60 minute read

PROJECTS

from MSc Sustainable Architecture_Emissions as Design Drivers_Professor Aoife Houlihan Wiberg

by aoife hw

PHYSICAL PROPERTIES

Advertisement

Thermal conductivity 1,2...3,4 W/mK Density 2,5...2,8 ton/m3 Fire resistance High Hygroscopicity Breathable Durability High, long lifespan Recyclability 100 % GWP A1-A3 255 kgCO₂eq Nearest origin to Stavanger - Transport -

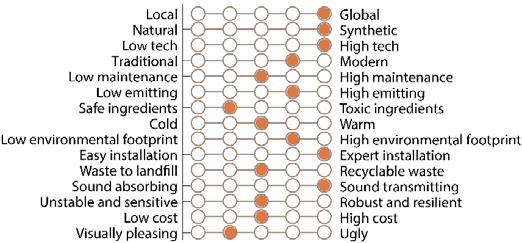

NATURAL STONE - AVERAGE

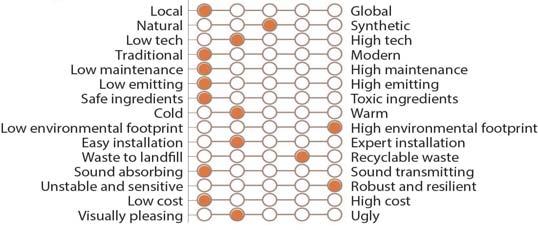

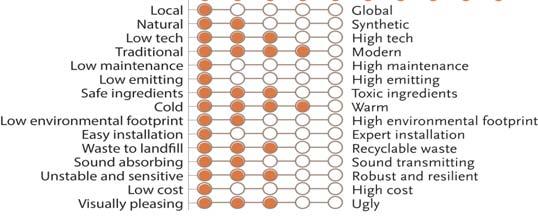

Local Natural

What is it? Average natural stone Compound Natural Building use Facade, roofi ng, pavings etc. Producer Average based on different manufacturers

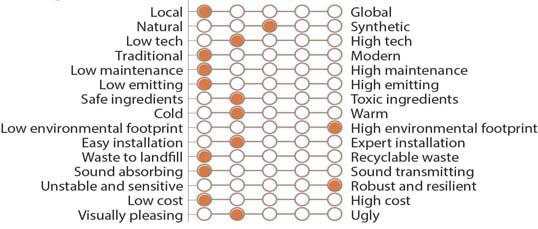

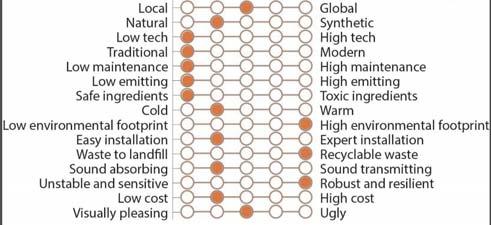

Low tech Traditional Low maintenance Low emitting Safe ingredients Cold Low environmental footprint Easy installation Waste to landfill Sound absorbing Unstable and sensitive Low cost Visually pleasing COMMENTS:

Global Synthetic High tech Modern High maintenance High emitting Toxic ingredients Warm High environmental footprint Expert installation Recyclable waste Sound transmitting Robust and resilient High cost Ugly

Strong Fire resistant Extremely long lilfespan Evens out temperatures Heavy to transport and install Surface is rough/irragular The declared product is an average natural stone with an average thickness of 40mm. The shares of the three rock types used for production are: igneous rock 27%, sedimentary rock 64%, metamorphic rock 9%. PHYSICAL PROPERTIES

Thermal conductivity 5 W/mK Density 2,7 ton/m3 Fire resistance High Hygroscopicity Breathable Durability High, long timespan Recyclability 100 % GWP A1-A3 83,7 kgCO₂eq broken edges 177 kgCO₂eq sawn edges Nearest origin to Stavanger Oppdal, Norway Transport 952 km *0,185 = 176,12 kgCO₂eq

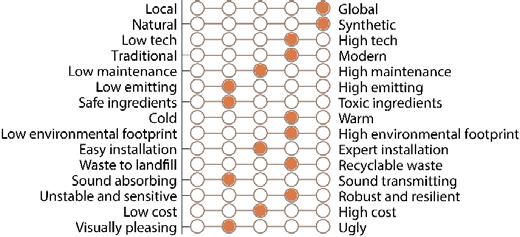

NATURAL STONE - QUARTZITE

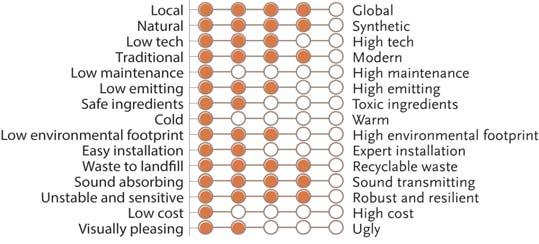

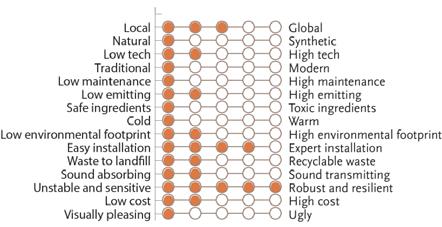

Local Natural

What is it? Natural stone quartzite schist, even thickness, with sawn or broken edges Compound Natural Building use Facade, roofi ng, pavingsv etc. Producer Minera Skifer AS, Norway

Low tech Traditional Low maintenance Low emitting Safe ingredients Cold Low environmental footprint Easy installation Waste to landfill Sound absorbing Unstable and sensitive Low cost Visually pleasing COMMENTS:

Global Synthetic High tech Modern High maintenance High emitting Toxic ingredients Warm High environmental footprint Expert installation Recyclable waste Sound transmitting Robust and resilient High cost Ugly

Strong Fire resistant Extremely long lilfespan Evens out temperatures Local production Heavy to transport and install Surface is rough/irregular Reference service life is same as for buildings and normally set to 60 years. However, natural stones have almost unlimited life time and is therefore normally not being replaced during service life.

PHYSICAL PROPERTIES

Thermal conductivity Ucw = 0.7 W / m²K Density 21.3 kg/m2 Fire resistance No fi re resistance or smoke control characteristics Hygroscopicity Durability 50 years of service life Recyclability Highly recyclable GWP A1-A3 -11,4 kgCO₂eq Nearest origin to Stavanger Montabaur, Germany (500 km approx.) Transport ,101*500= 50,5 kgCO₂eq Price -

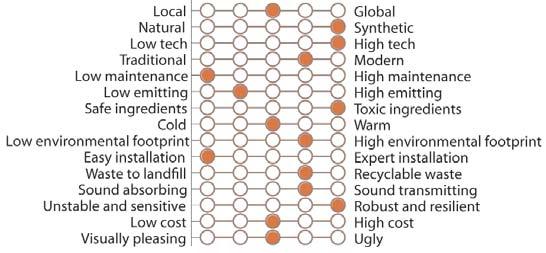

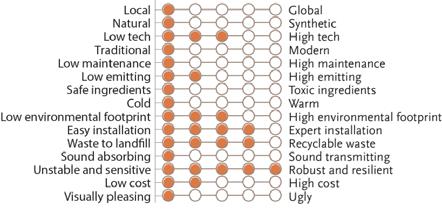

What is it? Supporting glass façade glued without ......................................metal profi les on a Glulam substructure. Compound Synthetic Building use Facade cladding Producer UNIGLAS GmbH & Co. KG

TIMBER-GLASS-COMPOSITE FAÇADE

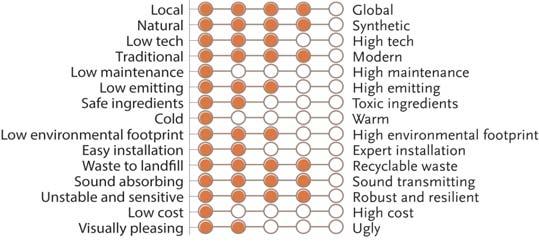

Local Natural Low tech Traditional Low maintenance Low emitting Safe ingredients Cold Low environmental footprint Easy installation Waste to landfill Sound absorbing Unstable and sensitive Low cost Visually pleasing COMMENTS:

Global Synthetic High tech Modern High maintenance High emitting Toxic ingredients Warm High environmental footprint Expert installation Recyclable waste Sound transmitting Robust and resilient High cost Ugly

High energy effi ciency, use of renewable raw materials, fast assembly and recyclable. Not locally produced The glass takes on a static load bearing function in the building envelope, wind bracing can be omitted in low rise buildings. The adhesive connection between the timber and glass ensures that the load bearing structure complies with all static requirements. PHYSICAL PROPERTIES

Thermal conductivity 0,4 - 0,7 W/mK Density 2240-2400 kg/m3 Fire resistance Shows cracks/damage after 600 ºC Hygroscopicity Water doesn't damage it, but it is not waterproof Durability High - can be reused as aggregate for new mix Recyclability 30% of new mix can be reused concrete GWP A1-A3 202,876 kgCO₂eq/m3 Nearest origin to Stavanger SandnesBetong, Sandnes Transport 26,3 km *0,185 = 4,9 kgCO₂eq/m3 (truck) Price -

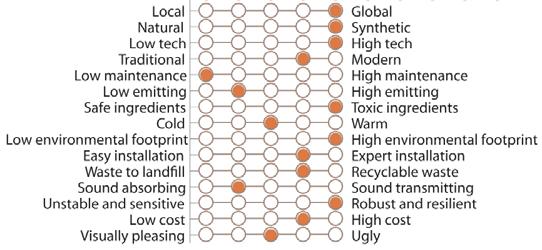

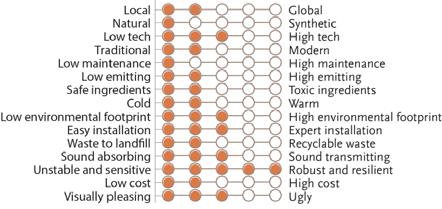

STANDARD CONCRETE MIX

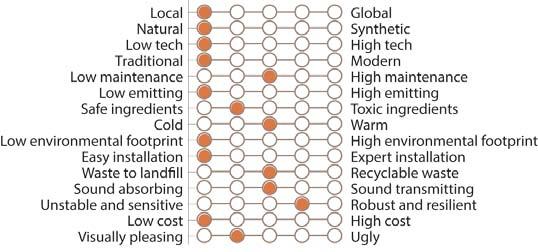

What is it? Mix of cement, mortar, sand, chemicals Known as Readymade concrete Compound Synthetic Building use Construction, foundation, fi re resistance, prefab elements

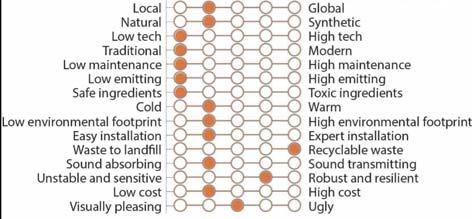

Local Natural Low tech Traditional Low maintenance Low emitting Safe ingredients Cold Low environmental footprint Easy installation Waste to landfill Sound absorbing Unstable and sensitive Low cost Visually pleasing

COMMENTS:

Global Synthetic High tech Modern High maintenance High emitting Toxic ingredients Warm High environmental footprint Expert installation Recyclable waste Sound transmitting Robust and resilient High cost Ugly

Strong Fire resistant Extremely long lilfespan Compressive strength Endures in wet climates High ghg emissions Chemicals ae used Non-biodegradable Non-demountable Breathing, so not waterproof ''Normal concrete'' does not exist, but this type is most commonly used. It is a readymade mix, which is easily appliable and known to be applied in a lot of different building elements. Like skin, foundation and loadbearing constructions.

PHYSICAL PROPERTIES

Thermal conductivity 0,4 - 0,7 W/mK Density 2240-2400 kg/m3 Fire resistance Fastly shows cracks with heat Hygroscopicity Water doesn't damage it, but it is not waterproof Durability High - can be reused as aggregate for new mix Recyclability 30% of new mix can be reused concrete GWP A1-A3 172,16 kgCO₂eq/ton Nearest origin to Stavanger Norcem AS, Brevik Transport 393 km *0,011 = 4,3 kgCO₂eq/m3 (boat) Price -

GREEN CONCRETE

What is it? Concrete mix with green cement Known as Lavkarbonsement/betong Compound Synthetic/natural Building use All concrete applications

Local Natural Low tech Traditional Low maintenance Low emitting Safe ingredients Cold Low environmental footprint Easy installation Waste to landfill Sound absorbing Unstable and sensitive Low cost Visually pleasing

COMMENTS:

Global Synthetic High tech Modern High maintenance High emitting Toxic ingredients Warm High environmental footprint Expert installation Recyclable waste Sound transmitting Robust and resilient High cost Ugly

Extremely long lifespan Can endure in wet climates Strong Fire resistant Compressive strength Less emissions Non-biodegradable Non-demountable Breathing, so not waterproof Not very local The GWP is calculated with the GWP value of green CEMENT (GWP = 503), compared to commercial cement (859), which is used for normal concrete (294). If you would assume that the proportions stay the same, the GWP of green concrete could be 503*294/859 = 172,16 PHYSICAL PROPERTIES

Thermal conductivity W/mK Density 2398 kg/m3 Fire resistance High - used to protect other materials as well Hygroscopicity Breathable Durability High - long timespan Recyclability Unknown GWP A1-A3 664,6 kgCO₂eq/ton Nearest origin to Stavanger Andersens Mek. Versted AS, Klekkefjord Transport 128km * 0,185 = 23,7 kgCO₂eq/m3 (truck) Price - kr/m3

SHOTCRETE

What is it? Concrete mix Known as Spray Concrete Compound Synthetic Building use Walls, Construction Other uses Fire resistance for steel construction

Local Natural Low tech Traditional Low maintenance Low emitting Safe ingredients Cold Low environmental footprint Easy installation Waste to landfill Sound absorbing Unstable and sensitive Low cost Visually pleasing COMMENTS:

Global Synthetic High tech Modern High maintenance High emitting Toxic ingredients Warm High environmental footprint Expert installation Recyclable waste Sound transmitting Robust and resilient High cost Ugly

Strong Fire resistant Extremely long lilfespan Compressive strength Appliable in cold wet environments Can be applied on site Can be applief on ceilings The reinforcement grids could stay visible Can show superfi cial cracks when dried More sensitive for environment than normal concrete, because provided ''In situ'' The mix is made that it can be applied with a high pressure tube and it will stick immediately to the surfaces it touches, is is known for an extreem fast building material, with low maintenance.

PHYSICAL PROPERTIES

Thermal conductivity 0,4 - 0,7 W/mK Density 2240-2400 kg/m3 Fire resistance Fastly shows cracks with heat Hygroscopicity Water doesn't damage it, but it is not waterproof Durability High - can be reused as aggregate for new mix Recyclability 30% of new mix can be reused concrete GWP A1-A3 193,09 kgCO₂eq/ton Nearest origin to Stavanger Structur betong, Stavanger Transport 13,1 km *0,185= 2,4 kgCO₂eq/m3 (truck) Price -

DECORATION CONCRETE

What is it? Concrete mix with fi ne elements Known as Dekorasjon Betong Compound Synthetic Building use Fine decoration elements, facade, physical architectural scale models.

Local Natural Low tech Traditional Low maintenance Low emitting Safe ingredients Cold Low environmental footprint Easy installation Waste to landfill Sound absorbing Unstable and sensitive Low cost Visually pleasing

COMMENTS:

Global Synthetic High tech Modern High maintenance High emitting Toxic ingredients Warm High environmental footprint Expert installation Recyclable waste Sound transmitting Robust and resilient High cost Ugly

Extremely long lilfespan This type of concrete can be used only for Can endure in wet surfaces, not for loadbearing constructions. climates Easy in forming complicated shapes Fine smooth surface Weak compression and tention properties Cracks easy with fi re Because of the fi ne structure, more sensitive for human touch. Non-biodegradable Non-demountable PHYSICAL PROPERTIES

Thermal conductivity 0,7-2,0 W/mK Density 240-1850 kg/m3 Fire resistance High Hygroscopicity Breathable Durability High - long timespan Recyclability 603 kg/ton GWP A1-A3 664,6 kgCO₂eq/m3 Nearest origin to Stavanger FABEKO NORSK FABrikkbetongforening, Oslo Transport 552km *0,011 = 6,1 kgCO₂eq/m3 (boat) Price - kr/m3

LIGHTWEIGHT CONCRETE

What is it? Concrete mix with higher air voids and cellular/porous structure. Compound Synthetic Building use Skin, Other uses Improves the insulation,

Local Natural Low tech Traditional Low maintenance Low emitting Safe ingredients Cold Low environmental footprint Easy installation Waste to landfill Sound absorbing Unstable and sensitive Low cost Visually pleasing

COMMENTS:

Global Synthetic High tech Modern High maintenance High emitting Toxic ingredients Warm High environmental footprint Expert installation Recyclable waste Sound transmitting Robust and resilient High cost Ugly

Less reinforcement. Lightweight concrete can make the jobs for Similar stength construction workers easier. Good fi re resistance. Can store water better than normal concrete. Higher costs Mixing is long and diffecult process. Non-biodegradable Non-demountable Physical stress can show cracks

CONSTRUCTION

STUDENTS

Mads Løkeland Slåke Martin Fischer Liisa Valdmann Janice Lobo

PHYSICAL PROPERTIES

Thermal conductivity 0,06 W/mK Density 125 kg/m3 Fire resistance Low Hygroscopicity High Durability Low - Renewable Recyclability 100% GWP A1-A3 -50.037 kgCO₂eq (100 years) Nearest origin to Stavanger Stavanger, Norway

Transport (km) - Price 450 kr/m2

STRAW BALE

What is it? Environmentally friendly building technique Invented in Paleolithic, Africa Compound Straw bale, Plaster, (Wood/ Wire) Building use Walls, Roof Other uses Fodder, Fertilizer +

Local Natural Low tech Traditional Low maintenance Low emitting Safe ingredients Cold Low environmental footprint Easy installation Waste to landfill Sound absorbing Unstable and sensitive Low cost Visually pleasing

COMMENTS:

Global Synthetic High tech Modern High maintenance High emitting Toxic ingredients Warm High environmental footprint Expert installation Recyclable waste Sound transmitting Robust and resilient High cost Ugly

Cost Locally available Renewable Carbon storage Insulative properties Regulations Strength Life expectancy Rotting, fungi, pests GWP is calculated for a 100 year timeframe. Makes use of leftovers from grain production. Alternative construction material for storing carbon. Requires wooden framework for better strength properties. PHYSICAL PROPERTIES

Thermal conductivity 1,5 W/mK Density 2200 kg/m3 Fire resistance Fire resistant Hygroscopicity Medium Durability Medium to High Recyclability 100 % GWP A1-A3 16 kgCO₂eq Nearest origin to Stavanger Stavanger, Norway

Transport (km) - Price Project-specifi c

RAMMED EARTH

What is it? Ancient building method using compresssed earth Invented in 5000 BC, China Compound Subsoil, (Cement) Building use Wall, Floor, Foundation Other uses Fortifi cation

Locally available Thermal mass Controls humidity Acoustical prop. Fire resistancy Labor-demanding constr. Non-homogeneous Tensile strength Height limitation Insulative properties

Local Natural Low tech Traditional Low maintenance Low emitting Safe ingredients Cold Low environmental footprint Easy installation Waste to landfill Sound absorbing Unstable and sensitive Low cost Visually pleasing

COMMENTS:

Global Synthetic High tech Modern High maintenance High emitting Toxic ingredients Warm High environmental footprint Expert installation Recyclable waste Sound transmitting Robust and resilient High cost Ugly

Not every soil is suitable for construction. A sandy soil with a clay content around 15% is best. On-site materials need to be tested for their suitability. Susceptible to water damage if inadequately protected or maintained. Not suitable to every climate. Need for formwork. Can be reused.

PHYSICAL PROPERTIES

Thermal conductivity 0,8 W/mK Density 1395 kg/m3 Fire resistance Fire resistant Hygroscopicity Medium Durability High Recyclability 100% GWP A1-A3 2,58E+02 kgCO₂eq (150 years) Nearest origin to Stavanger Højslev ,Denmark Transport (km) Mixed: Lorry - 381, Barge - 136 Price 510 kr/m2

BRICK

What is it? Structure of units composed of clay and mortar Invented in 7500 BC, Mesopotamia Compound Clay, Shale Building use Wall, Vaulted ceiling, Foundation Other uses Paving

Durability Fire resistancy Thermal mass Low maintenance Versatility Time consuming construction Low tensile strength Hard to clean

Local Natural Low tech Traditional Low maintenance Low emitting Safe ingredients Cold Low environmental footprint Easy installation Waste to landfill Sound absorbing Unstable and sensitive Low cost Visually pleasing

COMMENTS:

Global Synthetic High tech Modern High maintenance High emitting Toxic ingredients Warm High environmental footprint Expert installation Recyclable waste Sound transmitting Robust and resilient High cost Ugly

No production in Norway. High emissions in production phase. Low percentage of reusing. Requires sustainable deconstruction and cleaning from mortar. Not possible in newer buildings. PHYSICAL PROPERTIES

Thermal conductivity 16 W/mK Density 7820 kg/m3 Fire resistance Melts at 1370 C Hygroscopicity No vapour transmissivity Durability High - not biodegradeable Recyclability 99% GWP A1-A3 2,71 kgCO₂eq (100 years) Nearest origin to Stavanger Melhus, Norway Transport (km) Lorry: 1038 Price 466kr pr/m

PRE-ENGINEERED STEEL

What is it? Metal structure fabricated with steel for the internal support Invented in 1884, Chicago, USA Compound Iron, Carbon Building use Wall, Ceiling, Roof Other uses Bridges, Vehicles

High compressive and ensile strength No height limitation Fast construction Recyclable Emissions Fire resistancy Corrosion Weight Maintenance cost

Local Natural Low tech Traditional Low maintenance Low emitting Safe ingredients Cold Low environmental footprint Easy installation Waste to landfill Sound absorbing Unstable and sensitive Low cost Visually pleasing

COMMENTS:

Global Synthetic High tech Modern High maintenance High emitting Toxic ingredients Warm High environmental footprint Expert installation Recyclable waste Sound transmitting Robust and resilient High cost Ugly

GWP is given for cold-forming technology with higher emissions. 88% of steel is recycled. Steel looses structural properties at 750C. Can be protected against fi re and corrosion with coating and other protection methods.

PHYSICAL PROPERTIES

Thermal conductivity 16 W/mK Density 7820 kg/m3 Fire resistance Melts at 1370 C Hygroscopicity No vapour transmissivity Durability High - not biodegradeable Recyclability 96% GWP A1-A3 2,83 kgCO₂eq Nearest origin to Stavanger Peräseinäjoki, Finland Transport (km) Mixed: Lorry - 1442, Barge - 210 Price Project-specifi c

WELDED AND COATED STEEL TRUSS

What is it? Structure of two-force members which behaves as a single object Invented in 1857, Weichsel Bridge, Germany Compound Iron, Carbon, Coating Building use Roof, Ceiling Other uses Bridges

Local Natural Low tech Traditional Low maintenance Low emitting Safe ingredients Cold Low environmental footprint Easy installation Waste to landfill Sound absorbing Unstable and sensitive Low cost Visually pleasing

COMMENTS:

Global Synthetic High tech Modern High maintenance High emitting Toxic ingredients Warm High environmental footprint Expert installation Recyclable waste Sound transmitting Robust and resilient High cost Ugly

Precise engineering Emissions WeightHigh compressive and tensile strength Maintenance cost Long spans Fire resistancy Recyclable Transportation GWP is given for cold-forming technique with higher emissions. Steel looses structural properties at 750C. Can be protected against fi re and corrosion with coating and other protection methods. PHYSICAL PROPERTIES

Thermal conductivity 0,13 W/mK Density 470 kg/m3 Fire resistance Low Hygroscopicity High Durability 60 years Recyclability 98 % GWP A1-A3 -6,63E+02 kgCO₂eq (60 years) Nearest origin to Stavanger 230, Vatnestrøm, Norway

Transport (km) Lorry: 230 Price Project-specifi c

GLULAM TRUSS

What is it? Structure of two-force members which behaves as a single object Invented in 2500 BC Compound Wood, (Metal) joints, Coating Building use Roof, Ceiling Other uses Bridges

Precise engineering Volumetric changes Weight Rotting, fungi, pests Long spans Transportation Reuse Prefabrication Predictability in fi re sit. Recycling

Local Natural Low tech Traditional Low maintenance Low emitting Safe ingredients Cold Low environmental footprint Easy installation Waste to landfill Sound absorbing Unstable and sensitive Low cost Visually pleasing

COMMENTS:

Global Synthetic High tech Modern High maintenance High emitting Toxic ingredients Warm High environmental footprint Expert installation Recyclable waste Sound transmitting Robust and resilient High cost Ugly

GWP is estimated from Glulam beam Lower CO2 emissions, water pollution index and energy use compared to steel. Wooden trusses weigh less than comparative steel trusses.

PHYSICAL PROPERTIES

Thermal conductivity 0,13 W/mK Density 410 kg/m3 Fire resistance Infl ammable Hygroscopicity Highly capable for absorption of moisture Durability Life span of more than 60 years Recyclability Restoration, recycling, or thermal use GWP A1-A3 -663 kgCO₂eq Nearest origin to Stavanger Moelven Limtre AS, Avd. Agder, 4730 Vatnestrøm Transport 237 km * 11,9 kgCO₂eq/m3 = 2.820 kgCO₂eq Price 600-1.200 NOK/m Compressive strength (GL 28) 24 N/mm2 parallel/ 2,7 N/mm2 perpendicular

GLUE-LAMINATED TIMBER (GLULAM)

Local Natural

What is it? Layers fo dimensional lumber bonded togehter with adhesives Known as Limtre/ limtrebjelke Compound Synthetic or natural Building use Preferably used as beams in wide span structures

Low tech Traditional Low maintenance Low emitting Safe ingredients Cold Low environmental footprint Easy installation Sound absorbing Unstable and sensitive Low cost Visually pleasing COMMENTS:

Global Synthetic High tech Modern High maintenance High emitting Toxic ingredients Warm High environmental footprint Expert installation Recyclable waste Sound transmitting Robust and resilient High cost Ugly

Big spans Possible use outdoor Local availability Natural material Durable, moistureresistant structural adhesives often lower the fabrics inherent quality of being a green product Glulam has much lower embodied energy than reinforced concrete and steel, although of course it does entail more embodied energy than solid timber. However, the laminating process allows timber to be used for much longer spans, heavier loads, and complex shapes. It is 2/3 the weight of steel and 1/6 the one of concrete – the embodied energy to produce it is 6x less than the same suitable strength of steel. PHYSICAL PROPERTIES

Thermal conductivity 0,13 W/mK Density 430 kg/m3 Fire resistance Infl ammable Hygroscopicity Highly capable for absorption of moisture Durability Life span of more than 60 years Recyclability Restoration, recycling, or thermal use GWP A1-A3 -658 kgCO₂eq Nearest origin to Stavanger Norsk Massivtre, 2937 Begna Transport 500 km * 11,9 kgCO₂eq/m3 = 5.940 kgCO₂eq Price 736-1.369 NOK/m2 Compressive strength 24 N/mm2 parallel/ 2,7 N/mm2 perpendicular

CROSS-LAMINATED TIMBER (CLT)

Local

What is it? Plate-like product, the plank layers are perpendicularly glued Known as Massivtre, KL-tre Compound Synthetic/natural Building use Primarily for walls (Moholt 50/50)

Natural Low tech Traditional Low maintenance Low emitting Safe ingredients Cold Low environmental footprint Easy installation Sound absorbing Unstable and sensitive Low cost Visually pleasing

COMMENTS:

Global Synthetic High tech Modern High maintenance High emitting Toxic ingredients Warm High environmental footprint Expert installation Recyclable waste Sound transmitting Robust and resilient High cost Ugly

Local availability Natural material Short assembly time Adhesives Compared to bricks or concrete CLT has a low thermal mass and therefore a lower thermal storage potential CLT can be used for all elements of a building's superstructure, i.e. walls, ceilings, roof surfaces.

PHYSICAL PROPERTIES

Thermal conductivity 0,13 W/mK Density 420 kg/m3 Fire resistance Infl ammable Hygroscopicity Highly capable for absorption of moisture Durability Life span of more than 60 years Recyclability Restoration, recycling, or thermal use GWP A1-A3 -651,66 kgCO₂eq (milled profi le) Nearest origin to Stavanger - Transport 124,64 kgCO₂eq/ 1.000 km (by truck) Price Compressive strength 21 N/mm2 parallel/ 5,3 N/mm2 perpendicular

LOG WALL

What is it? Handcraftet or milled piled logs Known as Compound Natural Building use Outer walls Other uses -

Local Natural Low tech Traditional Low maintenance Low emitting Safe ingredients Cold Low environmental footprint Easy installation Sound absorbing Unstable and sensitive Low cost Visually pleasing

COMMENTS:

Global Synthetic High tech Modern High maintenance High emitting Toxic ingredients Warm High environmental footprint Expert installation Recyclable waste Sound transmitting Robust and resilient High cost Ugly

Creates a pleasant atmosphere Continuing with the traditional craftsmanship Roughness, superfi cial fi ssures that increase the more the material loses its natural moisture content Proneness to moisture and horizontal precipitation Handcrafted log wall: + Life cycle GHG: 183,35 kgCO2eq - Net carbon sequestration: -1.956,93 kgCO2eq = Net carbon balance: -1.773,59 kgCO2eq Viable outdoor usage in Stavanger is rather improper in both economical and structural sense. PHYSICAL PROPERTIES

Thermal conductivity 0,13 W/mK Density 420 kg/m3 Fire resistance Infl ammable Hygroscopicity Highly capable for absorption of moisture Durability Life span of more than 60 years Recyclability Restoration, recycling, or thermal use GWP A1-A3 -607 kgCO₂eq Nearest origin to Stavanger Byggmakker Sørbø Trelast , 4017 Stavanger Transport 5 km * 11,4 kgCO₂eq/m3 = 57 kgCO₂eq Price 10.000 NOK/m3 Compressive strength 21 N/mm2 parallel/ 5,3 N/mm2 perpendicular

STRUCTURAL LUMBER

What is it? Solid piece of timber Known as Konstruksjonsvirke Compound Natural Building use Joists (ceiling, roof), rafters, columns

Local availability Natural, vivid Untreated, manufactured Imperfections Warm, cosy No complicated shapes Quite long assembly time Usually it is treated to endure its resistance against moisture and pest infestation

Local Natural Low tech Traditional Low maintenance Low emitting Safe ingredients Cold Low environmental footprint Easy installation Sound absorbing Unstable and sensitive Low cost Visually pleasing

COMMENTS:

Global Synthetic High tech Modern High maintenance High emitting Toxic ingredients Warm High environmental footprint Expert installation Recyclable waste Sound transmitting Robust and resilient High cost Ugly

Structural lumber is the most frequently used construction material in Norway, produced all over the country. There are both on-site (C 24) or prefab (C 30) timber frame.

PHYSICAL PROPERTIES

Thermal conductivity 0,96 W/mK Density 2,5 kg/(mm*m2) m Fire resistance Highly fi re-resistance and non-fl ammable Hygroscopicity Watertight and no moisture absorption Durability High - can be reused as aggregate for new mix Recyclability 52% of GWP can be accounted for GWP-reduction GWP A1-A3 2,67 kgCO₂eq (without -1,39 EoL benefi t) Nearest origin to Stavanger 27283 Verden, Germany

Transport 984 km * 80 kgCO₂eq/m3 = 78.700 kgCO₂eq Price ~ 100 NOK/4mm and m2 toughened glass Compressive strength 1.000 N/mm2

FLOAT GLASS

What is it? Compound of silica sand 60%, soda 20% + dolomit & kalk 20% Known as Toughened glass Compound Synthetic Building use Construction, transparent systems, fi re resistance

Transparent Extremely long lilfespan No adsorption of odours, neutral smell Relies on framework Extremely brittle, breakable and sharp Heavy Un-natural

Local Natural Low tech Traditional Low maintenance Low emitting Safe ingredients Cold Low environmental footprint Easy installation Sound absorbing Unstable and sensitive Low cost Visually pleasing

COMMENTS:

Global Synthetic High tech Modern High maintenance High emitting Toxic ingredients Warm High environmental footprint Expert installation Recyclable waste Sound transmitting Robust and resilient High cost Ugly

The main advantage of glass as a load-bearing material is contained in its light transmittance. However, glass is a brittle material, so in its conventional use it needs to be prevented from defl ection or any other kind of displacement. Composite material of glass and glass fi bre reinforced plastic: due to the same coeffi cient of linear expansion the glass can take loads. That saves material, energy, weight and costs. PHYSICAL PROPERTIES

Thermal conductivity 0.238 W/mK Density 1700 kg/m3 Fire resistance Good Hygroscopicity Low vapour transmissivity Durability High - non biodegradable Recyclability 100% GWP A1-A3 40,7 kgCO₂eq Nearest origin to Stavanger Bremem, Germany

Transport (km) 1005 km Price ≈ kr/m3

ETHYLENE TETRAFLUORETHYLENE HYLENE

What is it? Flourine based plastic polymer Known as ETFE Invented in 1970s Compound Synthetic Building use Walls, Roof, Skin Other uses Thermoplastic liner for pipes

Lightweight Translucent Resistant to radiation Recyclable Non-biodegradable Poor acoustic insulation Complicated construction COMMENTS:

This material is intended to be used in large scale projects due to cost and complex installation method. Suitable for walls, roof and skin. Usually used as a glass substitute in translucent facades because of lightweight nature.

PHYSICAL PROPERTIES

Thermal conductivity 0.18 W/mK Density 745 kg/m3 Fire resistance Medium Hygroscopicity Low vapour transmissivity Durability High - not biodegradeable Recyclability 100% GWP A1-A3 - kgCO₂eq Nearest origin to Stavanger Kurim, Czech Republic

Transport (km) 1740 km Price - kr/m3

RECYCLED TETRAPAK

What is it? Compressed Tetrapak Board Known as Flexibuild Board Invented in Kurim, Czech Republic Compound Synthetic Building use Wall Other uses -

COMMENTS:

Lightweight Non-biodegradable Thermal resistance Non fl exible design Recyclable Low moisture absorbtion What is it? Recycled plastic sandwich panel Known as Ecoplasbrick Invented in 2011, Brindisi, Italy Compound Synthetic Building use Walls Other uses -

Material size and strength make it ideal for walls in small scale projects. Still in experimental stage so new data is regulary made. PHYSICAL PROPERTIES

Thermal conductivity - W/mK Density 634 kg/m3 Fire resistance High Hygroscopicity Low vapour transmissivity Durability High - non biodegradable Recyclability 20% GWP A1-A3 40,8 kgCO₂eq Nearest origin to Stavanger Brindisi, Germany Transport (km) 3015 km Price 185 kr/m3

ECOPLASBRICK

Lightweight Acoustic Insulation Thermal Resistance Recyclable Non-biodegradable Poor acoustic insulation Complicated construction COMMENTS:

The core is recycled plastic but the surface fi nish can be fl exible, changing the properties of the sandwich panel. Most commonly used for walls.

PHYSICAL PROPERTIES

Thermal conductivity 2,5 W/mK Density 2240-2420 kg/m3 Fire resistance Fastly shows cracks with heat Hygroscopicity Water doesn't damage it, but it is not waterproof Durability High - can be reused as aggregate for new mix Recyclability 30% of new mix can be reused concrete GWP A1-A3 119,8 kgCO₂eq Nearest origin to Stavanger Skedsmo Betong AS, Skedsmokorset Transport 576 km Price 1310 NOK/m3 Compressive strength ≈ 37 N/mm2

LOW HEAT CONCRETE

Local Natural Low tech What is it? Concrete with high amount of fl y ash Low maintenance Traditional Known as B45 M40 Lavvarmebetong, synk 200 Safe ingredients Low emitting mm Cold Low environmental footprintCompound Synthetic/natural Easy installation Building use Massive concrete volumes Sound absorbing Waste to landfill

Unstable and sensitive Low cost Visually pleasing

COMMENTS:

Global Synthetic High tech Modern High maintenance High emitting Toxic ingredients Warm High environmental footprint Expert installation Recyclable waste Sound transmitting Robust and resilient High cost Ugly

Long lifespan Lower chance of cracking Relatively low A1 - A3 emissions Non-demountable Relatively high A4 emissions This material is intended to be applied i big, massive construction elements, and is not appropriate for slim constructions. Due to its' low heat pouring, the likeability for cracks in the construction elements is lower than for other concrete products. PHYSICAL PROPERTIES

Thermal conductivity 2,5 W/mK Density 2240-2400 kg/m3 Fire resistance Fastly shows cracks with heat Hygroscopicity Water doesn't damage it, but it is not waterproof Durability High - can be reused as aggregate for new mix Recyclability 30% of new mix can be reused concrete GWP A1-A3 202,9 kgCO₂eq Nearest origin to Stavanger Sandnes betong AS, Sandnes Transport 21 km Price Slab 4700 NOK/m3, wall 5850 NOK/m3, column 1500 NOK/m Compressive strength ≈ 37 N/mm2

LOCAL ON-SITE CONCRETE

What is it? On-site poured concrete Known as Ferdigbetong B30 M60 D22 Synk 180 Compound Synthetic/natural Building use All concrete applications

Local Natural Low tech Traditional Low maintenance Low emitting Safe ingredients Cold Low environmental footprint Easy installation Waste to landfill Sound absorbing Unstable and sensitive Low cost Visually pleasing

COMMENTS:

Global Synthetic High tech Modern High maintenance High emitting Toxic ingredients Warm High environmental footprint Expert installation Recyclable waste Sound transmitting Robust and resilient High cost Ugly

Locally produced Low transport emissions due to location Non-demountable Higher embodied emissions than "greener" alternatives Easily available from Sandnes Betong AS, 21 km away.

PHYSICAL PROPERTIES

Thermal conductivity 0,32 W/mK Density 770 kg/m3 Fire resistance Good Hygroscopicity Water doesn't damage it, but it is not waterproof Durability High Recyclability Can be used as fi ll in or aggregate in concrete products GWP A1-A3 117,1 kgCO₂eq Nearest origin to Stavanger Weber Leca Norge, Torp Transport 523 km Price 106 NOK/pcs Compressive strength 2-3 N/mm2

LECA BLOCKS

Local Natural Low tech Traditional

What is it? Consists of clay expanded to small balls through a process of drying and burning Known as Leca Universalblokk 20 cm Compound Synthetic/natural Building use Load bearing walls and foundation

Low maintenance Low emitting Safe ingredients Cold Low environmental footprint Easy installation Waste to landfill Sound absorbing Unstable and sensitive Low cost Visually pleasing

COMMENTS:

Global Synthetic High tech Modern High maintenance High emitting Toxic ingredients Warm High environmental footprint Expert installation Recyclable waste Sound transmitting Robust and resilient High cost Ugly

Recycable Good heat insulation Good sound insulation Low A1 - A3 and A4 compared to other constructoinal blocks Non-demountable Not very local, limited production possibilities in Norway Not suitable in big buildings/ for heavy loads This material is intended to be applied in smaller buildings, especially in foundations, walls i basements etc. Yet, it has also been used in all walls, in combination with wood roof constructions in housing. PHYSICAL PROPERTIES

Thermal conductivity 2,5 W/mK Density 2240-2400 kg/m3 Fire resistance Good Hygroscopicity Water doesn't damage it, but it is not waterproof Durability High Recyclability Can be used as aggregate in concrete products GWP A1-A3 1387 (walls) and 1758 (fl oors) kgCO₂eq Nearest origin to Stavanger Block Berge Bygg AS, Kleppe Stasjon Transport 25,6 km Price Floor 2250 NOK/m3 and wall 5650 NOK/m3 Compressive strength 37 N/mm2

Wall elements: NEPD 189N Hollow core slab elements: NEPD 190N

PREFAB CONCRETE ELEMENTS

Local Natural Low tech Traditional

What is it? Prefabricated concrete elements of fl oors and walls Known as Hulldekkeelement and kompaktvegg Compound Synthetic/natural Building use Load bearing walls and fl oors

Low maintenance Low emitting Safe ingredients Cold Low environmental footprint Easy installation Waste to landfill Sound absorbing Unstable and sensitive Low cost Visually pleasing

COMMENTS:

Global Synthetic High tech Modern High maintenance High emitting Toxic ingredients Warm High environmental footprint Expert installation Recyclable waste Sound transmitting Robust and resilient High cost Ugly

Locally produced Resistant to moisture Demountable Relatively high A1 - A3 cradle to gate emissions Prefab concrete elements. The fl oors are hollow cored, while walls are non insulated elements.

INSULATION

STUDENTS

Håvard Auklend Zorbey Tuncer Claire-Elise Bard Mariya Stoyanova Winnie Po Ting Poon

PHYSICAL PROPERTIES

Thermal conductivity 0,030 - 0,038 W/mK Density 15 kg/m3 Fire resistance Melts, but low fl ame spread Hygroscopicity Low vapour transmissivity Durability High - not biodegradeable Recyclability 100% GWP A1-A3 2,2 kgCO₂eq (R = 1 m2K/W for 38 mm thickness) 57,9 kgCO₂eq/m3 Nearest origin to Stavanger Jackon - Oltedal (43 km drive)

Transport (km) Lorry: 43 Price ≈ 832 kr/m3

EPS - EXPANDED POLYSTYRENE

What is it? Rigid closed cell foam material Known as Styrofoam / Isopor Invented in 1954, Koppers Company Compound Synthetic Building use Roof, wall, fl oor and ground Other uses Packaging

COMMENTS:

Lightweight Thermal resistance Recyclable No fungae growth High ghg emissions Volatile ingredients, 2% Non-biodegradable What is it? PUR from plant based polyols Known as Icynene Invented in 1970, Unknown Compound Synthetic Building use Walls, Roof Other uses Thermal storage tanks

Graphite can be added to achieve lower radiative heat transfer. PHYSICAL PROPERTIES

Thermal conductivity 0,028 W/mK Density 40 kg/m3 Fire resistance Ignition temperature 543 °C Hygroscopicity Low vapour transmissivity Durability High - not biodegradable Recyclability Not recyclable GWP A1-A3 2,5 kgCO₂eq (R = 1 m2K/W for 28 mm thickness) 89.3 kgCO2eq/m3 Nearest origin to Stavanger BFSI - Crossmolina, Ireland Transport (km) Mixed: Lorry - 2362,4 , Barge - 246 , Train - 54,3 Price ≈ 360 kr/m2 (Uncertain)

BIO FOAM INSULATION

Low shipping bulk Thermal resistance Reduces air leakage No fungae growth Petrolium based Diffi cult to remove Not recyclable COMMENTS:

Although the name of the material implies that it is based on natural raw materials, only a part of the mix is based on plant polyol (Soy/castor oil). The rest of the material is petrolium based, but can be from recycled plastic bottles.

PHYSICAL PROPERTIES

Thermal conductivity 0,0044 - 0,007 W/mK Density 170-200 kg/m3 Fire resistance Normal combustibility Hygroscopicity Vapour impermeable Durability 30 to 50 years Recyclability 100% GWP A1-A3 42,2 kgCO₂eq (per m2 with 25mm thickness) 1688 kgCO₂eq per m3 Nearest origin to Stavanger Notodden(440 km drive) Transports 440 km (lorry) Price 470-940 kr/m3

What is it? Air tight panels Known as Vacupor/Kevothermal Invented in 1970's Compound Synthetic Building use Roof, wall, fl oor and pipes Other uses Refrigerators, thermal bottles

VIP - VACUUM INSULATION PANELS

Local Natural Low tech Traditional Low maintenance Low emitting Safe ingredients Cold w environmental footprint Easy installation Waste to landfill Sound absorbing

Unstable and sensitive Low cost Visually pleasing COMMENTS:

Global Synthetic High tech Modern High maintenance High emitting Toxic ingredients Warm High environmental footprint Expert installation Recyclable waste Sound transmitting Robust and resilient High cost Ugly

Low conductivity Low thickness Recyclable Compressive strength High ghg emissions Not so fl exible Expensive Vacuum is hard to keep constant, it gets less and less hard with time, especially in hot temperatures conditions. VIPs are very sensitive to puncture. PHYSICAL PROPERTIES

Thermal conductivity 0,040W/mK Density 100-130 kg/m3 Fire resistance Euroclass E Hygroscopicity High vapour transmissivity Durability High Recyclability Recyclable GWP A1-A3 32,62 kgCO₂eq per m3 Nearest origin to Stavanger Southern Europe (France, Spain, Portugal...) Transport Ca 3000km (lorry) Price ≈ 230 kr/m2

EXPANDED CORK PANELS

What is it? Steam-expanded cork Known as ICB - Insulation Cork Board Invented in 1891, factory of John T. Smith Compound Natural Building use Walls, Roof, ground Other uses

100% natural Renewable origin Thermal resistance Accoustic insulation Biodegradable Production only around the Mediterranean Sea

Local Natural Low tech Traditional Low maintenance Low emitting Safe ingredients Cold Low environmental footprint Easy installation Waste to landfill Sound absorbing Unstable and sensitive Low cost Visually pleasing COMMENTS:

Global Synthetic High tech Modern High maintenance High emitting Toxic ingredients Warm High environmental footprint Expert installation Recyclable waste Sound transmitting Robust and resilient High cost Ugly

"The perfect green insulation material."

PHYSICAL PROPERTIES

Thermal conductivity 0.13 W/mK Density 430 kg/m³ Fire resistance Euro-class D, smoke class s2 Durability Biodegradeable Recyclability 100% GWP A1-A3 25.8 - 49.8 kgCO₂eq Nearest origin to Stavanger Andebu, Vestfold county

Price ≈ 780 NOK per tonne Transports 415 km (lorry) or 550 km (ship)

TIMBER

What is it? solid wood/timber Building use Construction, roof, wall, fl oor and ground Other uses Packaging, heating

Recyclable Biodegradable Natural Thermal reovery Deforestation Habitat destruction

Local Natural Low tech Traditional Low maintenance Low emitting Safe ingredients Cold Low environmental footprint Easy installation Waste to landfill Sound absorbing Unstable and sensitive Low cost Visually pleasing

COMMENTS:

Global Synthetic High tech Modern High maintenance High emitting Toxic ingredients Warm High environmental footprint Expert installation Recyclable waste Sound transmitting Robust and resilient High cost Ugly

Relatively easy to treat - allows large variety of products. PHYSICAL PROPERTIES

Thermal conductivity 0,1-0,3 W/mK Density 380 - 485 kg/m3 Fire resistance Euro class A1, up to 4 hours (retains its physical properties) Durability Boundlessly stable Recyclability 100% GWP A1-A3 117,08 kgCO₂eq Nearest origin to Stavanger Sweden Price ≈ 1000 kr/m3 Transport 865 km (lorry)

LIGHTWEIGHT CONCRETE

What is it? Autoclaved aerated concrete Known as Lightweight concrete blocks Invented in mid-1800s Compounds Natural Building use Construction, Walls

No by-products No toxic waste products Lower transportation costs Compressive strength Precast Low tensile strength Porosity and angularity of the aggregate (Diffi cult to place and fi nish) Longer mixing time

Local Natural Low tech Traditional Low maintenance Low emitting Safe ingredients Cold Low environmental footprint Easy installation Waste to landfill Sound absorbing Unstable and sensitive Low cost Visually pleasing

COMMENTS:

Global Synthetic High tech Modern High maintenance High emitting Toxic ingredients Warm High environmental footprint Expert installation Recyclable waste Sound transmitting Robust and resilient High cost Ugly

Autoclaved aerated concrete (AAC) is well known as an environmentally friendly construction material. The fi nished product is twice the volume of the raw materials used, making it very resource-effi cient.

PHYSICAL PROPERTIES

Thermal conductivity 0,048 W/mK Density 235 kg/m3 Fire resistance - Hygroscopicity Absorbs and releases moisture as humidity changes Durability High - service life corresponds to the building lifetime Recyclability - GWP A1-A3 0,016 - 1,521 kgCO₂eq (R = 1 m2K/W) Nearest origin to Stavanger Gjøvik, Norway Transport (km) Lorry + ferry: 534 Price -

HUNTON BITROC INSULATION

Local Natural Low tech Traditional

What is it? Soft fi berboards impregnated with bitumen Known as Invented in 1970s, Gjøvik, Norway Compound Natural Building use External wind barrier

Low maintenance Low emitting Safe ingredients Cold Low environmental footprint Easy installation Waste to landfill Sound absorbing Unstable and sensitive Low cost Visually pleasing

COMMENTS:

Global Synthetic High tech Modern High maintenance High emitting Toxic ingredients Warm High environmental footprint Expert installation Recyclable waste Sound transmitting Robust and resilient High cost Ugly

Absorbs moisture Reduces cold bridges Small amount of chemicals in fi nal product is harmful to health as they are carcinogenic, mutagenic and reprotoxic. 15mm of Hunton Bitroc equates to almost 10mm of standard mineral wool and a reduction in U-value of 0,01 W/m2K PHYSICAL PROPERTIES

Thermal conductivity 0,038 - 0,05 W/mK Density 100 - 165 kg/m3 Fire resistance No contribution to fi re, melting point >1000 °C, Max. working temperature t°: 430°C Hygroscopicity No increase in weight at 90% relative humidity Durability High Recyclability Recyclable GWP A1-A3 109,23 - 212,22 kgCO₂eq (R = 1 m2K/W) Nearest origin to Stavanger FOAMGLAS - Klášterec, Czech Republic Transport (km) Lorry + ferry: 1480 Price -

CELLULAR GLASS INSULATION

Local Natural Low tech Traditional

What is it? Closed-cell rigid foam Known as Foamglass Invented in 1950s, Unknown Compound Synthetic Building use Walls, Roof Other uses Thermal storage tanks

Low maintenance Low emitting Safe ingredients Cold Low environmental footprint Easy installation Waste to landfill Sound absorbing Unstable and sensitive Low cost Visually pleasing

COMMENTS:

Global Synthetic High tech Modern High maintenance High emitting Toxic ingredients Warm High environmental footprint Expert installation Recyclable waste Sound transmitting Robust and resilient High cost Ugly

Moisture resistance Fire / chemical / vermin / corrosion resistance Thermal resistance Withstand high pressure Fragile Prone to induced damage Expensive (CAPEX + installation) It is lightweight, rigid material composed of millions of completely sealed glass cells. Each cell is an insulation entity, which means it is totally independent of the other cells surrounding it

PHYSICAL PROPERTIES

Thermal condvuctivity 0,015 W/mK Density 150 kg/m3 Fire resistance Not fl ammable Hygroscopicity Waterproof treatment Durability High - not biodegradeable Recyclability 100 % GWP A1-A3 12.5 kgCO₂eq Nearest origin to Stavanger USA Transport 1.80E-01 kgCO₂eq Price ≈ 374.34 kr/m2

AEROGEL

What is it? Silica solid derived from gel Known as Solid smoke, frozen smoke Invented in 1931, Dr. Samuel Kistler Compound Synthetic Building use Roof, wall, fl oor and ground Other uses Industrial, aerospace + –

Ultra Lightweight Very thin Super-insulator No fungae growth High ghg emissions High cost Non-biodegradable

Local Natural Low tech Traditional Low maintenance Low emitting Safe ingredients Cold Low environmental footprint Easy installation Waste to landfill Sound absorbing Unstable and sensitive Low cost Visually pleasing

COMMENTS:

Global Synthetic High tech Modern High maintenance High emitting Toxic ingredients Warm High environmental footprint Expert installation Recyclable waste Sound transmitting Robust and resilient High cost Ugly

Although it is being invented in 1931, the material is not being used commonly in building insulation. Main applications are mostly in oil industry and aerospace because of the high thermal properties and cost. PHYSICAL PROPERTIES

Thermal conductivity 0,036 W/mK Density 40-100 kg/m3 Fire resistance Non-combustable Hygroscopicity Water repellent Durability High - not biodegradeable Recyclability 97 % GWP A1-A3 1,27 kgCO₂eq Nearest origin to Stavanger Trondheim, Moss Transport 1,19e-02 kgCO₂eq Price ≈ kr/m2

ROCKWOOL INSULATION

What is it? Fibrous insulation Known as Stone wool, slag wool Invented in 1840, Edward Parry Compound Natural Building use Roof, wall, fl oor and ground Other uses Industrial

Thermal resistance Sound absorber Common No fungae growth Thick Non-biodegradable

Local Natural Low tech Traditional Low maintenance Low emitting Safe ingredients Cold Low environmental footprint Easy installation Waste to landfill Sound absorbing Unstable and sensitive Low cost Visually pleasing

COMMENTS:

Global Synthetic High tech Modern High maintenance High emitting Toxic ingredients Warm High environmental footprint Expert installation Recyclable waste Sound transmitting Robust and resilient High cost Ugly

It is the second most common insulator used in buildings. Can be rigid and semi-rigid panels to fi t various function in buildings.

FOUNDATION

STUDENTS

Emilie Botella Claire McConnell Kristian Bøe Fei Ding Jason Andrew Hannah

PHYSICAL PROPERTIES

Density 2382 kg/m3 Thermal conductivity 0.7 - 1.3 W/mK Permeability 1E-10 cm/s Lifetime 50-100 yrs Waste 23.7 (kg/ m3 (% recyclable) Embodied energy A1-A3 2230 MJ/m3 Water use 643 L/m3 GWP A1-A3 244 kgCO₂eq/m3 Nearest origin to Stavanger Tananger Transport (km) Lorry: 14 km Price 1305 NOK/m3

READY-MIX CONCRETE WITH FLY ASH

What is it? Concrete with cement using 19% fl y ash from coal-based electricity generation First used mid-1900s Compound Synthetic with some organic components Building use Foundation (walls, roof, fl oor)

COMMENTS:

Improved workability Increased strength Reduced permeability Coal production waste Reduced early strength Argued toxic ingredient Larger amounts of fl y ash can be added to cement for proportional increase in strength and decrease in embodied energy and emissions. Typically, ranges from 15-25% composition in portland cement. PHYSICAL PROPERTIES

Density 2420 kg/m3 Thermal conductivity 0.7-1.3 W/mK Permeability 1E-10 cm/s Lifetime 100+ yrs Waste 31.7 (~76%) kg (% recyclable) Embodied energy A1-A3 1687 MJ/m3 Water use 211 L/m3 GWP A1-A3 203 kgCO₂eq/m3 Nearest origin to Stavanger Sandnes Transport (km) Lorry: 21 km Price 1310 NOK/m3

READY-MIX CONCRETE WITH BLAST FURNACE SLAG

What is it? Concrete with cement using 29% blast furnace slag First used 1909 Compound Synthetic with some organic components Building use Foundation (walls, roof, fl oor)

COMMENTS:

Recyclable Industrial byproduc Reduced permeability More chemically stable Some strength reduction Larger amounts of slag can be added to cement. Higher levels of blast furnace slag (50% and above) have been proven to perform mechanically similar to concrete using regular portland cement.

PHYSICAL PROPERTIES

Density 7850 kg/m3 Thermal conductivity 26-48.6 W/m K Fire resistance Non combustible Tensile Strength 450- 600 MPa Lifetime ≥50 years. Dependent on place and protection. Recyclability 81% GWP A1-A3 9734 kgCO₂eq/m3 Nearest origin to Stavanger Ferrometall AS, Drammen Transport (km) Euro 5, 28t payl. (513 km drive) Price N/A

THREADED STEEL CORE PILES

Materials Steel with alloys How to use? Drilled into the ground or with steel tubes Scrap content 85% Building use Foundation

COMMENTS:

Resistant to water and salt Resistant to frost Recyclable and durable Compressive strength Cost and time saving Skin friction Bearing capacity error Ground displacement Disturbance of soil layers Since steel can be recycled indefi nitely, the effect of recycling on energy saving is asymptotically decreasing. For this study, Worldsteel data for hot rolled steel sections has been used, which gives an 85% scrap content averaged from European steel works. And the most signifi cant impacts of LCA comes from the production of steel, given in A1. PHYSICAL PROPERTIES

Density 7850 kg/m3 Thermal conductivity 24.3-65.2 W/m K Fire resistance Non combustible Tensile Strength 276-1882 MPa Lifetime Equal to the lifetime of the building Recyclability 92% GWP A1-A3 2551 kgCO₂eq/m3 Nearest origin to Stavanger Norsk Stål AS, Søgne Transport (km) Euro 6, 27t payl. (216 km drive) Price N/A

RIBBED REINFORCEMENT BARS ARS

Materials Iron 98-99%, Carbon 0,05-0,02% Silicon 0,2% Manganese 0,3-0,7% Scrap content 100% Building use Any reinforced concrete structure.

Resistant to water and salt Better Structural properties Recyclable and durable Lower Cost of reinforcement Less labour charge Heavy and transport cost Lower fi re resistance High demand COMMENTS:

Reinforcement bars are steel rods that are used as a tension device in concrete reinforcement. When embedded into concrete, the steel is able to alleviate the tension that is imposed on the concrete by distributing the tension evenly over a large area.

PHYSICAL PROPERTIES

Density 470 kg/m3 Thermal conductivity 0.13 W/mK Lifetime 60 yrs Water use -4.60E+00 l/m3 GWP A1-A3 -6.63E+02 kgCO₂eq/m3 Nearest origin to Stavanger Moelven, Norway Transport (km) Lorry: 546 km Price 14 000 NOK/m3

NORWEGIAN GLUE LAMINATED TIMBER

What is it? Glue laminated timber Invented in Dates back to 1866 Compound Natural Building use Roof beams, edge beams, joists, hall constructions

Good strenght to weight ratio Sustainable Locally available Flexibility Apperance If landfi lled, glulam could result in a greater greenhouse gas emission than steal COMMENTS:

Glulam is a very fl exible, locally available material, with a good strength to weight ratio. Glue laminated timber is a way to optimize the structural values of the renewable resource wood. Norwegian glulam is made of pine or spruce. PHYSICAL PROPERTIES

Density 430 kg/m3 Thermal conductivity 0.13 W/mK Lifetime 60 yrs Water use -2.51E+02 l/m3 GWP A1-A3 -6.07E+02 kgCO₂eq/m3 Nearest origin to Stavanger Gåsland Transport (km) 60 km Price NA

SPRUCE (FRESH TIMBER)

What is it? Timber for construction Compound Natural Building use Walls, Roof

L i g h tCould rot or be Easily accessibleexposed to mold TraditionalNot as strong as some C h e a pother materials Sustainable COMMENTS:

Beams and columns made of spruce or pine are cheap and easily accessible. Could be treated or non-treated. Often locally available, minimizing the need for polluting transport.

PHYSICAL PROPERTIES

Density 1,980 kg/m3 Thermal conductivity 0.8 W/mK Compressive Strength 18.7 MPa Lifetime 500+yrs (if there is not an overexposure to moisture) Waste 17.29 kg (100% recyclable) Embodied energy A1-A3 9,432.72 MJ/m3 Water use 80,114.76 L/m3 GWP A1-A3 461.34 kgCO₂eq/m3 Nearest origin to Stavanger Manurfactured in Denmark Transport (km) Lorry: 1,050km Price 8,154 NOK/m3

RED CLAY BRICK

What is it? Red clay brick First used Approx 4,000 BC Compound Natural products - Clay, sand, Water Building use Walls, fl ooring, paving Other uses Fireplace, Concrete aggregate + –

Durable/long lifespan High ghg emissions Thermal resistance Destructive to landscape Recyclable when mining clay Low maintenance Thermal mass properties COMMENTS:

The manufacturing process for clay bricks involves extraction of clay, crushing & grinding, shaping, drying and fi ring. Firing is typically undertaken in kilns under temperatures of 1000-1200°C using coal power. This process has a high environmental footprint. PHYSICAL PROPERTIES

Density 1,980 kg/m3 Thermal conductivity 0.8 W/mK Compressive Strength 18.7 MPa Lifetime 100+yrs (based on brick that has no signs of damage) Waste 3.27 kg (% recyclable) Embodied energy A1-A3 0 MJ/m3 Water use 421.74 L/m3 GWP A1-A3 0 kgCO₂eq/m3 Nearest origin to Stavanger Sourced from older buildings in Southern Norway Transport (km) Lorry: Upto 200km

RECYCLED RED CLAY BRICK

What is it? Recycled Red Clay Brick (Re-used or salvaged brick) First used Adopted 1000's of years ago Compound Natural products - Clay, sand, water Building use Walls, fl oor, paving Other uses Fireplace, concrete aggregate + –

COMMENTS:

Minimal GHG emissions More labour intensive to Durable remove old mortar Thermal resistance Life span reduced to a Low maintenance certain extent Thermal mass properties The use of recycled brick is increasing due to the high embodied energy of new bricks. In terms of use for a foundation, the roughened exterior of recycled bricks may make it uncomfortable under foot. The use of matting is an option to eliminate this factor.

PHYSICAL PROPERTIES

Density 1499 kg/m3 Thermal conductivity 0.74 W/m K Fire resistance Depend on the thickness of brick Compressive Strength 43.13 MPa Durability ≥ 100 years Recyclability 90% GWP A1-A3 N/A Nearest origin to Stavanger N/A Transport N/A Price N/A

Materials Red, yellow and black clay, Spent earth, Sludge waste. Building use Foundation, walling.

CLAY BRICK WITH OIL INDUSTRY WASTE

Strong and Durable Thermal Performance Recyclable Acoustic Performance Fire Resistance Time consuming Unresistant to earthquake Water absorbing Low tensile strength Hard for cleaning COMMENTS:

From the study, the incorporation of sludge from pomace oil extraction industry or spent fi ltration earth of clay was more benefi cial, with compressive strength values similar to bricks without waste and a 6 and 14% improvement in thermal conductivity, respectively. PHYSICAL PROPERTIES

Density 2600 kg/m3 Thermal conductivity 3 W/m.°C Compressive Strength 24,7 MPa Lifetime 500+yrs (dependent on thermal performance, resistance to chemicals and construction) Fire resistance Non combustible Hygroscopicity 0,1-0,5% GWP A1-A3 58,1 kgCO₂eq /ton Nearest origin to Stavanger Oppdal, quarry Minera Skifer Transport Lorry - 937km

QUARTZITE

What is it? Mainly quartz Known as Natural stone, quartzite schist Compound Natural Building use Walling, cladding plinths, fl oors, paving and stairs

COMMENTS:

Resistant to rain, frost, acids and soluble salts Recyclable and durable Compressive strength Thermal capacities Negligible maintenance Hard to work with Damages when fi xed to materials with differing thermal movement Low resistance to earthquakes Of all masonry products, natural stone is one of the most durable. Bricks and concrete deteriorate with water penetration, bricks cannot be placed below grade, concrete cracks and is hard to repair. Stone has not these problems. It came from the ground and can be buried for 1,000 years looking the same. Natural stone can be used as quarried or can be shaped with tools or machines, depending on the construction. Rubble (undressed stone) can be employed for foundations in all cases with or without mortar.

PHYSICAL PROPERTIES

Density 2400-2900 kg/m3 Thermal conductivity 3,0 W/m.°C Compressive Strength 50 MPa Lifetime 500+yrs (dependent on thermal performance, resistance to chemicals and construction) Fire resistance Non combustible Hygroscopicity 0,1-0,5% GWP A1-A3 58,1 kgCO₂eq /ton Nearest origin to Stavanger Jelsa, Rogaland, Norsk Stein AS Transport Lorry - 111 km

GRANITE

What is it? Mainly felspar, quartz and mica Known as Dimension stone Compound Natural, igneous magmatic rock Geological age Permian (250MA) Building use Walling, cladding plinths, surrounds and steps

Resistant to rain, frost, most of chemicals Recyclable and durable Compressive strength Thermal capacities Negligible maintenance Hard to work with Low resistance to earthquakes Effl orescence and spalling caused by certain salts COMMENTS:

Formed by the cooling of molten magma forced up through crakcs in the earth's crust. Extraction of rock is possible with simple tools, but skill and experience is essential to ensure accurate cuts. Granite requires more sophisticated mechanized equipement. It can be used completly, without wastage. It tends to have a preferred sawing plane, the direction to get the nicest looking slabs. PHYSICAL PROPERTIES

Density 1950-2550 kg/m3 Thermal conductivity 1,5 W/m/°C Compressive Strength 10 MPa Lifetime 500+yrs (dependent on thermal performance, resistance to chemicals and construction) Fire resistance Non combustible Hygroscopicity 2-8,5% GWP A1-A3 3,10E+00 kgCO₂eq /ton Nearest origin to Stavanger Florø, quarry Norwegian Sandstone Export Transport Ship - 360km

SANDSTONE

What is it? Quartz in all mica and felspar grains in some. Bonded largely with sillica or calcium carbonate Known as Natural stone, aggregates Compound Natural, sedimentary rock Building use Walling and cladding Other uses Concrete, roads and civil engineering construction

Easy to work with Thermal resistance Resistant to wheathering

Attacked by acids Affected by soluble salts Become soiled in urban athmosphere

COMMENTS:

Sandstone is a typical sedimentary rock, including lake sedimentation and sea sedimentation. It is a type of aggregate which can be used in the production of concrete. Older sandstones tend to be tougher and more suitable for aggregate use. Geological materials with different grain sizes, such as sandstone aggregates have been exploited as a popular building material from ancient times. It is relatively soft and resistant to weathering, make it easy to carve and work.

WINDOWS & DOORS

STUDENTS

Andrea Reinlund Hansen Orlane Guillouet-Lamy Deni Nae Isabella Netz Karine Hemstad

PHYSICAL PROPERTIES

Size Min:450 x 450 cm Max: 1240 x 2500 cm U-value 0,67-0,75 W/m2K Energy transmittance 53-61 % Sound reduction 32 dB Durability 40 years Recyclability 2 % GWP A1-A3 73,81 kgCO₂eq Origin Nordhorn, Germany Transport 1175 km EPD EPD-VAR-2017016-IBA1-DE

HOLZFENSTER ENERGYFRAME II

What is it? Triple glazed window with wooden frame and a thermal break made of polyurethane Produced by Variotech Compound Synthetic Building use Window

Local Natural Low tech Traditional Low maintenance Low emitting Safe ingredients Cold Low environmental footprint Easy installation Waste to landfill Sound absorbing Unstable and sensitive Low cost Visually pleasing Global Synthetic High tech Modern High maintenance High emitting Toxic ingredients Warm High environmental footprint Expert installation Recyclable waste Sound transmitting Robust and resilient High cost Ugly

COMMENTS:

Variotech is a known producer of high quality materials and components. High tech solutions and research ensures quality and lower emissions. The Variotech Energy frame II is a wood frame window with a thermally insulated wooden profi le. Noise protection and natural materials help improve the indoor quality. PHYSICAL PROPERTIES

Size 1,80 x 65 cm + arch U-value 0,8 W/m2K (passive house standard) Energy transmittance Sound reduction - Durability 40 + years Recyclability - GWP A1-A3 Origin Vikeså, Norway Transport 52 km EPD -

REUSING THE EXISTING WINDOW

What is it? Double glazed window with wooden frame. Adding one layer of glass and argon fi lling Produced by Sendt to Vikeså vindu Compound Synthetic Building use Window

COMMENTS:

Local Natural Low tech Traditional Low maintenance Low emitting Safe ingredients Cold Low environmental footprint Easy installation Waste to landfill Sound absorbing Unstable and sensitive Low cost Visually pleasing Global Synthetic High tech Modern High maintenance High emitting Toxic ingredients Warm High environmental footprint Expert installation Recyclable waste Sound transmitting Robust and resilient High cost Ugly

The existing windows of the building are not of high aesthetic value,and are not the original ones that carry any historic value, so they might not be worth keeping. However keeping them has several benefi ts like lowering the labour demand and reducing the impact on the environment. Since reusing the existing windows will result in creating less waste during the refurbishment and there will be a smaller need of newly-produced windows, keeping them will result in creating less carbon emissions. It will probably be sent to a company to place an extra glass and fi ll the cavatie with gass, in this case we chose Vikeså vindu close to Stavanger.

PHYSICAL PROPERTIES

Size Costum made U-value 0,8 W/m2K or better Energy transmittance - Durability 40 + yeas Recyclability - GWP A1-A3 - Origin Stavanger, Norway (Støperigata) Transport 0,2 km EPD -

What is it? Triple glazed window with frame made of reinforced composite Produced by Vinduskredderen Compound Synthetic Building use Window

IDEAL 600

COMMENTS:

Local Natural Low tech Traditional Low maintenance Low emitting Safe ingredients Cold Low environmental footprint Easy installation Waste to landfill Sound absorbing Unstable and sensitive Low cost Visually pleasing Global Synthetic High tech Modern High maintenance High emitting Toxic ingredients Warm High environmental footprint Expert installation Recyclable waste Sound transmitting Robust and resilient High cost Ugly

There is a lack of information due to absence of answers from Vinduskredderen. This window is however interesting because it is produced in the same street as the canning factory. Vinduskredderen are costum making windows and can make them fi t our building, the sourrounding buildings and passive house standards. PHYSICAL PROPERTIES

Size 1,23 x 1,48 m U-value 0,7 W/m2K Energy transmittance - - Durability 40/60 years Recyclability 0 % (but 15,4% energy recovery) GWP A1-A3 103/128 kgCO₂eq Origin Moy, Norway Transport 94 km EPD NEPD 00176E Rev. 1

NORDAN SAFETY

What is it? Inward opening tilt and turn Triple glazed window with wooden frame/ and alu clad. Produced by NorDan Compound Synthetic Building use Window

COMMENTS:

Local Natural Low tech Traditional Low maintenance Low emitting Safe ingredients Cold Low environmental footprint Easy installation Waste to landfill Sound absorbing Unstable and sensitive Low cost Visually pleasing Global Synthetic High tech Modern High maintenance High emitting Toxic ingredients Warm High environmental footprint Expert installation Recyclable waste Sound transmitting Robust and resilient High cost Ugly

The window is tested in the Norwegian climate, and has an indoor climate certifi cation: M3. The window can be opened and has 7 solid locking points. This can increase the comfort because it provides you with access to fresh air, and gives a feeling of security. The glazing is called “safety glass”, and has features that make it less likely to break, or less likely to pose a threat when broken. It is much harder to break in, something that is very relevant for our building in Stavanger, which has entrances and windows in different levels connected to the ground.

PHYSICAL PROPERTIES

Size Max: 2500 x 1500 mm (touhened: 4000 x 2000 mm) U-value 0,7 W/m2K Energy transmittance Sound reduction Durability 30+ years Use of recycled materials 25 % GWP A1-A3 - Origin Halmstad, Sweden Transport 859 km EPD -

PILKINGTON ACTIVE

What is it? Triple glazed window with argon filled cavities

Produced by Pilkington Compound Synthetic Building use Window

Local Natural Low tech Traditional Low maintenance Low emitting Safe ingredients Cold Low environmental footprint Easy installation Waste to landfill Sound absorbing Unstable and sensitive Low cost Visually pleasing Global Synthetic High tech Modern High maintenance High emitting Toxic ingredients Warm High environmental footprint Expert installation Recyclable waste Sound transmitting Robust and resilient High cost Ugly

C O M M E N T S :

The Pilkington Activ suncool™ glass is a self-cleaning glass. The unique dual-action of the glass coating uses the forces of nature to help keep the glass free from dirt, giving not only the practical benefi t of less cleaning, but also clearer, better-looking windows. Since the glass is self-cleaning, the need for manually washing the windows is heavily reduced, saving time and money. The glass also has solar control properties that reduces the need for cooling the indoor air, and therefore reduces the energy-use in the building as well as enhancing the comfort. PHYSICAL PROPERTIES

Size 100 x 200 cm Weight U- value 0,29 W/m2K Fire resistance 3 hours Air infi ltration 0,04 cfm/sqft Sound reduction - Durability 30+ years Recyclability 92 % GWP A1-A3 1,31E+02 kgCO₂eq Origin Milan, TN, USA Transport ?? EPD EPD-ASA-20130282-IBC1-EN

TRIO-E STEEL STIFFENED DOOR

What is it? Steel door made from cold rolled or galvanized steel with polyurethane foam in the core Produced by Assa Abloy Compound Synthetic Building use Door (inner or outer)

Local Natural Low tech Traditional Low maintenance Low emitting Safe ingredients Cold Low environmental footprint Easy installation Waste to landfill Sound absorbing Unstable and sensitive Low cost Visually pleasing

COMMENTS:

Global Synthetic High tech Modern High maintenance High emitting Toxic ingredients Warm High environmental footprint Expert installation Recyclable waste Sound transmitting Robust and resilient High cost Ugly

This trio-E steel stiffened door is greenguard certifi ed which makes it safe for both housing and schools. It is also certifi ed as a safety door due to its construction. 58,8 % of the steel used in the door is already recycled steel and Assa Abloy has an end of life program to make sure the door is recycled or reused after its lifetime has expired. The positive features of this door is its durability and strong materials which might suit the climate. The negative feature is the long transportation from the USA.

PHYSICAL PROPERTIES

Size 1100 x 2200 x 100 mm + Frame: 95 x 95 mm Weight U-value 0,62 W/m2K Fire resistance Airtightness V <1,3 m ³ / (hm) <2.25 m³ / (hm) at 100 Pa Sound reduction 30 dB Durability 35 years Recyclability 100% GWP A1-A3 41,27 kgCO₂eq Origin Nordhorn, Germany Transport 1200 km EPD EPD-VAR-2017014-IBA1-DE

VARIOTECH THERMOSAFE 100

What is it? Passiv wooden door Produced by Variotec GmbH & Co. KG Compound Pine, spruce, larch, oak, Building use Main entrance door

Local Natural Low tech Traditional Low maintenance Low emitting Safe ingredients Cold Low environmental footprint Easy installation Waste to landfill Sound absorbing Unstable and sensitive Low cost Visually pleasing

COMMENTS:

Global Synthetic High tech Modern High maintenance High emitting Toxic ingredients Warm High environmental footprint Expert installation Recyclable waste Sound transmitting Robust and resilient High cost Ugly

Variotec can offer a fully tested product range - from the "multifunctional door" on the certifi ed passive house door "Thermosafe 100" to the passive house certifi ed solid wood window "Energyframe". They produce high quality products with pure and untreated materials that are easy to recycle. Their windows are produced in a large scale factory but some of the datails are hand made. The negative feature of this door is that it is quite heavy to open. PHYSICAL PROPERTIES

Size 825 x 2040 x 52 cm Weight 52,3 kg U-value Fire resistance Class B30 Air infi ltration Sound reduction 35 dB Durability 30 years Recyclability(or reuse) 100 % GWP A1-A3 59,7 kgCO₂eq Origin Lyngdal, Norway Transport 160 km EPD NEPD 157E

NORDIC DOOR

What is it? Plywood door Produced by Nordic dørfabrikk Compound Synthetic Building use Door inside

COMMENTS:

Local Natural Low tech Traditional Low maintenance Low emitting Safe ingredients Cold Low environmental footprint Easy installation Waste to landfill Sound absorbing Unstable and sensitive Low cost Visually pleasing Global Synthetic High tech Modern High maintenance High emitting Toxic ingredients Warm High environmental footprint Expert installation Recyclable waste Sound transmitting Robust and resilient High cost Ugly

Produced in Lyngdal, Norway. The wooden door is tested in local climate, and has an indoor climate certifi cation: M3. The factory runs on 52 % renewable energy and all materials can be separated and recycled or reused.The factory is relatively small scaled and most of the details are made by hand, which supports the local craftsmanship and traditions.

WINDOWS & DOORS DISCUSSION

To compare the different windows and doors we made a table with grades from 1 to 10, where 1 is the lowest score, and 10 is the highest score. We selected 14 different types of parameters we found important for choosing the right products. Some of the values are scientifi c, from EPD’s and other information we gathered. Not all of the products had EPD’s, so it was diffi cult to fi nd comparable values, so we had to make some assumptions that are not equally accurate. We calculated the average value for each window and door to fi gure out which products had the highest total grade. When we calculated the total grade, all the values are weighted equally, meaning that the environmental damage count the same as for example the maintenance. Therefore the product with the highest total grade, might not always be the best choice. All the parameters should be looked at and taken into consideration when deciding a product for your project. Maybe cultural heritage and community gain is more important to you than the price, or maybe the environmental and u-value is more important for your project. The window with the best total grade was the window from Vindusskredderen, and the door with the best grade was the inner door from Nordic Dørfabrikk. Both of these products are manufactured locally, which gave them high grades for transportation, global-local and community gain.

DISCUSSION TABLE

PARAMETERS NorDan NTech Variotech Extra glass Vinduskredderen NorDan Safety Pilkington

u value (W/m2K) 0,7 0,7 0,8 0.8 0.7 0,7 GWP 102/115 78,8 103/128 (grades 1 to 10) u value grade 9 9 8 8 9 9 environmental damage 7 8 9 6 7 7 distance from production to site 8 4 9 10 8 5 global - local 6 2 9 10 6 6 synthetic - natural 4 4 6 5 4 2 heritage value 5 2 7 10 5 2 community gain 7 2 7 10 7 5 health 8 7 6 8 9 7 production time 8 8 4 6 8 8 expensive - cheap 7 7 4 3 6 3 recycling potential 5 7 4 4 5 5 lifespan 9 8 8 8 8 9 maintenance 5 4 3 3 7 8 repair 8 6 7 7 8 4

GRADE

6,9 5,6 6,5 7,0 6,9 5,7

producer Nordan Variotech Vikeså vindu Vinduskredderen Nordan Pilkington country Norway Germany Norway Norway Norway Sweden distance 94km 1175 km 52 km 0,2 km 94 km 859 km

PARAMETERS / DOORS Assa Abloy - Trio-E Steel Wood inner door Inner door Nordic dørfabrikk Variotech Thermosafe 100 u value (W/m2K) 0.29 - - 0,62

acoustic reduction Rw - Ctr (dB) - - 35 30

R value 2,7 - GwP [kg CO2-Eq.] 131 -14,61 60 41,27 (grades 1 to 10)

u value grade 9 5 5 5 acoustic grade 5 5 8 7 distance of production 1 4 8 4 global - local 4 6 9 4 synthetic - natural 4 6 6 7 heritage value 3 4 7 4 community gain 1 7 9 4 health 4 6 7 8 production time 8 6 7 8 expensive - cheap 7 8 8 7 recycling potential 9 8 8 8 lifespan 8 7 8 8 maintenance 8 7 8 8 repair 7 8 8 7

GRADE

5,6 6,2 7,6 6,4

order best to worse 3 2 1 2