3 minute read

Studying superconducting cables for ITER

INNOVATION FOR INDUSTRY Studying superconducting cables for ITER

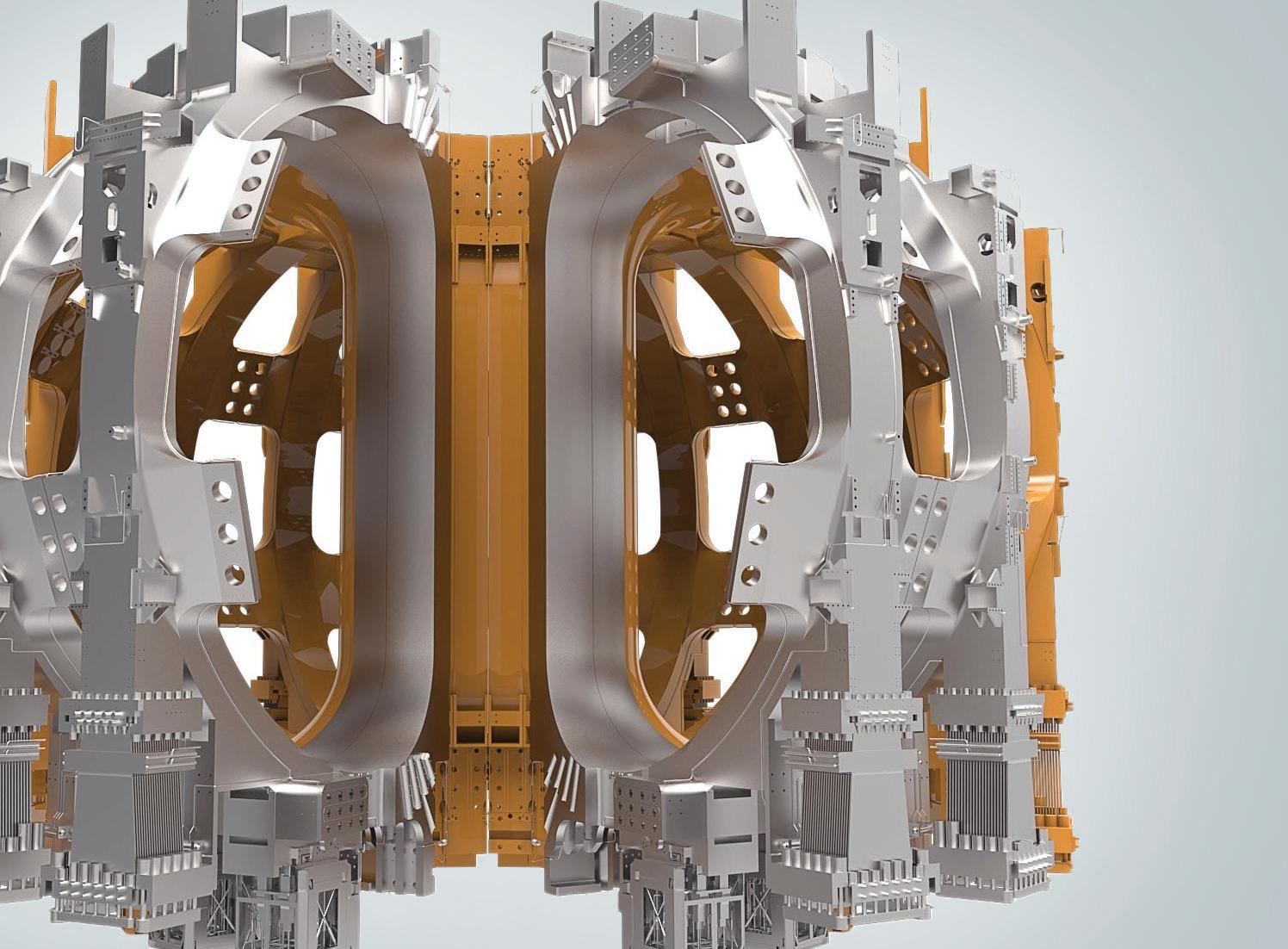

ITER (International Thermonuclear Experimental Reactor) is one of the major energy projects in the world, using fusion for energy-production and consequently involving many technological challenges.

Superconducting cables, designed to create plasma magnetic trapping and based on Nb3Sn superconductor media, are at the core of the project and therefore performance of the cables is a central issue.

The two most important superconducting cables for ITER are the toroidal field (TF) and central solenoids (CS) that have extremely complex structures. They both utilise the Cable-In-Conduit Conductors (CICC) design with a central spiral and a rectangular steel jacket with a thick wall of more than 8 mm (for CS) or a 2 mm thick circular jacket for the TF cable.

Superconductivity is provided by a large number of Nb3Sn-based strands (576 for CS and 900 for TF) mixed with pure copper strands (288 for CS and 522 for TF). Each Nb3Sn strand, while being only 820 µm in diameter, in its turn, is a composite structure; it has 12787 Nb3Sn filaments of 2.8 µm in diameter surrounded by a copper matrix. There are additional microelements, including a 8 μm thick Nb barrier and Cr 2.4 µm thick plating, making the design and production of the cables state-of-art.

It has been known for a long time that strain in Nb3Sn strands affects their critical current carrying capacity, and it is easy to see how significant strain is expected to be present.

During operation of the ITER CS conductors at a temperature of 4.3 K, the transverse electromagnetic (Lorentz) forces are generated by the current of 40,000 Amps under the magnetic field of 13.0 Tesla (68,000 Amps under 11.8 Tesla for TF) causing unevenly distributed loads at the strand-to-strand contacts along their length.

Moreover, the differential thermal contraction between materials of the strands produces thermal strains. Strain is also introduced in the production stage during thermal processing of the cables.

But the most dramatic problem is the long-term performance of CICC: according to previous studies on CICC prototypes, the critical current properties degrade with an increase in number of current / magnetic field cycles: in the very first tests, the CICC failed standards after just 1,000 cycles while the quality standards requested 60,000 cycles. The degradation of superconducting properties due to thermo-electromagnetic cycling is caused by accumulation of micro-damage from a build up of strains and stresses in the material.

Neutron diffraction is an ideal method of analysing the stress state of the cables because of the great penetrating ability of the neutron and the ability to measure phases separately and do this very accurately.

Since Japan is one of the main producers of the CICC (JASTEC, Hitachi, Furukawa), intensive analysis had been underway at the Japanese national neutron facilities, J-PARC and JRR-3. However, the measurements were halted and interrupted by the 2011 Tohoku earthquake, which resulted in a shutdown of the Japanese neutron facilities. Subsequently, ANSTO stepped in providing access to its neutron beam instruments to continue this vital work.

The Japanese line of research focused on the thermo-elastic response and anisotropy of copper and Nb3Sn at cryogenic temperatures, while the research at ANSTO has focused on phase, texture and residual stress characterisation of the CICC, both the TF and CS versions, using the residual stress diffractometer Kowari.

For the first time the residual stress state of all phases of the composite (88% Cu,

10% Nb3Sn and 2% Nb) was measured for three cable pieces cycled at different magnetic field conditions. A difference between stresses of the samples provided a direct evidence of microdamage due to thermo-electro-magnetic cycling and established a link to the deterioration mechanism.

The results of the measurements provide a solid experimental basis for further advancing the interpretation of the details of micro-mechanical damage mechanism and a dataset for validation of micro-mechanical modelling.

Contact

vladimir.luzin@ansto.gov.au

COLLABORATORS

1

ANSTO RESEARCHER TEAM

Dr Koichi AKITA

Dr Tsutomu HEMMI

Dr Vladimir LUZIN

Dr Hiroshi SUZUKI

2

2

1

2

2

Japan Atomic Energy Agency (JAEA)

RESEARCH FACILITY / TECHNIQUE

Australian Centre for Neutron Scattering (ACNS)

Kowari

Strain scanner

www.ansto.gov.au/acns/kowari

HUMAN HEALTH Human health

Using nuclear tools and techniques, ANSTO undertakes a range of research into common diseases including cancer, obesity, diabetes and influenza as well as Alzheimer’s, Parkinson’s and neurodegenerative diseases. ANSTO’s work improves patient health outcomes and ultimately improves the health of all Australians.