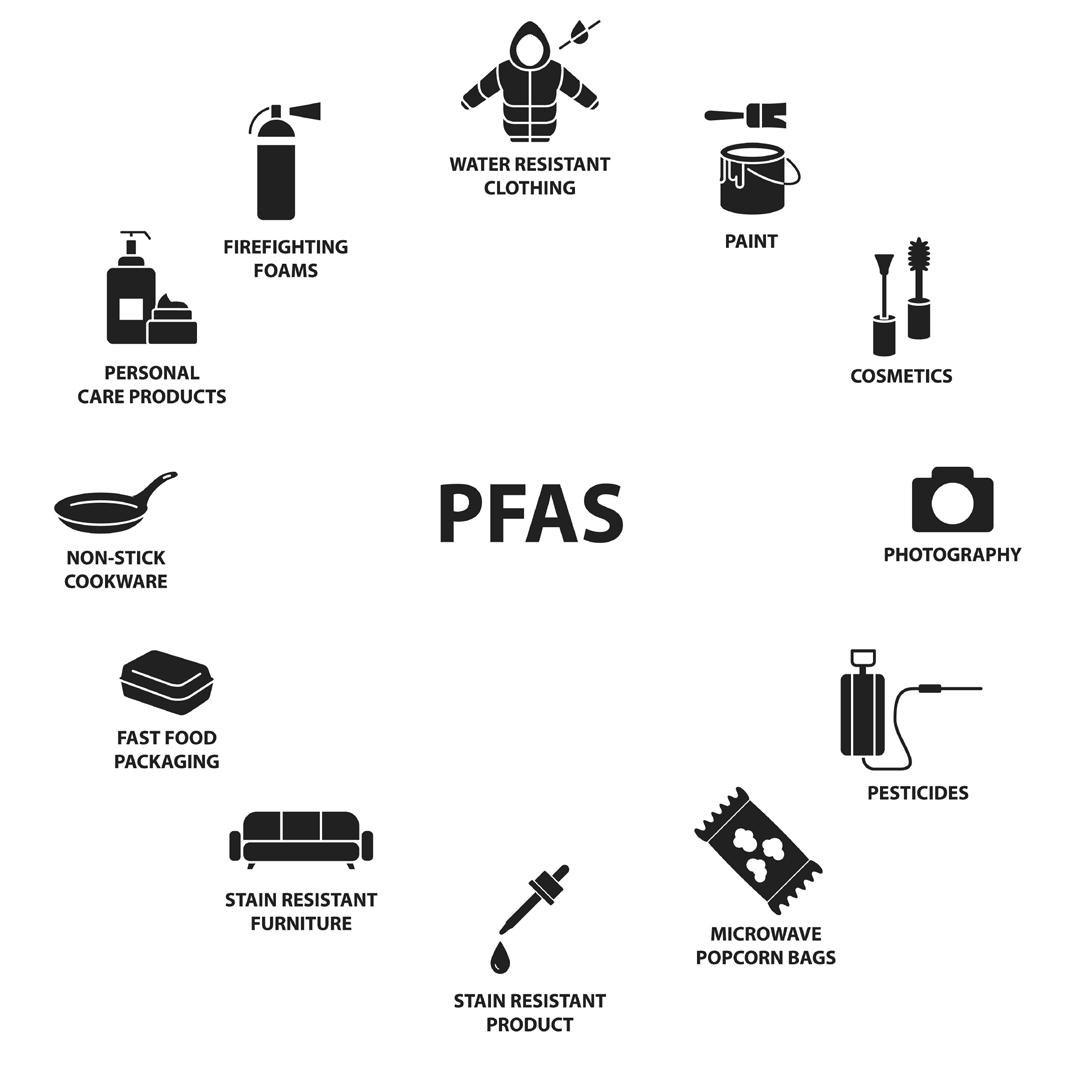

PFAS represent a large class of manufactured chemicals that have been used in firefighting and for stain resistance, water repellents, oil and fat repellents, lubrication, and many other industrial applications since the 1940s. Extreme high temperatures of around 1800 degrees Fahrenheit are required to destroy this ‘eternity product.’

Human exposure to PFAS is a global problem. PFAS have been linked to a number of adverse health effects, and exposure may occur via ingestion, direct contact, inhalation and occupational contact. According to a study executed by The Agency for Toxic Substances and Disease Registry (ATSDR) and published by U.S. Centers for Disease Control and Prevention (CDC), PFAS may cause damage to the liver and heart, also auto immune disturbances, cancer and hormone disturbances.

Today, most people in industrialised nations have measurable amounts of PFAS in their blood. In fact, according to the U.S.

Products that contain PFAS

National Groundwater Association, studies estimate that 95% of the U.S. population has been exposed to PFAS and have measurable concentrations in their blood.

Although PFAS are no longer manufactured in the U.S. or Europe, their effect will persist for generations to come. They are still produced in elsewhere around the world, and older products as well as imported materials ranging from textiles to coatings may still contain PFAS. And the damage done since the 1940s shall still haunt us for generations, even if we manage to eliminate these substances from use as of now.