1 minute read

CASE STUDY UASB/HRAP: Making Algal Wastewater Treatment Efficient

While finding alternative sources of water can help Australia deal with shortages, the country can use existing resources more efficiently. To support this, Andrew Ward and Urban Utilities developed a twostage algal wastewater treatment that produces more water for reuse in irrigation.

To treat wastewater, Australia uses Waste Stabilisation Ponds (WSPs), with over 600 presently in operation. However, the technology has not advanced in the past 50 years and struggles to meet modern water recovery requirements.

Advertisement

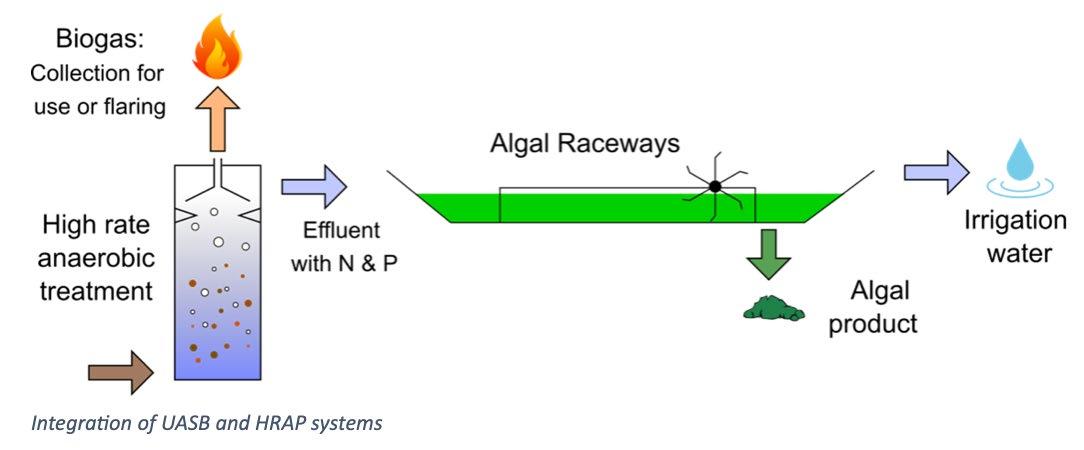

Integration of UASB and HRAP systems

The process begins with pre-treatment using high-rate anaerobic digestion (UASB), which makes nutrients soluble and enhances biological availability. Anaerobic digestion also promotes carbon recovery by capturing methane for energy production.

During the HRAP treatment stage, a microalgae culture treats wastewater and removes nutrients, such as carbon, nitrogen, and phosphorous, and pollutants such as coliform bacteria and heavy metals.

In the raceway ponds, a paddlewheel agitates effluent and prevents sedimentation. During the day, the algae produce oxygen, raising the dissolved oxygen concentration to 2-3 times saturation (>20 mg/L). This highly aerobic process helps bacteria decompose organic matter more efficiently.

HRAP reduces biological oxygen demand (BOD5), while the algae assimilate nitrogen and phosphorus, creating a harvestable biomass. Because the ponds are shallow with a high surface area, sunlight UV-disinfects faecal microbes and photo-oxidizes dissolved organic contaminants.

Pilot studies showed UASB/HRAP systems overcome the issues with WSPs. The improved wastewater treatment and lower retention times make more water available for reuse and improve quality significantly. UASB treatment takes 10-12 days, compared to 50-60 for WSP, reducing evaporation and salinity significantly. The process also lowers GHG emissions while preventing sludge build up.

Within a WSP, cyanobacteria blooms and algal growth mean long retention times and high evaporation rates, reducing the amount of water recovered. Build-ups of sludge and waste make it difficult to meet discharge limits, while organic matter and nutrients emit greenhouse gases (GHGs).

To address these problems, Andrew developed an integrated wastewater treatment using the same biological WSPs but with two stages, Upflow Anaerobic Sludge Blanket (UASB) and High-Rate Algal Ponds (HRAP).

Importantly, Australian water treatment plants can retrofit the scalable technology rather than undertake expensive civil work, meeting regulatory requirements at 50-75% of the cost of sludge-based systems. Utilities can upgrade their WSP technology and maximise the amount and quality of treated water available for reuse.

Technology Brings Hope

While Australia is at risk of water shortages, the country is producing technologies to overcome the problem. Between desalination to unlock new resources, greywater, using natural resources to purify and UASB/HRAP to reuse water more efficiently, there is hope.