15 minute read

o AV ms a m acin sustaina i it

EVERYTHING'S GONE GREEN: HOW AV FIRMS ARE EMBRACING SUSTAINABILITY

With sustainability more important than ever before as temperatures around the globe reach record levels, Installation sounds out some of the AV industry's leading manufacturers on their green credentials

ROUNDTABLE PARTICIPANTS

Jan Sandri [JS], president, FSR Inc

Mike Novak [MN], sales director, North America, Calibre UK

Paul Wilson [PW], Epson UK product manager for video projectors

Natalie Gould [NG], operations director, Pioneer Group

Paul Clark [PC], senior vice president, EMEA at Poly

Je May [JM], UK sales director, Konftel

HOW GREEN ARE YOUR PRODUCTS AND SERVICES?

JS: FSR made a decision many, many years ago to be as green as possible and incorporate as much recycled material as possible into our products. One of the ways we’ve lived up to that commitment is by building our products using steel with the highest amount of recycled content possible.

MN: Calibre's latest LEDFusion Pro All-in-One LED display reduces power consumption by over 30 per cent and surface temperature by 10°C/50°F compared to similar sized conventional LED displays.

We’ve implemented features such as easy transportation, installation and deployment. Flight case packaging fits in regular elevators and doorways and AV installers can reduce build times and manpower removing the need to use large cranes or heavy equipment. Calibre has a light aluminium LED panel design reducing installation times from what could be a full day by three people to just 33 minutes

by two people which further reduces the carbon footprint.

Calibre All-in-One LED video walls feature < 0.5W power and Lan standby mode which conforms with ErP regulations. The easy front maintenance service ensures LED tile replacement can be done in under ten seconds. These are the ‘green’ and energy saving designs we have innovated since 2018 when Calibre first launched the first All-in-One LED display.

PW: As a manufacturer, Epson has always asked itself what it can do to achieve a sustainable society and has worked for many years to increase the energy efficiency of its production processes and products, improve resource efficiency, and eliminate harmful and hazardous substances. To make a greater contribution, it seeks to drive work process innovations by minimising the environmental impacts incurred by customers when using Epson products and by raising operational efficiency and productivity.

An example of reduced environmental impacts to the customer is the new EB-PU2220B highbrightness projector, which thanks to optimised design improvements has 38 per cent less CO2 emissions in its lifecycle compared with its 20,000-lumen predecessor, the EB-L20000U, and achieves 33 per cent lower power consumption. The EB-PU2220B is also 70 per cent smaller and 50 per cent lighter than its 20,000-lumen predecessor, meaning customers can reduce their freight transport by the same proportions. In October 2021, Epson was ranked in the top one per cent of its industry for sustainability for the second consecutive year by third-party assessor EcoVadis. This assesses Epson across different themes including environment, sustainable procurement, labour and human rights, and ethics.

NG: Pioneer understands the environmental impacts of the technology we supply, and therefore we only work with suppliers who are also working to improve their environmental impact.

For example, when specifying screens to a customer, we look at the usage and longevity of products to ensure that the product selected is fit for purpose and that it is as 'green as possible' we don’t just look at the cost but the overall impact of each piece of kit we supply and ensure our clients are aware of the options available to them and which options are the most sustainable. We also actively review our suppliers and are continually looking for new developments and suppliers that are offering more sustainable solutions.

PC: Climate change is a global emergency that requires urgent action. We care passionately about the future of our planet, and as a global technology business, it is our responsibility to minimise our environmental impact. We aim to minimise emissions in our operations and through our supply chain, and most importantly, build sustainability into the design of our products.

Sustainable design is about ensuring that a product is manufactured and used in its most efficient way throughout its life cycle. No product can be fully sustainable. However, measures can be taken to reduce its environmental impact. For example, our packaging designs follow global best practice metrics from the Sustainable Packaging Coalition, and we have also implemented a phone takeback scheme, ‘Poly Renew’, initiated in the US, in which Poly receives and recycles second-hand phones in exchange for Poly gear.

JM: Konftel is proud to have secured official Climate Neutral status for the third year in a row. We became the first in the UC industry to become Climate Neutral certified, where all greenhouse gas emissions have been offset by credits, to support various projects around the world.

Achieving the standard was based on a far-reaching three step process which comprised measuring our 2021 greenhouse gas emissions footprint, purchasing verified carbon credits to offset that footprint and implementing plans to reduce emissions during 2022 and beyond.

DO YOU KNOW WHAT YOUR CARBON FOOTPRINT IS?

PW: Epson’s goals are to reduce total emissions in line with the 1.5°C scenario by 2030 and become carbon

negative and underground resource free by 2050. Epson discloses its progression towards its science-based targets (SBTs) and other environmental goals in its annual sustainability and integrated reports. Epson’s SBTs include reducing scope 1 and 2 greenhouse gas emissions by 19 per cent by FY2025, and reducing scope 3 (including category 1: purchased goods and services, and category 11: use of sold products) by 44 per cent by FY2025. It has so far achieved -21 per cent for scopes 1 & 2 (exceeding its target) and -3 per cent for scope 3.

PC: We’ve achieved an 18 per cent reduction in our carbon footprint of 11,092 tCO2e for our Scope 1 and 2 emissions compared to 2020. Going forward, we want to be carbon neutral for Scope 1 and 2 emissions by 2035. In addition to this reduction, we also achieved a seven per cent reduction in our total energy usage across our operations. Using sustainable sources of energy to run our manufacturing sites and offices is also key to positively contributing to environmental protection. We aim to have 100 per cent renewable energy used across all global sites by 2030.

JM: 1,290 tCO2e is Konftel’s carbon footprint. tCO2e (tCO2e stands for tonnes (t) of carbon dioxide (CO2) equivalent (e).

HOW COULD YOU BECOME A CLEANER COMPANY?

JS: We are always seeking ways to be kinder to the planet and that includes our never-ending search to find components built from even more recycled content.

MN: We will become a cleaner company by reducing our environmental footprint and those of our customers. Calibre focuses on green product design that helps our customers streamline their operation efficiency in installation, mobility, logistics and usage of our product.

PW: Epson is striving to achieve sustainability in a circular economy. As part of this, Epson is undergoing a series of environmental initiatives including closing its resource loop, developing environmental technologies, and creating products and services that reduce environmental impacts.

PC: Every company aspires to leave the smallest possible environmental footprint. As a manufacturer of audiovisual products, our first commitment naturally focuses on reducing our carbon footprint, the major by-product of all manufacturing and distribution businesses. The big picture focus is delivering absolute emissions reductions across Poly, our products and for our customers. But we also strive to build sustainability into our products, enabling better reclaiming and refurbishing down the line which ultimately reduces landfill waste. We also plan to complete more life-cycle assessment of our product catalogue, with the intention of calculating energy usage of all Poly devices. Fundamentally speaking, we’re in a constant quest for improvement, and we believe continuous assessment, adhering to proven global standards and focusing on innovation is the winning formula to stay firmly on our sustainability journey.

JM: As part of this year’s commitments Konftel will cut the use of plastic bags in some of our most popular products by 50 per cent, look to increase renewable energy at main manufacturing facilities and also reduce car commuting of staff by 40 per cent.

HOW EDUCATED AND ENGAGED ARE YOUR EMPLOYEES, AND WHAT ARE YOU DOING TO ENCOURAGE THIS?

JS: The engineering department is totally invested in seeking new manufacturing processes that will keep us green, and make us greener.

MN: From product planning, R&D, sales and marketing, all team members are devoted to sustainability. We believe in it and strive for excellence. We also set goals for optimising the product design. Our innovation is to create more efficient products for our customers.

PW: Mandatory training is carried out by Epson employees early in their tenure and annually to ensure they are aware of current societal and environmental challenges and how Epson is addressing these through its products and services. Epson publishes an annual sustainability report globally and has a local version for Epson’s CSR activities across Europe to educate and motivate its employees, partners and other key stakeholders around sustainability.

PC: Our employees are highly educated on sustainability issues and proactively engaged in tackling them. All Poly employees must undertake annual education programs to make sure they understand their obligations as a Poly rep. This includes training on corporate social responsibility; that is, the obligations that all corporations have in terms of acting ethically and developing sustainably.

Above:

Konftel is a Climate Neutral certified company

All our staff must understand Poly’s place in the wider world. On the engagement side, many of our staff participate in – and run – what’s called our Global Giving programme. This involves a mixture of charitable fundraising activities and donations.

As a company, we proactively reach out to our staff to find out which environmental or social causes interest them, and then help them donate to charities that match their interests. Via the programme, in 2021, Poly and our employees donated $127,000, and volunteered for a total of 229 hours, to support global causes relating to sustainability and other important issues.

JM: Our staff are fully educated and engaged about going Climate Neutral and what it means both to the company, our customers and the wider world. We provide regular updates and information which is regularly updated on our website too.

We find that our customers, our partners and our people really care about all of this. We have put it at the very heart of our business because it’s the right thing to do. Yes, the right thing from a commercial perspective, but also the right thing from an environmental and ethical perspective.

WHAT ARE YOUR KEY SUSTAINABILITY MEASURES?

PW: While Epson measures its reductions in greenhouse gas emissions based on science-based targets, Epson also aligns its broad range of commitments to addressing environmental and societal issues with the UN Sustainable Development Goals (SDGs).”

MN: The measures we have put in place to reduce our carbon footprint as a company are: n Reduce carbon usage through implementing an alternative transport, video call over face to face where possible n Reduce landfill usage by implementing recycling KPI targets, audits, and training n Reduce the use of non-sustainable resources n Over the next 24 months, we plan to move to an electric/hybrid vehicle scheme, standardising electric and hybrid vehicles where possible as company vehicles n Goods transportation, minimising the transportation of goods

PC: We’re currently working on a net zero carbon assessment to help establish a clear near-term and long-term route map to achieve net zero carbon emissions. As we are defining them, Scope 1 emissions are direct emissions resulting from Poly’s operations. Scope 2 emissions are indirect emissions resulting from the generation of purchased energy for our operations. Scope 3 emissions include all other indirect emissions which occur within our value chain. We have also invested in specialist life cycle assessment (LCA) resources and appointed a dedicated supply chain ESG manager to facilitate engagement with the supply chain on environmental targets. By focusing on both longterm goals and the intricacies of present-day supply chain management, despite challenges during the pandemic, we believe our business operations are on track to achieve long-term sustainability.

JM: Both Konftel and the Climate Neutral organisation believe every company should be climate neutral and invest in our planet. It’s about measuring, offsetting and reducing emissions to help the world become net-zero by 2050.”

HOW DO YOU SET GOALS FOR IMPROVEMENT AND MAKE YOURSELVES MORE EFFICIENT?

JS: Our engineering department has quarterly meetings dedicated specifically to reviewing our purchasing policies as they relate to obtaining the greenest materials for our manufacturing processes and production environment. While FSR has been aware of the importance of recycling and conservation for many years, there is always room for improvement, and we encourage our entire team to participate fully with ideas and be creative in their contributions.

MN: Continuous design innovation is a core value for Calibre and it gives us a unique and competitive edge. Our strategy is to invest resources in continuous innovation, providing reliable and energy efficient products. By working on the longevity, connectivity, reparability, and recyclability of our products, we make our products suitable for all business models.

We are continually improving the installation, energy efficiency and packaging efficiencies of our products. The install time and manpower has been reduced from one hour by three people to only 33 minutes by two people. Power consumption at maximum brightness is greatly reduced by 30 per cent and we have also redesigned and reduced packaging to be 28 per cent lighter in gross weight and 39 per cent smaller in volume and transportability.

PW: Epson’s environmental goal is to become carbon negative and underground resource free by 2050. As part of this commitment, the business is investing JPY 100 billion/£630m by 2030 on decarbonisation to reduce greenhouse gas emissions in the supply chain by more than 2 million tonnes. It aims to reduce the size and weight of products and increase product longevity to reduce total resource inputs, minimise production losses, and increase the role of recycled materials into product manufacturing.

NG: To maximise sustainability in our working processes, we have implemented a robust ISO 14001 accredited environmental management system (EMS). This has been developed in line with legislative requirements, including:

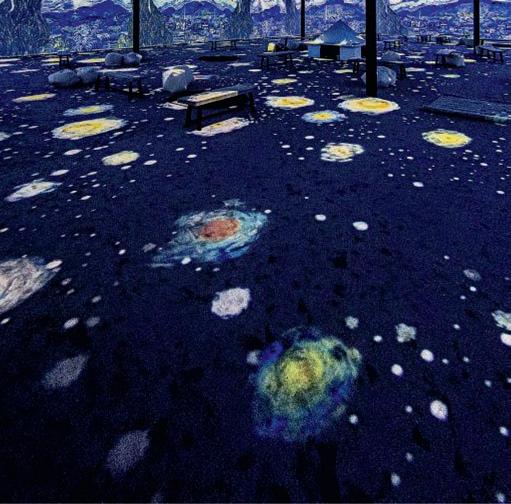

Above:

AV industry manufacturers appear to be embracing sustainability in a big way

CHRIS BROOME, DRAPER PRESIDENT, ON THE COMPANY’S GREEN INITIATIVES

Our biggest sustainability initiative is continuous improvement. We have been using the principles of continuous improvement/lean manufacturing to reduce waste for many years. Through this process, we have been able to make better use of our production space, reducing construction and heating/cooling expense. We have also placed a strong emphasis on integrating our manufacturing. Many of our lower-volume components are now made and/or nished on site, which increases our e ciency, reduces our inventory levels, and reduces the need to ship-in components. We have made lighting upgrades in our facilities over the past few years. We have LED lighting in our o ce and across much of our manufacturing space. Lighting in our manufacturing areas is motion sensitive to reduce electrical consumption. We have also chosen to use nishing processes (powder coating) and printing processes (latex printing) which have signi cantly less environmental impact than other options.

Draper manufactures in the US, and we source many components and materials here. This reduces shipping required for many of our products and components. Although we have drastically reduced scrap thanks to continuous improvement, we do still collect and recycle many tons of materials each year. We collect reusable packaging materials – including more than 100 inner and 100 outer cardboard cores per week – and return them to key suppliers like Phifer and Mermet. We also we also return and/or reuse skids. We send some back to the weavers along with the shade fabric packaging, and we reuse other skids to ship products. n The Environmental Protection Act 1990 n Waste Electrical and Electronic Equipment Directive (WEEE) n Waste (England and Wales) Regulations 2011 n The Environmental Permitting (England and Wales) Regulations 2010

Pioneer Group is a proactive company striving to reduce the impact our company-generated emissions have on the environment. We are committed to reusing, recycling, or safely and correctly disposing of waste off/on-site.

PC: We have devised goals and initiatives for becoming more sustainable and efficient. From a long-term perspective, we have set ourselves a series of low carbon emissions targets moving forward, which we think are ambitious but very much achievable. The first is to use 100 per cent renewable energy across all our sites by 2030. The second is to become carbon neutral for Scope 1 and 2 emissions by 2035. The third is to achieve net zero carbon emissions for Scope 1, 2 and 3 emissions by 2050. To help reach these goals, we have established inter-departmental CO2 reduction teams whose aim is to identify ways in which Poly can avoid carbon emissions across all aspects of the business. These findings are then reported to our ESG impact committee, whose role is to assess and continually monitor progress made by the reduction teams. As such, we believe we have both the right goals to become more sustainable and the immediate processes in place to achieve them. Taking an interdepartmental approach is likely to prove effective as a long-term strategy. We want sustainability to be the collective responsibility of the company at large, not just one or two C-level executives.

JM: When customers buy from us, they know they are buying from an organisation which has no carbon footprint whatsoever; zero net emissions. This is a major statement of intent. The tech we produce works in harmony with our climate neutral philosophy. More conference calling means less car and rail journeys, fewer flights, less busy offices, reduced gas and electricity consumption. By choosing Konftel users really can conference with a clear climate conscience from the very first meeting. We adopt a continual process to become more environmentally friendly.”

MORE ONLINE: An extended version of this article is available online. Please click here. Or go to: https://bit.ly/3zEvgvm