17 minute read

Technical

from Auto Service Professional - April 2020

by EndeavorBusinessMedia-VehicleRepairGroup

AVOIDING COMMON A/C SERVICE MISTAKES

Attention to detail avoids comebacks and increases pro ts.

WBy Edwin Hazzard When it comes to customers and their vehicles, the few things that seem to matter most to them is that the entertainment system is working correctly and their HVAC system is doing its job. Customers rely on their creature comfort amenities to get them from one place to the other. It seems that most customers don’t mind spending the money on these items as they feel they are getting more for their money as opposed to say repairing that leaking water pump or an axle boot that has a split in it. If the radio or the air conditioning stops working for whatever reason they notice it immediately as they will feel “inconvenienced.” When it comes to A/C service, we as technicians need to be aware of the potential service mistakes that can happen when servicing your customer’s air conditioning systems. Not paying attention to details will not only increase the cost of the A/C service, but it will also raise the temperature of your customer’s expectations. In this article we are going to look at a few common mistakes that can happen when servicing an A/C system and procedures we can use to avoid those costly comebacks that every technician dreads. First and foremost, the tools and equipment that are used to service the modern HVAC system must be in proper working order. is can range from recovery and recharge machines, leak detection tools as well as manifold gauge accuracy and scales that are being used to measure the proper amount of refrigerant that goes into each vehicle (see Figures 1 and 7). If any of these are found to be defective then the repair won’t be accurate which could impact a properly functioning system to not work to 100% capacity. Just having an inaccurate manifold gauge could skew your readings to an improper charge amount. Some of these systems are dialed down to a couple of ounces for an ac8

curate charge of either under lling or over lling the system. e same goes for that leak detection tool. Whether it’s an electronic tester with a sensor that has debris built up on its tip or the sensor that was damaged by some other source, nding leaks could provide a very di cult outcome, or worse it might miss a suspected leaking area all together (see Figures 2 and 3).

Also, the leak detection method of using infrared dyes as a source of nding a leak can fail if you are not careful. As an example, I began to use my oil dye on a vehicle to locate a leak and the dye I had hadn’t been used in a very long time. I injected the dye and it actually didn’t show up as a dye at all. I knew the area of the leak but the dye somehow lost its ability to work properly.

I purchased some new dye and the dye worked ne. I am guessing that the dye I used quite possibly had a shelf life and with it sitting around in different types of temperature conditions this might have neutralized the chemicals in the dye from working as they should have. at’s just one example. Paying attention to your equipment can go a long way to achieving a proper repair and avoiding some of the headaches along the way.

When servicing your customer’s vehicle, other than the proper tools needed to do the job, you need to have an accurate service information system with you and an idea of how the system is designed to work.

Also, it’s a good idea to ask the customer about prior repairs that have been done to the vehicle and if possible look at the previous service history on that vehicle. Gathering as much information as you can will not only help guide you in the direction you need to go but will also help save your customer some money as well.

As some of you know, some do-it-yourselfers will try to x their A/C systems themselves. Since

Figure 1: An A/C charging scale.

(COURTESY OF SOUTHEAST MOBILE TECH)

there isn’t any special license to buy certain kinds of refrigerant, they can pick up what they need at any convenience store or big box store. Some of the refrigerant that is sold will include some leak detection sealer already in the refrigerant. This sealer is supposedly designed to stop leaks from the inside the A/C system, presumably to avoid the costly repairs the service facility will charge. However, since the sealer is designed to stick on the internal components of the A/C system in the area of the leak itself, it can present a problem when you go to recover the vehicle’s refrigerant using your recovery machine.

Where do you think that sealer will go next? It will go into your equipment and will stick to the valves and solenoids of your recovery machine and that will impede the operation and possibly damage your equipment. Having your machine repaired because of refrigerant sealer contamination can be very costly (not only the cost of the repairs but the cost of down time that keeps your machine from doing any other A/C servicing).

Fortunately, there are tools that can check the state of the refrigerant that is in your customer’s vehicle and alert you that the system could be contaminated before you hook up your equipment.

An example is shown here (see Figure 4). It may

Figure 2: Mastercool Electronic leak detector and sensor.

cost a few dollars for the tool, but it could save you hundreds of dollars in repair costs. It is critical to investigate what you are working on before exposing yourself to these situations.

Another tool is a refrigerant identifier. These tools can check exactly what type of refrigerant is in the system you are servicing. Unfortunately, there are some service facilities that are not using 100% refrigerant in the vehicles they are servicing and some can be harmful or even flammable, posing a risk to the service technician. It’s important to be cautious when starting your A/C service.

One of the biggest mistakes that I have seen while repairing an A/C system is the advent of an A/C compressor failure. The single biggest reason that an A/C compressor fails is a lack of oil in the system.

Whenever you are servicing an air conditioning system and you are changing any component, you have to remember to make sure the system has the proper amount of oil required in the system and also the correct type of oil required for that particular system.

Does this all sound familiar? It should, as we have to do the same for the engines that we service. Correct oil quantity and proper oil viscosity are just as important in an A/C system.

Even though many replacement compressors state that oil is already added, it’s a good practice to check the oil level yourself before you install that compressor.

I like to drain the oil that’s in the new compressor and measure the oil that came out. Is it the correct amount? Does it look like clean, fresh oil? For peace of mind I like to fill the compressor with the correct amount and correct oil on my own.

Figure 3: DPS Electronic leak detector.

(COURTESY OF SOUTHEAST MOBILE TECH)

Another costly mistake is not knowing why the compressor failed. Did the internal bits of the compressor start to disintegrate and distribute pieces into the system? Don’t install that replacement compressor without knowing this rst. If the compressor failed internally you now have a contaminated system that needs to be ushed out or even replaced. All those contaminants will block the areas that the refrigerant needs to go which will in turn decrease the performance of the new compressor and more than likely lead to a premature compressor and avoidable failure (see Figure 5). e A/C systems on today’s modern vehicles have passages that are very small. e least bit of particles in the system will prevent the other components from doing their jobs as well.

Other costly mistakes with regard to compressor failure would include the drive belt, which can impact the front compressor clutch bearing by over-tightening the belt. A belt that is undertightened will allow the compressor to operate at a reduced speed and will a ect how the refrigerant pressures will be on the system. A loose belt will wear out a lot quicker and more than likely create some unwanted noise under the hood.

A compressor that is not mounted correctly will cause a vibration to the compressor and over a 10

Figure 4: Nueatronic refrigerant sealer identi er.

short period of time will damage the internal components of the compressor. A compressor that’s over-tightened or not tightened evenly can stress the compressor housing and reduce its life. It might even create a belt alignment issue as well.

Some mounting issues I have come across include the lack of the small round mounting retainers or alignment dowels that help keep the compressor mounted in place. Sometimes the replacement compressor does not include the mounting guides, requiring re-use of the original guides. Frequently this is overlooked. Always perform a good visual inspection of the mounting bosses once the old compressor is removed. Look for cracks in the mounting bracket, as well as take a look at the mounting bolts themselves.

When a compressor does fail it is extremely important to inspect the rest of the system. A failed compressor is the single most costly failure on an A/C system. It will take out anything in its path. e single most costly mistake that you can make is not conducting a complete analysis of the failure and to catch any potential issues a er the fact. Remember when I said customers don’t mind spending money to keep themselves comfortable? is just might challenge that thought process.

Another costly mistake in diagnosing an A/C system is overlooking the basics. Remember, if the engine isn’t working the way it’s designed to then the A/C system will follow suit. An A/C system op-

Figure 5: Image of a failed compressor on a Toyota Prius.

(COURTESY OF PRIUS CHAT)

Figure 6: A/C manifold tool.

(COURTESY SOUTHEAST MOBILE TECH)

erates on the basis of temperatures and pressures. If for any reason the engine isn’t building up the correct temperature the A/C system won’t work ef ciently. e engine’s cooling system has to work properly in order for the A/C system to do its job as well. An engine that is overheating and has a cooling fan that is malfunctioning, could be using that 12

same cooling fan for the A/C condenser as well. Obviously, a cooling fan cools the radiator to allow the engine’s coolant to stay at the correct temperature. at same cooling fan is also needed to keep the refrigerant temperature low and thus reducing the excessively high pressure that can build in the condenser.

Making sure that the base cooling system is working as designed will aid in your A/C system diagnosis. at is a crucial step that needs to be made in your diagnostic procedure before you continue with your next step.

Another costly mistake while performing repairs on an A/C system would be adding the exact amount of refrigerant that is called for. If a system calls for say 18 ounces, and you decide to recharge the A/C system using two of the one pounder cans (technically they are only 12 ounces each), then you would be overcharging the system by four ounces. at may not seem like a lot, but that can raise the pressure in the system to the point where the refrigerant will start to boil, placing undue strain on the compressor as well. is type of scenario happens many times and especially with the do-it-yourselfers out there. In the case of A/C service, more is de nitely not better (see Figure 5).

A/C system service is one of the best and most pro table services that a shop can provide. e customers expect to be comfortable and most are willing to bite the bullet when needed to stay that way, as they tend to place great importance on the comfort level. Making sure you follow the service procedures and speci cations to the “T” will make A/C service proceed more smoothly, keeping both customers and technicians alike within their comfort zones. ■

Edwin Hazzard owns South East Mobile Tech in Charleston, S.C., which is a mobile diagnostic and programming service providing technical service to many automotive and body repair shops. He has 37 years’ experience in the automotive industry. He currently is an automotive trainer, a board member of TST (Technician Service Training), a member of the MDG (Mobile Diagnostic Group), a member of the Professional Tool and Equipment advisory board for Pten magazine, a committee member of Nastaf, and is a beta tester for multiple tool makers.

FORD FUNKY MAPT Some 2018-2019 Ford Flex, Explorer, Taurus and MKT vehicles equipped with a 3.5L EcoBoost engine may exhibit a MIL on, Service Advance Trac message, Hill Start Assist Not Available message, and/or a lack of power along with DTCs P0107, P0108 and/or P0109. This may be due to a faulty MAPT (manifold absolute pressure and temperature sensor).

To correct the condition, using a scan tool with the key ON/engine OFF, access the PCM and monitor the following parameter identification: • BARO (press) • MAP (press) • TCBP (press) • TURBO INLET (press)

If the MAP (press) PID value does not read within 10.35 kPa (1.5 psi) of the other sensors, replace the MAPT sensor.

SUBARU SUBARU RECALL Subaru is recalling certain 2015 and 2016 Legacy 4-door and Outback vehicles manufactured July 3, 2015, to July 27, 2015.

Transmission oil may leak from a deformed seal cap on the propeller shaft yoke. If the transmission oil leaks onto the exhaust pipe, there is a possible risk of fire.

LINCOLN CHILLY FINGERS? 2017-2019 Lincoln Continental vehicles (as well as 2017-2019 F-Super Duty, 2015-2019 Edge, 2016-2018 MKX and 2019 Nautilus) may exhibit an inoperative heated steering wheel. For vehicles equipped with adaptive steering, the steering effort control module (SECM) controls the heated steering wheel feature and is internal to the vehicle’s steering wheel.

For vehicles not equipped with adaptive steering, the heated steering wheel module (HSWM) controls the heated steering wheel feature and is separate from the steering wheel.

Use the OASIS tab on the Ford scan tool, drop down > HVBoM > Features button or other scan tool to determine if the vehicle is equipped with adaptive steering. Refer to the workshop manual section 211-05.

T echnical Service Bulletin s TOYOTA BATTERY TESTER BREAKER CONCERN Toyota notes that the new DCA8000 Diagnostic Charger may cause your shop’s ground fault circuit interrupter (GFCI) breaker to trip. A GFCI breaker can be tripped for various reasons. One may be related to the DCA-8000.

Toyota notes that it is investigating the issue to determine the root cause. Other reasons the breaker may trip: circuit demand is too high for the GFCI rating, worn out GFCI internal contacts, or improper installation or wiring of the GFCI breaker.

If the DCA-8000 is causing the breakers to trip on separate circuits, protected by di erent GFCI breakers, then the DCA-8000 might be related to this issue.

Con rm that all other loads are disconnected from the GFCI breaker when testing your DCA8000. If the GFCI breaker continues to trip, contact Toyota’s SST Service Team by calling (800) 9338335 to report the issue. If the DCA-8000 is determined to be the cause of breaker trip, an interim countermeasure DCA-8000 will be exchanged. e DCA-8000 tester is applicable to a range of 2017-2020 Toyota vehicles.

ALL INFORMATION COURTESY OF MITCHELL 1, WWW.MITCHELL1.COM

CHRYSLER THIRSTY RAM DIFF Chrysler is recalling certain 2018-2019 Ram 1500 trucks built from April 2018 to August 2018. e rear di erential may have been insuf ciently lled, possibly resulting in its failure, involving a loss of drive or rear wheel lock-up.

BMW BMW SOFTWARE UPDATE This bulletin applies to 2018 BMW 340i GT xDrive vehicles. e engine may run rough or hesitate when accelerating from a stationary position and DTC FC 21A02D (combustion control valve li correction at idle) may be set in the DME fault memory. e cause is a so ware error in the DME (digital motor electronics). Update the vehicle so ware using ISTA 4. 10.20 or higher to integration level 18-03-520 or higher. Do not replace any parts to speci cally address DME FC 21A02D.

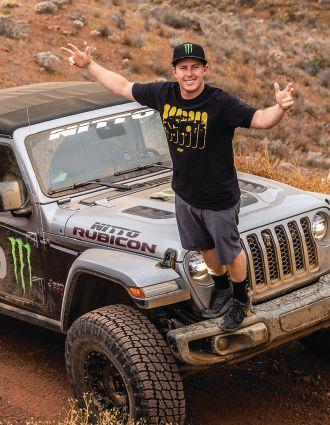

The Choice Of Champions

Technicians...You Could Win a Choice Between Two One-of-a-Kind Vehicles.

MAHLE Aftermarket Inc. introduces the firstever “MAHLE: The Choice of Champions” technician promotion – a unique sweepstakes in which eligible participants have the chance to win their choice between two custombuilt vehicles exclusively designed by racing and automotive enthusiast legends Vaughn Gittin Jr. and Casey Currie. The cars, a Ford Mustang Spec 5 by Vaughn Gittin Jr.’s RTR Vehicles and a Casey Currie Custom Jeep, will both feature high performance, high horsepower engines built by the team at Petty’s Garage.

This year marks the 100th anniversary of MAHLE and in celebration of this important milestone, this program really exemplifies the diverse and broad range of services and solutions MAHLE has to offer and what truly defines MAHLE as a ‘partner of choice’ for champions of all kinds in the automotive industry. ENTRY IS EASY!

n

n

n

n Register at mahlechampions.com Choose MAHLE products when making a parts purchase* Upload the receipt via Smart Device or Computer For every $100 in purchases, the Technician gains an entry

*NO PURCHASE NECESSARY TO ENTER OR WIN. Open to legal residents of the 48 contiguous U.S./D.C., age 18 or older, who are professionally employed by or the owner of a company whose primary business is commercial automotive repair at the time of entry. Void in AK, HI and where prohibited by law. Begins 12:00:01 AM ET on 03/02/20; ends 11:59:59 PM ET on 10/02/20. Total ARV of all prizes: $110,700. Odds of winning will depend on the number of entries received for each drawing. Limit: Fifty (50) entries per person per day. For Official Rules, how to enter without a purchase, list of qualifying products, prizes, and entry period schedule, see www.mahlechampions. com. Sponsor: MAHLE Industries, Inc., 23030 MAHLE Drive, Farmington Hills, Michigan 48335.

JEEP JEEP ESS FIX This bulletin applies to 2017-2019 Jeep Compass vehicles. The engine stop/start (ESS) may be inoperative. Customers may experience a MIL on. DTC P152F (engine hood switch 2/engine hood switch 1 correlation) may be set. The customer may also note that the ESS will turn off with a message displayed in the cluster and stay off while driving.

Using a scan tool with the appropriate diagnostic procedures available in Service Library/ TechCONNECT, verify that all related systems are functioning as designed. If DTCs or symptoms other than the ESS issue are present, record and repair as needed before proceeding. • Open and secure the hood. • Using a trim stick or equivalent, remove the old striker plate from the hood and discard. • Install a new striker plate by engaging the fastener into the hood. The new striker plate has an installation position and a locked position. Do not compress the striker pin before installation. Failure to do so will lock the striker plate and it will have to be discarded. • Once the new striker plate has been properly installed, push the striker pin into the striker body to engage the lock. • Close the hood. • Clear all DTCs that may have set.

A new striker plate is available as P/N 68417561AA.

GENERAL MOTORS TRAX RECALL GM is recalling certain 2015-2018 Chevy Trax vehicles built from July 2015 to June 2017. A joint in one or both of the front lower control arms may have been improperly welded.

An improperly welded joint may break, resulting in partial separation of the lower control arm from the vehicle.

PORSCHE PORSCHE RECALL Porsche is recalling certain 2017-2019 Porsche Cayman and Boxster vehicles.

In the event of a crash, a crossmember may detach from the luggage compartment bracket, possibly causing a fuel leak.