34 minute read

Henderson Rd

the awards...

Nominations for the APEAIndustry Awards have kicked off to a good start. Entry forms and full details on the judging criteria can be obtained from Jane Mardell at admin@apea.org.uk. The closing date for nominations is 12th September. Categories include Innovation sponsored by Toureen Mangan, Customer Care sponsored by Torex, Health, Safety & Environment sponsored by Shell, Personal Contribution to Industry sponsored by Elaflex, Small Enterprises sponsored by the APEA, and Quality sponsored by Coteba.

Advertisement

Coteba is a market leader in the provision of project management services in the field of petrol retail in the UK and across Europe, and are delighted to be able to support the APEAin this area. “Why quality?”, asks Mark Goldsworthy of Coteba, “Quality is the cornerstone of all we do, not only in the products we deliver for our clients but in the people, processes and supply chain we use to deliver such products… We’re hoping that entrants from not only suppliers or manufacturers apply, but also that providers of services or processes be encouraged to enter too.”

dinner and entertainment...

The evening’s welcome drinks, sponsored by Eurotank Environmental, will feature the sensational electric violinist, Sarah Tuke. Having recently toured with Take That, Sarah is the hottest act of her kind in the UK and will lend the APEAevent a certain amount of glamour!

Amulti-award winning line-up of comedians with an impressive clutch of TV and film credits to their names will be the entertainment at The Awards Dinner, which is sponsored by PetroTechnik. A Comedy Club-style evening featuring a consummate stand-up with acid wit, an Aussie with multiple personalities, an ex-championship boxer and the son of an East End villain should provide a hugely enjoyable and memorable evening.

If you haven’t booked your place at the dinner, contact annabel@downstream-events.com. Individual places are available at £80 per person + VAT– or tables of 10 or 12.

Don’t forget to book your accommodation!

Over 600 rooms of varying budget ranges have been reserved for APEAdelegates within a 10-minute drive of the conference centre. Rooms are being snapped up fast so early booking is advisable. To reserve your rooms, contact Event Links on 01952 281 561 and quote APEA.

Energy Institute • supporter of APEA2008

Ataste of what’s on show...

Fuel storage and pollution control equipment from PFS

PFS Ltd. is proud to be the leading company that specialises in the supply of pipe-work, valves, and leak detection systems to the fuel storage industry, which are designed to protect the environment from the accidental spillage or leaks of hydrocarbons.

Visitors to their stand will be able to view the COMpact modular fill and vent system, and the Risbridger modular tank top valve system, designed to raise installation standards and reduce the number of threaded joints used on fuel installations.

PFS will also be showing the Easyfit range of vacuum-tight, double-sided tank sump entry seals, vacuum sump testing and continuous electrical ducting.

Tokheim is the market leader in the design, manufacture and servicing of petroleum retailing solutions.

With the skills and capability to drive your business forward, Tokheim is dedicated to working with you and committed to building strong business partnerships.

Tokheim not only supply highquality petroleum retailing solutions with our extensive range of dispensers, accompanied by our unbeaten payment solutions, but also recognise the need for delivering proficient forecourt maintenance. Our highly skilled network of remote engineers is on hand to maintain and repair all manner of faults found on today’s modern forecourt.

At Tokheim we are dedicated to delivering improved quality of service year on year. Whether you are building a service station from the ground up or renovating and upgrading an existing forecourt, Tokheim service specialists are onhand to work in partnership with you to deliver the best all round solution.

FAFNIR shows sensor technology for petrol stations

At this year’s APEA, FAFNIR will once again present its highly innovative sensor technology for environmental protection at petrol stations. FAFNIR plans to display VAPORIX, the automatic monitoring system for active vapour recovery stage II that can be applied in all known active vapour recovery systems and dispensers; VISY-X, the highly accurate tank level gauge that is also available as a wireless version; and SEPARIX, the alarm system for separators that is suitable for all types of light liquids, especially for petrol and oil components.

FAFNIR GmbH in Hamburg, has been developing and producing filling sensors, over-fill prevention systems, vapour recovery monitoring systems, and continuous level measurement devices for the oil industry for more than 40 years. The close and trusting co-operation with customers is an important factor for putting innovative ideas into practice and thereby ensuring the functionality of the products.

David Plumb & Co is a leading specialist in forecourt demolition, decommissioning, de-contamination and fuel storage tank cleaning. Its enviable safety and environmental record is second to none.

The company is fully equipped for, and experienced in, all aspects of decommissioning fuel sites, including full building demolition, de-gassing of tanks, environmental surveying for soil contamination, excavation of tanks and pipework, decontamination of the ground and preparing the site for re-development. Its expert operatives can safely de-gas tanks to make them safe to work on, open them to remove sludge, and thoroughly clean the tanks.

Old above ground oil storage tanks can be cleanly cut up in situ and the pieces removed, without disrupting the building’s normal operation.

As much metal as possible is recycled, and any contamination that leaves the site only goes to a licensed disposal site.

All work is carried out to the highest safety and environmental standards by highly trained personnel.

CSD Sealing Systems have specialised in fire safe, gas and watertight sealing systems in the UK for over 15 years.

With close links to CSD International in the Netherlands, a company with over 35 years’ experience of development and production in this field, our clients can be assured of first class products and first class service, whatever their industry.

CSD are involved within many industries including the Petrochemical, Oil & Gas, Naval, General Construction and Utility sectors and have been involved with many high profile projects across the UK.

At CSD, we realise the importance of keeping to budgets and time scales, and that is why we have developed systems which require few components and materials, helping to lower costs of both inventory and installation.

CSD products which include the RISE Duct Seal System have been extensively tested by all major worldwide classification societies and independent institutes, and are proven to ensure the highest standards of quality, safety, reliability and durability.

The RISE duct seal can provide a water and gastight seal for all cable and pipe duct entries up to a pressure of 4 bar and with the

what’s on show...

inclusion of our fire resistant sleeves will provide up to 4 hours of fire protection. The system ensures compliance with ATEX regulations and will prevent the migration of dangerous gases in hazardous areas. The system has also been tested and shown to suffer no deterioration in performance after contact or submersion in both diesel and petroleum.

Cookson & Zinn, a PetroTechnik subsidiary, has been designing and fabricating tanks and process vessels for over 45 years.

Over 20,000 tanks have been supplied to 48 countries and trading relationships involving the transfer of design and fabrication technology have been established with companies in Central America and South Africa. Tanks are used in many industries: fuel, chemical, food, pharmaceutical, agricultural, aviation, water and general manufacturing.

By combining CZ tanks with PetroTechnik pipework, CZ can offer the modular PetroFast system. PetroFast is based on preengineered, pre-fabricated modular components incorporating storage tanks, pipework and associated equipment and can include canopies and pump bases. Each system is factory assembled, enabling rapid on-site installation, saving valuable time and money. For above ground storage, cylindrical or rectangular, from 1,000-100,000 litres, CZ offers a specifically tailored bunded unit or, if preferred, a more standard system, still offering cost effective solutions, but perhaps on a shorter lead time.

PetroTechnik’s fuel pipework solutions combine cutting edge technology with world class manufacturing standards consistently delivering excellent results. Efficiency, reliability and cost effectiveness are key benefits of the UPPSystem providing long term leak free performance. Carefully designed products ensure ease of installation requiring little or no ongoing maintenance. UPP is trusted by ‘blue-chip’ corporations including PetroChina, Sinopec, Shell, Exxon, BP, is internationally recognised as the industry standard, and approved for use in more countries than any similar product. The UPPSystem is a leak proof, underground pipework and containment system manufactured from high density polyethylene pipe and is available in a wide size range, in coils or straight lengths. All suction, pressure, vent, fill and vapour recovery lines can be installed using one type of pipe, making installation easier. PetroTechnik also supplies a secondary containment system and a wide range of fittings, terminations, sumps, access chambers, manhole covers, leak detection equipment and specialist installation tools.

The David Mclean Retail

Petroleum Division will be on hand to offer advice on all forecourt construction, shop construction and shop fit out planning and installation works. David Mclean Retail Petroleum Division has been designing and building Petrol filling stations and associated retail premises for over thirty years. David Mclean Ltd has always been committed to providing a reliable open book service to all its clients and has won many awards in the retail and construction industries for the quality of the work.

Hytek will showcase various forecourt tools from hand wipes and absorbent pads to fuel pump tab link belting, Ridgid® wrenches and sheet gasket material. Other products include fuel resistant mastic and water and fuel finding paste. Also on display the industry standard ALPHA commercial diesel pump with integrated fuel management system. Hytek offers customers a comprehensive back up service from sale and demonstration of the product to on-site commissioning.

Hytek is an official distributor of Goodyear forecourt equipment and UPPsecondary contained pipework systems, for transferring diesel, petrol or Adblue® in underground applications.

They are one of the few, if not the only, company that stocks a 20 litre test can with weights & measures certificate available for next day delivery.

With two recent acquisitions, one in fuel installation services and another in fuel distribution, Adler and Allan continue their dynamic growth and capability to run nationwide maintenance and service contracts across a wide sector. They have also focused on achieving high levels of compliance, waste minimization, pollution prevention, environmental reporting and the ability to run a national response network. Adler and Allan have teams at over 20 depots and locations representing divisions in Spill Response, Fuel Installation & Tank Services, Separator (Interceptor) Services, Tank Cleaning, Fuel Distribution, Industrial Cleansing (Water Jetting) and Waste Management. In recognition of the major project works undertaken at Buncefield from Dec 05 onwards and during the Fuel Contamination Crisis in March 07 they have won the APEA Customer Service Award for two years running (2007/08).

35

The 2008 UK Petroleum Retailing The 2008 UK Petroleum Retailing Industry Awards

The APEAis once again offering its members from every discipline a way of demonstrating and celebrating their commitment to Customer Service, Health, Safety and the Environment, Innovation, Quality, Personal Contribution to the Industry and a new award for Small Enterprises. One of the best ways to raise standards is to recognise and reward those organisations, teams and individuals who lead the field and to encourage others to follow their good example. The results of the Awards will be announced and trophies presented to the winners at the APEA 2008 Awards Dinner on 23rd October at the International Conference Centre, Telford.

The Awards Categories

Nominations are sought from individual or corporate members who may enter under their organisation or work group, or as an individual for each of the six categories.

The APEAInnovation Award is presented for the innovation which will have the most significant impact on our industry sector.

Sponsored by Toureen Mangan

The APEAHealth, Safety and Environment Award is presented to the organisation with the best managed Health and Safety or Environmental programme or system

Sponsored by Shell

The APEACustomer Service Award is open to those organisations or individuals who have put the customer first and demonstrated excellence in service provision.

Sponsored by Torex

The APEAQuality Award recognises excellence in the development and management of quality improvement initiatives or systems

Sponsored by Coteba

The APEAPersonal Contribution to the Industry Award will be presented to the individual who has shown the greatest dedication and drive to improve standards, engineering practices or operational procedures

Sponsored by Elaflex

The APEASmall Enterprise Award acknowledges the contributions made by sole traders and businesses with less than 10 employees within the petroleum retailing sector often without the resources and infrastructure of the larger organisations

Sponsored by APEA

Please contact Jane Mardell at admin@apea.org.uk for an entry form, please specify which award you wish to enter so that the appropriate form can be emailed to you, before the deadline of 12th September 2008

History of Petrol Filling Stations Part 7 The Early Petrol Stations

By Brian Baker

“In researching this part of the series, I am aware that further or indeed more factual information may be available that is not in the hands of the author. If this be the case I would welcome this knowledge to be forwarded”

With the introduction of mechanised vehicular transport, petroleum spirit came into greater demand as more and more cars took to the roads and the prospect, albeit mainly confined to the affluent classes, the popularity of the motor car gathered momentum.

On researching this article the earliest petrol filling (gas) station where a vehicle could be filled up from a pump served by a storage tank was actually constructed in the USAin 1907. It was located at 413 South Theresa Avenue in St Louis, Missouri and was operated by Clement Henry Laessing, an entrepreneur who started the World’s first oil retailer known as the Automobile Gasoline Company. A second site followed a year later in Market Street that saw growth all over the USAthat eventually spread to Europe

No photograph remains of the site except a very poor quality newspaper cutting but essentially it was a ship lapped wooden shed housing a hand pump connected by a steel pipe to a buried storage tank inside the structure. I did check for information through the St Louis Mercantile library only to draw a blank, but I did get two newspaper articles informing of Laessing’s death on 1st April 1940.

Laessing started out as an office boy with a company known as the International Oil Works aged 18. He spent 15 years there and then formed a partnership with his employer when he conceived the idea of a “Drive-In” gas station. At the turn of 1940 he suffered a severe heart attack at his home which was a room in the Hotel Claridge in St Louis.

There have been claims that the first ever kerbside site was originally at Bath Road, Aldermaston on the Berkshire/Hampshire county borders in 1920. Operated by the Automobile Association (AA), a single photograph does exist showing a uniformed pump attendant serving a motorist which is claimed to have come into existence in 1920, according to the National Motor Museum in England (Figure 1).

However, on studying old copies of the Bulletin journal a piece recorded in one of the very first issues in 1962 claims that the very first kerbside pump was in fact installed in Shrewsbury in 1912. Unfortunately no photograph exists though the article itself does give compelling evidence as I quote from Volume 1 of the Bulletin in 1962;

“A paragraph in a Sunday paper recently caught my notice. It referred to a claim that the first pump used in Britain to feed petrol straight into tanks of customer’s cars, instead of entailing manhandling 2-gallon metal cans, was installed at the Shrewsbury Garage of Messrs. Legge and Chamier in 1912.

Following it up, it was discovered that the garage referred to was at Betton House Abbey Foregate, now the site of the West Midland Motor Co. The 2,000 gallon underground tank for the pump is deep under the Service Manager’s Office, while the pump site is marked by a slab of concrete at the pavement edge. The pump was supplied by the Bowser Co. of Fort Wayne, Indiana, USAand is now in retirement in the Weights and Measures Dept of the Borough of Shrewsbury.

The pump has a capacity of one gallon per stroke, but it can be set by means of a stop lever to deliver smaller amounts. Apparently, Authority in those days doubted the accuracy of its delivery and someone was continually having to be sent down the manhole, to re-set the valves on a lifeline!

This was confirmed for the article by Mr Fred W. Helm, who went to work for Mr Legge in 1918 and who now has his own Motor R e p a i r business in Wellington. Another exemployee of Messrs. Legge and Chamier is Mr F r a n k Haynes who still works at Betton House. Mr Helm stated that Mr Legge was now retired and living in Wltshire, was one of the great characters of Shrewsbury with his tall build and infectious laugh. His father was one-time Bishop of Lichfield. He was a very go-ahead man of his day, being closely connected with the Wolsey Company. At the Raven Garage he installed the first garage turn-table in

the provinces, while at Betton House, Legge & Co as the firm became known after the break up of the partnership with Chamier, had sold a tyre press for use with customer’s vehicles – such as

Figure 1 AAsite at Bath Road Aldermaston 1920

Figure 2 First kerbside pump Legge & Co, Shrewsbury Figure 3

Figure 4

buses and other vehicles over 10 cwt –the first, we believe in the country” (Figure 2).

This short article seems to consolidate that fact that our first kerbside pump was installed in 1912 but over the next few years as car ownership grew, (Figures 3 & 4) kerbside pumps were being installed all over the country (Figures 5 and 6) and the type of pump that seemed the most common was the “Bowser” Pump, manufactured in the USA

From this time of 1912, we see

Figure 5 Old site in The Shetland Isles

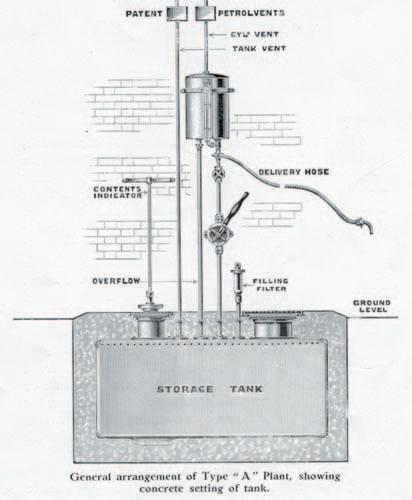

Figure 6 Early kerbside filling station Figure 7 Early diagram of a kerbside installation c191

Figure 8 Early type of roadside pumps

steady growth in pump numbers as existing cycle and hardware shops decided to retail petrol as another commodity as the motor car began to make a more widespread presence.

Typically simple installations comprised of a single riveted steel rectangular tank, a short pipe run with the mechanical Hand Pump mounted on the surface (Figure 7).

The petrol station as we know had arrived and in the coming 50 years an enormous increase in outlet selling petrol (and latterly diesel) were to spring up, not just ion the UK, but across the

Figure 9 Early Kerbside Site in Germany Figure 10 Early kerbside pump Wimbledon next to a butcher's

world as global fixation and the love of driving a motor car became not just popular but essential.

Next time, The Rise of Petrol Stations.

Acknowledgements To Jamie Thompson for figures 2, 7 and 10 from his private collection and to BPArchives for figures 5,6 and 8.

Testing Fireworks by Suffolk Trading Standards

By Carol Garrett, Suffolk Trading Standards

Public safety is a clear priority for both the Health and Safety Commission and Local Authorities (LAs) and so for the past three years, Suffolk Trading Standards department has worked with the Health and Safety Executive and HS Laboratories in Buxton in a coordinated programme of sampling and testing fireworks. In recent years, a number of serious accidents involving fireworks at both organised public events and private events have been investigated and therefore, one of the key objectives of the project has been to provide some reassurance to both the public and the industry that steps are taken to reduce this risk.

Fireworks are imported into the UK in large quantities. In 2007, 12,699,579.08kg of fireworks were imported to the UK of which 10,371,258.01kg (82%) arrived via the Felixstowe port from where they were subsequently redistributed throughout the UK to various storage sites prior to retail outlets.

Organising sampling and testing of fireworks at the point of import both reduces the risk of duplication of sampling by LAs and reduces the risk of failing to intercept and test hazardous or miss-classified fireworks before they are redistributed across the UK retail outlets.

Firework testing is undertaken for 2 main regulatory purposes:

1.Hazard classification using the UN scheme for transport of dangerous goods to determine what class of explosive they conform to

2.Consumer safety against the requirements of BS7114 (BS EN 17035) and the current Fireworks (Safety) Regulations for use by the general public.

The consumer protection testing also offers a valuable and effective approach to assessing the likelihood of noncompliance with the information provided for classification (a major concern to HSE), particularly failures to meet restrictions imposed by the explosives inspectorate in the form of a default classification list (derived from a series of incidents) and which restricts fireworks by size or composition to reduce storage hazards in licensed premises.

The results from the testing programme are immediately APEAtel/fax 0845 603 5507

disseminated to other relevant enforcement agencies for further action and/or for information. This has resulted in fireworks being withdrawn from sale. Monitoring the import of fireworks has also identified shipments on their way for import where appropriate classification has not been obtained and which therefore resulted in the Port authorities refusing to allow the ship to berth.

Results in 2007 were not dissimilar to those for 2006 as the following figures for last year show:

160 import entries were seen 276 samples were selected, including selection boxes 168 fireworks were tested 143 (85%) were correct

While 15% of samples tested failed, it has to be recognised that 85% passed. The project group felt this provided some reassurance to the industry. The project also provided an important assessment of the state of the market.

For further information, contact Carol Garrett at Suffolk Trading Standards. Tel: 01473 264890 or email carol.garrett@tradstan.suffolkcc.gov.uk

Articles

Interview with Ray King of King Tanktechnic

By Brian Baker

Within our downstream industry we have some very colourful and experienced individuals. One such character is Ray King, a Co Director of King Tanktechnic. I was able to track Ray down recently to ask him about his career and company and to get a take on his outlook of where we are going

I have known you some years now, how did you get into the “petroleum” business?

I started to serve my time at the age of 15 as an apprentice fabricator/welder. I was working in a fabricating shop and on site work in the field of oil, petrochemical and heavy industries. My experience was mainly “upstream” until the age of 52. I am now 68 years of age.

So where have your experience been over this long career?

As above but working on overseas contracts as an engineering manager for multinational oil companies + fabrication and heavy engineering construction companies. My duties varied between refineries, power stations etc the last two being a water treatment & bottling plant in the Maldives and being the Principal Fuel Storage Engineer for the Saudi Consolidated Electric Company in Riyadh, Kingdom of Saudi Arabia. I was responsible for system maintenance, fuel procurement and distribution to 28 gas turbine power stations. The fuel was stored in some 66 bulk storage tanks. This involved me in the handling of around 25 million barrels of crude and diesel oil per year. My main fuel movement contractor operated around fifteen hundred 85 tonne road tankers (Alittle bit bigger than the 40 tonners in Europe!)

How did King Tanktechnic start and for that matter. Why?

After about eight years in Saudi, I woke up one morning and asked myself “What am I doing here?” I also wanted to spend some time with my aged mother before she passed on I looked at employment in the UK but decided to adopt the German method of retail tank cleaning and testing and start my own business. I started King Tanktechnic with my son Stephen who had also just returned from working in Saudi. We built our first tank service unit ourselves and to this day it is still the pride of the fleet. Just go through the various services you offer with perhaps a little explanation of each?

King Tanktechnic is the sole UK representative/applicator of the ADISAtank lining system.

This system is the only system to have European Approvals and a proven 30+ years reliability record.

We are equipped to undertake any UK work connected with fuel storage tanks including uplifts, transfers, cleaning, inspection and relining.

If my memory serves me well it is basically a family business, is that right?

Yes myself and Stephen King as co directors and our wives Jean & Kai work in the administration side of the business.

Tell me some of the more interesting projects you and the company have been involved with?

In addition to the run of the mill tankage contracts we are involved in, we have been asked to convert a 45,000 litre underground petrol storage tank to a split compartment vessel for a large car importing company. They needed to store diesel and petrol but didn’t have the available space for another tank. My experience in fabricating and welding proved invaluable when we made a baffle in pieces small enough to pass through the manway and then built and installed it inside the tank.

One area you are very well versed in is corrosion of underground tanks. For perhaps a newer readers, can you briefly describe some of the various types of corrosion you have encountered? Well the most common form of corrosion we find is Microbial induced. It is our experience that 90% of corrosion of UST’s is from the inside out not as the common belief, from the outside to the inside. We almost without exception find it within the sludge line of the tank. I have written papers explaining the subject in an easy to understand format which have been published. They can be found, downloaded and printed from our website, www.kingtanktechnic.co.uk

Microbiological corrosion is fairly new to the downstream industry though commonly known in the marine industry for year. Could you outline some of the tell-tale signs and how this phenomena starts in the first place?

The first sign is usually the blocking of filters with a slimy deposit, usually a sludgy brown in colour. The reason for it is (In very basic brief terms) is that micro biological organisms live in the atmosphere and are drawn into tanks through the vents when fuel is dispensed. They live and grow in the interface between fuel and water at the bottom of the tanks. Any living organism which feeds must of course excrete and it is these excretions which form a type of acid which in turn corrode the metal of the tank shell.

What has been the most spectacular tank failure you have been involved with and what was its impact?

Petrol tank leakage going undetected during two delivery fills which were lost into the ground. Unfortunately the station was located in a town centre which had to be closed just prior to the Christmas shopping period.

What is new in the Company?

Well, not new to KTL/Adisa but new to the UK market –The double skin lining of existing above ground bulk storage tank bottoms with an interstitial monitoring system.

Those Fleet Vehicles of yours look impressive, what is on board?

Thank you, we like to think they are impressive. Think “Fire Engine” They are fitted with everything needed to uplift and transfer fuel, do tank cleaning with inbuilt vacuum pumps, transfer pumps (Vane and Blagden types) air compressor, water jetting equipment, vapour recovery and high level venting. They also carry full P.P.E. to undertake all tasks in the manner laid down in our approved work instructions and procedures

Where do you see the industry going over the next 5 to 10 years?

Much the same as now, the blind leading the blind with finance being the aim and not as it should be – safety.

If you had the choice, what is the biggest thing you would change in our industry?

More control of the methods of undertaking the most dangerous aspects of retail industry tank cleaning, inspection and lining to avoid the obviously possible disastrous impact on our environment and public safety. It saddens me to see in a boating magazine recently that a main contractor was fined £12,000 for pumping water contaminated with oil and silt into a brook during their work “Trying to improve environmental safety at a service station” No control – Cost cutting!

We have a quotation on the wall of all of our offices. It was said by Red Adair whilst standing near a burning oil field in Kuwait. We think it is very true.

“IF YOU THINK ITIS EXPENSIVE TO EMPLOYAPROFESSIONALTO DO THE JOB, WAITUNTILYOU HIRE AN AMATUER!”

Enough of work, when you are not “in the thick of it” what do you do to relax?

I live in a bungalow with a large garden that backs on to the Bridgewater canal. I have an 80 foot mooring so it has to be gardening and boats! I am working to complete the transformation of a 24 foot off shore cruiser into a canal “Gin Palace” This has been an ongoing project for a number of years.

Ray, it has been a pleasure and I see you are exhibiting at our Annual Conference as usual. I am sure many of us will drop by for a chat and maybe I will scrounge a coffee off you when I reach your Stand!!

Many thanks for talking to us and best wishes for the future

THE ASSOCIATION FOR PETROLEUM AND EXPLOSIVES ADMINISTRATION

Company Number: 2261660

ABBREVIATED ACCOUNTS

For the year ended 31 December 2007

I N D E X (page 1)

Page No:

1 INDEPENDENTAUDITOR’S REPORTTO THE COMPANY

2 ABBREVIATED BALANCE SHEET

3/4 NOTES TO THE ABBREVIATED ACCOUNTS

INDEPENDENT AUDITOR'S REPORT TO THE ASSOCIATION FOR PETROLEUM AND EXPLOSIVES ADMINISTRATION

UNDER SECTION 247B OF THE COMPANIES ACT 1985

We have examined the abbreviated accounts set out on pages 2 to 4, together with the financial statements of The Association for Petroleum and Explosives Administration for the year ended 31 December 2007 prepared under Section 226 of the Companies Act 1985.

This report is made solely to the company, in accordance with Section 247B of the Companies Act 1985. Our work has been undertaken so that we might state to the company those matters we are required to state to it in a special auditor's report and for no other purpose. To the fullest extent permitted by law, we do not accept or assume responsibility to anyone other than the company for our audit work, for this report, or for the opinions we have formed.

RESPECTIVE RESPONSIBILITIES OF THE DIRECTORS AND THE AUDITOR

The directors are responsible for preparing the abbreviated accounts in accordance with Section 246 of the Companies Act 1985. It is our responsibility to form an independent opinion as to whether the company is entitled to deliver abbreviated accounts prepared in accordance with Sections 246(5) and (6) of the Act to the Registrar of Companies and whether the accounts to be delivered are properly prepared in accordance with those provisions and report our opinion to you.

BASIS OF OPINION

We have conducted our work in accordance with Bulletin 2006/3 “The special auditor’s report on abbreviated accounts in the United Kingdom” issued by the Auditing Practices Board. In accordance with that Bulletin we have carried out the procedures we consider necessary to confirm, by reference to the financial statements, that the company is entitled to deliver abbreviated accounts and that the abbreviated accounts to be delivered are properly prepared. The scope of our work for the purpose of this report did not include examining or dealing with events after the date of our report on the financial statements.

OPINION

In our opinion the company is entitled to deliver abbreviated accounts prepared in accordance with Sections 246(5) and (6) of the Companies Act 1985, and the abbreviated accounts have been properly prepared in accordance with that provision.

ENSORS Chartered Accountants & Registered Auditors 46 St Nicholas Street IPSWICH IP1 1TT

4 June 2008

ABBREVIATED BALANCE SHEET (page 2)

As at 31 December 2007

FIXED ASSETS Note 2007 2006 £ £

Tangible Assets 2 1,349 1,206

CURRENT ASSETS

Debtors 73,974 62,241

Cash at bank and in hand 270,201 228,255

344,175 260,496

CREDITORS: amounts falling due within one year 114,720 93,264

NET CURRENT ASSETS

229,455 197,232

NET ASSETS

230,804 198,438

CAPITALAND RESERVES

Capital reserve 8,840 8,840

Profit and loss account 221,964 189,598

MEMBERS’FUNDS

230,804 198,438

These abbreviated accounts have been prepared in accordance with the special provisions for small companies under Part VII of the Companies Act 1985.

Approved by the board on 23 May 2008 and signed on its behalf:

M J Silmon Director

The notes on pages 3 and 4 form part of these financial statements.

NOTES TO THE ABBREVIATED ACCOUNTS (page 3)

For the year ended 31 December 2007

1. ACCOUNTING POLICIES

a) Basis of Accounting

The financial statements are prepared under the historical cost convention and in accordance with the Financial Reporting Standard for Small Entities (effective January 2007).

b) Tangible Fixed Assets

Depreciation is provided at the following annual rates in order to write off the cost of each asset over its estimated useful life:

Computer and Office Equipment – 33 1/3% on cost Fixtures and Fittings – 25% Reducing Balance

c) Foreign Currencies

Assets and liabilities denominated in foreign currencies are translated at the rate of exchange ruling at the balance sheet date. Transactions in foreign currencies are translated at the rate ruling at the date of the transaction. All differences are taken to the profit and loss account.

d) Cash Flow Statement

The company qualifies as a small company under the Companies Act 1985. The directors have elected to take advantage of the exemption under FRS1 not to prepare a cash flow statement.

e) Financial instruments

Financial instruments are classified and accounted for, according to the substance of the contractural arrangement, as either financial assets, financial liabilities or equity instruments. An equity instrument is any contract that evidences a residual interest in the assets of the company after deducting all of its liabilities.

NOTES TO THE ABBREVIAED ACCOUNTS (page 4)

For the year ended 31 December 2007

2. TANGIBLE FIXED ASSETS

Computer & Office Fixtures & Equip Fittings Total £ £ £

Cost

At 1 January 2007 5,119 4,938 10,057 Additions 449 741 1,190 Disposals - - At 31 December 2007 5,568 5,679 11,247

Depreciation

At 1 January 2007 4,571 4,279 8,850 Charge for the year 698 350 1,048 Disposals - - At 31 December 2007 5,269 4,629 9,898

Net Book Value

At 31 December 2007 299 1,050 1,349 At 31 December 2006 547 659 1,206

3. COMPANYLIMITED BYGUARANTEE

The company is limited by guarantee. In the event of the company being wound up, each member has undertaken to contribute such amount as may be required, but not exceeding £1, to the assets of the company.

APEAtel/fax 0845 603 5507

From a Tank Manufacturers Perspective!

By Mike Knight, Cookson & Zinn (PTL)Ltd

Introduction

For nearly 50 years Cookson and Zinn (PTL) Ltd has been manufacturing storage tanks and pressure vessels in all shapes and sizes, for storing a vast range of products, at their factory in Hadleigh, Suffolk.

Although the larger proportion of their business is now involved in making above ground tanks, they are still more widely known as the UK`s leading manufacturer of underground petrol and diesel storage tanks including their own PetroFast modular tank system.

The quality of their double skin tanks is well known throughout UK, Europe and beyond, but the precise manufacturing processes may not be known to everybody.

Commercial Director Mike Knight says “At each stage in the production cycle the standard of workmanship is assessed and verified before proceeding further”

Shown below is a brief introduction into how these double skin tanks are made.

Plate Utilisation

The beginning of the production process. All new, certified steel plates, cut to close tolerances by the suppliers, are stacked ready for the rolling process. Vacuum lifting equipment is used to lift and place each individual sheet in the plate rolls. The importance of receiving material cut by the suppliers to very exacting tolerances cannot be overstated prior to the assembly and welding of the tank.

Deuma Assembly

This assembly method is the key to providing a tank which needs to have maximum concentricity and straightness.

The machine is called a Deuma, named after the manufacturer, and each wrapper is slid along the roller bed and the ring is then closed hydraulically. Each subsequent wrapper is assembled to the previous one, and welded internally using submerged arc.

The alignment of the tank seams is extremely precise and much better than could ever be achieved by manual methods. This alignment will prevent much of the potential stresses which can occur through bad mis-alignment

Wrapper Rolling

Each wrapper is rolled and welded longtitudinally whilst on the rolls before proceeding to the Deuma assembly.

Submerged Arc Welding

Following assembly and internal welding the semi completed inner tank is moved to the external submerged arc machine where the circumferential and longtitudinal seams are welded.

The completed welds are not only faster and technically superior but provide a smooth even bead to allow subsequent painting operations to proceed without additional surface preparation.

Tank Fit Out

After the external welding is complete the manway and any additional brackets are fitted.

Testing

The inner tank is air tested in accordance with EN 12285 part 1

Skinning Process

The skin plates and skin heads are assembled to the inner tank, tack welded and then moved to the submerged arc welding machine for welding.

The skin plates are overlapped by a minimum of 50 m/m.

Skin Testing

Following sub arc welding of the skin, the welds are tested by air and then if a liquid system of leak detection is being used the space is filled with monopropylene glycol anti- freeze which has corrosion inhibitors, low temperature properties and is environmentally friendly.

This filling process provides a double check on the integrity of the double skin.

Blast Cleaning

The tanks are then ready to be blast cleaned to SA2.5 to remove mill scale and any surface rust. It is fundamental to the effectiveness of the coating that the correct degree of surface cleanliness is achieved and the blast