2 minute read

Rotech unveils entry-level coding system for bags & pouches

Coding and marking specialists, Rotech Machines, expand their range of RF Lite feeders – cost-effective systems for feeding and printing flat-form packaging –with a cleverly designed system specifically for small pouches and bags.

The new pouch edition of the RF Lite was recently launched. Like the original and shuttle variants, the RF Lite pouch is an entry-level solution for companies looking to automate their coding process for the first time. It is also well-suited to larger manufacturers looking to install multiple systems for multiple products and short/ trial production runs.

The system utilises vacuum technology to ‘pluck’ bags from a stack, before running them past a maintenance-free thermal inkjet printer, and returning them to a stack, ready for operator removal. This automatic process eliminates the need for coding and labelling by hand – which is often labour heavy, time consuming and inaccurate. Instead, users of the RF Lite can be reassured that their packaging will be coded quickly and accurately.

The system completes the RF Lite feeder range, proving that when it comes to costeffective coding systems, three really is the magic number.

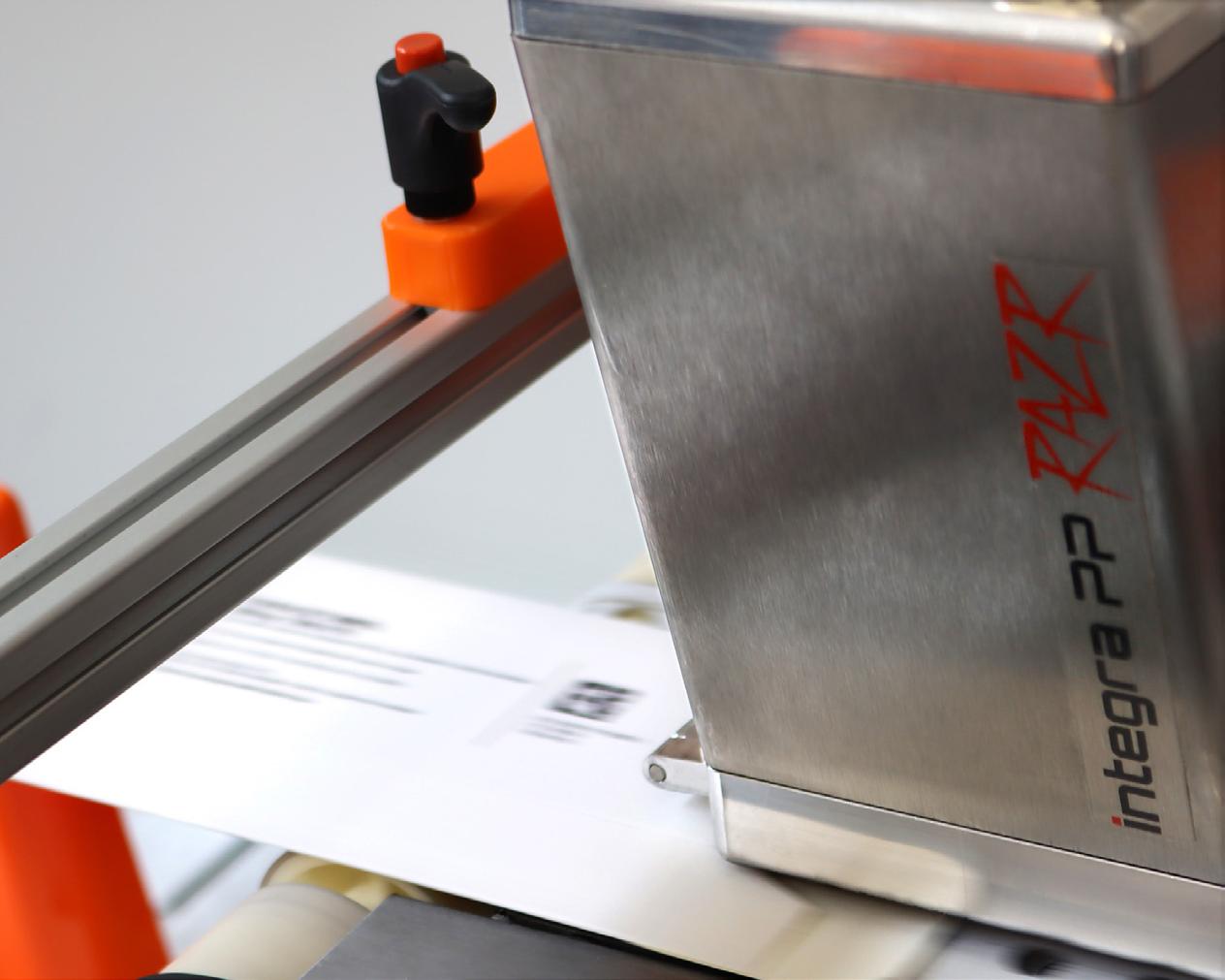

Printer for seamless large area printing on non-porous surfaces Also ideal for bag and pouch applications is the Integra PP Razr 34 – an impressive piezo printer that bridges the gap between the capabilities of a thermal inkjet printer and a large area printer.

The Razr, which runs with the same inks used in a thermal inkjet printer, can guarantee excellent resolution printing (up to 600dpi) on both porous and nonporous substrates. It can seamlessly print on areas up to 34mm, making it ideal for applications where thermal transfer (TTO) would have traditionally been used.

The cartridge-based technology also brings other benefits over other coding methods. It’s fast – it can run at high speeds up to 150m/min at 300dpi and it starts up and shuts down instantaneously. The printer also has two separate nozzle channels that can be controlled individually, guaranteeing optimal printhead life and quality of print.

The Razr is truly revolutionary in the world of coding and marking and is sure to be popular among manufacturers looking to improve their efficiency and reduce their waste. All without compromising on quality.