7 minute read

A year of growth and innovation for Meritics Ltd

In this issue of Industrial Process News, we are pleased to feature Meritics Ltd as our Particle Characterisation and Material Analysis Company of the Year.

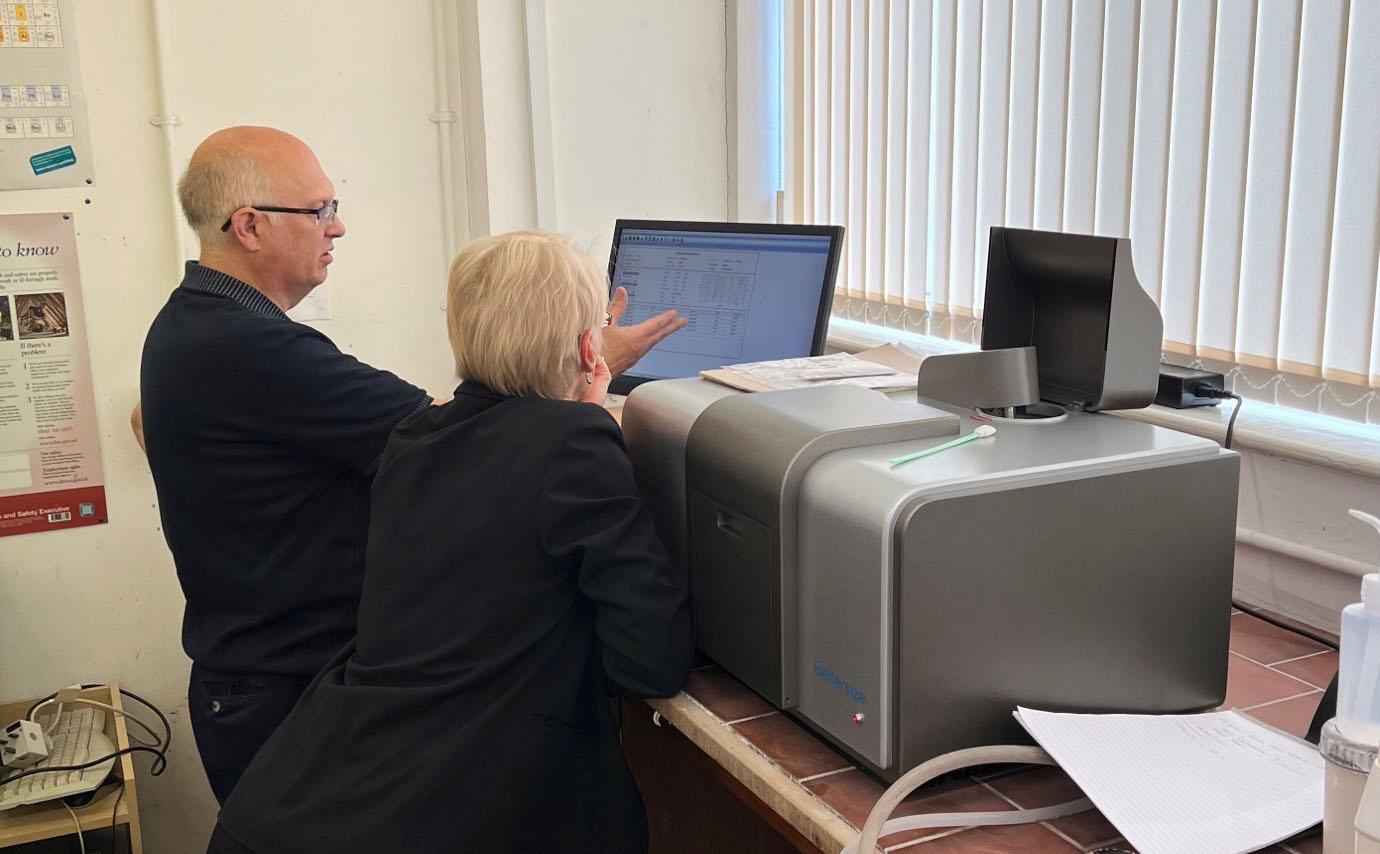

Formed in 2003 by Brian and Sandra Miller, originally Meritics Ltd was set up to solely distribute Beckman Coulter products, however, the company soon added complement analysers from other manufactures to create a one-stop shop for particle characterisation.

Today, Meritics Ltd represents a number of world leading manufacturers of particle characterisation instrumentation and is ideally placed to offer an independent view of the most suitable techniques to solve particle characterisation needs.

“Meritics supplies a broad range of industries with particle characterisation instrumentation along with assistance with method development, proof of concept and SOP implementation which is often required. These analysers are also regularly maintained and serviced by our factory-trained engineers. Meritics also has a comprehensive in-house contract sample analysis laboratory and instrument hire facilities,” stated Steven Miller, Managing Director.

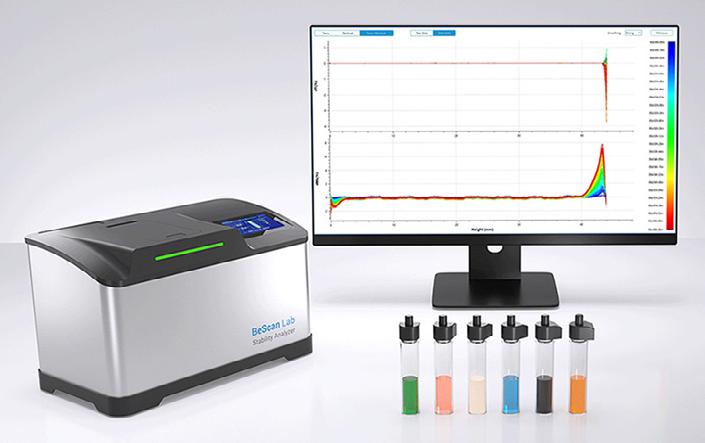

One key area of growth this year for Meritics was the increase in the use of sustainable energy sources. “Our analysers are involved in areas like the design of composite materials in renewable energy technology such as blades for wind turbines, as well as high strength and temperature resistance needed in direct metal printed parts. We have also introduced a very interesting formulation stability analyser called the BeScan Lab by Bettersize. This is easy to use, small and low cost,” said Steven.

BeScan Lab is the new benchmark in stability analysis, designed to analyse the stability of suspensions and emulsion in real-time. Using Static Multiple Light Scattering Technology (SMLS), it is predestined to detect stabilisation processes such as framing, agglomeration, sedimentation and coalescence at the earlier stages.

Some key benefits include: True Stability Measurement, Characterisation of the original sample, Identification and Quantification of Destabilisation Mechanisms, and Fast Detection of Destabilisation.

How does it work?A probe head which is equipped with a laser light source and two detectors (0° and 135°) moves vertically over the measuring cell, which is filled with the sample. During the movement, a transmission signal (0° – for transparent, diluted samples) and backscatter signal (135° – for concentrated opaque samples) are recorded continuously every 20µm over the entire sample height. Both signals are related to particle size and concentration and its change over time indicates destabilisation of the sample. Following each scan, an instability index (IUS) can be computed. Short-term or longterm stability can then be assessed based on the trend of IUS. In addition, the mean particle size can be determined by analysing the transmission, backscattering or particle migration rate.

BeScan Lab is ideally used in applications for Cosmetics, Food, Paint & Ink, Oil & Petroleum, Pharmaceuticals, and many others.

Meritics offers more than your average distributor, with servicing, training, instrument hire, method development, and contract sample analysis all being part of its exceptional level of customer service. This is something Meritics massively prides itself on when it comes to continuing future investment into its aftersales support and services.

“This was a key value Meritics was founded upon and an area which we excel at. A satisfied customer often means repeat business! It also reflects our industry influence and uniqueness, as we have been approached by a number of instrument manufacturers to help establish their technology here in the UK.

Although we are not a large company, this is part of our strength. Focusing purely on particle size and not being drawn in as a general lab supplier means we know our customers very well. All of our staff can talk about our customers, applications, key personnel and any issues that may have occurred without having to refer to a CRM. This means when they contact us, we have a genuine friendly interaction with them.

In 2024, our relationships with key clients have continued to evolve and grow as we navigate a period of product obsolescence. To support this transition, we have worked closely with customers investing in new analysers, ensuring seamless integration and the preservation of critical data continuity. This collaborative approach has been a cornerstone of our efforts, maintaining the reliability and accessibility of vital data points throughout this transformative phase,” said Steve.

Additive Manufacturing (AM) – better known as the 3D printing market, is becoming increasingly more popular. For this sector, Meritics produces a wide range of components that result in a more efficient, sustainable, and cost-effective outcome. “This is a fascinating area of which I have a personal interest. We have a number of systems that suit this industry very well, and it’s always an intriguing experience to go on-site to demonstrate how they are being used,” added Steve.

In order to achieve success for particle characterisation in AM, it is essential to accurately characterise raw materials, such as metal powders and polymer powders. The Bettersizer S3 Plus offers the correct characterisation solutions. The Bettersizer S3 Plus particle size and shape analyser combines laser diffraction and dynamic image analysis in one instrument. It can measure the size and shape of particles from 0.01µm to 3,500µm. Its exceptional sensitivity for either ultrafine particles or oversized particles, and unsurpassed resolution, makes it the most powerful size and shape analyser for enthusiastic researchers who conduct top scientific research. As well as for 3D Printing, this product is also ideal for applications involving Soy Milk, Advanced Ceramic Products, Ceramic Agglomerates, Lithium-Ion Batteries, Powder Coatings, Soils and Sediments, Abrasives, and Differing Abrasives.

Particle size is a critical factor in battery technology, profoundly influencing performance, efficiency, lifespan, and safety. In 2024, Meritics deepened its engagement in this sector, highlighting the pivotal role of particle size in advancing energy storage solutions and driving innovation in electric vehicles. As well as continuing this into 2025, we asked Steve what were the most important lessons learned in 2024, and how have these insights shaped the company’s planning for the future.

“While growth is significant in chasing shortterm goals, we keep a firm eye on where we are right now. As we believe that by maintaining what you have, will often pay you back in the long-term.”

As Meritics plans for the future and for what 2025 may bring, we asked Steve what trends or innovations does he expect to see.

“I can see AI helping in some ways, but possibly hindering in others! As an oldschool scientist, its essential you know how to evaluate and interpret results before you leave the job to AI. My fear is AI will be marketed as a time saver when, in reality, it may spoil production batches and cause more headaches than it solves if users rely on it too much. However, I am impressed with the ability to make (3D print) some component parts and believe this will make our customer service and repair rate even better than it has been. As a side note, this year, we have also welcomed two new employees: James Gregg (service) and Darren Bunker (sales support) to the team. With these new additions, we will continue to seek out new and innovate products whilst growing our customer relationships into long term collaborations.”

For more information, please see below: T 01582 704807info@meritics.comhttps://www.meritics.com