12 minute read

Member Profile: J. Pechauer Custom Cues By Anthony Stoeckert

By Anthony Stoeckert

It all began with a wager.

In 1961, Jerry Pechauer played a game of pool against a coworker of his at International Harvester Company in Green Bay, Wisconsin, where Jerry worked as a truck mechanic apprentice. Jerry won the match, and his colleague, lacking money, paid off the debt by giving Jerry a cue.

Not a bad deal, you say? Well, consider the fact that the cue was broken and didn’t have a shaft.

Still, Jerry accepted the stick as payment and got to work repairing it.

What he didn’t know at the time was that he was also taking the first steps that led to the establishment of J. Pechauer Custom Cues, which over the decades has earned a reputation as one of the most renowned cue makers around. “In the process of making that shaft, he tried until he finally got it made,” said Jerry’s son, Joe Pechauer. “Along that point, others asked him to fix their cues, and then it started. From trial and error and researching, he found different materials that he was looking for to make the various parts he wanted to make. Fred Mali helped along the way, and we even drove to New York in our homemade camper/bus to visit Fred and learn more from him. He is the mentor who really helped us, and I will never forget how wonderful of a man he was!”

A SHOP OF THEIR OWN

Jerry repaired and sold cues out of the family’s basement for many years until the 1980s. At that point, he decided to quit his job and join the pool profession full time. He began by selling Playmaster pool tables, a few brands of cues, and making the occasional custom cue.

“At that time, I just turned 16, so after school I installed the pool tables we sold – around 100 per year,” Joe remembers. “As we got more into the cue making, my dad took classes at the local tech school and built some machines as he figured out what he wanted. Those first couple years were mostly about table sales and other brand cues.”

Slowly but surely, more focus was applied to custom cues.

“I started doing more with the cues as we kept growing,” Joe says.

In 1983, the Pechauers bought a CNC machine and a few more lathes, then moved to a new location, which they remodeled to include a showroom, bar, six pool tables, a volleyball court, and a shop in the back.

“I ran the shop in the day and the bar at night,” Joe says. “As the cues got more in demand, we moved more shop space into the bar area until finally we were out of room. Our big expansion was in 1993, when we built our current 15,000-square-foot facility. It’s climate controlled to within 2 percent humidity.”

A HISTORY OF QUALITY

It’s in that space where Joe Pechauer continues to develop his craft, and where he and his staff are hard at work, making cues that reflect the commitment to quality that has earned J. Pehauer Custom Cues its stellar reputation.

“That started with my dad,” Joe says. “Always striving for perfection is really how we started out, and that forced us to do everything that has to do with our process in-house. We don’t contract any work out – every part that goes into our cue we make in-house, from joint screws to the butt plates to the joint collar.”

Joe and Jerry still drive many hours to select logs and talk with loggers in order to find the best birdseye and curly maple available. The beginnings of the cue starts when logs are cut in the shop and dried in their own vacuum kiln.

“The only way that we can ensure the quality of what we do is to kind of be in charge of all those different aspects of the materials,” he says.

A question that comes to mind when talking with Joe Pechauer is, “How long does it take to make a cue?” But because there are so many elements to the work, he is unable to give a specific answer.

“Because of the process, I can’t even put a time frame on it,” Pechauer says. “In between the stages, the cue’s always sitting. If we bought our materials from a supply house and just assembled the cues, it would be a lot easier to pinpoint that time frame. But because we control 100 percent of the process, there are so many steps involved, you can’t really give an accurate number.”

IT’S ALL ABOUT THE TEAM

Joe took over as president of the company in 2007, while continuing to benefit from the wisdom and counsel of his father. Key to the company’s success is its team of dedicated employees, and when talking about the company and its work, Joe uses the word “we” as opposed to “I.”

“Everybody in the shop, we’re all working together,” Pechauer says. “That’s important, and maybe that’s part of why I have such a great retention of people who have been with us for 20-plus years. That’s reinforced why the quality remains what it is – these dedicated people who have stuck with me and keep helping to make the process better.”

Those people have made the company what it is today.

“I’m blessed to have an amazing team working with me,” Pechauer says. “They’re a second family, for sure. Because of the longevity of our group, we can keep quality standards as our

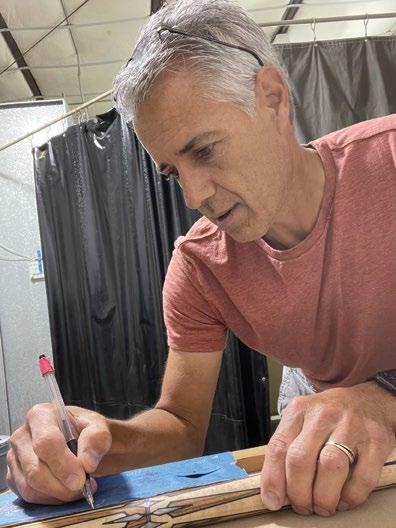

top priority. Our process has not changed much throughout the years. Every component is made in-house, and I am involved in every step along the way. We make hundreds of cues a year and I hand-sign every custom and Pro Series cue we make. I am always striving to improve my craft.”

THE ART OF CUE MAKING

In addition to being extraordinary cues for playing, J. Pechauer’s cues are stunning in their design and are true works of art. That is one characteristic where the teamwork Pechauer talks about comes into play.

“That’s pretty much a collaboration between myself and a couple of my guys in the shop and the sales team,” he says. “We work together and bounce ideas around, one of us comes up with something, and then someone else adds an idea. When you look at how a cue comes together, it’s taking in the ideas of people, and when you come down to the end of it, we have something pretty amazing.”

STRIVING FOR PERFECTION

Pechauer and his team work on each cue for as long as they possibly can. For example, on the day he did an interview for this story, Pechauer said that work on the new Pro Series line was just getting finished that day, with photos being taken the following day, a timetable that pushed deadlines to their limits.

“The reason is because when we finish up these prototypes, there’s always that one more thing we can do to make it really complete, and that’s what I find myself doing – that next little change you can to make it really a knockout,” he says. “That’s what makes it fun.” And while there is artistry to his cues, Pechauer says he’s never considered himself an artist.

“I just put together what appeals to me,” Pechauer says. “Starting out early, every time I would make a cue in our retail store, I would set it on the cue rack and within that week, my dad would end up selling it. I never had a cue for long, but it forced me to have to keep making myself a new cue.”

A DEVOTED STAFF

Among his loyal employees is Steve, who was the first person that Jerry hired.

“Steve is my right and left hand,” Pechauer says. “I still remember him coming in late the first few years because he rode his bike to work over 20 miles. The early years were a few mistakes and a lot of learning. I still remember our first trade show and the biggest order we received. It was a big retailer, and we skipped a coat of finish. We got every cue back, redid them, and learned the value of quality no matter what. At the time it was devastating, but in reality, it was the start of ‘quality first.’”

As a testament to the caliber of the work of Pechauer and his team, many of pool’s top players use Pechauer cues.

“From Oliver Ortmann in the early years to Jin Powell today, to every pro and junior player in between,” Joe says when talking about the athletes who compete at the game’s highest levels who use Pechauer cues. “I can’t possibly name all of them, but I will say it has been my absolute honor to get to know these people and their families and call them my friends.”

He also takes pride in sponsoring players from around the world.

“I don’t look to sponsor the No. 1 player, as far as someone who’s going to win first place in tournaments all the time, I look for someone who’s a No. 1 as far as their personality,” Pechauer says. “Just a good all-around person who we enjoy working with and who is of value to the sport. That, to me, is worth more than first-place trophies and big prize amounts.”

LEARNING ON THE JOB

As successful as he’s been, Pechauer has also had to deal with his fair share of challenges.

“The biggest challenge for me started when I became president of the company in 2007,” he says. “At that time, in addition to running the shop, I took on the weight of everything else in the company – marketing, sales, finances, you name it. The COVID problem added the new aspect of, ‘Will we be open tomorrow or next month?’ More specifically, ‘Will any of our people get sick? Will the shop have to shut down?’ I never run out of challenges!”

Things have obviously changed over the years – how could they not? And one of the biggest factors has been advances in technology.

“It seems that there is a race to come up with the next best thing,” Pechauer says. “I still believe that if we can make a great, solid-playing cue, we are most of the way there.”

But with all that change, the basics of Pechauer’s craft have remained consistent.

“Our equipment and workshop haven’t changed much,” he explains. “We have to be as efficient as possible to keep prices down and maintain the highest quality. There really are no fancy machines, just good people!”

BUILDING ON A LEGACY

With its roots dating back 60 years, J. Pechauer Custom Cues is steeped in tradition, but that doesn’t mean the company is stuck in the past. In fact, nothing could be further from the truth.

“As the sport evolves, we evolve with it,” Pechauer says. “We try to listen to the needs of our players and adjust our products accordingly. For instance, we considered the increasing importance of breaking and safeties in the game and how jumping balls has become more popular. This observation led to the development of break and jump cues. Likewise, due to higher demand for accuracy and the increased competitive nature of the game, we have accommodated the changing field with new low-deflection and carbon shafts.”

Joe Pechauer’s success comes down to a lot of hard work. A typical workday for him begins at 6 a.m. and ends around 3:30 p.m. “The old days were much longer,” he says, adding that the business has been his full-time job pretty much since the day he started driving, and that it’s been non-stop ever since.

When asked how much longer he wants to continue to work, and what he hopes the legacy of J. Pechauer Custom Cues is, Joe says he’s still working on that.

“It’s a passion, but it’s still a job, it’s both, but I wouldn’t want to be doing anything else,” he says. “I’ve been recharging my brain by getting away a little bit more during the summer, and that’s helped me a lot. That’s something that is difficult to learn when it’s your business and you’ve done it all your life.”

WOOD FI R E G R I LL S

Elevate Your Elevate Your Outdoor Experience with Outdoor Experience with a Memphis Wood Fire Grill! a Memphis Wood Fire Grill!

Nothing beats the flavor of wood fire cooking… and no one make it easier than Memphis

Prepare a perfectly seared steak, smoke fall-off-the-bone ribs, bake a wood fire pizza or roast your Thanksgiving turkey all on one grill. With temperature ranges from 180° to 700°, a convection oven system and stainless steel double wall insulation, you can do it all with a Memphis Wood Fire Grill.

New IntelliBurn Technology™

Our new IntelliBurn Technology™ gives you the ability to grill your meals to perfection with precise temperature control. With a secondary combustion system, our new pellet grills produce more heat with less fuel, providing the most efficient and clean burn available in wood fire grilling today. In addition to conserving pellets and extending cooking time per hopper load, our award-winning grills are more convenient than ever before. The Bluetooth Wi-Fi app lets you monitor your cook from the golf course, on the lake or anywhere in the world. 304 stainless steel carts, built-ins and doors/drawers available.