3 minute read

BIG plant, tires and investment

from Modern Tire Dealer - December 2014

by EndeavorBusinessMedia-VehicleRepairGroup

Bridgestone opens frst radial OTR tire plant outside Japan

By Joy Kopcha

Building Bridgestone’s biggest tires requires 40 tons of rubber a day, equipment that stands three stories tall and a plant that spans 1.5 million square feet. And that’s just the beginning.

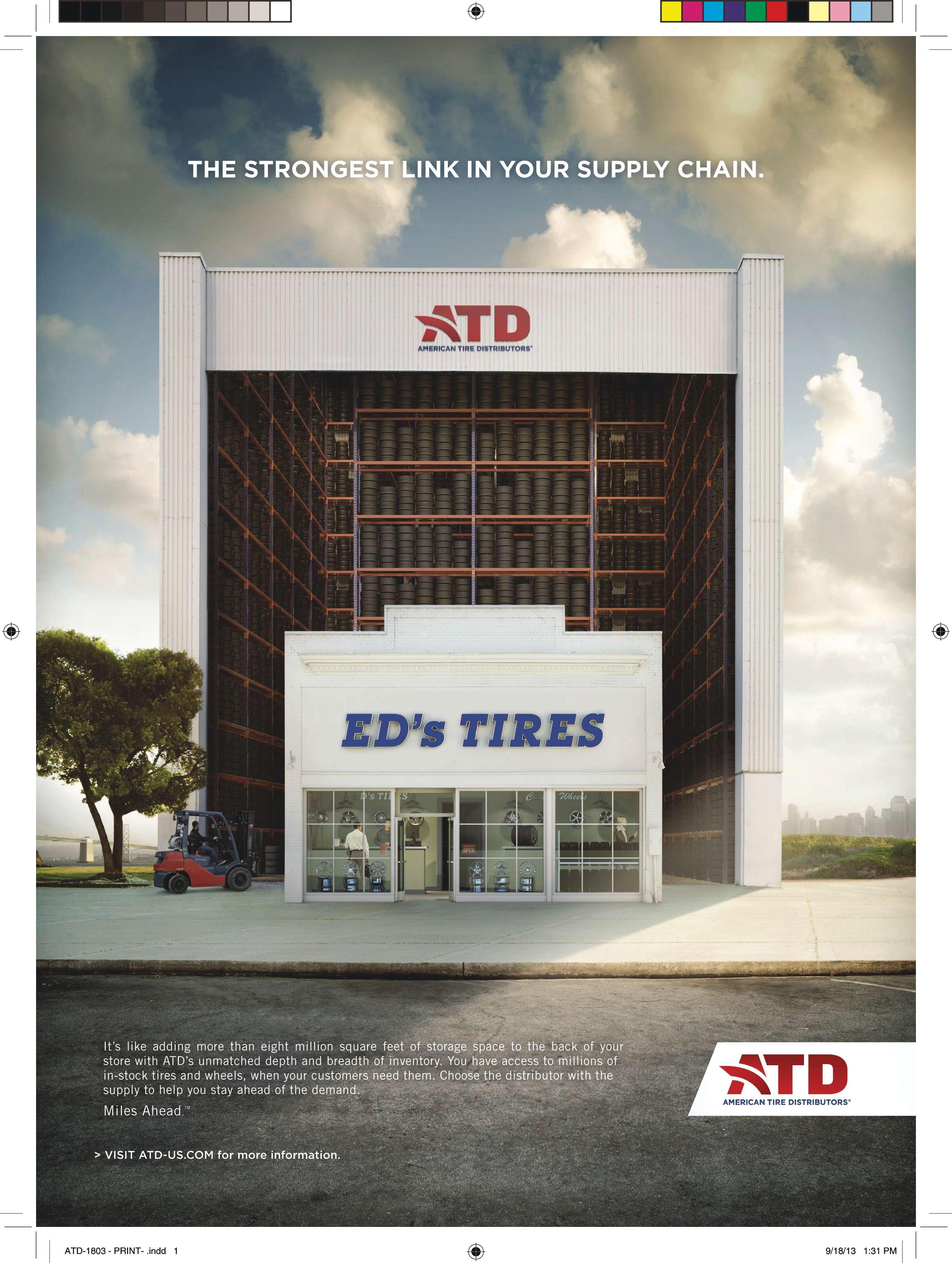

Te Bridgestone Americas Tire Operations Aiken County Of Road Radial Tire Plant is producing 49-inch tires that are eight feet tall and weigh 2,800 pounds. By 2019, when the plant reaches its full capacity, it will produce 130 raw rubber Bridgestone offcials gather in front of the new OTR tire tons per day and manufacture four sizes of tires, the largest plant for a ribbon cutting. From left to right, front row: weighing 13,000 pounds and measuring 63 inches. Tat’s just Mazakasu Sekiguchi, Gordon Knapp, Asahiko “Duke” Nishi2,000 pounds shy of the hef of an average African elephant. yama, Kazuhisa Nishigai, Gary Garfeld, Christine Karbowi

Bridgestone spent $970 million constructing and outfting ak, Ron Brooks. Back row: Mick Suzuki, Ryutaro Ishii, Steve

Shelton, Kurt Danielson, S.C. State Rep. Bill Taylor.

its frst OTR plant outside of Japan. Built on 550 acres in Aiken County, S.C., the plant is more than a third-of-a-mile long. “Tis is the biggest single investment Bridgestone has ever

And as big as it is, there’s room to grow. made in manufacturing in the United States,” said Gary Garfeld,

When executives gathered in November for the plant’s grand CEO and president of Bridgestone Americas Inc. “Within the opening and ribbon cuting, there were multiple mentions of walls of the 1.5 million-square-foot facility, we will produce the space available to expand even more. Aiken County govmany of the world’s largest massive of-road radial tires to keep ernmental and economic development leaders noted in their industries such as mining and construction on the move.” congratulatory remarks they were available to stay late if the Te OTR plant produced its frst tires in the spring of this Japanese leaders wanted to talk before they lef for the airport. year. By late August the tires met Bridgestone’s quality controls

In 1997 the company announced it would build a $435 and passed the inspection process so regular production could million radial passenger and light truck tire plant on 585 acres begin. Te plant is running seven days a week, though not yet in Aiken County. It was the largest investment any company at a full 24-hour pace. had ever made in South Carolina. Additional equipment will be installed. Te current mixer,

Tat record has since been broken — but only by Bridgewhich combines 1,000-pound batches of rubber compounds, stone’s OTR investment. will be augmented by two more, said Adam Barfoot, operations

Tomohiro Fukuda, vice president, ofcer and chief quality manager. Te plant is expected to operate at full capacity with ofcer of specialty tire business for Bridgestone Corp., called 550 employees by 2019. the Aiken County plant “a golden opportunity to produce Bridgestone already has expanded production at its now-fvesuperior giant tires for our customers in the U.S., Canada year-old OTR tire facility in Kitakyushu, Japan, by about 20 and Latin America.” tons a day, to approximately 165 tons a day. Still, that ramp-up didn’t eliminate the inevitable 30 days OTR tires spent on a ship traveling to the western hemisphere. Aiken County takes the water, and variables like ongoing labor disputes at America’s West Coast ports, out of the equation. “We don’t have to sufer through a glitch of the seas or the ports,” said Kurt Danielson, president of the U.S. and Canada Commercial Group, a division of Bridgestone Americas Tire Operations LLC. A U.S. plant also provides the company with a production backup plan for the future. When an earthquake and tsunami hit Japan in March 2011, Bridgestone said none of its plants sustained major damage. Still, it exposed a risk to the company’s OTR business. Production was contained inside a single Tires are weighed, country, while customers across the globe needed tires. inspected by X-ray and “Trough Japan we’ve been increasing our capacity in ultrasound before both a lot of our facilities so it’s just inevitable that we needed the interior and exterior a plant outside of Japan,” said Danielson. ■

are examined by hand.