14 minute read

Mechanism of Yellowing

Yellowing of textile fabrics is one of the oldest and most widespread quality problems known. The yellowing can be seen directly in the case of market whites, pastel shades or even after-washed denims. However, shade change noticed in darker colored fabrics can often be attributed to chemical change or degradation of the fiber or some chemical agent either purposely applied to the fabric in finishing or inadvertently absorbed by the fabric in its storage and shipment to market or during its end use. As a general statement, yellowing of textile materials is an indication of unanticipated chemical degradation. Very often, as colorless chemicals decompose, they form light to moderate yellowish colors. Of

Advertisement

course, if this chemical is a textile finish or additive or has been absorbed by a textile product, this color formation is noted as fabric or garment yellowing. It should also be

noted that continued chemical decomposition could form moderate to dark brown colors or, in some extreme cases, even black colors.

As consumers, we may have experienced our white clothing and other fabrics turning yellow at some point. As unsightly as it may seem, this ‘yellowing’ of white and lightly

colouredtextiles is a common occurrence, which is usually due to chemical and environmental factors, and fabric ageing.

With around 20% of all textiles produced globally being finished as ‘white’, it is crucial

that manufacturers take the correct precautions to ensure their fabrics and garments stay white during production and storage, so that they reach consumers in the best condition -

ensuring no financial loss due to rejections and consumer complaints.

Yellowinginparticularofwhiteorpastelshadeelasticfabricsduringfinishing,storageand transit is a big challenge for the textile finisher. The trouble of yellowing can

complaintsandconfrontationsbetweenthetextilefinisherandgarmentmanufactureror

ultimatecustomer.Thereisalsothefactthatprocessesforavoidingoreliminatingyellowing on fabrics are very time-consuming and involve high costs. So this problem cannot be

neglected.

Generally spoken, the textile industry has to deal with thermal and storage yellowing. But the phenomenon of yellowing of elastic fabrics is more complex which has to be considered

in order to avoid it.

Thehighvarietyofanti-yellowingagentsavailableonthemarketprovidesagreatpotential

fortheapplicationtofinishingprocessesofelastictextiles.However,manyproductswith

nearlythesamepropertiesareusedwhereasthebenefitsofusingspecialtyproductsare

mostlyunknown.

L.N.Chemicals offersacompleterangeofeffectiveanti-yellowingproductsforalmostevery

of finishing of stretch fabrics which grants the textile industry optimal process

reliabilitybycustom-madechemistry.

All types of textile products have been subject to yellowing including those made from natural fibers such as cotton ,wool or silk, as well as those composed of synthetic fibers such as polyester, nylon, or spandex. It should also be noted that in the cases of blended fabrics, at times only one fiber in the blend may be affected by the yellowing. However, at other times several or all fibers in the blend are affected. Specifically, the cause of the yellowing often determines which fiber(s) in the blend exhibit the yellowing. This fact can be used as a diagnostic tool to help determine the source of the observed yellowing and aid in the development of a strategy to prevent future problems.

In recent years, the various causes of these yellowing issues have been studied extensively

with the subsequent publication of numerous technical papers and reports. Generally, the causes can be grouped into the following broad categories with the understanding that

there can be crossover or combinations of causes that yield observed fabric yellowing:

1. Fiber Degradation Destruction, decomposition, internal change of the fiber structure due to chemical or biological degradation, exposure to excessive heat, intensive or long term exposure to light radiation and/or fiber aging are all primary causes of fabric yellowing. Additionally, specific fiber blends may actually increase the occurrence of these problems.

2. Chemical Additives or Auxiliaries It is well known that the overuse or misuse of chemical finishes such as softeners, lubricating oils, resins, optical brightening agents, or metallic salts can lead to unwanted fabric color change including fabric yellowing.

3. Atmospheric Pollutants As was stated previously, atmospheric contaminants from both natural and industrial sources can lead to pronounced fabric yellowing. The specific pollutants include, but are not limited to oxides of nitrogen, sulfur dioxide, and ozone. The mechanisms for the actual fabric contamination are numerous and varied but are normally directly related to specific fiber or fiber blend content along with fabric finishing processes.

4. Transferred Contaminants The contaminants often are contained in cardboard boxes or dividers, plastic sheets, films, or bags and in auxiliary materials such as pumice stones used for garment after-washing processes. In recent years this type of yellowing has been both frequent and also difficult to minimize.

1. Fiber Degradation

As mentioned earlier, normallyfiberdegradation is notconsidered amajorsource of fabricyellowingbuttherehavebeenstudiesthatdoindicatethatthisdoesoccur.These investigationshaveshownthatnaturalfiberssuchascottondegradeandshowyellowing, aswellassyntheticfiberssuchasnylon.Thisfiberyellowingisnormallyacceleratedby exposuretoexcessiveheat,especiallyinthepresenceofhighhumidity,highexposureto ultravioletlight,orlongtermstoragesothatthefibersage.

Wenoticethatincottonfabricthereisyellowing,alossofbreakingstrength,adecrease inmoistureregainandadecreaseindyeuptake.

Itiswellknownthatnylonandpolyesterfabrichaveatendencytoyellowuponstorage overlongtimeperiodsorinhighheatcontainingwarehouses.

Greigespandexblendfabricsarenotoriousfortheirpoorstoragestabilityandnormally shouldbefinishedwithintwomonthsoftheirmanufacture.

2. Chemical Additives or Auxiliaries

Textile finishing of modern textile fabrics employs varied and complex chemical

formulationsdependingontheenduserequirementsforthetextileproducts. Oneofthemostwidelyusedchemicaladditivesaretextilesoftenersbecausetheycan

beaddedinhomeorcommerciallaundries,aswellasbythetextilemanufacturer.The sourceofthesechemicalscanbenaturalproductssuchaschemicallymodifiedanimal

fats and oils, vegetable fats and waxes orsynthetic products such as hydrocarbon waxesorsiliconematerials.Becauseofthechemicalcompositionofthesematerials

manyofthemaresubjecttoyellowingduetoexposuretohighheat,longtimestorage, orincorrectchemicalformulation.Additionally,becauseoftheiroily,greasynature,

heavyapplicationofthesesoftenersleadstoexcessiveattractionofoilydirtbythe fabricsurface,whichinturncreatesatendencytowardyellowing.

3. Atmospheric Pollutants

Studies haveshownthatoneofthemostpotentagents forcausingyellowingcomes from atmospheric pollution (from both natural and man-made sources). The single biggestsourceofyellowinghasbeenidentifiedasoxidesofnitrogen.Forexample,these oxides are formed by the action oflightning in the atmosphere. Man-made sources includetheburningofgasolineanddieselfuelintowmotors,automobiles,trucksand trains, gas- and oil-fired heating systems, and various types of industrial and commercialprocesses.Themostprevalentpollutant,nitrogendioxide,mayreactwith small amounts of chemical residues, oils or greases on the fabric surface. High concentrationofnitrogendioxidehasbeenshowntoyellownylonfiberdirectly.

Other gaseous pollutants shown to induce fabric yellowing include sulfur dioxide, hydrogen sulfide, and ozone. It must be emphasized that fabric yellowing in the presence of these atmospheric contaminants is usually the result of a chemical interaction between the specific pollutant and some chemical components on or near the fabric surface. For factories or warehouses, it is important to ensure that gas or oilfired heating systems are well maintained. Proper air ventilation within the facility is also very important, especially if emissions from tow motors can concentrate within fabric or garment storage areas.

4. Transferred Contaminants

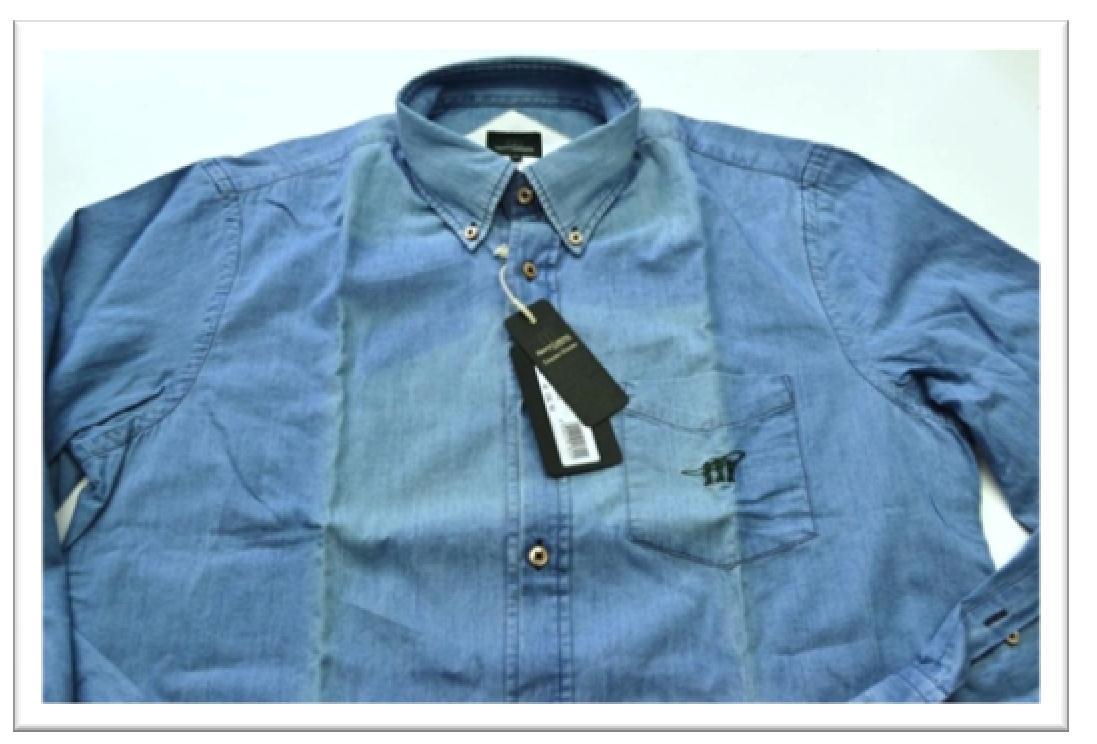

The frequency of fabric or garment yellowing while in storage markedly increased. This is a particular problem for white and pastel shades. The problem was not particularly uniform, in that, within a carton of rolls of fabric, some rolls would exhibit severe yellowing while other rolls showed no yellowing at all.

The source of the problem to be what is now known as phenolic yellowing resulting from fabrics wrapped in polyethylene film or bags. Phenolic antioxidants, most notably butylated hyroxytoluene(BHT), blended into the polyethylene film as a protectant and preservative react with nitrogen dioxide from atmospheric pollution to form yellowing on the fabric surface.

This yellowing can be in patches and is normally reversible. It often can be removed by an acidic scouring of the fabric or exposure of the fabric to direct sunlight.

This phenolic yellowing has since been discovered to be much more widespread throughout fiber-textile-cut & sew-retail chain than anyone initially believed.

More or less yellowing can be caused as a result of:

Thermosetting

Molding due to contact heat

Storage

Thermosetting and storage due to oxides of nitrogen

Molding of fabrics with foam interlinings (e. g. foundation garments).

Photobleachingor photo yellowing due to light

It has to be taken into account that the yellowing propensity of stretch fabrics is

different depending on the individual substrate and fibreadditive applied.

Factors influencing the yellowing

Various factors influence the yellowing of white textile goods in presence of antioxidants :

Storage conditions o Atmosphere composition in store, shop and home (NO X beside other pollutants) o Humidity and temperature o Heating and ventilation o Storage time o Illumination o Ozone fading Composition of hot air, particularly on drying / curing/heat-setting equipment with direct gas heating when nitrogen oxides are produced due to unproper burning conditions.

Causes of yellowing during storage

Theintensiveyellowingofwhiteorpastelcoloredtextile goodisveryoftenaresultofthepresenceofphenol-based antioxidants(butylatedhydroxyltoluenederivates).

Thischemistryislowincostandhighlyeffective. Dueto itslowvaporpressureitisvolatileandcanbetransferredto textilegoodseasily.

Productsofthistypearecommonlyusedasstabilizersin Fibre production, Further textile processing. Packing materials(e.g.polyethylenewrappingfilms,packingmaterial ingeneral)

Causes :

Reaction of nitrous oxides (No x ) in the air with phenolic substances : Antioxidants e.g. based on butylated hydroxytoluene(BHT) often used in cardboards, synthetic materials, plastic films or plastic parts.

+Phenolic substance

+ Nitrous oxides

Yellowing is favouredby pH > 6 ( yellow colourof BHT-No x reaction products is pH –dependent )

Yellowing can be favouredby cationic charges on the fabric (affinity of BHT-No x

reaction products to cationic charges)

Fabric finished with cationic softeners or cationic after treatment : cationic

charges, attract antioxidants.

Heavyyellowingmayoccurduringthermosettingofgreygoodsongas-firedstenters,as aresultofcontactheattreatments(molding)andduringbondingprocesses.Thestretch fabricsthatareespeciallyconcernedarethosemadefrompolyamideandincreasingly polyester.Theproblembecomesevenmoreseriousincaseofmicrofiberarticlesdueto theirextremelylargesurface.Anincreasingissuehavealsobecomeknittedgoodsfrom cotton/elastane mixtures which have to be subjected to a preliminarythermosetting processinordertoeliminateedgecurlingandtoobtainsufficientdimensionalstability. Often,thegoodsturnbrownafterthistreatmentsothattimeconsumingandhigh-cost scouringandbleachingproceduresarenecessarytoachievethewhitenessdegreethat complieswithfullwhite.

Auxiliariesthataredesignedtoprovideprotectionofthegoodsfromthermalyellowing preventorminimizeyellowingincaseofthermalstresses.

Theselectionofthemostsuitableproductdependsonthekindofthermalstress,typeof substrateandprocessconditions

Causesforyellowingduringheatsettingormolding: Decompositionoflubricants/spinfinishes(yellowingofsubstancesonthefibres) Decompositionofcationicsofteners(yellowingofsubstancesonthefibres) Reactionofmonomers, oligomersorfunctionalgroups(yellowingoffibreitself)

Yellowingofsubstancesonthefibre: Scouringthefabricpriortoheattreatment Pre-emulsifyingofspinfinishesandlubricantsbypaddingwithsuitableproducts andwashingoffduringsubsequentdyeing/finishing(especiallyimportantincase ofmicrofibres)

Yellowingofcationic softeners Useofsuitablepseudocationicsofteners(qualityof controliscrucial) rawmaterialsandreaction

Yellowingduetoreactionwithinorduetoyellowreactionproducts. Applicationtofibrestabilizers[radica/scavenger]

PhenolicYellowing,sometimesreferredtoasElusiveYellowing,isthediscolourationof textilescausedbytheactionofoxidesofnitrogen(NOx)onyellowablephenols,andisa simple,relativelylowcost,predictivetesttoassessthepotentialofwhiteorpastelcolouredyarns,fabricsorgarmentsto‘yellow’intransitorinstorage.

Yellowing occurs when certain conditions are present while fabrics or garments are being stored.

These conditions are:

Alkaline finishing

The presence of moisture

Nitrogen dioxide present in the air, and

storage in polyethylene bags or film containing butylatedhydroxytoluene(BHT) or similar compounds

The effects of BHT on white and lightly coloured textiles

BHT is also widely used as an antioxidant in the manufacture of polyethylene films used for packaging. BHT sublimes and migrates easily to items in close proximity.

The chemistry of BHT

Typically, the fabric or garment is finished by the manufacturer or washed by the launderer in slightly alkaline conditions. It is steamed, covered with a polyethylene wrap or bag containing BHT, and stored in a mill, warehouse, or plant, usually in darkness.

With time, nitrogen dioxide reacts with BHT released from the bag or film, especially around openings, perforations, or holes, and this reaction causes yellow stains. The compound produced from this reaction, 2,6,2',6'-tetra-tert-butylstilbene-4:4'-quinone, is intensely yellow (often described as canary yellow, or lemon yellow).

Yellowing caused by the action of oxides of nitrogen depends to a high extent on the fibresubstrate used which is similar to the phenolic yellowing.

Thus depending on their elastanecontent, elastic polyamide or polyester articles show more or less slightly yellowish up to reddish discolorations when exposed to nitrogen oxide gases.

Fibrelubricant deposits and fibreadditives have an additional influence on the intensity of the NOxyellowing

Causes:

Unsuitable cationic softeners

Reaction of indigo with ozone and nitrous oxides

Prevention :

Useofsoftenersavoiding minimizingozonefading yellowingand

Packing avoiding exhaust. of or ready-made denim articles minimizing exposure to

Fumesinstores.

All textiles can undergo photodegradation upon exposure to light. When wool is exposedtolight,itsphysicalandchemicalpropertiesarenormallyaltered,giving risetoyellowingorfadingandlossofmechanicalproperties.

Theproblemofphotoyellowinghasbeentheobjectofagreatdeal.Theyellowingof woolexposedtosunlightisaseriouscommercialshortcomingcomparedtocotton andsyntheticfibres,particularlywhenphotostablebrilliantwhitesandbrightpastel shadesarerequired.

Preventphotoyellowingof wool&othernaturalfibres whichisundergoingphoto fading when exposed to sunlight. When wool carpets are exposed to light, particularlysunlight,visiblecolourchangescansometimesbeobserved,particularly inpastelshades.Thiseffect,knownasphotobleachingorredshift,maybeobserved soonafteracarpetis laid, aperiodwhenconsumers are particularlysensitive to productperformance.

The effectis particularly noticeable when furniture is moved, revealing a colour differencebetweentheareasofcarpetwhichhavebeenexposedtolightandthose whichhavenot.

Source of problem:

All wool, including bleached wool, will photobleachto some degree, but the extent of photobleachingis influenced by the following factors:

Theinitial colourof the wool. The base colourof undyedwool is creamy yellow. The more yellow the wool, the greater is its propensity to photobleach.

Yellowing resulting from processing, for example, dyebathyellowing and heat yellowing will rapidly photobleach.

Depth of dyestuff.Photobleachingis less of a problem with carpets dyed to shades greater than 1/12 standard depth . Hue.Green and blue shades tend to highlight photobleachingmore than redder shades.Beige is particularly sensitive to photobleaching.

As longas BHTtype antioxidants are used itis virtuallyvery difficulttopreventsuchyellowing. Toreducethisyellowingwe recommend:Quench/Neutroxseries

Warncustomerstoensurethatfibresandauxiliariesarefreeof phenolicantioxidants.Especiallypackingorwrappingmaterials should be free of antioxidants (phenol free low density polyethylenebags)

Adjustthefinalfinishwithsomenonvolatileorganicacid(shade andopticalbrightenershouldbeacidstable)

To avoid the presence of nitrogen oxides production and storage (no direct gas heat, all systems such as fork-lift trucks with electric ventilationinwarehousetoavoidairpollution).

(NO X ) during transportation motors, good

Altranol GR:

“Altranol-GR” is a unique product that prevents yellowing of polyester, polyamide & their blends with elastaneduring the heat setting process. Specially designed for the production of pale shades & optically brightened whites

Quench UWP

It protects all types of polymidefibers and their blends with elastomer fibers against oxidative damage, thus reducing yellowing due to thermic and photochemical influence. Avoids yellowing of optical brightened polyamide and it blends during heat setting or molding processes. Prevents shade changes of pastel dyed polyamide and its blends during heat setting or molding treatments.

Neutrox PAT:

Specially designed to reduce the high-temperature yellowing of nylon and its blends during pre-forming, post-setting and molding. It prevents the oxidative embrittlementof various polyamide fibers and their mixtures with elastic fibers, and reduces the damage caused by heat and photochemistry. NeutroxPAT should be used before heat treatment to obtain the best fiber protection effect.

Quench AYXL:

Protective agent for the prevention of yellowing of Polyamide goods during storage caused by phenolic substances and the oxides of nitrogen. Prevents phenolic yellowing of polyamide goods during storage by blocking the free amino end groups of polyamide fibres

Neutrox CT:

Neutrox CT on nylon/ polyester helps prevent storage yellowing

Blocking free amino groups on nylon fibers Nitrophenol derivatives that prevent fiber from absorbing butylated hydroxytoluene

Allenol PYP:

Prevents all kind of Polyamide fibres and its blend with Elastomeric fibres against yellowing by pollutants. Applicable for preventing phenolic yellowing by BHT Yellowing by BHT : The

BHT (2,6 –Dibutyl-hydroxy-toluene) which is very often used as an antioxidant in plastic bags is the main cause of the sporadic yellowing on white and pastel made-up garments wrapped in such PE-bags.

Aquasorb OZ:

It is a fatty acid amidoaminesoftener used to protect indigo dyestuff against ozone & Noxfading. It prevents fading of denim due to ultraviolet radiation, ozone & nitrogen oxide - “photochemical smog”.

Quench APB:

Quench APB is used to prevent photo yellowing of wool & other natural fibres which is undergoing photo fading when exposed to sunlight. When wool carpets are exposed to light, particularly sunlight, visible colour changes can sometimes be observed, particularly in pastel shades.This effect, known as photobleachingor red shift, may be observed soon after a carpet is laid, a period when consumers are particularly sensitive to product performance. The effect is particularly noticeable when furniture is moved, revealing a colour difference between the areas of carpet which have been exposed to light and those which have not.

Product

Altranol GR

Allenol PYP

Neutrox CT

Neutrox PAT

Quench APB

Quench AYXL

Quench UWP

Aquasorb OZ

Aquasorb HIS

Thermal Yellowing Storage yellowing Ozone/NOx Yellowing Photo yellowing

OFFICE ADDRESS :

403, “Antariksh”, Makwana Road, Marol Naka, Andheri (E), Mumbai -400 059 Tel.-91-22-4221 6789 (30 Lines) 91-22-6692 4112 Fax -91-22-2836 6434

FACTORY ADDRESS :

D-14 /10, TTC, MIDC Industrial Area, Turbhe, P. O. K. U. Bazar, Navi Mumbai -400 705 Tel.-91-22-4141 9899 (100 Lines) Fax -91-22-4141 9888

Email ID: ketan@lnchem.in nayana.lnchem@gmail.com

INTEGRATED MANAGEMENT SYSTEM (IMS) CERTIFIED: ISO 9001 : 2015 , ISO 14001: 2015, ISO 18001 : 2007 GLOBAL REPORTING INITIATIVE GRI-G4 CERTIFIED CRISIL RATING : MSE 1*