32 minute read

An Overview of Cooling Towers, Legionellosis, and Water Management Programs

Christopher J. Nagle, EVAPCO, Inc.

Introduction The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) adopted Standard 188-2015 titled “Legionellosis: Risk Management for Building Water Systems” in 2015. The stated purpose was “to establish minimum legionellosis risk management requirements for building water systems” (1). The standard was subsequently updated in 2018.

Regulations aimed at controlling Legionella bacteria in water systems had been enacted as early as the 1990s (2) and the early 2000s (3). More recently, several jurisdictions have proposed or adopted regulations (4, 5) referencing sections of ASHRAE Standard 188 without inclusion of all potable and non-potable building water systems, which are also included in the standard. Some of these regulations imposed rigid, prescriptive requirements on the program team, including control limits, monitoring, testing, and/or corrective actions. These more narrowly focused regulations have historically failed to produce measurable reductions in the occurrence of legionellosis. Data from two such jurisdictions will be presented as a preface to a broader discussion on water management programs, including cooling towers.

Water management programs need to have a broader view encompassing all the building’s water systems rather than focusing solely on cooling towers as “the source” of Legionella. As part of the program team, water treatment professionals are relied upon to offer technically sound recommendations regarding treatment solutions, control limits, control measures, and validation steps for the evaporative cooling equipment at their customers’ facilities. These recommendations should be based on a thorough understanding of the different types of evaporative cooling equipment and how the design and age of this equipment can impact the water management program. A review of different equipment will be presented to highlight similarities and differences for the water treatment professional to consider while developing site-specific treatment programs, control limits, and validation steps.

AWT’s Legionella 2019 (6) notes, “While cooling towers and evaporative condensers are also a potential source related to Legionnaires’ disease, and long thought to be the major source of Legionella-causing disease, current data suggest that domestic (potable) water plumbing systems are responsible for an even larger number of cases of Legionellosis.” This highlights the need for the “whole building” approach laid out in Standard 188, which can be broadened to include the municipal water supply to form a comprehensive water management program. This more comprehensive approach to developing a site’s water management program is needed to minimize the risk of Legionella bacteria amplification associated with all water-use end points and reduce the occurrence of legionellosis.

Background Many AWT members routinely provide water treatment expertise and solutions to end-use customers across a wide range of applications. Since its founding in 1985, AWT has worked to support members through education, training, and technical resources. Readers who have not done so already are encouraged to review Legionella 2019: A Position Statement and Guidance Document (6), which is available at www.awt.org.

The ASHRAE website, www.ashrae.org, includes a Legionella Resources tab, which water treatment professionals should also review. This website notes, “ANSI/ ASHRAE Standard 188-2018, Legionellosis: Risk Management for Building Water Systems, establishes minimum legionellosis risk management requirements for building water systems” (1). The standard provides water treatment professionals with a framework to use when developing a water management program with their customer.

Several regulations focused on legionellosis risk prevention or disease reduction have not included the entire building water system approach detailed in Standard 188-2018. Note, legionellosis is a term that refers to both Legionnaires’ disease and Pontiac Fever, both of which are caused by Legionella bacteria.

Overview of Regulatory Efforts In this section, we will examine two areas where regulations to control Legionella have been implemented.

France

France was one of the first countries to implement regulations intended to reduce the incidence of Legionnaires’ disease by focusing on evaporative cooling equipment as a possible source of infection.

France experienced an outbreak of Legionnaires’ disease in the Pas-de-Calais District between November 2003 and January 2004. Following that outbreak, France’s Ministry of Ecology and Sustainable Development issued new regulations (3) on December 13, 2004, which focused solely on evaporative cooling equipment.

Title II of the 2004 regulation begins with the goal of Legionellosis Risk Prevention. A partial list of regulation requirements includes drift eliminators with a drift rate certified to at least 0.01% of water circulation rate (Article 4), monthly sampling for the analysis of Legionella during periods of operation (Article 8), and shutdown and disinfection for any Legionella test result above 100,000 colony forming units per liter (CFU/L) (100 CFU per milliliter [CFU/mL]) (Article 9).

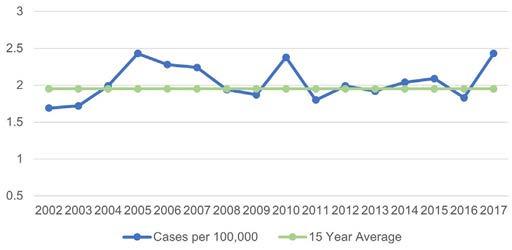

The regulations also include prescriptive Legionella testing schedules coupled with low maximum control limit requirements for all evaporative cooling systems operating in France beginning at the end of 2004. The French regulations provide many years of data to study the efficacy of narrowly focused, evaporative-cooling-only regulations with regard to the stated goal of Legionellosis Risk Prevention. Figure 1 shows a history of Legionnaires’ disease in France from 2002 through 2017.

Figure 1 shows the incidence of reported cases of Legionnaires’ disease in France per 100,000 people. The 15-year average of 1.949 is calculated from the beginning of the outbreak year 2003 and runs through the most recent data available from 2017. Beginning with the regulations in 2005, reported cases of Legionnaires’ disease in France ranged from a low of 1,170 cases in 2011 to a high of 1,630 cases in 2017 with a 13-year average of 1,362 cases. Since 2005, the average has increased slightly to 2.095 per 100,000 people. France provides more than a decade’s worth of data, which does not support the belief that regulation focused solely on evaporative cooling systems positively impacts the goal of Legionellosis Risk Prevention.

Figure 1: 15-year average of Legionnaires’ Disease in France (2002 through 2017). The blue line shows the number of cases per 100,000 each year. Source: Data from European CDC Legionnaires’ Disease Surveillance Report (2017).

New York City

In 2015, New York City experienced multiple outbreaks of Legionnaires’ disease. One of the city’s outbreaks occurred in the South Bronx during July and August. The New York City Department of Health and Mental Hygiene focused on cooling towers as the suspected source of the outbreak. On August 6, 2015, NYC Health Commissioner Dr. Mary Bassett issued an order requiring all owners of cooling towers within New York City to inspect and disinfect their evaporative cooling equipment within 14 days (7).

On August 11, 2015, Commissioner Bassett promoted new regulations to members of the city council. During her testimony (8), the commissioner stated, “New York City’s drinking water supply is safe and unaffected by the Legionella.” Her testimony also noted that “the Administration strongly supports the registration of

cooling towers and reaching inspection and testing for microbes in order to help prevent and investigate future outbreaks of Legionnaires’ disease.” Commissioner Bassett concluded her prepared remarks by stating, “Legionella exists in the environment, and we will continue to see sporadic cases of Legionnaires’ disease in New York City, but we believe that this important legislation will go a long way towards reducing the number and severity of these outbreaks.”

The hastily prepared Local Law 77 (4) was passed on August 13, 2015, and was signed by the mayor on August 18. This law requires owners of cooling towers to register them with the Department of Buildings. The law also referenced the new Administrative Code 17-194.1, which contained mandated requirements for owners of evaporatively cooled equipment, including cleanings, corrective actions, disinfections, inspections, Legionella bacteria testing, and a water management program based primarily on only Section 7.2 of ASHRAE 188. Additional requirements and details were in effect by November 2015.

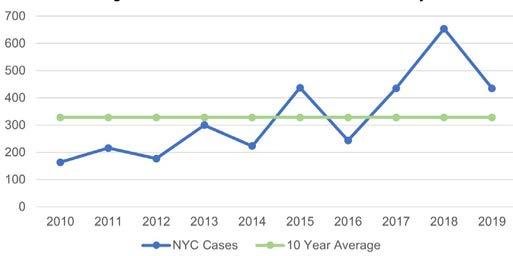

Figure 2: Cases of Legionnaires’ disease over a 10-year period in New York City. Source: Data from U.S. CDC Wonder Table Nationally Notifiable Infectious Diseases and Conditions.

Figure 2 shows the cases of Legionnaires’ disease reported over the past 10 years in New York City, with an average of 328.5 reported cases per year. New York City regulations for registration and maintenance of cooling towers were enacted in 2015 “to minimize potential contamination by Legionella bacteria to prevent outbreaks of Legionnaires’ disease” (9). In the four years since this cooling-tower-focused regulation was put in place, the annual average of reported cases of Legionnaires’ disease in New York City has increased to 442. Data from both France and New York City strongly suggest that focusing regulations or water management plans on evaporative cooling equipment alone does not reduce the incidence of legionellosis.

AWT members are not likely to be surprised that regulations seeking to register evaporative cooling equipment, mandate specific treatment programs, prescribe Legionella-specific testing, or propose low-CFU/ mL corrective action levels have historically failed to reduce the incidence of legionellosis. Legionella 2019 supports the need for an ASHRAE 188-based analysis of building water systems when it notes (6), “While cooling towers and evaporative condensers are also a potential source related to Legionnaires’ disease, and long thought to be the major source of Legionella-causing disease, current data suggest that domestic (potable) water plumbing systems are responsible for an even larger number of cases of legionellosis.”

Cooling Towers as One Part of a Water Management Program Many customers will want their water treatment supplier to participate on the program team to help assess the risk associated with all building water systems when developing a site-specific water management plan. Buildings or facilities that use evaporative cooling towers would assess the risk and incorporate these systems as a component of the broader site-specific management program. What information would a water treatment professional need to assess the risk and corresponding control limits for their customer’s cooling tower?

The answer to that question should begin with an understanding that “industry standards” or “simplistic required response tables” should not be equally applied to all cooling towers. The reason appears to be missed in many cited works, commercially motivated brochures, and well-intentioned regulations. There is no “one-sizefits-all” cooling tower.

In fact, some of the systems cited in reference works are not cooling towers at all. As an example, an oft-cited work titled “Assessing the Environmental Health Relevance of Cooling Towers – A Systematic Review of Legionellosis Outbreaks” includes data from a 2005

outbreak in Norway with a reported Legionella pneumophila culture of only 2 X 103 CFU/L (10). However, the abstract (11) for this referenced paper notes “Those living up to 1 kilometer (km) from a particular air scrubber had the highest risk ratio, and only for this source did the risk ratio decrease as the radius widened.” The authors noted that the air scrubber had high air discharge velocity, high organic content, high temperature (40 °C/104 °F), and a large amount of drift. The combined operating characteristics of the studied air scrubber are materially different than a cooling tower.

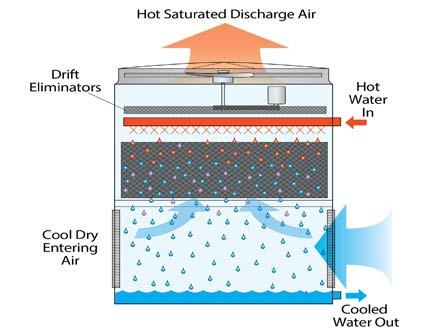

Drift Evaporative cooling equipment rejects heat from a building or process via evaporation of pure water (H2O). Under certain atmospheric conditions, the supersaturated discharge air exiting the tower may form a visible plume. Some documents have incorrectly suggested that plumes from cooling towers pose a risk for transmission of Legionella bacteria.

Drift is separate and distinct from plume. Drift refers to the very small percentage of recirculating cooling water that exits the evaporative cooling equipment with the exhaust air discharge. Hennon and Wheeler (12) provide a useful description in their Cooling Technology Institute (CTI) paper on tower emissions: “Baffles, called drift eliminators, are placed between the nozzles and the fans to minimize (through inertial impaction) the amount of entrained water droplets that leave the cooling tower and are discharged into the atmosphere. The escaping droplets are called drift. An important distinction between drift and the normally visible condensing plume is that the drift contains the same chemicals and solids present in the circulating water, whereas the condensation is pure water vapor.”

Drift is one of the key factors that must be understood by anyone seeking to assess risk or define risk management for evaporative cooling equipment as one component of a broader building water systems approach. There are two components of drift that should be of interest to the water treatment professional: drift rate and drift size.

The previously referenced CTI paper (12) presents a droplet size distribution analysis from a full-scale cooling tower test in Figure 2 of that paper. Data from Figure 2 shows that more than 86% of the drift droplets exiting the tested tower were larger than 60-micron (µm), which is more than 1,000 times larger than the 5-µm size cited by AWT and others as respirable. A 2008 International Water Conference (IWC) paper (13) contextualizes this concept, stating, “Most of the volume of drift as it leaves the tower is in droplet sizes too large to be deeply inhaled. The bacteria contained in those droplets can cause disease only if the droplets evaporate to a respirable size before falling to the ground.”

The drift rate may be even more important than drift particle size when evaluating potential risk or defining corrective action levels. Recall that the 2004 vintage regulations for cooling towers in France required drift eliminators with a drift rate certified to at least 0.01% of water circulation rate. Although not identical, the French regulations are close to an evaporative condenser attributed to a 1988 outbreak that was modeled by Bugler et al. in the IWC paper. The 1988 vintage condenser was estimated to have a 0.02% drift rate and reported spray water Legionella test result of 9,000 CFU/ mL. Table 1 (13)in the IWC paper suggests that a person near the 1988 evaporative condenser attributed as the source of the outbreak might be able to inhale one (1) Legionella bacteria in as little as three (3) seconds.

Since that era, substantial improvements have been achieved in reducing drift rates from evaporative cooling equipment. Current crossflow equipment designs typically achieve drift rates of 0.005% of water recirculation rate, while current counterflow equipment designs can be rated as low as 0.001% drift. This order of magnitude reduction in the amount of drift escaping the cooling tower significantly reduces the potential risk of disease compared to older equipment. Table 1 (13)3 suggests that a person near a modern counterflow cooling system containing 100 CFU/mL Legionella bacteria in the tower water probably needs to spend at least 52 to 106 minutes near the evaporative cooling system to have a similar chance of inhaling one (1) Legionella bacteria.

Both drift rate and drift size impact the risk of legionellosis from an evaporative cooling system. Bugler et al. (13) note, “Only a very small percentage (on the order of 1%) of the drift as it leaves the cooling tower is of respirable size, and hence able to cause infection.” Because the majority of drift would need to evaporate

to become respirable, the authors state that “a person breathing undiluted exhaust air from a well-maintained cooling tower with what might be considered a moderate concentration (100 CFU/mL) of Legionella would need to be in the exhaust much longer (possibly 99 times longer) than the time indicated in Table 1 before he statistically would inhale a single Legionella bacterium deeply into his lungs.”

Revisiting the Outbreak in France Older, less-efficient drift eliminators might have contributed to the outbreak in France, as suggested in the title of the oft-cited work titled “A Community-Wide Outbreak of Legionnaires’ Disease Linked to Industrial Cooling Towers—How Far Can Contaminated Aerosols Spread?” In the article, Nguyen et al. (14) report, “In Plant A, the epidemic strain was found in the cooling towers (CTs), in wastewater and sludge from the basin, and in the air in the vicinity of the basin (19 isolates in total). The level of contamination was high (106 1010 CFU/L) in Plant A as well as in Plant B. Plant B supplied biological sludge for Plant A waste basin and was located ~40 km away, in another district.”

Most water treatment professionals would view the reported counts of 1,000 CFU/mL to 10,000,000 CFU/mL Legionella sero group 1 in either a wastewater aeration basin or cooling tower as a system that likely warrants corrective actions. Interestingly, this article (14) notes, “After the present outbreak, the national authorities issued new regulations concerning the installation and maintenance of CTs.” The title of this article and the regulatory response attribute the outbreak to the cooling towers as the root cause.

Those who take the time to read the article by Nguyen et al. (14), however, might reasonably conclude that the cooling towers were not the root cause but rather were victims of their neighborhood. The authors explain, “The contaminated waste-basin sludge was traced back to its origin—an industrial site in another district—but no LD cases were detected there.” Plant B’s waste-basin sludge was supplied to Plant A where the wastewater processing basins included aeration systems “located ~300 meters (m) from the CTs.” Nguyen et al. noted, “a considerable amount of Legionella bacteria in the wastewater basin of the plant might have become airborne in aerosol produced by surface ventilators, since air samples collected after final closure of the CTs and as far as ~300 m from the basin demonstrated Lp-1 Lens in aerosolized, respirable (≤5 µm) water droplets.”

Works typically cited in the mythical quest for “one-size-fits-all” action levels or dispersion distances from potential point sources seldom, if ever, include detailed information regarding the evaporative cooling unit type, age, drift eliminator type and condition, fan size, or fan cubic feet per minute (cfm), which would be needed to correlate microbiological test results to risk. All other things being equal, a 50 CFU/mL test result in a cooling tower with a 0.02% drift rate represents a higher risk than a cooling tower with a 0.001% drift rate and a 500 CFU/mL test result. Those who proclaim that a test result of 50 CFU/mL in each example tower above indicates the same risk or requires the same corrective action may lack a basic understanding of how evaporative cooling equipment operates.

Water Treatment to Manage Risk A water treatment professional equipped with an understanding of drift rates and drift size should prioritize review and documentation of the site’s evaporative cooling equipment early in the water management program process before developing treatment programs, testing frequency, control limits, or corrective actions. Records should include manufacturer, type (i.e., cooler, condenser, or tower), model number, serial number, and date of manufacture. This information can help identify customers operating older systems for whom upgrading to modern high-efficiency drift eliminators is likely to provide the greatest return on investment with regard to reducing risk. Adding annual or semiannual equipment inspections to the water management program could help to ensure that mechanical systems and drift eliminators remain in good working order.

The management plan should differentiate between open cooling towers and closed-circuit cooling systems, or evaporative condensers designed with integral spray water pumps. Water professionals who understand the type and age of evaporative cooling equipment used at their site will recognize that more frequent testing, lower positivity in test results, or lower test result action levels are not likely to reduce risk. Rather, they should focus on developing a site-specific treatment program with associated feed and control equipment designed to consistently

deliver good treatment results for the evaporative cooling equipment used at their customer’s facility.

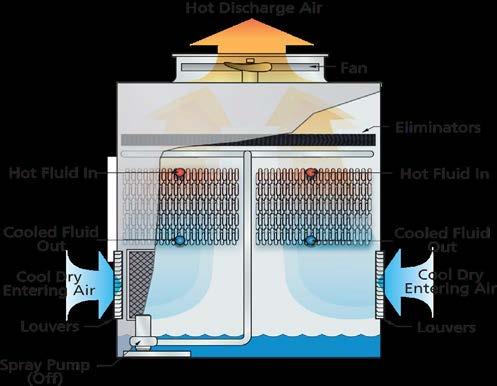

Closed-circuit coolers and evaporative condensers with integral pumps differ from open cooling towers or systems connected to a remote sump in ways that may impact treatment program selection. Coolers and condensers include closed-loop coils where most of the heat exchange occurs. When equipped with integral spray water pumps, these systems tend to have very low water volumes with very high water turnover rates. It is not uncommon for these systems to circulate 100% of the basin water volume in one minute or less of spray pump operation. Accordingly, low retention times make biocide selection and feed frequency important considerations for the water treatment professional. AWT’s non-oxidizer Biomatrix spreadsheet is a useful tool for selecting biocides with fast or moderate kill times for coolers or condensers with integral pumps. The volume of biocide added is typically much less than the amount fed to a cooling tower, but the frequency of timed addition may need to be higher to account for the faster turnover of system water volume. Biocides with a tendency to foam may create additional challenges in these small water volume, high turnover rate systems.

Figure 3: Closed-circuit cooler.

Figure 3 shows an inside view of a closed-circuit cooler.

The selection and installation of chemical feed and control equipment for coolers or condensers operating with integral spray water pumps may also differ compared to larger open cooling towers or systems operating on remote sumps. To begin, the water treatment professional should recognize that units with integral spray water pumps typically operate at low water pressures (≤5 pounds per square inch [psi]), which may require a small supplemental in-line booster pump if conductivity manifolds, or chemical injection points are piped at a distance from the unit. Units operating in colder climates may warrant additional thought regarding freeze protection for both side-stream piping and chemical storage associated with the selected treatment program.

Closed-circuit coolers and evaporative condensers operating with integral pumps typically eliminate the potential for dead-leg areas. This fact, in combination with more frequent wet-dry cycling, makes these systems less prone to sessile bacteria growth than more complex piping systems that are connected to open cooling towers. The tendency for increased wet-dry cycling should not be underestimated when selecting and programming conductivity controllers. Thought should be given to matching programmed chemical feed times with parts of the day when the unit’s spray water pump is likely to be in operation. It may be wise to schedule timed chemical additions in the heat of the day to avoid no-flow conditions that may cause a timed feed to be missed completely.

Some may suggest that materials of construction do not directly fit into the water management program. There are, however, a few things worth considering when developing a water treatment program for an evaporative cooling system, which includes a heat exchange coil. The most prevalent material of construction for these coils is hot dip galvanizing on carbon steel. A site-specific passivation plan will help minimize white rust on new galvanized coils, thereby extending equipment life and reducing localized areas of corrosion that may foster bacterial growth. Some systems may include copper coils and stainless-steel coils, which recently are becoming a more common option. For stainless-steel applications, the proactive water treatment professional will want to understand the designed coil inlet temperature to establish and track maximum cycled chloride concentrations in the spray water to minimize the chances of pitting and stress corrosion cracking.

Cooling towers do not include the heat exchange coil found in coolers or condensers. Rather, recirculating

water is cooled as it falls through a fill pack and evaporates as it comes in contact with air moving either in a crossflow or counter-flow direction.

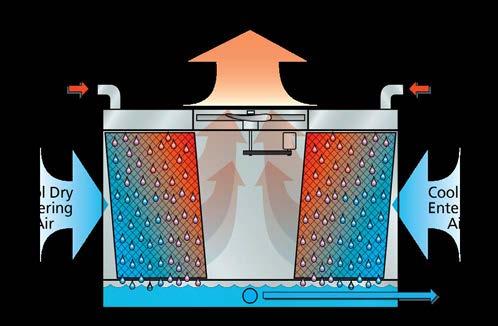

Figure 4: Sideview of a crossflow cooling tower.

Crossflow cooling towers (Figure 4) move air through the fill pack perpendicular to the direction of water flow. Drift eliminators are integrated into the fill block, and current models are rated as low as 0.005% of the recirculation rate. The crossflow design may allow areas on the water distribution pan or cold-water basin to be exposed to sunlight. In that case, algae may become a treatment concern for some crossflow towers.

Figure 5: Sideview of a counter-flow cooling tower.

Counter-flow cooling towers (Figure 5) move air up through the fill counter to the direction of the falling recirculating water and include drift eliminators located above the spray header. Current counter-flow models can achieve drift rates as low as 0.001% of the recirculation rate. Most counter-flow designs do not allow sunlight to contact the cooling water, thus making algae less of a treatment concern. The use of supplemental dispersants should be considered carefully during development of the water management program. Dispersant selection, feed rate, and retention time may create a negative impact on the performance of the drift eliminators. It was noted earlier that modern drift eliminators generally do not allow water droplets of respirable size to exit the tower with air exhaust. Dispersants or surfactants, which work by reducing the surface tension of the cooling tower water, have the potential to decrease water droplet size and/or increase the amount of drift exiting the tower.

Ganzitti and Rincones’ (15) recent paper (“Impact of Water Surface Tension on Drift Eliminators”) presented at the 2020 Cooling Technology Institute should be considered a “must read” for any water treatment professional who routinely supplies supplemental dispersants for evaporative cooling systems other than offline cleanings. Ganzitti and Rincones note, “Most of the cases with abnormal drift levels are due to incorrect installation or use of the drift eliminators panels.” This supports the suggestion that annual or semiannual inspections of the drift eliminators should be included in the water management program. Their technical paper also notes, “Surfactants can have a significant impact on the drift rate, depending on their concentration and their ability to migrate to new interface air/liquid (fast or slow response surfactant).” This suggests that the selection, application, feed strategy, and feed control of any supplemental dispersant should be documented in the water management program, based on a thorough understanding of both system water volume and retention time.

Contrary to some prescriptive regulations, treatment programs for heating ventilation air conditioning (HVAC) cooling towers have not always included the use of an oxidizing biocide. Early members of AWT will recall a time when many middle-market accounts were routinely treated using a dual non-oxidizing biocide approach. Whether driven by the once-popular Wisconsin Protocol, competitive selling based on price, or well-intended regulations, the “necessity” of halogen or oxidizer chemistries appears to have been ingrained in a generation of water treaters almost without question. Some reflection regarding the need for and application of oxidizing biocides might be appropriate in an era when even experienced water treatment professionals do not

think twice about manually adding undiluted granular halogen to a stainless-steel tower basin as part of a “routine” service.

Developing the water treatment regime and water management program will require a clear understanding of both the quality and consistency of makeup water supplied to the evaporative cooling system. The possibility of sporadic increased bacterial loading from the makeup water, a process contamination, or other nearby industrial processes should be considered and addressed in the water management program process.

An industrial cooling tower using non-potable makeup water or cooling a process that contributes organic contaminants is likely to require a different water treatment program than an HVAC tower using municipal makeup water to air condition a building. There is no “one-size-fits-all” definition of a cooling tower, so there should not be a “one-size-fits-all” treatment program, whether in terms of selected biocide(s), feed rate or feed schedule, control limits, monitoring, validation, or corrective actions. As described in ASHRAE 188-2018, the program team has the responsibility for “developing, implementing, and maintaining the Program” as it relates to evaporative cooling and the other building water systems.

Control Limits, Testing, and Validation The water treatment professional requires a clear understanding of their customer’s mechanical system to be able to select an appropriate treatment program that includes installation and operation of automated feed and control equipment. From this point in the water management program development, attention will likely turn to control limits, control measures, and validation. A decade before Pas-de-Calais, Shelton et al. (16) reported outbreaks associated with mean CFU/mL >1,500 while noting, “Colony counts from the two outbreak-associated facilities were significantly higher than colony counts from other facilities.” Even before the advent of high-efficiency drift eliminators, it was generally accepted that the occurrence of outbreaks associated with evaporative cooling systems was low and that implicated systems were associated with very high Legionella concentrations or the lack of an automated water treatment program.

In Reference 6, AWT notes, “L. Pneumophila stands alone today as the single species responsible for more than 90% of legionellosis cases. More than 80% of these cases are attributed to only one serogroup—L. pneumophilia serogroup 1—one of more than 15 identified L. pneumophila serogroups.” The logical conclusion is that control limits for serogroup 1 should be lower than serogroups 2–14 based on risk of legionellosis. Conversely, serogroups 2–14 could have higher control limits compared to serogroup 1 without increasing risk. Environmental Safety Technologies (17) demonstrates a way to incorporate this concept into a water management program in its Legionella Report Interpretations and Recommendations document.

The use of Legionella-specific testing as a validation step may be appropriate. Some references and regulations have suggested that a very low CFU/mL one-size-fits-all control limit is required to minimize the risk of legionellosis. These recommendations may be well-intentioned but are likely based on a limited understanding of the accuracy, precision, repeatability, and sensitivity of the test results available from current culture-based testing. Regarding a microbiological culture for Legionella, Swalla et al. (18) note, “Such methods are complicated by the use of multiple parallel testing approaches, optional treatment steps, and a requirement for significant analyst expertise and judgement. Furthermore, the accuracy of these methods may be affected by a variety of factors that increase measurement uncertainty, such as interference from non-Legionella organisms, subjective interpretation of test results, and differential performance of media and reagents.”

A reread of a 2013 Analyst Technical Supplement article (19) titled “Validation of Hazard Control in Building Water Systems” could benefit the water treatment professional’s understanding of “the analytical problems associated with Legionella testing of building water systems.” In that article, McCoy et al. illuminate some of the scientific challenges associated with establishing aggressive control measures based on low CFU/ mL action levels. The possibility of false negative, false positive, and “amplified-positive” test results detailed in the article should help to challenge the assumption that a result of 20 CFU/mL, 50 CFU/mL, or even 80 CFU/mL represents a statistically different indication of either microbiological activity in or risk from a modern evaporative cooling system. An understanding of the advances made in drift eliminator efficiency would suggest that any of those results indicate a very low risk of legionellosis.

ASHRAE 188-2018 allows the water treatment professional, as part of the program team, to develop a range of control limits that can be mapped to increasing levels of intervention as risk increases based on higher serogroup specific test results. Limiting the focus to cooling towers alone, however, has a demonstrated history of failing to reduce the incidence of legionellosis. The water management program should include all of the building’s water-use end points that present an opportunity for Legionella amplification and transmission.

Moving Beyond a Singular Focus on Cooling Towers The water treatment professional is often uniquely positioned to help the owner evaluate potable and non-potable building water systems beyond the evaporative cooling system. During this phase of the risk management plan development, it can be helpful to recognize that the most common way for Legionella bacteria to enter the various building water systems is through the municipal water supplied to the building.

The concept of Legionella bacteria entering the building water system along with the potable water is not a new one. The American Water Works Associations M68 (20) titled “Water Quality in Distribution Systems” notes, “Even after treatment, including disinfection, neither drinking water nor the distribution system are free of microbes. Every drinking water distribution system contains free floating (planktonic) microorganisms and surface-associated (such as biofilm and those attached to particles) microorganisms, which are important with respect to active biomass.” This document goes on to state, “Microorganisms present in biofilms can reach customers through changes in water quality or flow patterns. These changes result in sloughing or erosion of the biofilm from pipe surfaces and introduction of microorganisms into the potable water that moves through the distribution system pipes.”

Water service disruptions are noted in ASHRAE 188-2018, yet not all water management plans include notification requests to help identify when these upset conditions occur “upstream” of the building. Requesting notifications from the water utility can help the program team identify planned or unplanned events that could temporarily increase the variety or level of planktonic microorganisms entering the building water systems. Routine testing and tracking of the incoming water’s disinfectant residual may also assist the program team in identifying changes in the quality of water supplied to the various building water systems.

The historical focus on “cooling towers first” or, worse, “cooling towers only,” will need to evolve for the framework laid out by ASHRAE 188 to be effective in reducing the incidence of legionellosis. The data presented in this article suggest that a continued myopic focus on evaporative cooling equipment alone will not reduce the incidence of disease regardless of how often it is trotted out or proclaimed as necessary. The time has come for water treatment professionals to help educate their customers on the need to broaden the water management evaluation to address risks from the source water supplied to the building through all building water-use end points. ASHRAE 188 provides the framework for the additional surveillance of all potable and non-potable water sources required to reduce Legionella proliferation so cases of legionellosis can be reduced.

References

1. ASHRAE (2018). ASHRAE Standard 188: “Legionellosis: Risk

Management for Building Water Systems.” American Society of Heating,

Refrigerating and Air-Conditioning Engineers, Atlanta, Georgia. 2. HSE (1991). “Legionnaires’ Disease. The Control of Legionella Bacteria in

Water Systems,” Approved Code of Practice and Guidance, United

Kingdom Health and Safety Executive. 3. The Minister of Ecology and Sustainable Development (in Paris,

France) (December 13, 2004). Arrêté du 13 décembre 2004 relatif aux installations de refroidissement par dispersion d’eau dans un flux d’air soumises à autorisation au titre de la rubrique n 2921. (Order of 13

December 2004 on cooling installations by dispersion of water in an air flow subject to authorization under heading No. 2921.), accessible at http://www.admi.net/jo/20041231/DEVP0430480A.html. (Translated with www.DeepL.com). 4. City of New York Local Law 77 (Aug. 18, 2015). “A Local Law to amend the administrative code of the city of New York, in relation to regulation of cooling towers,” accessible at https://www1.nyc.gov/assets/buildings/ pdf/ll77of2015.pdf. 5. City of Vancouver (November 2018). By-Law 12512, “A By-law to amend the Building By-law No. 12511 Regarding New Requirements for Certain

Water Systems and Energy Efficiency,” accessible at https://council. vancouver.ca/ctyclerk/cclerk/20181205/documents/cfsc2.pdf. 6. AWT (2019). “Legionella 2019: A Position Statement and Guidance

Document,” Association of Water Technologies, Rockville, MD. 7. New York City Department of Health and Mental Hygiene (Aug. 6, 2015). “Order of the Commissioner.” 8. City of New York (Aug. 11, 2015). “Transcript of the Minutes of the

Committee on Housing and Buildings,” City Council City of New York. 9. City of New York (Dec. 3, 2015). “Notice of Adoption of Chapter 8 (Cooling Towers) of Title 24 of the Rules of the City of New York,“ New

York Department of Health and Public Hygiene, New York, New York, details available at https://www1.nyc.gov/assets/doh/downloads/pdf/ notice/2016/noa-chapter8-title24.pdf. 10. Walser, S.; Gerstner, D.; Brenner, B.; et al. (2014). “Assessing the

Environmental Health Relevance of Cooling Towers— A Systematic

Review of Legionellosis Outbreaks,” International Journal of Hygiene and

Environmental Health, 217, pp.145-54. 11. Nygard, K.; Werner-Johansen, O.; Ronsen, S.; et al. (2008). “An Outbreak of Legionnaires’ Disease Caused by Long-Distance Spread from an

Industrial Air Scrubber in Sarpsborg, Norway,” Clinical Infectious Disease 46(1), pp.:61-9. 12. Hennon, K.; Wheeler, D. (February 2003). “Cooling Tower Emissions

Quantification Using the Cooling Technology Institute Test Code

ATC-140,” Cooling Technology Institute, Paper No. TP03-08. 13. Bulger, T.; Lane, J.; Miller, R.; et al. (October 2008) “Cooling Towers,

Drift, and Legionellosis,” Paper No. IWC 08-21, International Water

Conference, San Antonio, Texas. 14. Nguyen, T.M.; Ilef, D.; Jarraud, S.; et al. (January 2006). “A Community-Wide Outbreak of Legionnaires’ Disease Linked to Industrial Cooling

Towers—How Far Can Contaminated Aerosols Spread?” Journal of

Infectious Diseases 193(1), pp. 102–11. 15. Ganzitti, V.; Rincones, J. (February 2020). “Impact of Water Surface

Tension on Drift Eliminators,” Paper No. TP20-19, Cooling Technology

Institute. 16. Shelton, B.; Flanders, W.; Morris, G. (1994). “Legionnaires’ Disease

Outbreaks and Cooling Towers with Amplified Legionella Concentrations,” Current Microbiology, 28, pp. 359-63. 17. Environmental Safety Technologies (n.d.) “Legionella Report Interpretations and Recommendations,” Rev 1.0., Louisville, Kentucky, accessible at www.estechlab.com. 18. Swalla, B.; Knight, T.; Newport, V.; et al. (Spring 2019). “What Are

Strategies for Reducing Uncertainty in Legionella Analysis?” Spring

Analyst 26(2), pp. 37–51. 19. McCoy, W.; Leonidas, L. (Summer 2013). “Validation of Hazard Control in Building Water Systems,” Summer Analyst Technical Supplement, pp. 15–21. 20. Smith, Kira S.; Slabaugh, R. (2017). M68 Water Quality in Distribution

Systems, AWWA manual (M68), ISBN 9781625762269, American Water

Works Association, Denver, Colorado.

Like his father and grandfather, Christopher Nagle began his water treatment career with Betz Laboratories. He started in the Entec division and earned several roles of increasing field responsibility through the BetzDearborn and GE Water years. During his 13 years with these companies, he gained extensive sales, service, and sales management experience by serving both heavy and middle market customers. Mr. Nagle moved to EVAPCO in 2007 as the director of sales and marketing for its newly formed water systems business. In 2010, he launched EVAPCO’s Water Treatment Partner program, which helped develop strong business relationships with many AWT companies. The following year, he took on an expanded role as vice president of Water Systems and began working with customers across the Americas, China, and Europe. He may be contacted at chris.nagle@evapco.com.

This article is based on a presentation given at the 2020 AWT Interactive Annual Conference, which was conducted September 29–October 2, 2020.