47 minute read

Commercially viable

from Modern Tire Dealer - August 2013

by EndeavorBusinessMedia-VehicleRepairGroup

Bridgestone premium Ecopia truck tire

Bridgestone Commercial Solutions, a business of Bridgestone Americas Tire Operations LLC, has introduced the Bridgestone M760 Ecopia tire, a premium drive radial that is U.S. Environmental Protection Agency SmartWay verif ed. The M760 delivers high traction and long mileage in a unique fuel-eff cient and retreadable design, according to Bridgestone. The M760 Ecopia comes in four sizes. The 295/75R22.5 is now available while remaining sizes (285/75R24.5, 11R22.5, 11R24.5) will launch in 2014. BRIDGESTONE COMMERCIAL SOLUTIONS Quik-Link: (800) 687-1557, ext. 19160 www.mtdquiklink.com/19160

VDO RoadLog for compliance reporting

The new VDO RoadLog Electronic On Board Recorder (EOBR) developed by Continental Commercial Vehicles & Aftermarket offers f eets and independent operators a simple, all-in-one solution for daily log book and other compliance reporting. VDO RoadLog EOBR allows drivers to record and report hours of service as well as other key compliance data quickly and easily. It’s a complete regulatory compliance system that can help carriers and drivers protect their CSA scores, so they can qualify for the most prof table loads and lower insurance rates. CONTINENTAL COMMERCIAL VEHICLES & AFTERMARKET Quik-Link: (800) 687-1557, ext. 19161 www.mtdquiklink.com/19161

Cooper Tire & Rubber Co. offers the new RM234 regional haul, all-position tire for high scrub situations in which durability, tread wear and extended mileage are important. It features deep tread grooves and a premium tread compound for “excellent wear and cut and chip resistance,” according to Cooper. Cooper has four Roadmaster tire lines that are recognized as SmartWay low rolling resistant tires. Cooper offers the availability of SmartWay products for all wheel positions; they include the Roadmaster RM180 steer tire, RM871 trailer tire and RM851 drive tire. COOPER TIRE & RUBBER CO. Quik-Link: (800) 687-1557, ext. 19162 www.mtdquiklink.com/191620

Toyo M144 all-position medium truck tire

The Toyo M144 regional steer tire from Toyo Tire U.S.A. Corp. was developed to deliver high mileage. Capable of being used in all positions, it provides highly competitive, low-cost mileage performance and better retreadability for both f eet operators and independent owner/ drivers. Technology and design features work together to provide smoother, more even wear as well as longer life and improved traction. The tire is available in two sizes, 305/70R22.5 and 315/80R22.5. TOYO TIRE U.S.A. CORP. Quik-Link: (800) 687-1557, ext. 19163 www.mtdquiklink.com/19163

Trelleborg expands row crop tire line

Trelleborg Wheel Systems Americas Inc. has introduced a new size in its row crop tire offering, the TM600 380/80R38 142A8 (142B) R1W row crop tire. The special design of the tire’s lug surface area minimizes the contact pressure in the center of the tread. This ensures uniform footprint pressure and good tire f otation while reducing compaction and providing high traction capability in all soil conditions. The Trelleborg TM600 tire line is now available in 30 sizes from 20 to 54 inches. The TM600 is designed to maximize the productivity of modern farming operations. TRELLEBORG WHEEL SYSTEMS AMERICAS INC. Quik-Link: (800) 687-1557, ext. 19164 www.mtdquiklink.com/19164

Yokohama TY517 drive tire

The TY517 from Yokohama Tire Corp. is an ultrawide base drive tire that highlights the company’s latest technology in casing design, tread design and rubber compounding. The TY517, which is a SmartWay-verif ed tire, delivers optimum traction, long, even wear, maximum durability and increased retreadability — all designed to cut the bottom line, notes Yokohama. It is available in size 445/50R22.5. YOKOHAMA TIRE CORP. Quik-Link: (800) 687-1557, ext. 19165 www.mtdquiklink.com/19165

A European perspective on a ‘hidden prof t booster’ in every tire center

When we talk about the tire industry, the popularity in wheel alignment can be summed most common points of debate seem up in a single word — training! to hover around sales and pattern Wheel alignment specialists such as Superdesign and how dif erent manufacturers come up tracker now provide a series of comprehensive with new innovative benef ts to make their tires training schemes to help retailers’ staf undermore appealing than their competitors’. stand the theory and operational capabilities of Looking for a moment at how the retail tire alignment which are not only open to their own dealers approach their market, it would be true customers but to anyone interested in learning to say the world over that their ultimate priority more about professional wheel alignment and is to convert every sales inquiry into a hard cash By John Stone the surprising prof t to be made from the service. deal leading to a percentage of prof t. To get a real “insider view” on wheel alignment Over the past couple of months I have been looking at training, I recently at ended (as an observer) a special the whole concept of how European tire retailers, garage one-day training course jointly held by a wheel alignment outlets and general mechanical repair businesses can boost equipment specialist and a leading independent UK-based their prof t margins even further. T e conclusion I have tire retail chain. T e course was intensive and explained reached is that the answer lies in a piece of equipment why wheel alignment isn’t just about the equipment being that can usually be found tucked away somewhere in used, but primarily concerns understanding the physics most outlets. Of course I am referring to wheel alignment of the operation. machinery, which quite bluntly can be easily developed T ere also was a certain amount of participation by into a “hidden source” of prof t from a majority of tire sales. the tire f t ers at ending the course in order to underline We all know that the dif erent aspects surrounding alignment including drivers do not come manufacturers’ data and issues to look for when inspecting willingly to buy a a vehicle prior to carrying out a wheel alignment check. new tire, which will Other areas covered included over- and under-steer and always be considchecking the steering arm and camber levels. I came away ered a “stress purfrom the training session with a much clearer understandchase.” However, ing of alignment service both prior to and during a wheel if they can leave alignment check. with a vehicle that With these highly important training events taking place will perform more on an increasing level throughout Europe, there has never safely and economibeen a bet er time for the automotive servicing market to cally, then I believe appreciate and act upon the immense potential in of ering some would be a highly professional service in wheel alignment which interested in havin the long-term will actually extend the life of a car tire. ing their wheels By of ering a free wheel alignment check when f t ing aligned. a tire, drivers feel they are receiving additional customer I have noticed service. And it is surprising how the tracking on most vehicles that a grow ing becomes misaligned over a period of time, especially now A typical European training session on number of Eurowith the serious conditions of Europe’s roads, which are wheel alignment. pean tire retailers lit ered with dangerous potholes — now that’s another story! and garages are ofIn conclusion, with prof t margins on tire sales becomfering a free wheel alignment check as part of their customer ing increasingly tighter due to the economic situation in service package which in turn can lead to an additional Europe, many retailers are now realizing the encouraging prof t margin. In fact, some retailers (who have to remain benef ts to their business which can be achieved through nameless) have informed me that wheel alignment has wheel alignment. ■ signif cantly boosted their daily income. In an ef ort to f nd out what has instigated this increasing John Stone has been working within the global tire industry interest in wheel alignment services, I spoke with several for the past 20 years. In 2004 he launched his own company, companies in the UK and European alignment market Sapphire Media Services, as a business media consultant including Supertracker, one of the elite specialists leading with clients around the globe. Stone also writes for tire and this innovative industry. automotive-related publications in Europe, South Af ica What I discovered is that the reason for this surging and Asia.

T e art of closing the sale: the last time, until the next time

Wrapping up the new-school ABCs of selling

We have been looking at the ABCs of time before the next time. You are both closing selling, the old-school approach of the sale for this time and opening the door to Always Be Closing, and the newthe sale for the next time. school approach of Align, Balance and Closure. People buy products and remember experiI like the sound of Always Be Closing; it has a ences. We have all been to a restaurant when the rhythm to it, a sense of control. initial experience is less than satisfactory, and the

Well, as we all know, control has shif ed toward server or manager intervenes at the end of the the consumer; the impact of the Internet is felt meal to, in ef ect, put a smile back on our face. everywhere, especially the retail sales counter. At the start, it may have been less than ideal, but Consumers have more information, more questions, By Wayne Williams you are likely to return; they are, in ef ect, closing and a more challenging set of expectations. T e the door on the negative experience and opening old-school approach of Always Be Closing is a much less the door for future positive experiences. ef ective method of dealing with customers today. Over the I’d like to introduce the concept of closure curation. A last few months, we have looked at (A) Aligning our thinking curator at a museum is the person responsible for set ing with the customer, and (B) Balancing their expectations the environment inside the museum so your visit will be with our shop’s capabilities. T is interesting, informative, enjoyable, etc. T e def nition month we will discuss closure/ of a curator is one who cares, who takes care of, and the cash-out and the concept of term “closure” is the act of closing, bringing to an end or closure curation. conclusion. My idea is that a closure curator is one who T e last transaction in any ef ectively, ef ciently and dynamically closes the curproduct or service sale is critical rent transaction while opening the possibility of future to the customer’s experience transactions. and overall satisfaction. During Keep this thought in mind: Customers need their tire my initial retail training at the and service work performed, but their greater need is counter, I remember trying to f nding someone whom they can trust to not only sell the cash-out customers at the end products, but deliver a positive experience. When you do of the day without preparing the this, a relationship is developed and strengthened, and you ticket for cash-out. Customers always want that relationship to close on a positive note. became very annoyed with One way to test a customer’s trust and satisfaction me while I was adding and is to ask a few questions at the closing transaction. For re-adding the ticket (before example: “Would you like to receive reminders or special computers) to make sure it of ers occasionally by email?” or, “May we have your email was accurate. Customer af er address?” or, “Would you like to receive a free oil change customer walked out upset. on your birthday?” My store manager then taught If we have followed the new-school ABCs, if we were me how to prepare the ticket/ able to align our thinking with the customer’s, and align the invoice in advance for smooth customer’s thinking with ours, if we were able to balance closure to the sale. Back then it was of en cash, check or expectations and share information while listening and charge, a signature, and a “thank you” with a smile. validating our shared research, concerns and experiences,

Today more than ever we must dot the i’s and cross the then the closure is a great time to bring the sale to a successt’s, but the same principle applies; the customer must walk ful conclusion and open the door to future opportunities. out satisf ed. It’s our job to ensure that the last contact/ Today, everybody has access to information. T ose who transaction is both pleasant and satisfying. T is is the last practice “counter intelligence,” the ABCs, know how to chance we have to leave a good impression. turn information interactions into trusted transactions.

Not every sale goes smoothly, not all vehicles are ready It’s nice to be nice! ■ when promised, the final price might be higher than expected, etc. We must do our best to make it right before Wayne Williams is president of ExSell Marketing Inc., a they leave. I can’t emphasize this enough. “counter intelligence” f rm based in La Habra, Calif. He can

T ink about my next point for a minute: T is is the last be reached at exsellmkting@gmail.com.

Quik-Link: 800-687-1557 ext. 19129

Sailun launches second generation of Atrezzo, Terramax lines

Exclusive supplier TBC Corp. tells dealers it’s ‘With you through every turn’

By Bob Bissler

With the help of TBC Corp., Sailun Tire Corp. is positioning itself as a premier Tier T ree tire company in the United States.

As part of that initiative, the companies will be of ering a new Sailun Atrezzo passenger tire and more sizes in the Terramax light truck tire line. T ey also have launched a new tagline, “With you through every turn.”

Special delivery

TBC is the exclusive supplier of Sailun tires in the U.S. T e companies recently held a ride-and-drive event for dealers at Palm Beach International Raceway in Jupiter, Fla., to review the products.

T e companies now of er Sailun’s Atrezzo Z4+AS allseason high-performance tire in 21 sizes from 205/55R16 91W to 255/35R20 97W.

Other tires in the Atrezzo passenger tire line include the SH402 all-season performance tire in 37 sizes from 175/70R13 82T to 245/50R16 97H, the Touring LS all-season performance tire in 25 sizes from 195/70R14 91T to 225/55R17 97T and the ZS-R UHP tire in 24 sizes from 195/45R15 SL to 245/45R18 RF.

T e Atrezzo light truck tire line now includes the SVR LX high performance SUV tire in 15 sizes from 275/40R20 XL to 295/40R24 XL, the Terramax CVR all-season luxury/CUV/SUV tire in 18 sizes from 205/70R15 SL to 255/50R20 XL, the Terramax H/T all-season LT/SUV tire in 22 sizes from 215/75R15 SL to LT265/70R17 10 and the Terramax A/T on-/of -road LT/SUV tire in 20 sizes from 235/75R15 XL to LT285/70R17 8.

TBC of cials said the company is consistently updating its product of erings to ensure its dealers have access to quality products at competitive prices.

Attendees compared Sailun’s Atrezzo Z4+AS against a leading tire brand in a blind test conducted by TBC Corp. and Sailun Tire Corp. at Palm Beach International Raceway in Jupiter, Fla.

“We have an extended workmanship and material warranty for a f ve-year period across the life of the tire,” said John Vance, senior director product marketing, TBC Wholesale.

“That’s the same type of workmanship and material warranty that we have from the Tier One manufacturers.”

As part of the second genThe Sailun Atrezzo Z4+AS eration of Sailun products, ultra-high performance the companies are of ering all-season tire is manufactured with special silica warranty enhancements that blends that maximize grip include extended mileage, and handling stability. and tire performance programs that include a road hazard warranty and roadside assistance.

According to Brian Mielko, vice president of marketing for Sailun, the company stands out as one of the premier Tier T ree tire companies in America and is commit ed to delivering a quality “value” brand to consumers.

“Like most leading tire brands available in North America, Sailun also manufactures in China,” said Mielko. “It is important to remember that quality has nothing to do with country of origin, but everything to do with the technology in the factory of origin. Sailun’s manufacturing facilities use state-of-the-art building machines which produce a f nished product that rivals the industry’s largest manufacturers.”

Mielko said Sailun sells more than 50 million tires a year in 50-plus countries. T e company’s reach extends to six continents, and it has f ve corporate of ces across the globe.

“I consider our tires to be part of the ‘value tier,’” said Mielko. T ere are dozens of brands in this tier that of er consumers performance and value, he noted. “My goal is to show that our tires perform as well as a major brand at a fraction of the cost. T e average consumer gets more than what he needs out of our tires, and he does not have to spend a lot.”

“TBC Wholesale is the largest marketer in North America of proprietary or private brand products,” said Vance. “When we took on the marketing and distribution of the Sailun brand a few years ago, we knew we found a product and a partner that could continue our legacy of conf dence, quality and performance.” ■

Eco Products line lowers operating costs by 7%

Bridgestone of ers mid-level Firestone-brand, eco-friendly commercial truck tires

By Ann Neal

Bridgestone Commercial Solutions, a business unit of Bridgestone Americas Tire Operations LLC, says operators who equip their vehicles with its Firestone-brand commercial tires can save up to $1,200 a year.

During an event kicking of its Firestone Drives America Tour in Akron, Ohio, Bridgestone of cials talked about their ef orts to reinvigorate Firestone as the company’s mid-level truck tire brand. A key to that is its new Eco Products line.

Previously announced at the Mid-America Trucking Show, the Eco-Products line lowers operating costs by 7%, or $1,200 a year, according to Bridgestone.

T e SmartWay-verif ed tires provide 19% longer tread life and 1% bet er fuel economy compared to previous Firestone products. T e company credits new applications of existing technologies for the improved wear and rolling resistance of the FS591 steer, FD691 drive and FT491 all-position trailer tires.

• T e FS591 steer radial combines low rolling resistance tread and an energy-saving casing design. T e tire has a wide, deep tread and proprietary shoulder design for greater removal mileage and irregular wear resistance.

T e company’s patented sidewall technologies promote smooth wear. A continuous shoulder of ers long, even wear and lower rolling resistance. • The FD691 drive radial has a continuous shoulder design and high-rigidity tread pat ern to promote long, even wear, helping increase tread life and lower rolling resistance. Flow-through design evacuates water to

The FS591 steer radial has an energy-saving casing design to improve fuel eff ciency.

increase road grip. T e tire’s optimized bead design and proprietary compound in the sidewall lowers rolling resistance and improves fuel ef ciency throughout the life cycle of the casing. • T e FT491 all-position radial uses the company’s Ulti

Rib and Defense Groove sidewall designs to combat irregular wear. Sidewall protector ribs help protect the casing from curbing damage and abrasion. T e wider tread spreads the load over a larger area, distributing footprint pressure to promote long, smooth wear.

T e wider design also takes a full-size drive cap when retreaded for extended life.

All Eco Products tires use Bridgestone’s patented NanoProTech polymers, a technology that limits energy loss for bet er rolling resistance and fuel ef ciency. In addition, the company says its innovative sidewall design reduces overall tire weight to improve fuel ef ciency without sacrif cing durability.

Mat Stevenson, vice president of marketing for Bridgestone Commercial Solutions, says the Eco Products line is aimed at small business owners. “T anks to customer feedback, our new products specif cally cater to the needs of these owners — a lower cost-per-mile through long wear, fuel savings with our Firestone Eco-Products, and excellent retreadability, which extends the life of the casing.” ■

Sports tour targets dealers, f eets and drivers

Bridgestone Commercial Solutions is promoting its new tires with the Firestone Drives America Tour, a cross-country road show that introduces the mid-level Eco Products line to dealers, f eet customers, and professional drivers; offers Class 8-CDL holders a chance to enter a sweepstakes for a Class 8 tractor; and highlights the Firestone brand.

The 2013 tour is stopping at select minor league baseball games throughout the summer and NCAA college football games in the fall. The tour is part of the company’s “Those With Drive, Drive a Firestone” brand marketing campaign. Its f rst stop was the minor league ballpark in Akron, Ohio, on July 16.

Quik-Link: 800-687-1557 ext. 19131

TPMS

Warning light may activate if pressures are not adjusted cold

SUBJECT VEHICLE: 2008-10 Mercury Mountaineer RELEARN PROCEDURE? Yes. SPECIAL TOOLS NEEDED? Yes, a TPMS Activation Tool (P/N 204-363) or equivalent.

The tire pressure monitoring system (TPMS) on the 2008-10 Mercury Mountaineer monitors the air pressure in the four road tires with wheel-mounted tire pressure sensors (TPS). T e sensors transmit radio frequency signals to the Smart Junction Box (SJB) approximately every 60 seconds when the vehicle speed exceeds 20 mph, and every six hours when the vehicle is stationary.

Each tire pressure sensor transmission is compared against a low-pressure limit (pressure listed on vehicle certif cation label minus 25%, which will be about 6 psi to 9 psi). If it is determined that the tire pressure has fallen below this limit, the SJB sends a message to the instrument cluster, which then illuminates the low pressure warning indicator and displays the appropriate message(s) in the message center (if equipped).

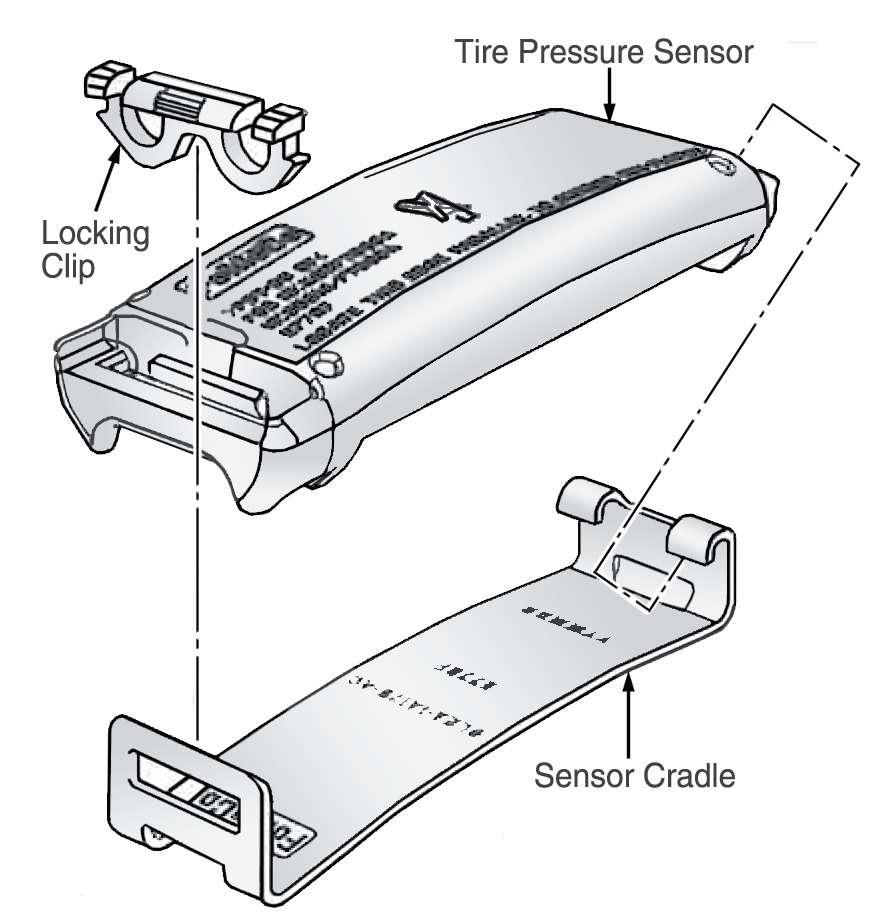

T e bat ery-operated tire pressure sensors are mounted to metal brackets (called cradles) on the wheels inside the tires. T e sensors are mounted 180 degrees from the valve stems. T e tire pressure sensor may be serviced separately, but the cradle and strap must be replaced together.

Under the following conditions, the TPMS may not function properly:

• Low tire pressure; • T e TPS is missing or damaged; • Spare tire is installed as a road wheel; • An incorrect TPS is installed; • T e TPS is installed incorrectly; • Non-OEM wheels are installed; • Non-OEM equipped run-f at tires are installed; or • T ere are other non-OEM modif cations (roll cages, service barriers, part racks, ladder racks, etc.). TPMS warning indicators

NOTE: As ambient temperature decreases by 10 degrees Fahrenheit, tire pressures decrease 1 psi. If tire pressures are not adjusted at cold temperature, the tire pressure may drop enough to be detected by the TPMS, which will activate the low pressure warning light.

When the tire pressure warning light comes on solid and the message center displays “LOW TIRE PRESSURE,” check the air pressure of all tires and adjust to the specif ed cold pressure listed on the vehicle certif cation label (found on the driver’s door or door pillar).

Drive the vehicle at 20 mph for at least two minutes. Make sure the warning light goes of . If the warning light stays on, there is a malfunction in the TPMS. See appropriate manufacturer service information.

When the tire pressure warning light f ashes for 20 to 30 seconds af er a bulb check has been performed and the message center displays warning messages, there is a malfunction in the TPMS. See appropriate manufacturer service information.

Reset procedures

NOTE: If a TPS is replaced, it will need to be trained. T e TPMS is not af ected by wheel and tire rotation.

Drive the vehicle at 20 mph for at least two minutes. If the vehicle has been stationary for more than 30 minutes, the sensor will enter into a “sleep mode” and stop transmit ing. A TPMS activation procedure may be needed.

See the instructions for TPS activation. Make sure the warning light goes of .

TPS training

NOTE: In the following procedure, TPMS Activation Tool (P/N 204-363) or equivalent must be used.

NOTE: T e TPS training procedure must be done on a single vehicle, in an area without radio frequency (RF) noise and at least three feet away from any other vehicle equipped with TPMS. RF noise is generated by electrical motor and appliance operation, cellular telephones and remote transmit ers, power inverters and portable entertainment equipment.

NOTE: A new TPS is shipped in an OFF mode (or battery saver mode), and must be turned ON before it can be trained.

To turn the sensor on, inf ate the tire to the recommended inf ation pressure and wait at least two minutes, then continue with the sensor training procedure. T e sensor also can be activated using the TPMS activation tool. See TPS activation.

1. Turn the ignition switch to the OFF position, then press and release the brake pedal. 2. Turn the ignition switch from the OFF position to the RUN position three times, ending in the RUN position. Do not wait more than one minute between each key cycle. 3. Press and release the brake pedal. 4. Turn the ignition switch to the OFF position. 5. Turn the ignition switch from the OFF position to the RUN position three times, ending in the RUN position. Do not wait more than one minute between each key cycle.

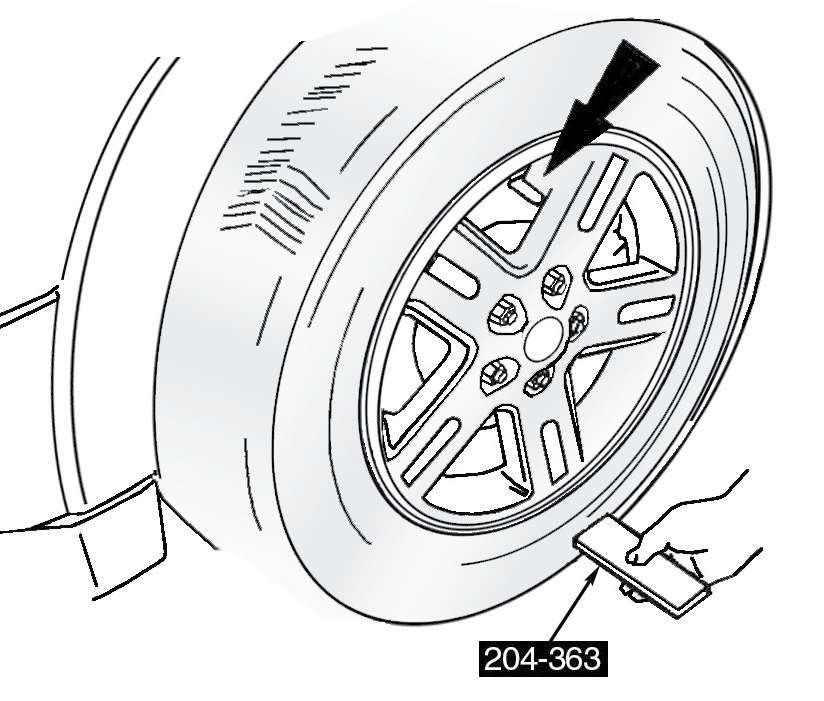

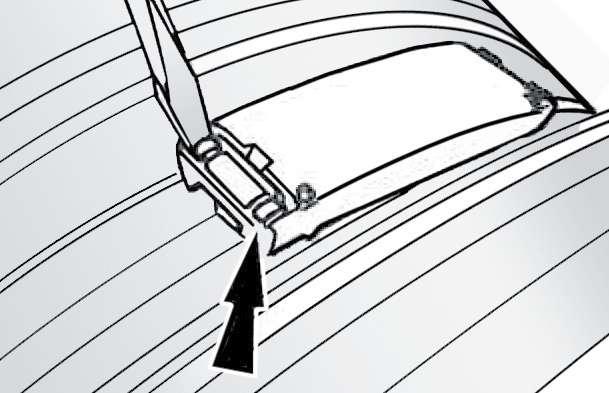

NOTE: It may take up to six seconds to activate a TPS. During this time, the activation tool must remain in place 180 degrees from the valve stem (see Figure 1).

If a sensor does not respond to the activation tool, at empt to activate the same sensor using the activation tool. If the sensor still does not respond, move the vehicle to rotate the wheels at least one-quarter of a turn and attempt to activate the same sensor again.

If the SJB does not recognize any one of the four TPSs during the tire training procedure, the horn will sound twice and the message center (if equipped) will display “TIRE NOT TR INED

Figure 1: Training tire pressure sensors (1 of 2).

Figure 2: Training tire pressure sensors (2 of 2).

REPEAT.” Repeat training procedure from the beginning. 6. T e horn will sound once and the tire pressure warning light will f ash if the train mode has been entered successfully (if equipped, the message center displays “TRAIN LF TIRE”). Place TPMS activation tool (P/N 204-363) on the lef front tire wall opposite (180 degrees) from the valve stem. T e horn will sound brief y to indicate that the TPS has been recognized by the SJB.

NOTE: Do not wait more than two minutes between training each sensor. 7. Within two minutes af er the horn sounds, place the activation tool on the right-front tire wall opposite (180 degrees) from the valve stem (see Figure 1). Repeat the same procedure for the right-rear and lef -rear tires (see Figure 2). 8. When the tire training procedure is complete, the message center (if equipped) will display “TIRE TR INING MODE COMPLETE.” For vehicles not equipped with a message center, successful completion of the training procedure will be verif ed by turning the ignition switch to the OFF position without the horn sounding. If the horn sounds when the ignition is turned of , the training procedure was not successful.

2. Place the activation tool on the left-front tire wall 180 degrees from the valve stem. NOTE: A green light will f ash and a beep will sound on the activation tool for each successful TPMS sensor response. 3. Press the test but on on the activation tool to activate the TPMS sensor. For best results, activate each sensor twice. NOTE: If the tire pressure warning light is still illuminated af er adjusting tire pressures and activating sensors, there is a malfunction in the TPMS. See appropriate manufacturer service information. 4. Repeat steps 1-3 for each tire.

Demounting/mounting procedures

CAUTION: T e tire should be demounted from the wheel using the tire changer manufacturer’s instructions. Use the following information to avoid damage during the service procedures.

CAUTION: T e tire and wheel must always be correctly matched. It is very important to determine the size of each component before any assembly operations commence. Failure to adhere to these instructions can result in an explosive separation and cause serious bodily injury or death.

Use only wheels and wheel nuts that have been designed for current model year Fords. TPSs are not designed to be used with af ermarket wheels. Af ermarket wheels or wheel nuts may not f t or function correctly, and can cause personal injury or damage to the vehicle. A wheel and tire assembly equipped with TPS will have the following verbiage stamped or cast on the wheel: “Sensor May Be Inside.”

Retighten the wheel nuts at 500 miles af er any wheel change or any time the wheel nuts are loosened. Failure to retighten wheel nuts at the mileage specif ed can allow wheels to come of while the vehicle is in motion, possibly causing loss of vehicle control and collision.

NOTE: T e use of run-f at tires (tires with steel body cord plies in the tire sidewall) when the vehicle is not originally equipped is not recommended, as it may cause the TPMS to malfunction.

If possible, use Digital Tire Gauge (P/N 204-354) any time tire pressures are measured to be sure that accurate values are obtained. Ford Motor Co. recommends the use of a digital or dialtype tire pressure gauge rather than a stick-type gauge for increased accuracy.

Removal 1. Remove the wheel and tire assembly. CAUTION: When using a paddle-type bead separator, ensure that the valve stem is positioned at 6 o’clock to prevent damage to the TPS.

CAUTION: Do not allow the tire beads to move beyond the wheel mid-plane when breaking the beads, or damage to the TPS may occur.

NOTE: Some machines may have a nylon roller bead separator at the 12 o’clock position instead of the paddle-type bead separator at the 3 o’clock position. 2. Position the wheel and tire assembly on a suitable tire machine with the valve stem at the 6 o’clock or 12 o’clock position, and separate both beads of the tire from the wheel. NOTE: Index mark the valve stem and wheel weight positions. 3. Place the wheel and tire assembly on the turntable of a tire machine with the valve stem between the 5 and 6 o’clock positions, and the machine arm at the 12 o’clock position. Demount the tire. CAUTION: Do not use a large screwdriver or apply excessive force in the following step, or damage to components will occur. 4. Using a pocket screwdriver, remove the sensor locking clip (see Figures 3 and 4 on page 80). Detach the sensor from the cradle and remove sensor (see Figure 5).

Installation 1. Position the sensor into the cradle by inserting the hinge end of the sensor into the hook end of the cradle, and pushing the opposite end of the sensor down onto the cradle. Ensure the sensor is fully seated into the cradle (a “click” noise will be heard). NOTE: T e locking clip can only be fully seated when installed in the correct orientation. If the locking clip cannot be fully inserted, the sensor may not be fully seated on the cradle or the locking clip may be inserted backward. 2. Insert a new locking clip into the TPS. 3. Place the wheel on the turntable of the tire machine so that the TPS is at the 6 o’clock position, and the valve stem and machine arm are at the 12 o’clock position. CAUTION: Use only a soap and water solution to lubricate the tire. Use of anything other than soap and water may result in damage to the TPS. 4. Lubricate and mount the tire onto

Quik-Link: 800-687-1557 ext. 19133

Figure 3: Exploded view of the tire pressure sensor.

the wheel starting 90 degrees from the sensor, moving away from the sensor. CAUTION: Do not inf ate the tire higher than the maximum pressure stamped on the tire sidewall. 5. Inf ate the tire to the pressure specif ed on the vehicle certif cation label (located on driver door or door pillar). 6. Install the wheel and tire assembly. 7. Train the TPSs. See Training under Reset procedures.

Figure 4: Removing the tire pressure sensor locking clip.

TPS strap and cradle

NOTE: While the TPS is available separately, the cradle and strap are only available as a kit. T ough there are several dif erent strap kits available based on wheel diameter, all kits share the same base part number.

Removal 1. Remove the TPS. WARNING: T e strap is under tension. Always use safety goggles or a face shield and gloves when removing the band/strap. Failure to follow these instructions may result in personal injury. 2. To remove a dealer-installed strap, go to the next step. To remove a factoryinstalled strap, perform the following.

• Locate the strap buckle. Secure strap to wheel using duct tape on both sides of the buckle, about 0.98-inch from the buckle. • Using a large screwdriver and a twisting motion, unbuckle the strap. • Discard the strap.

3. To remove a dealer-installed strap, turn the worm gear screw until the strap is fully released from the worm gear. Discard the strap. NOTE: To aid assembly, mark the location of the cradle prior to disassembly. 4. Remove the cradle by inserting a screwdriver under the cradle and prying up.

Installation 1. Position the sensor into the new cradle by inserting the hinge end of the sensor into the hook end of the cradle, and pushing the opposite end of the sensor down onto the cradle. Ensure the sensor is fully seated into the cradle (a “click” noise will be heard).

CAUTION: Metal scrapers can damage the wheel. When removing the cradle adhesive strip residue, use only plastic or non-metallic scrapers. NOTE: T e sensor and cradle must be positioned

Figure 5: Removing the tire pressure sensor.

with the hinge side of the sensor on the right side when viewed from the curb side (beauty side) of the wheel. The sensor has raised markings indicating how to position it. 2. Clean the area where the sensor and cradle are to be installed. Remove the adhesive tape liner from the cradle, and position the sensor and cradle into the wheel drop well 180 degrees from the valve stem. 3. Install the tapered end of the strap through the opening of the cradle on the hinge side of the sensor. T is will position the worm gear on the locking clip side of the sensor. CAUTION: Steel wheels have a “high spot” along their circumference. Ensure the strap is positioned in the lowest spot possible for correct sensor and cradle retention. 4. While keeping the strap parallel with the wheel f ange, position the worm gear one-half to one inch away from the sensor and tighten to 27 in.-lbs. (3 N.m). 5. Place the wheel on the turntable of a tire machine so that the tire pressure sensor is at the 6 o’clock position, and the valve stem and machine arm are at the 12 o’clock position. 6. Lubricate and mount the tire onto the wheel starting 90 degrees from the sensor, moving away from the sensor. 7. Inf ate the tire to the pressure specif ed on the vehicle certif cation label (located on driver door or door pillar). 8. Install the wheel and tire assembly. 9. Train the sensors. See TPS training. ■

Information for this column comes f om Mitchell 1’s ”Tire Pressure Monitoring Systems Guide” for domestic and import vehicles through 2012. Headquartered in Poway, Calif., Mitchell 1 has provided quality repair information solutions to the automotive industry for more than 80 years. For more information, visit www.mitchell1.com.

The Nokian WR G3

The WR G3 is an all-season highperformance tire with a mountain snowf ake severe service emblem on its sidewall. It has different compounding than its European counterparts, resulting in better mileage and handling for the North American market. The f rst wave of asymmetric sizes for the WR G3 will include 25 XL sizes ranging from 205/65R16 99 H through 245/40R18 97V. There also will be two run-f at sizes: 205/55R16 91H and 205/45R17 91H. The six sizes for the directional WR G3 range from 175/65R14 82T to 195/55R15 89V XL. NOKIAN TYRES PLC Quik-Link: (800) 687-1557, ext. 19170 www.mtdquiklink.com/19170

XtraSeal TPMS Tools Assortment

The XtraSeal TPMS Tools Assortment (P/N 17-168) from 31 Inc. is a compact, 14-piece TPMS tool kit to handle tire pressure monitoring system work. The TPMS Tools Assortment comes with all the precision torque tools needed, as well as a 1/4-inch adjustable torque wrench and sockets. The kit also contains the “grommet slide” for fast and easy grommet removal and installation. The tools come in a high-quality blow-molded storage case. 31 INC. Quik-Link: (800) 687-1557, ext. 19171 www.mtdquiklink.com/19171

Atturo adds A/T to Trail Blade family

The new Trail Blade A/T from Atturo Tire Corp. is the company’s second member of the Trail Blade family, joining the M/T. The Trail Blade A/T is available in nine LT sizes ranging from LT235/75R15 to LT265/70R17. The A/T pattern continues the evolvement of the Atturo brand in the growing SUV/LT market. Atturo tires are distributed via factory-direct containers, as well as from Atturo’s growing group of domestic and worldwide distributors. The Trail Blade A/T is covered by a three-year warranty. ATTURO TIRE CORP. Quik-Link: (800) 687-1557, ext. 19172 www.mtdquiklink.com/19172

Updates for Bartec TPMS tool

Bartec USA LLC has released a software update that enables its Tech400SD TPMS repair tool to program aftermarket sensors. Bartec says software update R50 adds the ability to program popular aftermarket sensor solutions from the Alligator, Orange and Schrader brands. The R50 software update contains additional OBD relearn coverage for Ford and General Motors vehicles, and introduces TPMS OBD relearns for Volvo cars. BARTEC USA LLC Quik-Link: (800) 687-1557, ext. 19173 www.mtdquiklink.com/19173

Centric rotor upgrades for Acura TSX

StopTech, the performance and racing brand from Centric Parts, offers StopTech two-piece AeroRotor replacement kits for the Honda Acura TSX. The kits also f t certain TL, CL and MDX models as well as certain Honda Accord, Pilot and Odyssey models. The new direct-replacement 300 x 28 mm rotors are available for front axles and include preassembled StopTech two-piece, f oating, directional AeroRotors with iron friction rings and aluminum AeroHats. CENTRIC PARTS Quik-Link: (800) 687-1557, ext. 19174 www.mtdquiklink.com/19174

Cooper CS3 mid-range touring tire

The CS3 Touring tire from Cooper Tire & Rubber Co. was designed with the company’s StabilEdge technology to add to the tire’s dry handling stability, steering response and overall ride comfort. The tire has a newly developed f ve-rib tread pattern for all-season performance. The CS3 Touring replaces the Lifeliner GLS in the mid-range product segment. It is available in T- V- and H-rated sizes designed for modern sedans and crossover vehicles. COOPER TIRE & RUBBER CO. Quik-Link: (800) 687-1557, ext. 19175 www.mtdquiklink.com/19175

Falken launches FP8000 Ohtsu tire

The Ohtsu FP8000 tire from Falken Tire Corp. is a UHP summer performance tire featuring an aggressive directional tread design. Sizes range from 19- to 22-inch, W-rated. The company also introduced the ST5000 (not pictured), an M+S all season SUV and light truck performance tire produced in 15- to 26-inch sizes covering H, S, T and Q speed ratings. FALKEN TIRE CORP. Quik-Link: (800) 687-1557, ext. 19176 www.mtdquiklink.com/19176

Hercules Terra Trac AT II SUV/LT tire

The Terra Trac AT II from Hercules Tire & Rubber Co. is a premium, all-terrain tire that replaces the Terra Trac A/T and is available in SUV and LT sizes. The Terra Trac AT II is available in 46 SKUs comprised of SUV and LT sizes, bringing Hercules Tire’s coverage of the premium, all-terrain replacement segment to nearly 90%, according to the company. All sizes offer a 60,000 mile/100,000 km limited mileage warranty, industry-leading road hazard protection and Hercules’ 30-day “Trust Our Ride” test drive. HERCULES TIRE & RUBBER CO. Quik-Link: (800) 687-1557, ext. 19177 www.mtdquiklink.com/19177

KYB ride control catalog

KYB Americas Corp. has released its 2013-14 ride control components catalog, which features more than 3,100 items over 380 pages. The company says all new part numbers are designed and meticulously tested to the highest KYB performance standards. The company says a complete, accurate, easy-to-use catalog is important to earning sales. In addition to the paper catalog, KYB offers an interactive online catalog with application, product photos, VIN and part number lookups. KYB AMERICAS CORP. Quik-Link: (800) 687-1557, ext. 19178 www.mtdquiklink.com/19178

SMP clone-able TPMS sensors

Standard Motor Products Inc. has added eight new cloneable sensors to its TPMS sensor line. The new Standard and Intermotor part numbers, which match the original for f t, form and function, cover an additional six million VIO for Buick, Chevrolet, Dodge Ram, Hyundai, Jeep, Kia, Saturn, Toyota, Toyota truck and Volvo through the 2013 model year. STANDARD MOTOR PRODUCTS INC. Quik-Link: (800) 687-1557, ext. 19179 www.mtdquiklink.com/19179

Tire Carousel does heavy lifting

The motorized Tire Carousel from Stanley Vidmar provides quick, convenient storage and retrieval for tires up to 36 inches in diameter. The Tire Carousel does all the heavy lifting, allowing a single operator to rotate carrier frames, locate desired tire sets, stop at proper positions and safely remove tires at f oor level. The Tire Carousel maximizes storage eff ciency by fully utilizing vertical storage space and is available in a range of preconf gured or custom sizes. STANLEY VIDMAR Quik-Link: (800) 687-1557, ext. 19180 www.mtdquiklink.com/19180

Vision Wheel Torque for muscle cars

Vision Wheel Inc. has introduced the Torque model designed to enhance the visual impact of newer-model muscle cars as well as the classics. Torque features a dynamic gun metal painted f nish with a machined lip. It is available in staggered 15-, 18- and 20-inch sizes. The wheel is the newest addition to the company’s popular Legend Series. An optional spinner is also available. VISION WHEEL INC. Quik-Link: (800) 687-1557, ext. 19181 www.mtdquiklink.com/19181

Michelin Pilot Sport A/S 3 UHP tire

Michelin North America Inc. has introduced its Michelin Pilot Sport A/S 3 ultra-high performance tire designed to offer high levels of both dry and wet grip for enhanced conf dence and control in a variety of weather conditions. The Michelin Pilot Sport A/S 3 tire is now available in a wide range of replacement tire f tments, from a Fiat 500 to a Mercedes-Benz SL or from 175/65R15 to 285/35R20. It comes with a 45,000-mile warranty. MICHELIN NORTH AMERICA INC. Quik-Link: (800) 687-1557, ext. 19182 www.mtdquiklink.com/19182

To request free product information by phone, call 800-687-1557, enter the extension number listed below, and you will be immediately transferred to the company you want to talk with — it takes only seconds.

To request information online, log on to www. mtdquiklink.com/ plus the corresponding Quik-Link number. You’re just a click away from receiving free information on the new products that interest you.

Advertiser

AAPEX Show American Omni Trading Company American Tire Distributors ASA Automotive Systems LLC Atturo Tire Corporation Bartec USA BKT Tires USA Inc. Cooper Tire Cooper Tire Falken Tire Falken Tire Gaither Tool Company Inc. General Tire GITI Tire (USA) Ltd. Goodyear Tire & Rubber Company Hankook Tires Hennessy Industries Inc. Hercules Tires Kenda USA Kumho Tire USA Marangoni Tread North America Inc. Maxxis International—USA Mastercraft Tires Nexen Tire America Inc. Nexen Tire America Inc. Nucap Industries Inc. Perfect Equipment Inc. Pirelli Tire North America Plombco Inc. Raybestos Brake & Chassis Reliable Int’l Exhibition Services Co. Ltd. Robert Bosch LLC Schrader International SEMA Show SEMA Show Sentaida International Inc. Superior Tire & Rubber Corporation Tire Centers LLC Tire Centers LLC Yokohama Tire Corporation Page

81 50 59 52 40 80 11 29-30 47-48 71 73 65 15-20 44-45 85 9 41 69 IBC 5 63 25 77 IFC 75 61 13 33 67 43 24 23 79 35-38 87 7 60 53-56 OBC 83

800-687-1557 + Toll Free Extension

19135 19119 19122 19120 19114 19134 19105 19111 19118 19129 19130 19126 19107 19117 19137 19104 19115 19128 19139 19102 19125 19110 19132 19101 19131 19124 19106 19112 19127 19116 19109 19108 19133 19113 19138 19103 19123 19121 19140 19136 Web site

www.mtdquiklink.com/19135 www.mtdquiklink.com/19119 www.mtdquiklink.com/19122 www.mtdquiklink.com/19120 www.mtdquiklink.com/19114 www.mtdquiklink.com/19134 www.mtdquiklink.com/19105 www.mtdquiklink.com/19111 www.mtdquiklink.com/19118 www.mtdquiklink.com/19129 www.mtdquiklink.com/19130 www.mtdquiklink.com/19126 www.mtdquiklink.com/19107 www.mtdquiklink.com/19117 www.mtdquiklink.com/19137 www.mtdquiklink.com/19104 www.mtdquiklink.com/19115 www.mtdquiklink.com/19128 www.mtdquiklink.com/19139 www.mtdquiklink.com/19102 www.mtdquiklink.com/19125 www.mtdquiklink.com/19110 www.mtdquiklink.com/19132 www.mtdquiklink.com/19101 www.mtdquiklink.com/19131 www.mtdquiklink.com/19124 www.mtdquiklink.com/19106 www.mtdquiklink.com/19112 www.mtdquiklink.com/19127 www.mtdquiklink.com/19116 www.mtdquiklink.com/19109 www.mtdquiklink.com/19108 www.mtdquiklink.com/19133 www.mtdquiklink.com/19113 www.mtdquiklink.com/19138 www.mtdquiklink.com/19103 www.mtdquiklink.com/19123 www.mtdquiklink.com/19121 www.mtdquiklink.com/19140 www.mtdquiklink.com/19136

Reader asks, ‘Will customers be smiling after their next tire purchase?’

Dear Editor:

Automobile manufacturers continue to add tire sizes and specialized options in their requirements for original equipment (OE) f tments. T is has also required the tire manufacturing industry to build more sizes, speed ratings and f tments to stay up with the ever-changing landscape of SKU assortment. For those of us who have been in the tire industry for a long time, we would love to go back to the days of 20 to 30 SKUs that would f t every car or truck on American roads. Unfortunately, the good old days are gone forever. T e tire industry has def nitely changed!

T e latest trends are “green” technology and additions of high performance (HP) and ultra-high performance (UHP) tires from every tire manufacturer. With the latest trends, is there a slowly building f re storm of reaction by the end user, the customer, who buys these tires at the retail outlet?

As tire sellers, we tend to salivate at the thought of UHP tires that last 20,000 miles. Who in their right mind wants tires that last 100,000 miles? T e faster the tires wear out, the more tires we get to sell.

We know that the industry has seen its challenges in the last few years. Raw material cost increases, increased regulation, tarif s, and across-the-board price increases have pushed tire prices to a level that is unaf ordable for many in the depressed economy of the last four to f ve years. As more and more HP and UHP tires are built, there will be some economies of scale that should bring the prices down, but will the price reductions be enough to get the average consumer’s at ention?

Here is the problem: Customers are searching for and purchasing used tires at a level we haven’t seen in 40 years. Nationwide, states are considering all kinds of legislation to regulate or ban used tire sales. Shouldn’t that tell us how price sensitive customers are in today’s environment?

As tires have increased in price, and f tments to match the new vehicles are being changed to more high performance tires, the prices of tires have escalated, while the life of the tires has been reduced. How will the end users react? You may have already talked to the guy who purchased a really sporty, high performance Chevrolet Camaro and now has to replace his tires. Out of pocket, he is going to spend $800 to $1,200 for a set of four tires. T is is the guy who can barely af ord the payment and insurance on his high prof le automobile. When he prices tires, they will probably be wishing they were driving a Ford Fiesta.

T e tire industry may be set ing itself up for a groundswell of negative consumer reaction. T e other possibility for the major tire manufacturers is that they will inadvertently drive more consumers to imports and “cheap” tires. We are seeing a flood of imported tires, especially since the expiration of the tarif . Is this the first sign that the consumer will dictate the future of the tire industry by voting with their pocketbook?

We, in the tire industry, continue to talk about the “good-bet er-best” product screen. In the past we have f lled our inventory to match this model. For the short term it appears that our product screen may become, “good enough-best.” For people who have the money, price is not necessarily a factor. For people who are f nancially struggling like never before, used tires or “good enough” tires seem to be their only option.

Certainly the economy is driving much of this price sensitivity. However, we should all be aware of the response of the customer to the increased ticket price of the of ering of HP and UHP product lines.

Tires are designed to roll safely and ef ciently down the road, while put ing a smile on the driver’s face. Performance and handling are great, if you can af ord it. T at smile on the customer’s face can soon disappear when they discover what it costs to replace their tires. Jerry Wright, President Burggraf Tire Corp. Quapaw, Okla.

‘Remanufacturing’ is a much bet er term

Dear Editor:

Your June 2013 article on aircraf tires (“Up, up and away! Aircraf tires are unique, so is their distribution”) did not suff ciently cover the technological and economical importance of aircraf tire retreading.

In March 1984, I called it “tire remanufacturing,” a much

bet er term, when I presented a paper on the subject at the Tire Society in Akron, Ohio, titled “Manufacturing and Remanufacturing Radial Tires.”

In today’s dif cult economic times for the mainstream American as well as for trucking f rms (and airlines), tire remanufacturing should be brought to the forefront and vigorously applied, in order to provide af ordability to this large segment of tire users. Jacques Bajer, Founder Tire Systems Engineering Inc. Grosse Pointe, Mich.

Bajer is a f equent contributor to MTD. For more than 55 years, Bajer, a mechanical engineer by trade, has championed the cause of tire structural integrity. His work with Ford Motor Co., beginning in 1955, led to the creation of a tire uniformity grading machine. He is possibly best known for radializing the domestic automotive industry. Bajer opened his own consulting company in 1970s. You can f nd his articles online at www.moderntiredealer.com.-Ed. Jacques Bajer

Question of the month:

We asked our National Advisory Council (NAC) members:

Apollo Tyres recently made a bid to acquire Cooper Tire & Rubber Co. What is your opinion on the proposed purchase? Will this af ect the way you do business?

Here are some of their responses: 1. I hope Apollo Tyres understands the American tire market and sees the current trends of downward momentum. Cooper has some great products but will experience challenging sales in the next six months. With the heavy debt for the acquisition, it may be dif cult to meet f nancial obligations due to slow sales. A year from now we might know if this was a brilliant move or a disaster. 2. We do not expect a change until sometime next year. T e changes that we fear the most are those having to do with business culture. Will the new leadership embrace and understand the relationships and the key market drivers? 3. If Apollo Tyres does acquire Cooper Tire, I feel Cooper will bring Apollo tires to the U.S. and produce fewer private brand tires. 4. I don’t think it will have any real ef ect, except for possibly the Roadmaster plant in China. T e Chinese consider the Indians their major competitors, and that could af ect production in the plant. T ey already have had several work stoppages, as I understand! 5. Too early to tell. T e impact is at least two years away. T e fact that they are not in the same markets internationally lessens the chance of any short-term impact. 6. T is is a wrong deal. Cooper Tire has very good products and market position. T e management needs to run the operations bet er. Cooper should have OE presence in the U.S. Apollo does not have the money to buy Cooper, borrowing $2.1 billion of the $2.5 billion price. Apollo stock in India is down 40%. T ere are no synergies between the two companies. T e deal needs to be rejected. 7. I believe Cooper had some real traction going to market as an American company prior to this acquisition. T ere’s still a demand/market for American products and Cooper could satisfy this niche. For the immediate future, though, I would not anticipate any real changes with Cooper Tire. 8. I think they are crazy to make the of er. 9. I am bothered by the fact that another American company has sold out to foreign interests, f rst and foremost. I am not surprised, however, since the company has hired many people new to the industry who don’t seem to have the same values of those who built the company and were the reason why it was able to grow and prosper for so many successful years. When you have nothing but bean counters and yes men, sooner or later the lack of core values takes over and a company becomes lax in doing what’s best for its customers long term. T ey sold out the long-term factor! 10. We are no longer a Cooper dealer, but it’s a shame that American tire companies, except for Goodyear, are no longer owned and run by Americans. ■ More NAC comments on the industry:

It would be great if all of us would get a lit le smarter when it comes to our business plans. Instead of f nding ways to give things away, we need to f nd ways to charge for the services and products we provide our customers. We hide from the fact that our margins continue to shrink while our overhead continues to rise. We at ack the problem in every meeting with supervisors and managers, but in our society, thankfully, the customer decides on the playing f eld. Our problems stem from the players who continue to think that giving things away will somehow generate a prof t, and it just doesn’t work that way. Charley Gowland, Manager/Owner Chabill’s Tire Service LLC Morgan City, La.

Manufacturers have caused chaos. T e tire manufacturers are producing so many SKUs that they cannot have a good f ll rate. Who is steering the ship? Jef Cohen, Co-owner Traction Wholesale Center Bensalem, Pa.

Join Modern Tire Dealer’s National Advisory Council Each month, Modern Tire Dealer is guided and inf uenced by a select group of readers — members of our National Advisory Council. T ese members’ opinions are the heart of the monthly Your Marketplace column, compiled by industry analysts Nick Mitchell and John Healy. If you’d like to join this prestigious group, please let us know. We’d love to hear from you. Contact Editor Bob Ulrich at Bob.Ulrich@bobit.com or call (330) 899-2200, ext. 11.