89 minute read

Numbers that Count

from Modern Tire Dealer - December 2018

by EndeavorBusinessMedia-VehicleRepairGroup

Modern Tire Dealer’s 2018 Tire Dealer of the Year John Quirk, center, celebrates alongside members of his team from VIP Inc., dba VIP Tires & Service.

2018 SEMA Show/Global Tire Expo

TIPS FOR RECRUITING, A TRIBUTE TO WAYNE WILLIAMS AND NEW PRODUCTS, TOO

By Modern Tire Dealer staff

The struggle to find and retain good employees doesn’t take a break when tire dealers gather in Las Vegas to attend the Specialty Equipment Market Association (SEMA) Show. Fortunately, educational sessions and forums at this year’s show offered tips, tools and best practices to help dealers with the process.

During a panel discussion of tire dealers, Mark Smith, owner of Midas of Richmond, a four-store operation in Virginia, revealed how much he values a good technician.

He asks if they have someone to recommend. If he makes that request in the morning, Smith said he’s certain he’ll have three names by the afternoon.

“We spiff it. We have great luck,” he said.

It’s a generous spiff for the technician who made the recommendation — worth $6,000 if the new person is hired and works at least six months.

Here’s how it breaks down: $500 the day the technician is hired; $500 at the end of the first week; $1,000 at the end of 30 days; $2,000 after 90 days; and another $2,000 after 180 days. “Hard, cold cash.”

Craig Tate, owner of Tate Boys Tire & Service LLC, said his family-owned dealership recruits employees “nonstop,” using online hiring platforms like Indeed, as well as visits to college campuses. The company, with six locations in northeast Oklahoma, also has created a Manager in Training (MIT) program to guide prospective store leaders.

Tate said the company did a good job of finding employees for the front counter. “We would get great personalities, throw them right up front, and then two years later I’m frustrated because they don’t

know what a ball joint is.” The problem was those employees had no experience in the bays.

The MIT program is designed for “future leaders of the company.” One participant had earned a Master’s Degree in Business Administration. Another was a trained engineer. “We recruited them and sold them on our business.” But they had no automotive experience. MIT participants spend 90 days working in the Tate Boys quick lube lanes, six months in the tire lanes, and another 90 days alongside the company’s technicians.

“It’s worked out well. Three of our store managers have graduated from that program,” Tate said. The result is that those store managers are great tire changers who understand what needs to happen in the bays to make the business operate efficiently and profitably.

The participants are paid at a higher grade than the jobs they’re assigned to in the shop, but Tate said the store where they’re assigned doesn’t have to cover their full salary. The extra pay is assigned to the corporate payroll, while the store has to cover the portion that would have been paid to a tire technician or quick lube technician.

Like Smith, John Quirk, chairman and CEO of VIP Inc., dba VIP Tires & Service, said, “Our people are our best recruiters.” And the company rewards them for their efforts with up to a $2,000 referral bonus.

With 58 stores in four New England states — Maine, Massachusetts, New Hampshire and Vermont — Quirk said his company has turned to psychological testing to help it find the right people. “We don’t want to put that square peg in a round hole, because in years past we just got a bigger hammer and made it fit.”

VIP Tires & Service uses the predictive index, which Quirk boils down to this — is the candidate an introvert or an extrovert? He said it helps the company place people in the right jobs. “If you don’t have the DNA to be in front of customers all day, you’re going to be so worn out,” he said. “There’s a lot of older technicians, when their body is starting to break down, they want to work on the counter. We’ve had great successes on a few of them, but most of them aren’t wired (for that job).”

Quirk, Tate and Smith were the stars of a forum hosted by the Tire Industry Association. Tires at 2: Successful Tire

Tire dealers Mark Smith, John Quirk and Craig Tate (left to right) discussed their tactics for recruiting employees in a forum hosted by TIA.

Dealers Share Their Secrets featured Quirk, Modern Tire Dealer’s 2018 Tire Dealer of the Year; Tate, Tire Review’s 2018 Top Shop; and Smith, winner of the Tire Business 2018 Tire Dealer Humanitarian Award.

MOBILE APPS HELP KEEP EMPLOYEES Tactics for retaining employees, especially members of the most tech-savvy generation ever, were covered in an educational session led by Gene Marks.

Human resources platforms for perking, managing and reviewing employees are exploding in popularity, according to Marks. He said millennials are desperate for more feedback from their employers, and HR apps give it to them.

“We are horrible at providing feedback to millennials,” said Marks, a columnist, author and owner of Marks Group PC, a Pennsylvania firm that provides technology and consulting services.

He recommended four mobile apps to the business owners attending “Talent Management: Trends & Tech Tools for Finding, Motivating Millennials.” They are: Namely; Paychex; Bamboo and Performance Pro.

“These HR apps are huge not just for performance reviews but for all other things regarding payroll. It’s a great productivity tool and gets your employees engaged,” he said. The apps are inexpensive and integrate with all payroll systems, according to Marks.

Key features of performance apps include reminders, alerts and workflows; immediate and frequent feedback; collaborative comments and responses; ways to document good and bad reports; track vacation and sick time and measure progress against goals and objectives.

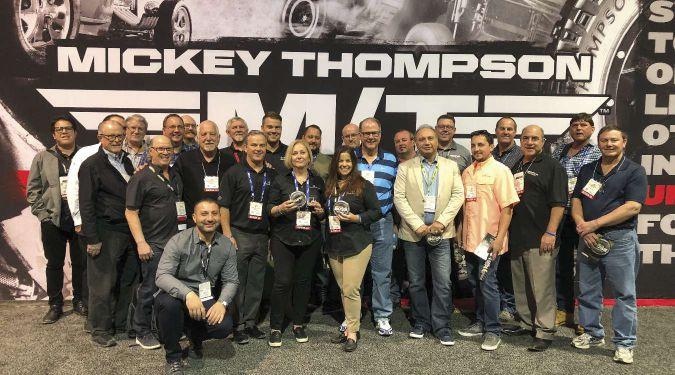

ITDG HAS A NEW PARTNER Members of the Independent Tire Dealers Group LLC (ITDG) and employees of Mickey Thompson Tires & Wheels celebrated a new partnership and a new tire at the SEMA Show.

The ITDG has entered into a partnership with Mickey Thompson to distribute their products throughout the group’s network, according to ITDG CEO and President Dave Marks. The group currently has 150 members in 675 locations in 42 states.

“It is a great opportunity for ITDG to be partnered with a company like Mickey Thompson, which has history and longevity in the specialty tire business,” said Marks.

“Mickey Thompson cherishes the dealer relationship over selling a set of tires. That’s the priority for them,” said Marks.

Blake Warner leads ITDG market development for Mickey Thompson. He said Mickey Thompson is founded on the basis of being a partner to retailers. “The retailer is the heart and soul of our business. We want to be a part of the ITDG members’ businesses, and we want them to feel like partners in our business.”

BAJA BOSS HAS A 6-PLY TREAD The gathering at the Mickey Thompson booth to mark the new partnership did double duty as an official product launch. Mickey Thompson unveiled its newest tire, the Baja Boss extreme mud tire, to ITDG members.

The new mud terrain tire has a three-ply

sidewall and six-ply tread. Improvements over the prior model of the tire include side biters that are 50% larger and one ply that is 150% stronger, according to Robert Dejarnette, marketing program manager.

The Baja Boss will be available in 18 high load-carrying capacity sizes from 17 to 24 inches for a variety of light truck and SUV models — with 18 additional sizes coming later. The load ranges are developed for today’s popular and extreme leveled/lifted applications.

The Baja Boss was one of thousands of products in more than 2,400 exhibit booths in the Las Vegas Convention Center. Here are more of the products and news from the show floor.

NITTO ENTERS SIDE-BY-SIDE MARKET Nitto Tire U.S.A. Inc. unveiled its first tire for side-by-side (SxS) vehicles, the Trail Grappler SxS.

Product development engineer Ryan Parszik says the new tire is a smaller version of Nitto’s race K-spec tire. The first size for the Trail Grappler SxS is 30 x 9.50 R15LT.

The Nitto booth also showcased the Trail Grappler MT tire in a new size: 40 x 15.50 R26LT. Customers were asking for the Trail Grappler MT in a 26-inch rim diameter, according to Parszik. The new size becomes available in early 2019, to bring the Trailer Grappler MT offering to

Independent Tire Dealers Group members and Mickey Thompson Tires & Wheels celebrated their new partnership during the 2018 SEMA Show.

15-inch up to 26-inch rim diameters with a maximum overall diameter of 40 inches.

In addition, Nitto introduced the NT420V tire in 20-, 22- and 24-inch sizes for luxury SUVs. The NT420V will be released in early 2019. It replaces the NT420S.

NEW TBR LINE IS COMING TO NORTH AMERICA Prinx Chengshan (Shandong) Tire Co. Ltd. is entering the North American tire market with its own line of truck and bus tires. The company has hired industry veteran John Aben as its president for North America.

Aben most recently was with Giti Tire (USA) Ltd. as a senior vice president of original equipment and consumer sales. Prior to that, he spent 10 years with Nexen Tire America Inc. as vice president of sales.

Aben said the company will begin shipping a line of truck tires to North America in early 2019. No brand name has been finalized. In other countries, the company sells under the Prinx, Chengshan, Austone and Fortune labels.

The North American operations will be based in Southern California, and Aben hopes to have a team of between seven to 10 people on board by next year. The initial plans are for the company to sell 80% of its tires on a container-load basis, with the remainder flowing through third-party logistics.

China-based Prinx Chengshan (Cayman) Holding Ltd. was listed on the Hong Kong Stock Exchange (code 1809.HK) in October. Che Baozhen is an executive director of the holding company and also serves as CEO of Prinx Chengshan

The 3 big T’s: tariffs, technology and trends SEMA’s Wheel & Tire Council holds panel discussion to map out the future

Before the 2018 Specialty Equipment Market Association (SEMA) Show began, the association’s Wheel & Tire Council convened a panel of experts to talk about the three big T’s: tariffs, technology and trends.

TARIFFS Stuart Gosswein, senior director of federal government affairs for SEMA, said the association supports fair trade, but “the tariffs are going in the wrong direction.” Plus, he said the tariffs imposed by President Donald Trump over the past year have been implemented on parties who “had no idea they were coming.”

Gosswein said rather than imposing tariffs, such as the steel duties that have been assessed on steel from nearly every country, the association believes a better solution is to address the problem of Chinese imports.

But Gosswein acknowledged the difficulty in doing that, especially as Trump continues to push more tariffs. The same day the Wheel and Tire Council panel spoke on the issue, Bloomberg reported the U.S. government planned to impose yet another round of tariffs on $257 billion worth of Chinese imports if the high-level trade talks between Trump and Xi Jinping failed. That new dollar amount would be on top of the tariffs already leveraged on $250 billion of imported goods.

“The president believes this brings our trading partners to the table, but that’s not happening,” Gosswein said.

John Healy, a managing director and research analyst for Northcoast Research Holdings LLC — and Modern Tire Dealer columnist — said the tariffs, along with a 10% rise in raw material costs, have increased prices by 30% in the last year.

SEMA Wheel and Tire Council Chairman Gregory Parker, on the left, moderated a panel discussion of experts during the group’s meeting on Oct. 29. Participating, from left, were Stuart Gosswein, John Healy, Myles Kovacs and Tyson Boyer. The council hopes to host another event next year.

Myles Kovacs, whom WTC Chairman Gregory Parker introduced as someone who “has probably designed more wheels than any person living,” has a background in the fashion industry. He expects the tire and wheel industry to respond like fashion did years ago. Production will move to countries outside the control of tariffs, and the industry will find ways to lessen the financial impact of tariffs. In fashion, Kovacs said, it’s less expensive to import clothing that’s sprayed and designed to be waterproof. Thus, there are more waterproof items available.

The big question on tariffs is this: what comes next? Gosswein provided a straightforward answer: “I don’t have the foggiest idea.”

TECHNOLOGY Healy suggested that the advancement of new technologies in tires and tire pressure monitoring sensors has made motorists safer, and more aware of their tires, and the need to maintain them. But it’s also led to a downturn in the replacement market, he said.

“I think the next wave of technology will be on the fleet side,” Healy said.

Tyson Boyer, sales manager for Dill Air Controls Products, said the complexity of vehicles has already required that tire dealers upgrade their equipment. Alignment equipment that’s 10 years old isn’t suitable for a standard four-wheel alignment. But the good news is there are partnerships emerging to address the changes. They feature both traditional and new parties – including medical companies familiar with imaging who are focusing on the images and impressions of tires.

TRENDS In wheels, Kovacs said the outlook is for bigger and wider wheels, different finishes and wheels made of different materials. Each new innovation brings in partners from other areas of the world — India, Vietnam, China and Europe are already in the game. He said when it comes to plastics there are products coming from Russia.

Healy said millennials’ view of vehicle ownership is “very different” from older generations, and it will have an effect on the marketplace. But at the same time, a transition from individual owners of personal cars to fleets owning and operating cars for consumers “creates more miles driven,” which leads to the need for more replacement tires, and that’s “a boost for the industry’s outlook.”

But the pressure at the retail level isn’t going away, Healy said. “I think people want to shop at fewer places, not more places.” So he sees the convenience factor as key for consumers who might research tires online, but ultimately buy them and have them installed at Costco while they shop.

Kovacs still sees a place for brick and mortar — “if it’s a niche product that Walmart doesn’t sell.” He pointed to the fact that major home improvement chains sell paint, but there are still standalone, specialized stores that sell paint, too.

touchless alignment inspection system, Quick Check Drive. Both systems are connected with HunterNet, the company’s smart technology platform. HunterNet automatically displays digital inspection findings on a Flightboard screen, allowing customers to see their vehicle’s inspection results first-hand. All of these products were integrated in Hunter’s booth, so attendees could see the seamless connectivity in action each time a car was driven over the Quick Check Drive system.

Hunter also demonstrated its partnership with TCS Technologies to enable shops to integrate alignment machine results with work orders and a customer’s record using TireWorks HD software. In addition, service providers can access alignment results from any location. The software offers an optional TCS Live Feed feature that allows customers to view their service and alignment history online 24/7.

“We are excited to tie alignment results into the point of sale to help shops be more productive and provide a better customer experience,” said Alan Hagerty, product manager.

Hunter also introduced a HunterNet

Jefferson Carpenter, director of software sales for TCS Technologies, (left) and Alan Hagerty, Hunter product manager, demonstrated TireWorks HD software that connects a Hunter alignment machine with a shop’s point-of-sale system.

feature that transmits connected equipment results to shops. Called Push Reports, the feature eliminates the need to pull information manually, which creates opportunities for service providers to make immediate data-driven decisions. “Imagine getting a report on how productive your store is being with its alignment and balancing equipment,” said Madeline Triplett, advertising development manager.

A wide range of tire and wheel servicing equipment, including the new Revolution

Wayne Williams is inducted to Wheel & Tire Council Hall of Fame

The members of the Specialty Equipment Market Association (SEMA) Wheel & Tire Council Hall of Fame exhibit “the best in the industry.” And for 2018, the group gave that honor to only one man: the late Wayne Williams.

He was known as a writer — and monthly columnist for Modern Tire Dealer — as well as a salesman, designer, husband and father, said Gregory Parker, chairman of the Wheel and Tire Council. He also founded ExSell Marketing Inc. And he exuded the characteristics of the council’s Hall of Fame members, with his “creativity, dignity, integrity, (and) being industrious.” Parker said Williams enhanced the status of the industry “while significantly contributing to its growth, progress and professionalism.”

Williams died July 19.

Among all of those words, it was Williams’ creativity that stood out. Parker said it was as if Williams was nearly too creative, because “he had so many creative ideas, so much zeal for these ideas, so much passion for every idea that it was hard to choose which great idea to put into effect.”

Parker said there are times leaders have to know when to set aside good ideas to reach for the great ones. “I truly believe our hall of fame inductee tonight lived that principle more than most.”

Williams was committed to doing things the right way, and delivering innovating solutions to make business better for everyone. “He was a visionary, a damned hard worker and a friend.”

Williams’ wife Tia and his son Ryan attended the Wheel & Tire Council event at the

Ryan Williams honored his father, the late Wayne Williams with a tearful, heartfelt speech the night Wayne was inducted into the Wheel & Tire Council Hall of Fame.

2018 SEMA Show. Ryan Williams said it would have been he and his dad’s 16th show they attended together.

He said his dad’s “passion for the wheel and tire aftermarket (business) will forever be remembered” by anyone he worked with. Williams outfitted all of his vehicles with custom wheels, and would stand behind someone else’s tire counter to sell tires — just for fun. He loved to sell a good tire at a great price, and pushed new ways to move units.

The younger Williams also shared one of his father’s trademark tips: “You always said communication is 90% of everything, and the last 10% is just showing up.”

tire changer with WalkAway capability, was featured in the Hunter booth. At about 7,000 square feet in size, the booth was the largest display by a non-original equipment manufacturer at the SEMA Show, according to Triplett.

SEAT AND FILL TRUCK TIRES HANDS-FREE For Martins Industries Inc., the focus in developing new products is threefold. They must enhance safety, be ergonomic, and help a user be more efficient. One of the new products that hits all three marks is a hands-free solution to fill truck tires while they’re inside a cage.

The Inflation Pit Stop combines the seating and inflation of truck tires into one step, safely done within the confines of the cage. The user rolls the tire into the cage, and a roller in the bottom of the unit helps the technician easily rotate the tire to get access to the valve. After it’s connected, users need to press three buttons to select the pressure, fill the air tank, and then push ‘go.’

Martin Dépelteau, president of Martins Industries, said the company spent twoand-a-half years developing the product. It requires technicians to handle the tire for 54 seconds, “and then you can walk away,” said Dépelteau.

The inflation system is available on both a four-bar cage, as well as an enclosed tire cage.

Martins Industries spends time in the

Hennessy Industries’ Mike Wade (left) demonstrated the features of the Coats APS 3000 leverless tire changer to SEMA Show attendees.

field alongside tire dealers and fleets looking for ways to solve their problems. Dépelteau says handling truck tires safely is one of the two biggest concerns those customers identify year after year (the other is how to safely and efficiently unload large loads of tires).

The company provided the U.S. market with its first look at the Inflation Pit Stop during the 2018 SEMA Show.

PLASTEEL GETS A NEW LOOK A metallic finish and a corrosion-resistant material have been added to the new genera

tion of Plasteel wheel weights. “We added an aluminum flake to give the wheel weight a metallic appearance,” said Jerilyn Henegar, senior marketing specialist for Wegmann Automotive USA Inc. The premium wheel weights consist of a steel core wheel weight encased in a plastic outer shell.

Henegar says the plastic outer shell, which is unique in the industry, has been enhanced with “corrosion-resistant material that provides a scratchless install.” Tapered edges further distinguish the wheel weights from the original Plasteel product, which was introduced in 2012. The updated version of Plasteel weights will be available in 2019.

HENNESSY EXPANDS SERVICE The new Coats APS 3000 leverless tire changer from Hennessy Industries Inc. comes with a wheel lift, a bead sealer and reverse mount adapter to eliminate scratching of the rim. Released in 2018, the center post, tilt back tire changer is ideal for run-flats, low profile tires, expensive aftermarket rims and difficult original equipment wheels, according to Mike Wade, product marketing associate. It services up to a 47-inch tire and 16-inch wide rim.

The Coats APS 3500 is a touchless diagnostic wheel balancer with two radars. One measures the outer wheel width and the other performs wheel diagnostics. “If you have an egg-shaped tire, the machine will let you know you have a high spot on the

BARTEC AND TCS PAIR UP Bartec USA LLC is combining the capabilities of its Tech200Pro tool with software provider TCS Technologies. It’s the first time Bartec has integrated any of its tools with a software company, and Bartec believes it will help tire retailers talk to consumers about the condition of their tires and tire pressure monitoring systems (TPMS).

Scot Holloway, CEO of Bartec, said, “It starts with our tools. We built in wireless technology.”

The tool reads signals like sensor fail codes, tire pressure and tread depth. And then those signals are translated into a consumer-friendly report that a salesperson can show on a monitor at the front counter or on a larger monitor in the showroom. The sales team also can generate a printout to give to the consumer. Failed sensors are marked with a red warning label, and ones performing adequately are labeled green.

The tools capture the data and relay it to the TCS Digital Inspections app, as well as the Tireworks HD software interface. Bartec said consumers can make better and more informed decisions when they know the precise condition of their tires and TPMS system.

Holloway said “front counter people are missing opportunities” to sell sensors and TPMS components. He said tire dealers need to follow a basic rule: “If a car has TPMS on it, you need to inspect it.”

This technology will help tire dealers talk about TPMS sensors, and “at the end of the day tire shops are going to sell more tires,” Holloway said.

A NEW WAY TO REMOVE OLD FASTENERS Removing an old, worn or weathered fastener no longer requires any hammering, thanks to what Apex Tool Group LLC calls an uncommonly simple solution to this common problem — GearWrench Bolt Biter Extraction Sockets.

The extraction sockets don’t cut or dig into rounded, damaged fasteners with one-direction spiral blades like other extraction sockets do. Instead, the Bolt Biter is designed as a set of incrementallysized sockets with tapered, internal flutes. They slide over stripped and corroded fasteners and grip the rounded sides and remove them.

And because the removal process doesn’t destroy the fastener, it can actually be

Health care and training TIA introduces two programs to its members

The Tire Industry Association (TIA) announced two new initiatives for its members. They include a health benefits program for employees.

Through an alliance with National General Benefits Solutions, TIA is able to offer flexible group health insurance. “Basically it’s a self-funding program,” said Tim Chandler III, TIA’s health benefits manager. “It’s ideal for small and midsize business owners (with from) two to 200 employees.”

The program, which is designed to be “to be efficient and cost effective,” includes the following options: • Core Value Plan. The reference based pricing plan pays providers based on a multiple of the Medicare reimbursement rate (or other derived equivalent) regardless of the billed amount. It is not associated with any networks, so members have the freedom to use any provider they choose. • Core Value Flex. The level-funded, reference-based pricing option allows members to choose a referencebased pricing plan, with the option of switching to a PPO network mid-year without a change in monthly payment.

Tire Industry Association CEO Roy Littlefield (right, pictured with Kevin Rohlwing, center, and TIA President John Evankovich) said the “unprecedented growth” of

TIA’s membership — 13,783 and counting — is coming

from two areas: government affairs and training.

“If you max out your coverages for the year, you are not liable as a business owner to pay for anything that exceeds your maximum coverage,” said Chandler. In addition, if you have a low claims year, you will get a refund.

For more information on the program, contact Chandler at tchandler@tireindustry.org.

TIA also is developing new 100-level introductions to both its ATS (Automotive Tire Service) and CTS (Commercial Tire Service) training programs. Kevin Rohlwing, TIA’s senior vice president of training, said the programs are geared toward teaching industry personnel who do not service tire and wheel assemblies the basics. Each program will include a sales module.

“What we’ve found here is that we have very welltrained technicians in the back of the shop, but the people at the sales counter and people actually interacting with the customers don’t have the same level of knowledge, so there’s a (communication) gap. We are trying to bridge that gap so the people at the sales counter know what the service people know… and can make promises they can keep.”

The introductory ATS and CTS training programs are only available through TIA’s Online University. Pricing will be announced with the final release schedule in the first quarter of 2019.

removed and re-installed using the same Bolt Biter socket. GearWrench said that’s a big benefit when working with nonstandard parts.

Here are three more benefits: 1. No hammering. The socket is placed onto the rounded, dull fastener. 2. It’s easier to disengage the socket from the fastener once the fastener is removed. 3. The Bolt Biter extraction sockets will last longer than sockets that cut into the fastener. GearWrench says the Bolt Biter

extraction sockets will last 10 times longer than other fastener extractors.

Bolt Biter Extraction Sockets can be used with both hand and power tools. They incorporate a square drive with a hex outer shape for easy use with an impact gun, ratchet, wrench or pliers.

EBAY WANTS TO BE YOUR SUPPLIER One year after unveiling a partnership with American Tire Distributors Inc. (ATD) to provide tire installation to customers, eBay Motors said ATD’s TireBuyer remains its lone service partner.

When asked about its ongoing relationship with ATD, given the tire distributors’ bankruptcy, Jordan Hettinga, senior director of parts and accessories for eBay Motors, said, “We’re all in.”

TireBuyer provides eBay shoppers with 9,000 tire installation locations.

Hettinga said the tire installation service has “gone great,” and that eBay continues to look for ways to improve the experience for consumers. He used the availability of manufacturer rebates as an example. He said eBay is working on “how we highlight that with the installation to drive the best

Jordan Hettinga is an ASE technician who joined eBay after working for Snap-On and JD Power and Associates. He said at eBay, “Tires still remain a very strategic focus for us.”

value to the customer. We want to make sure we take advantage of these things.”

When asked if eBay is looking for other installation partners, Hettinga said eBay is “constantly evaluating how we can expand and do more. The great news about a marketplace platform is it gives us an opportunity to start in one place and grow it from there.” But he also said the company isn’t set up to sign up installers one at a time. “Our goal is to capture as many as possible by casting a wide net.”

Aside from tires, eBay Motors has launched a service tool it thinks will help professional technicians, as well as do-ityourselfers, find the right part for every repair. Shop by Diagram makes schematic diagrams of vehicles interactive. eBay technology matches parts listings with the visual diagrams, and the company guarantees fitment for the year, make and model of the vehicle when selected by the shopper.

Hettinga says, “A lot of what we’re working on right now is reminding shops that we’re here as a viable parts source. It’s about getting the word out to shops, ‘hey you’re used to shopping on a visual diagram; here’s a way to do it.’”

FREE SERVICES HELP BOOST PROFITS Visitors to the Mighty Auto Parts booth learned about two business services designed to improve a shop’s profitability. The services are available to any tire dealer, according to Gary Vann, senior vice president of marketing for Mighty Distributing System of America Inc.

The Performance Watch service is a free analysis of a shop’s preventive maintenance services designed to uncover sales opportunities. Comparative data is used to quantify the profit opportunities along with specific steps to capitalize on them.

“The analysis looks at 20 categories of services and compares their performance to national averages, which reveals profit opportunities,” said Vann. He cited an example of a shop that sold seven batteries out of 216 oil changes in a single month, or 3%. The national average is 15%, which means 33 batteries should have been sold for a profit potential increase of $4,284.74.

“This quantifies what the shop owner already knows. We put a number to it. Then come the solutions. Let’s train, incentivize and make batteries a part of inspections and see if we can get those sales up,” said Vann.

The other free service is called Custom Vehicle Inspection Forms. A vehicle inspection form is customized with a shop’s logo, hours of operation and points of inspection. Five templates are available.

2018 AAPEX 2018 AAPEX: Resources, equipment and tools for the aftermarket

By Ann Neal and Joy Kopcha

Knowing the vehicle issues that may be coming into their shops can help techs plan training, stock parts and have appropriate service tools ready. Such data is available at

Technician Nation, a free online community.

“Every user of a scan tool powered by Bosch is providing us with insight on vehicles worked on around the nation,” Alison

Accavitti, Technician Nation publisher and marketing communications manager, told

Modern Tire Dealer at the 2018 Automotive

Aftermarket Product Expo (AAPEX).

Robert Bosch LLC created Technician

Nation to be a resource for addressing vehicle issues. The online and on-tool platform includes a dashboard aggregating nationwide service trends that can be segmented by geography, vehicle and code, based on vehicle scans from technicians using diagnostic tools powered by Bosch.

The dashboard reveals trending vehicle issues in a shop’s area and can be used to identify if vehicle problems are trending locally or nationally and provide the best information to help properly diagnose the vehicle. Knowing the geographic occurrence of specific vehicle codes can help technicians to plan for tool and equipment purchases, to anticipate the training they will need, and to validate vehicle issues with customers.

“There is no other dashboard that tells out-of-warranty vehicle service trends,” said Accavitti.

Anyone can sign up to join the Technician Nation platform, and technicians who currently use a Bosch diagnostic tool or an

OTC tool with Bosch hardware will have access to sign up for the e-newsletter through their current software.

A MANAGEMENT TOOL FROM ADVANCE AUTO PARTS Professional technicians across the country have a new tool to help them manage multiple facets of their business in a single spot, whether it’s ordering parts, offering

Jack Ogden, senior product specialist for diagnostic product marketing, said the Technician Nation online resources drills down to specific vehicle trends from geographic location to trouble code.

promotions or accessing customer support. MyAdvance is available to aftermarket customers nationally.

Via the MyAdvance (advancepro.com) web portal, Advance Auto Parts Inc. has created a one-stop tool to help professionals manage their businesses.

MyAdvance was designed with feedback from customers, and provides access to more than 30 business programs and services. Key benefits include: mobile friendly capabilities for the shop owner or employee, the ability for customization for each shop based on its programs, an “expert corner” with training and business solution advice from leaders in the automotive aftermarket, and a feature where users can submit support requests and troubleshoot directly with the Advance staff.

“The MyAdvance website improves the way professional customers interact with our team members, and enables them to interact digitally with Advance and among themselves in new ways,” said Walter Scott, senior vice president of professional marketing and programs.

CarMD ENTERS THE B2B WORLD CarMD.com Corp. is jumping into the business-to-business market with its first product designed for the aftermarket, the CarMD Pro Scan. The hardware plugs into

Walter Scott said the new MyAdvance platforms helps the company better communicate with its professional technician customers.

a vehicle’s OBD port, and while a technician performs the customary visual inspection, the Pro Scan checks all of the vehicle’s systems for signs of a problem. When the scan is complete, the results are compiled into a report that provides an overview of the vehicle’s health.

That report covers an overview of freeze frame, I/M status, network scan results, OBD II codes, pending DTCs, possible causes, upcoming maintenance and predicted diagnostics. It spots potential repairs before a warning light appears on the dashboard.

Shops can customize the reports to feature their logo, and incorporate coupons for upcoming maintenance or service needs. There’s even an option for an instant coupon a consumer could use immediately on a needed repair.

“As vehicles become more reliable, customers bring their cars into the shop less frequently, which is why it is vital to help shops capitalize on each visit,” said Jim Dykstra, vice president of business development and strategy for CarMD and CEO of Dytech Auto Group. “The CarMD Pro Scan solution is designed to help take care of customer cars more fully than with just a visual inspection by finding hidden work to drive sales.”

CarMD has also partnered with Epicor Software Corp. Epicor’s Smart Inspection 2.0 will be integrated with the CarMD Pro Scan.

Denso’s Joe Mejaly said the company is launching a new marketing catchphrase. “With Denso, you’re ready” tells consumers they can trust the quality and reliability of their auto parts.

EPICOR STREAMLINES THE INSPECTION PROCESS Epicor said its newest inspection software helps improve workflow in the shop while also equipping consumers with easier to understand repair information.

“The Smart Inspection 2.0 solution helps service businesses grow by streamlining and digitizing several of the most time-intensive steps in an automotive service transaction,” said Stephen Gannon, senior director of automotive product management and development. “It also helps users both in the repair bay and at the service desk avoid mistakes and more quickly and accurately identify needed repairs.”

Accessible via any mobile device, Smart Inspection 2.0 allows the user to start an inspection by scanning the vehicle identification number or manually entering a make, model and year. That information provides a database of specifications and part and labor lookups specific to the vehicle. Users also can document scratches or dents on the vehicle prior to service to prevent damage claims.

Inspection results then are used to create a comprehensive estimate that can be printed or even emailed to a customer for approval. The pricing and availability of parts can be integrated, and the parts can be ordered with a single click after the customer approves the work.

DENSO CONTINUES EXPANSION In 2018 Denso Products and Services Americas Inc. added part numbers, invested in two new warehouses and made major improvements to a third to increase the company’s capacity by 30%. And all that growth came after the company set a sales record the year prior.

President Hal Kato said in 2017 sales in North America exceeded $10 billion for the

Ben Johnson said Mitchell 1 has added a mobile vehicle inspection application to its Manager SE software.

first time. And there’s no plan to slow that momentum, company officials said.

Globally, Denso has made a $3 billion investment in research and development related to automated driving, said Joe Mejaly, senior vice president of operations, sales and marketing for Denso. Mejaly also announced the company’s acquisition of Ease Simulation Inc., a Pennsylvania company that specializes in automotive diagnostics technology.

MITCHELL 1 SIMPLIFIES ADAS REPAIRS Mitchell 1 is working to make Advanced Driver Assistance System (ADAS) technologies easier for technicians to navigate.

“The term ‘ADAS’ may not be immediately familiar to all shops, but everybody knows about blind-side monitoring, lane departure warnings and adaptive cruise control,” said Ben Johnson, director of product management for Mitchell 1. “But the complexity is going to increase exponentially and independent shops need to be ready.”

In the Mitchell 1 ProDemand software, every bit of ADAS data has been housed in a single spot. A click of the “Driver Assist — ADAS Quick Link” button directs users to a table of all the driver assistance systems in a particular make and model of a vehicle.

The dashboard view offers an overview of the related components, and information on whether those components need calibration, or if they require a special tool or scan tool to complete the job.

TENNECO TARGETS RIDE CONTROL ON PICKUPS Tenneco Inc. has designed a ride control product specifically for half-ton pickup trucks that might play nice on the roads during the week, but on the weekend need extra stability when pulling a boat, hauling a load of mulch or pushing a snow plow.

The Monroe Magnum loaded strut assemblies will be available in early 2019 in

AAPEX brought about the unveiling of a new booth and combined presence for the merged Tenneco Inc. and FederalMogul LLC companies. Ethan Bregger, marketing manager for Tenneco in North America, showed off one of the combined assemblies on display, and said together the companies provide “complete, around-the-wheel coverage.”

eight SKUs. Fitments include the 2007-2017 Chevrolet Silverado 1500, 2006-2018 Dodge Ram 1500 4WD, 2004-2013 Ford F-150 4WD, and 2007-2018 Toyota Tundra. The assemblies will be engineered and assembled in the U.S.

Monroe Magnum loaded strut assemblies feature the components for durability and exceptional ride characteristics under a wide range of loads. These include a premium, gas-charged Monroe Magnum strut featuring 10-stage, acceleration-sensitive damping technology (on most applications), nitrocarburized piston rod and PTFE-coated bearing; a variable-rate coil spring; OE-style upper strut mount and bearing; enhanceddesign dust boot; and jounce bumper.

GM ROLLS OUT PERKS FOR PARTS PURCHASES “We want to make sure we’re easy to do business with.” What does that mean for the owner of an independent tire store or automotive repair center? David Mestdagh, general director of global product at General Motors Co., said the company will roll out a new, simplified loyalty program to reward aftermarket shops for purchases of all GM parts.

The “my GM Partner Perks” program is designed to reward independent service centers, body shops and fleets for their purchases of GM Genuine Parts and ACDelco, Chevrolet Performance and Chevrolet, Buick, GMC and Cadillac accessories. The program will debut in the first quarter of 2019.

Mestdagh said a key component is that the buyer will receive “perks” for the purchase of GM parts no matter where they’re purchased. The program’s benefits include marketing sup

Dawn Gonzalez, marketing communications manager for Lumileds, is next to a vehicle retrofitted with Extreme Ultinon LED fog lamps and Ultinon LED lights.

port, purchase rewards, training and repair assistance and business support discounts.

LUMILEDS HAS A NEW INSTALLER PROGRAM Lumileds LLC’s new installer program is designed to help shops sell upgraded vehicle lighting to consumers. The Philips Lighting Specialist Program runs to April 30, 2019.

The Philips Lighting Specialist Program offers incentives for warehouse distributors (WDs), shops and consumers. The program focuses on the Philips X-tremeVision upgrade headlight and offers shops a $25 Visa gift card for every 10 pairs of Philips X-tremeVision upgrade headlights sold and gives shop customers a $10 mail-in rebate for each pair of Philips X-tremeVision headlights purchased.

Lumileds displayed its line of LED lighting solutions for vehicles interiors and exteriors at AAPEX. The company says the bedrock of the LED line is the Philips Ultinon LEDs. Lumileds’ latest LED innovation, the Philips X-tremeUltinon LED Fog Lamp, is designed to be an extremely powerful, plug-and-play replacement for H8, H11, and H16 halogen fog bulbs.

NEW IB PULSE TESTS BATTERY IN JUST TWO STEPS The insights of 2,000 technicians guided the development of the new IB Pulse battery tester from Interstate Batteries Inc.

Cliff Sewing, Interstate Batteries’ category manager of testing, said the company went to the field to find what technicians need in their battery testers.

The result is a handheld tester that easily scans a vehicle identification number (VIN) and battery UPC to provide fast, accurate results. “A typical battery tester might have ten to fifteen steps in the screen flow. The IB Pulse completes the test in as few as two

Cliff Sewing says the new IB Pulse tester is small, compact and can be mounted on a wall.

steps. You scan the VIN of the car, scan the UPC of the battery and hit the start button.”

When the test is complete, the IB Pulse displays the Interstate Batteries part numbers that fit the vehicle tested. “I’ve seen no other tester on the market that gives the battery part number,” said Sewing.

ARCTICPRO MACHINES ARE SMALLER The latest ArcticPro air conditioning handling systems from Mahle Service Solutions are smaller than earlier versions. “These sleek, newly designed high-performance units are smaller in size than previous models taking up less space in automotive repair shops,” said Rich Wolf, general manager. “Mahle has set a new standard for the industry in servicing A/C machines with its new and most popular feature: an ergonomic, hinged cabinet service door for easy access to all internal components.”

The newly designed machines include four units (ACX2180, ACX2180H, ACX2150 and ACX2120H) to recover, recycle and recharge vehicles equipped with R134a refrigerant. Two new units (ACX2280 and ACX2250) are available to service vehicles that are factory filled with the new R1234yf refrigerant.

DELPHI EXPANDS GDI SERVICE PROGRAM Delphi Technologies PLC has added gasoline direct injection (GDI) and multiport gas fuel injector testing equipment to its GDI service program in North America. The expansion coincides with the introduction of the Hartridge Excalibur GDI Master, which gives technicians the ability to test GDI and port fuel injection (PFI) up to 250-bar pressure, in test cycles as little as five minutes. “GDI market growth outpaces most other automotive categories, so quality

Delphi Technologies’ Mary Gustanski (left), senior vice president and chief technology officer, and Chad Smith, vice president of North America aftermarket, are shown with the new Excalibur GDI Master for testing GDI and PFI injectors.

parts and diagnostic equipment for GDI systems will be a must for garages to be competitive,” said Alex Ashmore, president, Delphi Technologies Aftermarket.

Delphi currently offers around 100 GDI high pressure fuel pump SKUs in North America and plans to expand. In addition, the company announced plans to reach a full-line steering and suspension offering by 2020 and a more comprehensive suite of engine sensors.

NGK ADDS PRODUCTS AND A BRAND NGK Spark Plugs (U.S.A.) Inc. introduced a spark plug, a sensor line and a vehicle electronics brand.

The new product is NGK Ruthenium HX spark plugs. The new line is NTK Technical Sensors. The new brand is WVE Vehicle Electronics.

The company says the Ruthenium HX is the latest in high-ignitability spark plug technology comprised of the precious metal ruthenium. This new product contains 25 part numbers covering over 200 million vehicles currently in operation.

In addition, NGK is launching a spark plug service interval resource by including original equipment manufacturer suggested spark plug replacement recommendations in its ngksparkplugs.com parts finder and the company’s Aces catalog content.

NGK Spark Plugs has also expanded its NTK product portfolio beyond oxygen sensors. The NTK Technical Sensors portfolio contains position, pressure, speed, temperature, fluid level, emissions and specialty sensors.

The new WVE Vehicle Electronics brand offers bumper-to-bumper products covering electrical components for both domestic and import vehicles.

Tanya Hines said Johnson Controls’ YouTube channel and website presents information to help technicians translate the features of AGM batteries into benefits that resonate with consumers.

JOHNSON CONTROLS ANSWERS AGM QUESTIONS Focus group research conducted by Johnson Controls International plc found that awareness and understanding of Absorbed Glass-Mat (AGM) batteries are low even though the technology has been available for 30 years.

The research also found that difficulty articulating the benefits of AGM batteries and a misperception about the price contributes to technicians’ reluctance to recommend AGM batteries when the benefits would solve many of their customers’ frustrations about battery reliability, safety and durability.

The focus group provided insights between what consumers want and what technicians are recommending, according to Tanya Hines, vice president of global sales and marketing.

Paul Wise said the new PQ Pro premium brake pad line has more than 903 SKUs, covering 74 vehicle makes and more than 1,500 models from 1961-2019.

Johnson Controls has resources designed to help technicians translate the technical features of AGM batteries into consumer benefits: The Battery Shop YouTube channel and the AutoBatteries.com website. “By understanding the benefits of AGM, they can address consumer needs and frustrations,” Hines said.

CENTRIC PARTS HAS NEW PREMIUM BRAKE PAD The Centric Parts division of APC Automotive Technologies LLC has released Posi Quiet Pro, a premium performance disc brake pad. Paul Wise, vice president of corporate marketing and communications for APC, said the flagship brake pad line, known as PQ Pro for short, addresses key service issues such as brake fade, weak braking response, excessive noise and time consuming break-in procedures.

Every set of PQ Pro brake pads is backed

Permatex’s Donny Braga said SprayNine Grez-Off Parts Cleaner and Degreaser is ideal for the two- or threebay shop that does not want to invest in a professional parts cleaning system.

by a 1-year Centric-Assured Roadside Assistance Guarantee. “The installer has no comebacks, no complaints and no worries,” said Wise.

PERMATEX OFFERS DEGREASER AND PARTS CLEANER New Spray-Nine Grez-Off Parts Cleaner and Degreaser is the only product in the market that can be used as both a traditional spray degreaser and a parts cleaner solution, according to Donny Braga, senior marketing and product manager for the Permatex division of ITW (Illinois Tool Works Inc.). He said the biodegradable and aqueous-based formulation is a much safer alternative than traditional solvent-based degreasers and parts cleaners. The cleaner also features a proprietary corrosion inhibiting formula that prevents flash rusting. It is non-flammable and does not generate fumes.

D U R A B L E S P EC I A L T Y TI R ES

A Leader in Specialty Tires Deestone does it all... farm, tractor, implement, industrial, loader dozer, compactor, grader. The Deestone group is one of Thailand’s leading multi-national companies & our tires are always duty-free.

DEESTONETIREUSA.COM CONTACT US AT 281-600-TIRE

THANKS FOR VOTING OUR

CONSUMER TIRES #1 FOR PROFIT

Alton Degenhardt installs an Alliance brand VF tire on a tractor at McHugh Farms.

PHOTO: ALLIANCE

By Ann Neal

Degenhardt Tire helps growers see the value in proper inflation

THE LATEST AG TIRES CARRY MORE WEIGHT AND REDUCE COMPACTION

When Alton Degenhardt suggested lower inflation pressures of farm equipment tires would reduce soil compaction, his customers were skeptical.

“I had guys tell me it’s never going to work,” says Degenhardt, a third-generation member of the family that owns and operates Degenhardt Tire Inc. in western Wisconsin. “They would say, ‘I don’t know, this seems like a bunch of hocus-pocus.’”

The skeptics have since become believers thanks to technology that allows a tire to carry the same loads at lower inflation pressures or heavier loads at standard inflation pressures than a conventional bias or radial ag tire in the same size.

“Several guys told me they drove around with a full load of corn and beans trying to leave ruts in the field, and they couldn’t,” says Degenhardt. “They never thought that a few pounds of air would make such a difference. They are seeing that there is value in proper air inflation.”

Degenhardt explains that an IF (increased flexion) tire is designed to carry the same load as a standard tire at 20% lower air pressure or carry 20% higher loads at the same air pressure. A VF (very high flexion) tire can carry the same load at 40% lower air pressure or carry 40% more load at identical pressure.

IF and VF technology dates back to the mid-2000s. Michelin was the first tire manufacturer to introduce high-flexing tires in North America with its AxioBib tire, according to David Graden, operational marketing manager-agriculture for Michelin North America Inc.

“Running at a lower air pressure reduces cost of production by improving traction and fuel economy while reducing slip and soil compaction,” says Graden. “Farm machinery has continued to get larger, helping farmers to be more efficient and productive. But with larger, heavier equipment has also come the risk of increased soil compaction which can significantly impact crop growth and yield performance.”

Graden says growers can take proactive steps to manage the risk by being aware of the factors that cause compaction and how to minimize it. “The primary cause is contact pressure, which is exerted by the pressure of tires on the soil surface. Numerous studies have shown the benefits of IF

and VF tires that can operate at a lower air pressure under increased loads, compared to standard radial tire technology.”

Until a couple of years ago, growers were showing limited interest in IF and VF tires. Bill Haney, agricultural and industrial sales manager for Apollo Vredestein Tyres North America Inc., notes that IF tires require close monitoring of air pressure. “VF tires answered the requirement for higher load carrying capacity at more standard air pressures,” he says.

In addition, the initial technical specs for IF and VF tires called for wider rims, which made them expensive in the replacement market. “Since then the specifications in many cases changed to allow standard rims,” says Haney. “The point is that lower air pressures are possible in the field for use with ever increasing tractor horsepower and weight. Lower air pressures are the goal for reducing soil compaction. VF tires are a higher load version of the IF concept.”

FOCUS ON SERVICE There are two Degenhardt Tire stores serving growers in Wisconsin. Reuben Degenhardt, Alton’s grandfather, opened a store in Norwalk in 1962. A store in West Salem, about 25 miles away, followed. Today Reuben’s sons, Jim and Pete, own the company. Jim is Alton’s father.

There are five employees, plus Alton Degenhardt’s mother, Roberta, his aunt, Nicki, and two cousins, Jordan and Zach. The retread shop, which has capacity for up to 100 tires a week, uses the Oliver process to retread skid steer and medium truck tires for agricultural use.

The two stores do not offer mechanical service and focus entirely on tires. “We’ll do anything from a 410/350x4 tire for a lawn cart all the way up to a 29.5/R25 OTR tire. And everything in between from tractors, combines, skids steers, and graders,” says Degenhardt.

The company also offers mobile road service. Degenhardt’s uncle services the area around the Norwalk store, and Degenhardt covers a roughly 80-mile radius around the West Salem store. A typical day is spent on the road making service calls for customers. “I can change any tire on the road, but we cater to the farmers after hours for emergencies, especially during planting and harvesting.”

Local growers know that if they have an issue, they are not going to be down overnight waiting for a tire. “I’ve got pretty much any farm tire you could want on hand. Anything round and rubber, big and small, we’ve got it all,” says Degenhardt.

POUNDS ON THE GROUND Degenhardt is working closely with Patrick McHugh, a grower who is conducting a soil compaction study on his farm. Compaction interferes with a root’s ability to grow into the soil and extract the nutrients and moisture a plant needs. Roots and water cannot infiltrate compacted soil, creating problems for growers.

McHugh uses a device called a penetrometer to measure the resistance in soil in foot pounds. The key metric is the pounds per square inch exerted by a tire on the surface of soil. “I needed to know pounds per square inch. When you first talk to tire people, they talk about how many pounds you put into the tire. Well, I talk about how many pounds are on the ground,” says McHugh.

As part of the study, McHugh has replaced standard radial ag tires on one of his tractors, a Massey Ferguson 8680, with VF tires from Alliance Tires Americas Inc. He is measuring and comparing the amount of compaction under the standard and VF tires. “You need to know the exact weight of that equipment and tire,” says McHugh.

Degenhardt believes he is the only tire dealer in the area using portable scales to weigh farm equipment. He purchased

ALSO IN CTD

Farm tire market shares........................ 70 AG Tire Talk: Proper tractor ballast..... 71 Commercially viable ............................. 76 the portable scales in the fall of 2017. He began carrying them with him on visits to customers’ farms, where he weighed equipment and explained how tire pressure could reduce compaction.

Degenhardt uses footprint boards, which he makes out of white plywood, to demonstrate to customers how lower air pressure expands a tire’s contact area. The tire is positioned on the board before and after the pressure is lowered and sprayed with black paint to show the number of

PHOTO: ALLIANCE

Alton Degenhardt places portable scales under each tractor tire. Knowing the weight exerted by a tire on the surface of soil enables him to calculate the air pressure needed to optimize the tractor’s performance and reduce compaction. He also uses the scales to determine the correct weight split of the tractor.

bars on the footprint board. More bars mean more of the tire is on the ground. “You can see the difference in the number of bars on the footprint board and in the way the machine performs,” he says.

In the spring of 2018, interest in the portable scales “just blew up” along with Degenhardt’s sales of tires for reducing soil compaction. “You want to get the most value for your dollar out of your tires, so that’s why weighing and making sure your weight splits are correct sets that tire and tractor up for optimum performance,” says Degenhardt. “That’s where you are going to get less soil compaction, better traction and minimal amount of slip percentage. You’re getting more power to the ground and getting more work done with less effort.”

For peak performance, the typical mechanical front wheel drive tractor weight split is 60% on the rear axle and 40% on the front axle. “I usually try to get 125 to 136 pounds per 1 PTO (power take off) HP (horsepower),” says Degenhardt.

OPTIONS FOR GROWERS Degenhardt first learned about a tire’s effect on soil compaction at a dealer meeting hosted by Titan International Inc. about two years ago. The company’s LSW (Low Sidewall) technology is exclusive to Titan and Goodyear Farm brand tires. Like VF tires, LSW tires can carry 40% higher loads at the same inflation pressure as standard tires, or they can carry the same load as standard tires at 40% lower inflation pressures. But instead of more flexibility in the sidewalls, LSW tires have larger wheel rims and lower sidewalls.

LSW tires were developed not only to reduce compaction but to minimize road lope (swaying and bouncing during road transport) and power hop (bouncing while pulling in the field), according to Scott Sloan, ag product manager/global LSW at Titan. “With the LSW tire’s sidewall being physically shorter, we can run lower inflation pressures.”

Sloan says super single tires, which replace dual tires on farm equipment, were developed to reduce soil compaction. Super single tires use both LSW and VF technologies. The company’s most popular sizes are the LSW1250/35R46 and LSW1400/30R46, which is the world’s largest farm tire, according to Sloan. “Replacing two tires on the corner of a tractor with one big tire gives you a lot more surface area, contact area and a lot better flotation and less compaction,” he says.

Degenhardt meets the preferences of individual customers with Titan’s super single tires and Alliance’s IF and VF tires. He says he likes Titan’s Goodyear Farm line because of the unique LSW technology and Alliance tires because they are the only ones in the market with all steel casings and IF/VF technology in standard sizes.

“I’ve done a lot of playing around with air pressure, and it really is the final piece in a lot of situations,” he says. “With the Titan LSW for the super singles and Alliance with the duals I was able to bring everything home,” says Degenhardt.

“It all comes down to looking at what you have for a footprint now and how many

PHOTO: ALLIANCE

Alton Degenhardt says correct inflation pressure is helping growers get the most value out of their agricultural tires.

more square inches per tire you gain on the ground by going to an IF or VF tire. A guy who wants his duals can have his duals, and a super singles guy can have his super singles.”

For example, one of Degenhardt’s customers puts dual tires on his equipment for planting but removes them for sidedressing (fertilizer application). “LSW wasn’t going to work for him. So I have Alliance VF duals on the back of his tractor and the Alliance IF duals on the front.”

Using both IF and VF tires on the same machine enables Degenhardt to make sure the weight distribution across each axle is correct. The weight split depends on the size of the tractor and the amount of weight it will be carrying. In this case, using a VF tire with a heavier load index on the front of the tractor was not necessary. “You are taking more power and effort than what is required so you are decreasing the efficiency of your tractor,” says Degenhardt. “If you don’t balance the tractor to get the tires to perform, it’s a waste.”

Another customer had a pair of duals on the front of his tractor. “We put singles on the front. I weighed it when we set it up. I dropped his air pressure down in the back. He was running 25 psi; he’s running 15 now and 12 in the front,” says Degenhardt. “He told me they could never go full speed on the road because it hopped so badly. But with the air pressure adjusted correctly, he can wind it out all the way and run it at top speed,” says Degenhardt.

PHOTO: ALLIANCE

After weighing the tractor, Alton Degenhardt (left) discusses the correct inflation pressure with his customer, Patrick McHugh, who farms 2,000 acres.

The pricing of the two types of tires is comparable. “You can put LSWs on a tractor or put duals on a tractor for about the same amount of money,” says Degenhardt.

LOWERING PRODUCTION COSTS Larger farm equipment is helping to boost efficiency but it may cause soil compaction that can reduce yield. “Equipment in the last 20 years or so has really gotten big. The size of equipment wasn’t an issue when I was a kid,” says the 39-year-old McHugh.

McHugh has standard radial and bias tires on his other equipment, which includes four tractors used in the field, two combines, a sprayer, several planters and four semi tractor-trailers. He grows corn, soybeans, rye and wheat. His approximately 2,000-acre farm also includes organic production of heirloom corn varieties and small grains for a local distillery.

McHugh says road and field travel is smoother with the Alliance VF tires compared to standard ag tires. The Alliance tires also proved themselves as far as reducing compaction. “We see less of a footprint in the field, not only visually but scientifically,” says McHugh. “The tractor we have the VF tires on actually weighs more than the other tractor. From what I’m seeing from my studies, we’re leaving less of a footprint with the heavier tractor because of the tires. It’s nice to see this technology. The pros of tires are that they are much lower maintenance compared to a track system.”

In addition to traditional metrics like bushels per acre, growers like McHugh are focused on lowering their production costs. For example, controlling wheel

slippage, which occurs when the tires are turning faster than the ground speed of the tractor, helps save fuel. Lowering inflation pressure enlarges the tire’s footprint, which increases traction and fuel economy and lessens compaction.

“Slip is wasted horsepower,” says Degenhardt. “The less slip percentage you have, the less wasted fuel and the less wear and tear on the tractor. With less slip percentage you are going to burn less fuel per hour, there’s going to be less wear and tear on the machine.”

Degenhardt tells his customers they can’t do anything about rain and sunshine, but they can minimize their input costs by using properly inflated tires. “The way I look at it, they are going to save money on fuel and potentially save money on repairs. They can minimize input costs with more efficiency, so they cover more acres per hour and use less fuel per hour.”

James Crouch is national product manager-agriculture for Alliance Tire Americas. He says farmers are starting to see the advantages of IF and VF tires. “The opportunity to choose between benefits — carrying more load at the same inflation pressure or carrying the same load at a lower inflation pressure — is really powerful. As farmers get more engaged in improving the efficiency of every aspect of their operations, they are including tire choice and inflation pressure along with

The Agrimax V-Flecto from BKT is designed to resist wear even at low operating pressure and features reduced soil compaction, lower operating costs and increased load capacity.

PHOTO: ALLIANCE

Alliance says the Agriflex 372 IF 1250/50R32 CFO for harvesters, grain carts, and other heavy machinery, which is nearly 7 feet tall with load capacity of up to 22,480 pounds at 46 psi, reduces soil compaction at harvest.

their decisions on other inputs, from seed to fertilizer to chemicals, that affect crop yields and profitability.”

Crouch notes that there are substantially more options for IF/VF tires than ever before. “Just from the Alliance perspective, we have more than tripled our IF/VF offer this year alone. All the major manufacturers seem to have clearly aligned their future product plans to bring low-pressure solutions to as many areas as possible.”

The implement market has transitioned from the demand being super-low-cost commodity bias tires to IF/VF radials seemingly overnight, according to Crouch. “For years, there has been a demand for something better than a cheap bias because of the incredible loads imposed on implements now, as well as the amount of roading they do. When a large planter or tillage tool is folded up into the transportation configuration, the load placed on the primary tires is incredible. A bias tire simply is not built to withstand it. We believe that the trend to IF/VF implement tires is going to dramatically increase over the next few years as more brands offer these solutions to the market.”

NEW PRODUCTS PLANNED

Modern Tire Dealer asked manufacturers for an update on products designed to help reduce soil compaction. Along with Crouch from Alliance, Haney from Apollo Vredestein, Graden from Michelin and Sloan from Titan, five other tire makers responded. They are: Dave Paulk, managerfield technical services for Balkrishna Industries Ltd. (BKT); Brad Harris, manager of global agricultural field engineering for the Firestone Ag unit of Bridgestone Americas Tire Operations LLC; James Enyart, manager of technical services for CEAT Specialty Tires (Cavi Elettrici e Affini Torino Ltd. (CEAT) is part of the RPG Group); Rick Harris, regional manager-U.S. for Global Rubber Industries Pvt. Ltd. (GRI); and Norberto Herbener, OEM technical manager for Trelleborg Wheel Systems Americas Inc.

Not all respondents have IF/VF tires on the market yet. Enyart says CEAT has plans for IF and VF production to reach the market late in 2019. Harris says GRI will have the capacity to produce IF/ VF tires at its Sri Lanka plant by early 2019. Continental Corp. is ramping up development and production of VF tires in Lousado, Portugal, with an anticipated launch at the end of 2019.

“The share of high-flexion tires has increased over the last few years and trends show a larger growth in the upcoming years,” says Andreas Emde from the product development and product industrialization for agriculture tires group at Continental Commercial Specialty Tires. “More and more machines have been equipped with high-flexion tires by original equipment manufacturers and now these tires need to be exchanged. For our market launch, we will focus on the main tractor sizes as well as on harvester steering tires.”

DEMAND FOR IMPLEMENT TIRES

MTD asked manufacturers if demand for IF/VF tires was increasing in any sizes, applications or implements and if so, why? Their responses follow.

Alliance: IF and VF tires have had a long, steady increase in the tractor and combine segment—big, high-visibility tires on machinery where it’s easy to see the benefit of greater load-carrying capacity and lower inflation rates.

Alliance has introduced tires in those categories, all the way up to a massive IF 1250/50R32 CFO combine tire. Over the past few years, we’ve also added an emphasis on IF and VF row crop tires for self-propelled sprayers. That’s another application where the added load capacity and a longer, flatter footprint really make a huge difference.

What’s really exciting now is our expansion into implement sizes. Air seeders, planters, carts, and even tillage equipment can be extremely heavy, which causes soil compaction. Until recently, farmers could

use IF, VF and flotation tires to minimize the compaction caused by their tractors, combines, grain carts and manure tanks but then go back out on the field with an air seeder that weighs 20,000 or more pounds, running on highly inflated tires, and cause the exact problem they had been trying to avoid. With the introduction of Alliance VF implement tires over the past year or so, farmers can go all season on low inflation pressure and minimize their compaction from spring fieldwork through harvest.

Apollo Vredestein: Both IF and VF are increasing in popularity for very large tractors. Typical applications are 4WD (four-wheel drive) tractors (8 equal size tires) and large MFWD (mechanical front wheel drive) tractors, many coming here from Europe. Implements such as grain carts and heavy tillage tools are also starting to use them.

PHOTO: BRIDGESTONE

Bridgestone says its Destination Turf radial implement tire combines its IF and VF technologies with a new turf tread design that deflects stubble and absorbs more damage.

BKT: The demand for IF/VF tires seems to continue gaining steam. More are being used as original equipment on implements and sprayers. Most heavy self-propelled sprayers are coming with IF or VF tires to carry the heavy weight and 40 mph speeds that they run. More IF and VF tires are being used on implements as they get bigger and heavier. The sizes are taller and wider. The demand for these tires will only increase as equipment changes.

Bridgestone: IF/VF tires are more often used in applications that require heavy axle loads, like high-clearance sprayers, combines, grain carts, and transport tires on large implements. As customers require more and more productivity from the equipment they purchase, equipment manufacturers are meeting the need for more capacity. When equipment gets bigger or has more capacity, the axle weights increase. Heavier loads require either larger tires or an increase in inflation pressure to carry the load. A high-clearance sprayer with 120-foot booms and 1,200 gallons of liquid requires each tire to carry 12,000 to 14,000 pounds. Class 8 and 9 combines’ front axle weight can exceed 65,000 pounds with a 40-foot draper platform or 16-row corn head with 400 bushels of crop in the bin. Implements that are 50- to 60-feet wide in the field have to fold narrower for road transport, which transfers the implement’s weight to the four tires. These applications are using IF or VF tires to carry the increased weights while minimizing the need for more inflation pressure.

CEAT: This technology fits the self-propelled row crop sprayer market extremely well with the development of GMO row crops. Due to the additional trips across the fields with herbicide applications, the row crop sprayers have increased in size to improve efficiency and help get the applications completed on a more timely basis. These sprayers are running the same tracks with each application so it became much more important to carry these large loads and to minimize compaction.

Implement tires are a more recent development for the IF and VF tires. The largest planters along with other heavy implements have always had trouble carrying these big loads. Larger equipment has led to adding additional tires to manage these loads. Incorporating the IF and VF tires on these large, heavy implements can provide the load carrying capacity and reduce the compaction compared to the standard bias or radial implement tires. Planting windows seem to be tighter than ever and reducing down time has become more critical. Adopting the IF and VF tires for these large planters does reduce potential down time and of course allows the planting operations to proceed under less than ideal conditions.

GRI: IF/VF started with row crop, sprayer and flotation R1 and is expanding in all sizes including radial implements. Manufacturers are now adding more sizes as IF/VF advantages increase service life and reduce overweight failures/adjustments.

Michelin: Demand is increasing for more applications, fitments and implements. Today’s latest tire technologies enable farmers to carry a heavier load at the same air pressure compared to standard radial technology, or the same load at a lower pressure. In addition, a larger tire footprint allows for better traction in the field, less slippage and improved fuel economy. Michelin offers a portfolio of IF and VF tires for tractors, sprayers and harvest machines in a selection of sizes.

Trelleborg: All tire manufacturers are continuously introducing more sizes under IF and VF technology. As new equipment is launched in the market and their power and weight increase, they require larger tires and/or tires that can hold more load. The fastest segment adopting the IF/VF technology is the sprayers, followed by large tractors.

ADVANCEMENTS IN TECHNOLOGY

MTD also asked manufacturers for an update on their latest IF and VF technologies.

Alliance: IF and VF tires are very demanding to design and manufacture; they require state-of-the-art compounds, and everything from the bead to the tread has to be built to exacting standards. At Alliance, we’ve combined the expertise we’ve developed in IF and VF tires with our decades of leadership in flotation tire technology to help pioneer the VF flotation tire category.

To complement our IF and VF R-1 and R-1W tires, we introduced the Alliance

The contact patch of the secondgeneration CerexBib 2 from Michelin expands up to 35%, which helps reduce soil compaction and protect the soil for future harvests.

Agriflex+ 389, which is the world’s first VF flotation tire. This tire can operate at up to 30% less pressure than a standard radial flotation tire, and it is also optimized for use with a central tire inflation system (CTIS). We are looking ahead and seeing how we can further reduce compaction, and combining our advanced tire technology with CTIS is one of the next big steps.

Apollo Vredestein: Vredestein has embraced the VF technology, offering Vredestein Traxion Optimall as our VF tire. The Traxion Optimall, introduced in November 2017, allows lower inflation pressure in the field and a larger footprint than our current IF offerings.

BKT: BKT has a VF sprayer tire (Spargo) that is rated to run at 40 mph. It is also rated to carry the heavy weight needed for sprayers. We have added several new sizes to this lineup. We make IF tires in the Rib 713 (radial implements) in 15-inch sizes. We make VF tires in the SR713 in a couple of 22.5-inch sizes. We are making a couple of IF/VF sizes in the AW711 (radial implement) in 17- and 18-inch sizes. We continue to add sizes to these groups as demand increases for them.

BKT’s Agrimax Force is an IF rated tire made for higher horsepower tractors and rated to run at 40 mph. The Agrimax V-Flecto is a new VF tractor tire that BKT is building with lower aspect ratios. We continue to add sizes as needed.

Bridgestone: The latest advancement in the technology has been the release of IF/CFO tires. CFO stands for Cyclic Field Operations, which is the service found on combines and grain carts. On combines

PHOTO: TITAN

Titan says the Goodyear-branded LSW1400 is a super single VF tire designed to eliminate power hop and road lope, reduce soil compaction and improve flotation.

and grain carts, the grain bin is filled and emptied in the field, changing the axle weight in a cyclical pattern. IF/CFO tires are designed to carry the heavier loads found on the Class 8 and 9 combines without needing 50 to 60 psi. These tires are also used on single-axle 1,300-bushel grain carts.

Michelin: New central tire inflation systems (CTIS) are being used in conjunction with IF and VF tires. CTIS enables a tractor operator to change tire pressures on the go for optimum performance when changing from road conditions to field conditions. Footprint boards placed under the tires will showcase differences in tire footprints from road to field. The tire pressure can be adjusted with the touch of a button on the tractor’s control panel. CTIS is widely used in Europe and has been increasingly used in North America to minimize compaction and increase traction, fuel economy and tire performance.

Trelleborg: In addition to new IF and VF tire sizes released, Trelleborg is advancing this range by combining it with Trelleborg technology. Each new tire is developed with the patented ProgressiveTraction design to improve traction, inter-lug terraces for superior self-cleaning, and side wings for a wider footprint. A wider footprint on the same tire size reduces pressure on the ground and directly reduces soil compaction.

The VF sizes in Trelleborg’s new TM3000 range are designed to carry a high load capacity while reducing soil compaction during spreading operations.

PHOTO: APOLLO VREDESTEIN

Market Analysis Farm tire market share

BKT AND FIRESTONE REMAIN THE TOP 2 REPLACEMENT BRANDS

By Bob Ulrich

Farm tire market share in the U.S. is being divvied up among more brands than ever before. In the next few years, it wouldn’t be surprising to see Continental, GRI,

Petlas, Vredestein and Maxam agricultural tires represented on our lists.

“There are newer tire manufacturers and products, which are effecting our mix,” says Bill

Haney, regional manager for the

Northeast and Canada, Apollo