4 minute read

Waste-to-protein for greener future

Xiaoyan Huang, Jianhua Song, iCell Sustainable Nutrition Co. Ltd.

With the development of the feed industry and the continuous increase in feed production, there is a rising gap between the supply and demand of feed proteins. In 2018, the UN Food and Agriculture Organization estimated that the aquaculture output will reach 201 million tons by 2030 and the protein required for fish farming will increase by 10% annually, while the production of fishmeal, the most important protein ingredient, will remain at 5 million tons per year (International Fishmeal and Fish Oil Association).

Microbial protein

Microbial protein is becoming a more and more popular option for its application in aquaculture and agricultural production as a potential sustainable feed ingredient used in aquaculture, livestock and poultry farming.

The main sources of microbial protein are bacteria, yeast and fungi, as well as microalgae. Norwegian University of Life Sciences (NMBU) studied microbial protein production with Methylotrophs, Methylococcus and a small number of Allobacteria utilizing natural gas as energy and carbon source for the fermentation.

The Feed Institute of Chinese Academy of Agricultural Sciences recently announced a major breakthrough in the field of one-carbon biosynthesis. It becomes the world's first to achieve synthesis from carbon monoxide to protein and has developed a 10,000-ton industrial capacity where the industrial exhaust gas, mainly comprising of carbon monoxide and carbon dioxide, and the ammonia water can be used as raw materials to produce ethanol Clostridium protein.

Another new technology solution is via the utilization of carbon and nitrogen-rich process water from food manufacturers. Through a fermentation technology, microbial strains produce high value-added functional feed protein ingredients and through technological processes such as autolysis, hydrolysis, microwave, among others, they can increase nutritious value and be used as a feed ingredient for aquaculture, livestock and poultry.

This new technology utilizes the low valueadded organic process water generated by food manufacturers, such as breweries, beverage plants, sugar plants, LB-RAS systems, etc. (Fig. 1, 2) to produce

Figure 1. Food plant process flow chart.

Figure 2. LB-RAS flow process chart.

special microbial strains with patented technologies for “digestion of organic matters in the process water” via aerobic fermentation process. The process grows a large amount of high-quality microbial proteins for further yielding premium proteins (iCell SCP) through a series of production processes, thus providing a source of premium feed protein ingredients for animal feed.

The conversion of microbial protein into animal protein creates an effective circulation between mass and energy in the whole food industry to achieve zero pollution and zero emissions. It also provides economic, environmental and social benefits.

iCell SCP trial results

iCell SCP is rich in nutrients required for animal growth, such as protein, carbohydrates, fat, nucleotides, minerals and vitamins. Since its initial research and development more than ten years ago, iCell SCP experimental studies showed it can be used as a protein ingredient in the farming of livestock, poultry and aquaculture.

In the past two years, we have conducted field trials to test iCell SCP effect on the growth performance of aquaculture species, such as sturgeon, snakehead, tilapia and shrimp. iCell SCP groups showed an increased weight gain rate, specific growth rate (SGR) and survival rate under test conditions of either direct inclusion of iCell SCP or inclusion for partial replacement of fishmeal.

Figure 3. Effect of different additions of iCell SCP on growth performance of juvenile sturgeon (initial weight about 19.15 g).

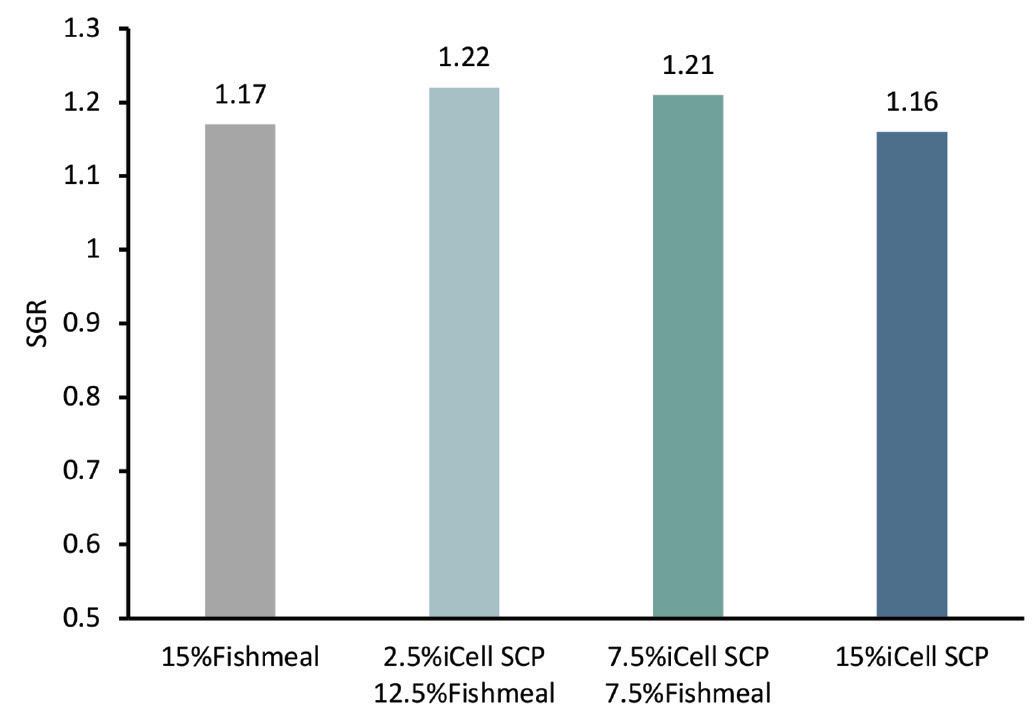

Figure 4. Effect of replacing fishmeal with iCell SCP on specific growth rate of Litopenaeus vannamei.

Figure 5. Effect of iCell SCP on the growth performance of tilapia.

A trial to assess the effect of dietary supplementation with different inclusion levels of iCell SCP on the growth performance of juvenile sturgeon showed that, compared with the control group, the 2.5% iCell SCP group had an increase in 60-day end weight and SGR by approx. 3.2% and 2.7%, respectively; the 5% iCell SCP group had an increase in 60-day end weight and SGR by approx. 3.4% and 3.2%, respectively (Fig. 3).

Fishmeal replacement trials were carried out on Litopenaeus vannamei. With an initial average body weight of 9-10 g and after 8 weeks of feeding, results showed that iCell SCP improved the growth performance of shrimp when added for replacement of about 25% and 50% fishmeal, while there was no significant difference in growth performance when iCell SCP was added for full replacement of fishmeal (Fig. 4).

A recent trial in tilapia conducted at Shanghai Ocean University assessed iCell SCP’s effect on digestibility (quantitative feeding with the same amount of protein). Results showed an equivalent growth performance of SCP to that of fishmeal and it was superior to the control, rapeseed meal and soybean meal groups (Fig. 5). The growth data showed that iCell SCP had better digestibility on tilapia and was superior to the plant protein group and non-SCP treatment groups, delivering a similar result to that of the fishmeal group.

Conclusions

The above test indicates that iCell SCP has a positive effect on improving the growth performance of aquaculture species and can be used as an alternative protein ingredient while the action mechanism is still under further study. iCell SCP not only fills the global supply gap of highquality proteins but also contributes to sustainable development recycling nutrients and water with multiple merits in carbon emission reduction and environmental improvement and protection.

More information: Xiaoyan Huang

Director of Products and Nutrition iCell Sustainable Nutrition Co. Ltd. E: info@icellsustainable.com

Jianhua Song

VP iCell Sustainable Nutrition Co. Ltd. E: songjianhua@icellsustainable.com