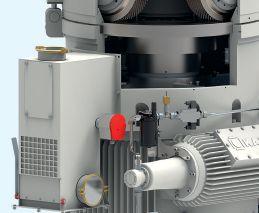

When it comes to safety in the world of wood products, few things are as essential as dust management and fire protection.

Companies are seeking fire and explosion suppression technologies to minimize or eliminate expenses linked with production collateral damage, process equipment collateral damage, incident downtime costs, facility collateral costs, and human injury.

AIRPLUS Industrial is a leading and integrated provider in industrial dust control, ventilation, OEM fan applications, spark detection, fire and explosion suppression, and complete compressed air solutions including air dryers, air receivers, filters, and air piping systems. We are also a leading supplier of breathing air systems, industrial vacuum, abrasive blasting, clean air, and aftermarket parts and services.

The Firefly Water Mist Suppression System is a highly innovative, continuous-duty technology, with the ability to detect and extinguish fires within a process without halting production. The system also has the capability to detect hot black particles, which contain enough energy to start a fire. We have delivered three large Firefly projects to major mills across Western Canada and are in the process of delivering a fourth.

Conventional sprinkler or deluge systems offer effective

overall protection for facilities, but they are unsuitable for highrisk locations or critical systems. In the time it takes a sprinkler system to activate, a fire has most likely already caused damage and spread throughout the facility. The Firefly Quick Suppression System is designed to respond within seconds to avoid or minimize property damage and production downtime losses, as well as preventing a fire from spreading and growing into other areas, to enhance workplace safety.

AIRPLUS Industrial is an authorized Service Center for Firefly systems. Please call us for your annual re-certifications.

SonicAire fans are used in major mills across Western Canada, including a recent delivery of 40 to one Alberta facility. The use of SonicAire fans is a major contributor to controlling combustible dust mitigation by driving dust down from high settling points, facilitating efficient housekeeping, and drastically reducing secondary explosion risks.

AIRPLUS, located in Langley, B.C., is a specialized company that works alongside leading manufacturers of dust and fire suppression technologies to meet the demands of the wood products sector in Western Canada.

Please visit our website to learn how we can assist with process protection and dust mitigation strategies in your facility.

www.airplusindustrial.ca.

Now, more than ever, Canadians are searching for sustainable heating options for their homes and businesses. With eco-friendly, carbon-neutral fuel options, biomass boilers are becoming increasingly popular.

From wood pellets to wood chips and logs, biomass is made of residual wood from domestic forests and the sawmill industry. In this way, the local economy is promoted, and waste wood is recycled in a sustained matter.

Treating nature with care and caution is part of Hargassner’s philosophy. With the lowest emissions and highest efficiency, maximum comfort and longevity, we are the future-oriented boiler manufacturer.

We provide you with state-of-the-art pellet boilers, wood chip boilers, heating containers and more. The emphasis on research and quality management is our modern understanding of tradition.

All our products are delivered with the latest fully automatic biomass heating technology for all power ranges. Lowest maintenance and long operational life

are guaranteed.

With the remote control via phone or tablet, you may easily change settings on your biomass boiler or even check the current status. Simple, intuitive and boast a design that’s perfectly tailored to your needs!

Sit back and relax. We offer solutions from 32 kW (108,800 BTU/h) to 330 kW (1,122,000 BTU/h) and in cascade up to 2 MW (6,700,000 BTU/h).

Hargassner offers an individual biomass boiler system for each demand. From single-family homes up to largescaled installations for farms, greenhouses, hotels and industry.

We are proud to have 40 years of experience building biomass boilers and more than 140,000 satisfied clients worldwide.

Our boiler systems are officially certified and approved by objective authorities like the U.S. EPA or the CSA.

Hargassner expanded to North America almost 20 years ago. In recent years, a great deal of time and energy has been invested in building up a local infrastructure – ensuring that your needs are fulfilled by your boiler supplier, Hargassner. Order processing has been improved further by optimizing internal processes. To meet the demands of our North American clients, dedicated production lines have been established. Thanks to our local partners we are able to offer our clients excellent customer support coupled with an efficient service structure.

We are currently looking for sales and distribution partners. Become part of our success story and partner up with a leading biomass heating technology pioneer.

For more information, visit us at: www.hargassner-northamerica.com.

After some lengthy setbacks from familiar challenges such as labour shortages and supply chain disruptions, Premium Pellet’s $10- to $12-million expansion project is nearing the finish line.

WorkSafeBC’s Budd Phillips and Alexandra Skinner explain why wood processing facilities should be continually evaluating their dust management programs.

Natural Resources Canada researchers have confirmed that replacing diesel fuel with woody biomass can help mitigate greenhouse gas emissions in northern remote communities.

The Toronto Zoo Biogas Project is converting zoo manure along with other food waste into enough renewable energy to power about 250 homes.

Canadian Biomass presents the official 2022 Wood Pellet Association of Canada Conference show guide.

Canadian Biomass’ annual Pellet Gear Buyers Guide rounds up suppliers of pellet production equipment.

his year was the 10th anniversary of the two B.C. sawmill explosions that killed four people and injured many others.

WorkSafeBC’s investigation for both incidents pointed to a combination of the concentration of dispersed wood dust in the air and friction from moving equipment. Ineffective dust control measures were found at both sites.

It’s an important reminder that complacency can be fatal, especially in an industry that processes a combustible material.

For the sixth year in a row, Canadian Biomass, along with our sister magazine Canadian Forest Industries, turned the spotlight on dust with our annual Dust Safety Week. Over five days from July 11 to 15, we shared on our website and social channels new and archived content from our partners to highlight best practices when it comes to dust management in wood processing facilities.

a tragedy like that from ever happening again,” Phillips says.

From what I’ve seen over the past few years, the wood pellet industry has certainly stepped up to the plate.

The Wood Pellet Association of Canada regularly takes the lead in creating, sharing or participating in initiatives to promote safer pellet operations. They’ve hosted summits, workshops, virtual events and webinars all dedicated to sharing the latest safety research. Their latest webinar on July 18 was on deflagration isolation in wood pellet production, presented by Kayleigh Rayner Brown, an expert in process safety and hazard analysis.

Volume 22 No. 3

Reader Service

Print and digital subscription inquiries or changes, please contact Angelita Potal, Customer Service Rep. Tel: (416) 510-5113 Fax: (416) 510-6875 email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400 Toronto, ON M2H 3R1

Editor - Maria Church (226) 931-1396 mchurch@annexbusinessmedia.com

Contributors - Gordon Murray, Ellen Cools, Anthony Capkun, Alexandra Skinner, Jeff Passmore Group Publisher - Todd Humber 416-510-5248 thumber@annexbusinessmedia.com

Account Coordinator - Kristine Deokaran (416) 510-6774 kdeokaran@annexbusinessmedia.com

National Sales Manager - Rebecca Lewis Ph: (519) 429-5196 rlewis@annexbusinessmedia.com

Quebec Sales - Josée Crevier Ph: (514) 425-0025 Fax: (514) 425-0068 jcrevier@annexbusinessmedia.com

Western Sales Manager - Tim Shaddick tootall1@shaw.ca Ph: (604) 264-1158 Fax: (604) 264-1367

Audience Development Manager - Serina Dingeldein sdingeldein@annexbusinessmedia.com Ph: (416) 510-5124

Media Designer - Curtis Martin COO - Scott Jamieson

Canadian Biomass is published four times a year: Winter, Spring, Summer and Fall. Published and printed by Annex Business Media.

Publication Mail Agreement # 40065710 Printed in Canada ISSN 2290-3097

We’ve included one of those contributions on page 14. WorkSafeBC’s Alexandra Skinner writes about the importance of reviewing dust management programs regularly. She quotes WorkSafeBC prevention field services manager Budd Phillips, who says the pandemic likely drew away resources from proper maintenance and evaluation of those programs. Now, he says, is the time to revamp dust management programs to reflect evolving operational needs.

“We owe it to those who lost their lives or were injured to never forget the impact those explosions had on their families, their job sites and their communities –and to remain vigilant in order to prevent

In her presentation, Rayner Brown recommended pellet operations keep in mind the “inherently safer design” principles of moderation and simplification when building new facilities, considering cap-ex programs, and more. Find the full presentation on the BC Forest Safety Council’s YouTube page.

Why not make Dust Safety Week your yearly reminder to book in a review of your plant’s dust management program? We’ll keep the reminder coming.

And I’d like to once again thank this year’s Dust Safety Week sponsors for making it all possible: Biomass Engineering & Equipment, Fike, VETS Group, Fagus GreCon and Rembe. Access the landing page year round on our website’s menu under Information. •

Subscription Rates: Canada - 1 Yr $57.00; 2 Yr $102.00 Single Copy - $9.00 (Canadian prices do not include applicable taxes) USA – 1 Yr $121.50 CDN; Foreign – 1 Yr $138.00 CDN

Annex Privacy Officer Privacy@annexbusinessmedia.com Tel: 800-668-2374

Occasionally, Canadian Biomass magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above. No part of the editorial content of this publication may be reprinted without the publisher’s written permission ©2022 Annex Business Media, All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

www.canadianbiomassmagazine.ca

Ottawa has published the final version of its Clean Fuel Regulations (CFR), replacing the current federal Renewable Fuels Regulations.

The federal government said in a news release the CFR will drive the development and use of clean fuels and technologies. Once fully implemented, the regulations are expected to help cut up to 26.6 million tonnes of greenhouse gas pollution in 2030 by focusing on emissions throughout the lifecycle of fuels.

The new regulations, along with the previously announced $1.5-billion Clean Fuels Fund, are expected to encourage domestic production of biofuels, strengthening the market for biomass feedstock providers.

Environment and Climate Change Minister Steven Guilbeault said the CFR aims to prop up industries that “will help Canada achieve net-zero emissions while continuing Canada’s role as a global supplier of energy.”

The government estimates that about 2.2 billion litres of additional low-carbon-intensity diesel and 700 million litres of

Ottawa has announced a $515,000 investment in Nova Scotia-based TorchLight Bioresources to study a district energy system that would connect over 90 per cent of buildings in the community and reduce greenhouse gas emissions and heating costs for citizens in New Glasgow, N.S.

The feasibility study will design a heat network that uses renewable biomass and wind energy.

The Town of New Glasgow, TorchLight, Rathco ENG based in Guelph, the Federation of Nova Scotia Woodland Owners and ACFOR (a small New Brunswick-based ecological forestry company) are also contributing to the project, bringing the total investment to $755,000.

Federal funding for this project is provided by Natural Resources Canada’s Smart Renewables and Electrification Pathways (SREPs) program.

“We are incredibly thankful to Natural Resources Canada for supporting this project and to the Town of New Glasgow for placing its trust in us,” said Jamie Stephen, managing director of TorchLight Bioresources.

“District energy systems are proven to provide significant local economic and community resiliency benefits, and we are eager to work with the Town of New Glasgow to design a system that maximizes these benefits for New Glaswegians,” he said.

additional ethanol will be needed in 2030 under the CFR.

Renewable Industries Canada welcomed the final regulations, noting their technical analysis shows that using the CFR GHG calculation methodology, biofuel use in Canada today – including blending ethanol in gasoline and biomass-based diesel in diesel – reduces GHG emissions by 6.1 million tonnes annually.

The B.C. government has earmarked $4 million of its CleanBC funding to expand the existing Indigenous Forest Bioeconomy Program to include a new accelerator stream for scaling up low-carbon forest-based products.

B.C. Forests Minister Katrine Conroy made the funding announcement at the BC Council of Forestry Industries (COFI) annual convention in April. “Our government is taking action to promote healthy forests as a legacy for our children and grandchildren while building a sustainable, innovative forest economy that’s led by Indigenous Peoples,” Conroy said.

B.C.’s Indigenous Forest Bioeconomy Program has delivered 41 projects with 24 Indigenous communities and organizations, such as: essential oils extracted from conifer needles; engineered wood product made from dead and degraded wood from fires and beetle kill; textiles made from bark; and insulation made from scrap wood fibre.

INCA Renewable Technologies announced plans to build a state-of-the art 200,000-square-foot fibre processing and composites manufacturing facility in Vegreville, Alta.

Their chosen location is adjacent to InnoTech Alberta –the Alberta government’s premier research facility for hemp composites, genomics and agronomics. The INCA factory is expected to be operational in early 2024 and create 70 jobs, scaling to about 100 jobs by 2026.

“When ramped to capacity, INCA’s operation will purchase 54,000 tonnes of biomass per year generated from farmers growing hemp for plant-based protein,” said David Saltman, chairman and CEO of INCA. “We will process this renewable resource into highly refined fibre. The short fibre will be transformed into INCA BioBalsa, a direct substitute for the balsa wood used as an essential core material in the construction of boats and wind turbine blades. The long fibre will be sent via rail to our second factory in Bristol, Indiana where we will manufacture BioPanels for the RV industry and BioPlastics for the automotive industry. Winnebago and Toyota are commercialization partners for these products.”

INCA chose Alberta in part thanks to the provincial government’s investments over the past 20 years to develop a thriving hemp supercluster and research capability. Alberta is now a global leader in the production of sustainably grown hemp and responsible for 40 per cent of Canada’s hemp production. INCA’s purchase of waste hemp fibre from local farmers will make hemp a dual use cultivar and one of the most valuable cash crops in the prairies.

Alberta Agriculture Minister Nate Horner said, “by purchasing hemp directly from Alberta’s farmers, and processing it here in the province, this project will mitigate production risks for producers, and create new value-added hemp products that will help grow Alberta’s thriving hemp industry.”

Green Impact Partners Inc. is moving forward with the development of the Future Energy Park – an innovative clean energy project connecting Alberta’s agriculture and energy sectors. Located within the City of Calgary, Future Energy Park is a proposed net CO2-negative biofuels facility using non-food grade wheat to produce renewable natural gas (RNG), and ethanol.

“A first of its kind, Future Energy Park is an exciting opportunity for us to link the circular economy and decarbonize agriculture and our energy future,” said Jesse Douglas, CEO. “The facility will be fully integrated, co-producing two forms of renewable fuels using advanced technology, including CO 2 capture from the production process to go beyond the goal of net zero CO 2 emissions.”

Future Energy Park represents a nearly $1-billion investment in Alberta and Calgary. Once operational, the facility is expected to produce approximately 3.5 million MMBtu per year of RNG, over 300 million litres of ethanol annually, approximately 235,000 tonnes of cattle feed annually, and create carbon credits.

Douglas added, “This significant investment in Alberta will advance the local contribution to the province’s existing Renewable Fuels Standard which requires no less than five per cent renewable fuel content for gasoline blended in the province. Currently, there is a domestic ethanol supply gap which we hope to fill by using a unique and technologically advanced process. The Future Energy Park will forge a new path between Alberta’s energy and agriculture sectors as we work collectively towards making a positive impact and building sustainable, resilient communities for generations to come.”

The proposed facility is being sited in an industrial area in southeast Calgary and will be constructed and operated on 52 acres of land designated for future industrial use. Subject to receipt of major regulatory approvals, Green Impact Partners is targeting completion in late 2024 to early 2025.

The federal government has announced a $81.5-million call for expressions of interest to support research, development and demonstration (RD&D) projects in carbon capture, utilization and storage (CCUS).

Project applications are open now until Oct. 3, 2022, and include three intakes: capture, storage and sequestration, and utilization.

In a news release from Natural Re -

sources Canada, the government said the projects are aimed at emission-intensive industries, such as steel and cement.

“Many of the technologies needed to reach our goal of net zero by 2050 are still in various stages of development, including decarbonization solutions such as CCUS.

The Government of Canada is investing in innovative clean energy RD&D projects to help grow the economy, fight climate

change and create good jobs for Canadian workers,” Natural Resources Minister Jonathan Wilkinson said in the release.

This is the second call in support of CCUS innovation, the first of which focused on front-end engineering and design studies for large-scale projects. Eleven projects were selected in April 2022, including SAF+ Consortium Inc., in Montreal, Que.

By Gordon Murray

Despite the record global demand for wood pellets over the past two decades, biomass, particularly wood pellets, is in the infancy of its evolution. Both domestically and internationally, biomass’ potential in the transformation to a low-carbon, clean and renewable world is almost limitless.

Our vision at the Wood Pellet Association of Canada (WPAC) is two-fold. First, to grow a resilient pellet sector that creates green, renewable products at the forefront of the global transition to a low carbon economy, and second, to maximize the sector’s innovation in the bioeconomy.

In our recent video The Power of Pellets:

Innovation in the Bioeconomy, Fahimeh Yazdan Panah, Ph.D., director of research and technical development at WPAC, explains that the bioeconomy is really the sustainable production of renewable resources and the conversion of these materials into higher value products such as food, bioenergy and bio-based materials.

“Wood pellets offer a world of possibilities not only to meet the targets of greenhouse gas emissions, but also to opening doors to having new and improved products. If you look around your home, everything that is made of plastic today could be made from wood and look exactly the same,” says Yazdan Panah.

Much of the bioenergy opportunities already realized by the Canadian wood pellet sector have been developed over the last decade, supported with nearly $1.6 million in public funding from Natural Resource Canada and Forestry Innovation Investment’s Expanding Market Opportunities program. This funding, directed through WPAC, enabled our sector to grow markets by 260 per cent and to generate $335 million in new sales, which has been invested in new plants, research, technology and people. In sum, we generated $211 for every taxpayer dollar spent to displace fossil fuels with responsible, renewable, clean energy in the form of wood pellets.

By creating a valuable energy product from material that once went to waste, Canadian wood pellet producers can take pride in providing global customers with responsible, low-carbon energy, yet this is really just the tip of the iceberg for the pellet sector.

Our sector has a significant role to play in the growing bioeconomy as well as alleviating energy poverty in places like Canada’s Maritimes and remote Indigenous communities, which are more dependent on fossil fuels.

Today, the wood pellet sector operates more than 50 pellet plants nationwide and is a major employer in many rural areas, providing Canadians with high paying jobs and strengthening local communities. The fact is that global markets also support expansion of domestic opportunities in Canada such as development of new bioproducts and reducing energy poverty.

Ironically, as our vessels depart Canadian ports destined for our export markets that use Canadian pellets to reduce

GHG emissions, those vessels are passed by incoming ones to Canada loaded with coal and crude oil for domestic use.

Science shows that when you increase the demand for bioheat locally, you also contribute to better managed forests. In Sweden, bioenergy, largely in the form of wood, provides 37 per cent of the energy supply. Since 1990, Sweden’s bioenergy consumption has doubled and, at the same time, its standing timber volume has increased by 40 per cent. This increase in standing timber volume is not despite bioenergy, but because of it. With tens of millions of cubic metres of slash left in Canada’s forests every year, we can learn from this Swedish approach.

In Canada, the Williams Lake First Nation and the Tŝideldel First Nation are already at the forefront of this evolution. They have initiated several projects, with funding from the BC Forest Enhancement Society, to rehabilitate Douglas fir forests after a catastrophic wildfire, improve forest resiliency, and transport

uneconomic residuals to support the Atlantic Power facility, which provides power to more than 50,000 homes in British Columbia. The future is here!

The fact is, to realize the full potential of wood pellets, it will take a strong commitment and stable support from government. WPAC looks forward to continuing to work with governments at all levels to realize those opportunities for the benefit of all Canadians and to support global efforts to tackle climate change.

I will give the last word to Gary Bull, Ph.D. forestry economics, professor and head of department for the University of British Columbia’s Department of Forest Resources Management who says, “wood pellets have an incredibly important role to play and we will see a huge evolution. The opportunities for using wood pellets right here at home and around the world are basically limitless.” •

Gordon Murray is the executive director of the Wood Pellet Association of Canada.

This includes Rotary Drum Dryers coupled with Heat Energy systems; TSI also builds Wet Electrostatic Precipitators when required to meet Client’s emission goals. TSI also offers technology for Torrefaction. TSI machinery is custom designed and ranges from 50,000 tons/year to 450,000 tons/year.

By Maria Church

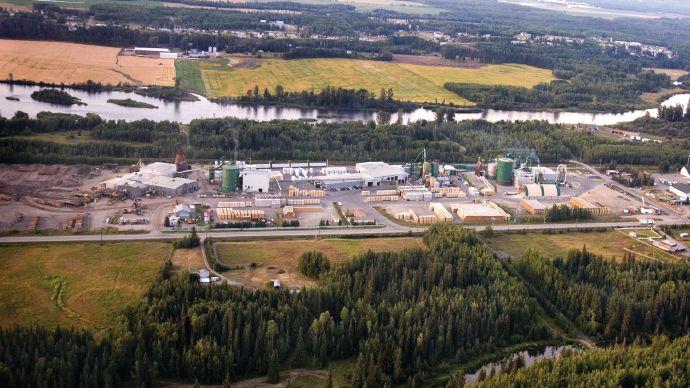

Premium Pellet in Vanderhoof, B.C., is in the midst of a massive cap-ex project that will nearly double its capacity while allowing the facility to accept more low-grade forestry residuals.

The $10- to $12-million expansion project has been more than a year in the making with several lengthy setbacks from now-familiar challenges such as labour shortages and supply chains, but the team is finally eying the finish line.

Site manager Darrel Mohns tells Canadian Biomass the project is mainly driven by the shift in fibre balance within the region. With increased fibre demand, Premium Pellet has had to rely on more harvesting residuals or biofibre to meet its needs.

“Because of that wetter fibre, we knew we needed to add more drying capacity,” Mohns says. The project saw a new triple-pass rotary dryer as well as four additional pellet mills installed, among other components to handle the additional capacity.

Premium Pellet is one of three arms of Nechako Lumber, part of Prince George, B.C.-based Sinclar Group Forest Products Ltd. About an hour’s-drive west of Prince George, the Vanderhoof site is home to a small-log sawmill, a bioenergy plant, and the pellet plant. The fully integrated operation adds value to every part of each log that enters its gates.

Premium Pellet began operations in 2001. The pellet producer offers a unique product, exclusively producing high-grade white wood pellets with about 10 per cent of the pellets bagged for the residential market and 90 per cent shipped in bulk to overseas markets.

With all expansion components in place, Premium Pellet expects to consume nearly 240,000 oven-dried tonnes and have a production capacity of 275,000 tonnes annually – making it the fourth highest producing pellet plant in Canada.

Before 2018, the plant ingested around 60 per cent dry fibre from sawmill residuals and 40 per cent wet material that required drying. Today, that mix has flipped, and sourcing the dry fibre is becoming more and more difficult, Mohns says.

“Lumber operations are now running reduced shifts, fewer days. And [sawmill residuals] supply was tight before they started to do that. A couple sawmills have

come offline making it more difficult to source dry fibre,” Mohns says.

Bio log is now the most readily available feedstock, but the plant needed to retool for it. Premium Pellet sourced used equipment for this project, purchasing everything from a recently dismantled U.S. pellet plant.

“We ended up going into an expansion project, had that old mill dismantled and shipped to us, and we’ve been basically

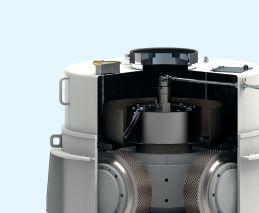

Our pellet mill 65-1500 outperforms the competition: With a throughput of up to 12 t/h, it is currently the largest flat die pellet mill for the wood sector. Worldwide, flat die pellet mills from AMANDUS KAHL produce more than 10 million tons of domestic fuel and industrial pellets from hardwoods and softwoods every year, and the trend is rising.

assembling that around the plant here. It’s been over a year already, with Phase 1 ready to run once we receive our Ministry of Environment (MOE) permit. We’re well into Phase 2, which is installing all the pellet manufacturing equipment and external pieces,” Mohns says.

Phase 1 involved the installation of a Brunette BioSizer to run alongside the current Bliss 4460 hammermill, ensuring the fibre – whether it’s sawmill residuals or chipped bio logs – is a consistent size. The used MEC 12x60 dryer was also installed in Phase 1, along with a Kinedizer 14-inch 40 MBTU gas burner. The drying equipment runs parallel to the current MEC 56000 pounds/hr WB dryer. A Fisher Klosterman Multi Cyclone has been installed.

Phase 2 of the project is focused on increasing pelletizing capacity. A third dry hammermill was installed as well as four additional Bliss Pioneer 200 pellet mills, bringing the plant’s total up to nine. Additional pellet cooling and storing equipment was also added to the current BM&M shaker screen and Bliss cooling tower to handle the extra capacity. Phase 2 also saw the relocation of the Hamer packaging system to fit in the new equipment.

“Inside the plant, we’ve had to add some expansions on to fit some of the equipment coming in. We’ve had to break into the concrete, reinforce the footings for the roof supports for everything coming in and hanging off of it,” Mohns says. “We’ve had to put in new transformers, electrical rooms, power distribution centre (PDC) rooms, and run power to feed all of the equipment”

The Nechako site has a stockpile of bio logs on site that have been drying out for a year and a half, giving them an ideal lower moisture content. The logs are currently processed on site with a Peterson mobile horizontal grinder that is brought in as needed by a contractor. Mohns says they’re eyeing a more permanent solution.

Phase 3 of the project is focused on the plant’s air emissions controls and includes studies to determine if and what size of a wet electrostatic precipitator (WESP) would be needed. The WESP would be a substantial initial investment as well as continual maintenance.

“We’re trying to put the best technology out there in place,” Mohns says. “In our studies, [the current system] ran much cleaner than we anticipated.”

“There have been multiple challenges finding supplies and people for the project. Then you add in COVID. You name it, we’ve run into it,” Mohns says. “So, we made some changes. We’ve been doing a lot of this project internally with our onsite fabrication team”.

The in-house aspect has led to both savings and additional challenges, he says. “It slows it down maybe a little bit, but it does really reduce our costs. Being a smaller town, usually any contractors are driving up, driving back. All that travel and LOA [living out allowance] costs really start to add up.”

While staff built a new set of skills by taking on the integration project, other aspects of their jobs such as preventative maintenance often drop down the list of priorities. That has once again become a focus as the project dust settles.

Rail transportation continues to be a challenge for many forestry operations across the country, and Nechako is no exception. The company recently completed a study on their rail line that may lead to a large rail expansion that would give Nechako and Premium Pellet increased flexibility when it comes to shipping their product to market.

All regulatory requirements and public consultations on the expansion are completed and submitted for review at this point. “We’re hoping to have everything up and running by September or October,” Mohns says.

As the project wraps up, Mohns’ attention is turned again to the larger challenges with fibre supply in B.C. “With the provincial government’s various fibre initiatives, we are continuing to focus on building relationships with key stakeholders and looking for internal opportunities to add value to marginal logs,” Mohns says.

For years Nechako has partnered with First Nations logging groups and mills. Nechako Lumber has enjoyed a long-term relationship with Saik’uz First Nations and currently has an agreement co-managing a 10-year forest licence targeting small profile wood within the Saik’uz traditional territory. The small profile includes mountain pine beetle-killed pine, which provides biofibre for Premium Pellet.

Also, on the horizon for Premium Pellet is a branding refresh that will proudly display the company’s wood pellet quality and sustainability certification. In 2017, Premium became the first pellet producer in Canada to hold both Sustainable Biomass Program (SBP) Certification and ENplus/CANplus certification.

Premium Pellet is a founding member of the Wood Pellet Association of Canada and continues its support today and into the future. •

Don’t wait for an incident to revisit your dust management programs

By Alexandra Skinner

Adecade ago, two people died and 20 were injured in an explosion at the Babine Forest Products facility in Burns Lake, B.C. Just three months later, two more people died and 22 were injured in a similar explosion at Lakeland Mills in Prince George, B.C. The incidents, caused in part when fine sawdust from wood ignited, are a sombre reminder of the importance of dust management programs in the wood manufacturing industry.

“Tragically, we know too well that if combustible dust is not managed properly, it can catch fire and burn or cause a deflagration and explosion, potentially resulting in serious and life-threatening injuries to workers,” says Budd Phillips, prevention field services manager at WorkSafeBC.

Over the past decade, WorkSafeBC has seen significant progress to ensure the hazards associated with combustible dust are effectively managed, by working alongside industry partners and employers to share and promote tools, techniques and knowledge about wood dust mitigation and control.

However, recent factors such as the COVID-19 pandemic and timber supply issues have impacted plant operations and changed the work environment in many mills and wood processing facilities. In addition, the risks can be hard to spot. Combustible dust can accumulate in out-of-site areas like basements, ceiling beams, and trusses.

“Over the past couple of years, manufacturers have been impacted significantly. Many have had to vary their production levels or reduce their workforce, which may draw resources away from proper maintenance and evaluation of dust management programs — leaving them vulnerable to potential hazards,” Phillips says. “Employers need to stay focused.”

Phillips says now is the opportune time for all employers to revisit their dust management programs. “Dust management programs should be constantly evaluated to ensure they meet the needs of current operations and keep workers safe.”

This begins with a risk assessment to determine what operations are generating dust and where vulnerabilities exist in any given workplace. Find someone qualified – such as a health and safety professional or industry representative – to assess the fire and explosion risks associated with combustible dust.

“Look at your processes, equipment, and buildings to ensure you can accurately evaluate your current handling practices, equipment, fire extinguishing systems, and other dust mitigation efforts,” Phillips says.

Risks should be logged in a comprehensive report that is readable and well-presented. When the risks are clearly defined and understood, optimal controls

can been identified, and implemented –typically through a combination of robust cleaning programs and engineering controls – to mitigate dust build-up when it exceeds allowable limits.

“While cleaning processes are important, there is also a human factor to consider,” adds Phillips. “Ensuring cleaning crews are conducting proper assessments and can keep up with the pace of work can sometimes be challenging in a plant that generates lots of dust.”

Phillips says that high-speed chainsaws can generate 33 pounds of sawdust per minute in multiple locations, which is why capturing dust at its source is critical to a successful dust management program.

Employers should examine ventilation systems to ensure proper airflow and have mechanisms to encapsulate dust such as covering conveyers. Employers should also ensure proper electrical cabinetry is

in place and cleaned properly so it does not become an ignition source.

Phillips notes that technology for dust management has improved over the years.

“There are many engineering controls available that extract excess dust more effectively and also help monitor dust levels. For example, some mills have comprehensive monitoring systems that include new sonic fans that help remove dust from high elevation surfaces.”

However, enhanced technology does not replace the need to consistently evaluate dust management programs to ensure they’re sustainable. Plans should be re-evaluated and new risk assessments should be done if any of the following occur:

• Staffing changes

• New or different work duties for staff

• Equipment changes: including new equipment, upgrades, or downgrades.

• Structural changes to the facility

• Operational changes, including changes in production levels or processes.

“The smallest change in personnel or operations could make a difference, so employers must regularly evaluate their programs to ensure they have the capacity required to keep dust levels below the allowable limits,” says Phillips.

Even if nothing changes in a workplace, employers should review their programs at least once a year to ensure they meet occupational health and safety

standards, and do not put workers at risk.

Phillips says most employers know their business and are aware of where and when dust is generated. The challenge is controlling and mitigating it.

Engineers that specialize in ventilation can also provide employers with a detailed assessment of a system’s effectiveness.

WorkSafeBC’s prevention efforts, inspection initiatives and collaboration with industry partners have been successful in combating combustible dust in wood manufacturing. One of the challenges, however, is providing guidance and regulation to support smaller operations and other industries that face similar risks.

“Current legislation does not address all industries that are generating hazardous amounts of combustible dust, like cabinet shops for example,” Phillips says.

Pulp and paper waste, commercial laundry facilities, iron fillings, and sugar plants are just a few examples of the thousands of manufacturers that could experience catastrophic outcomes if dust levels from those products accumulate over certain levels.

“Our current regulations for combustible dust are minimal in terms of what we can require for combustible dust programs, and are limited to specific employers groups,” explains Phillips. “Since our

combustible dust strategy was developed in 2012, we realized that there is a significant risk in many industries that needs to be addressed to keep workers safe.”

New proposed legislation changes are currently in the consultation phase in B.C. These revised regulations will become part of the B.C.’s Occupational Health and Safety Regulation providing WorkSafeBC prevention officers with the opportunity to enforce safety programs in a broader range of industries.

In the 10 years since the sawmill explosions in Burns Lake and Prince George, there has been significant progress and tangible improvements in managing hazards associated with combustible wood.

“We owe it to those who lost their lives or were injured to never forget the impact those explosions had on their families, their job sites and their communities –and to remain vigilant in order to prevent a tragedy like that from ever happening again,” Phillips says.

WorkSafeBC has developed several dust management resources, available on their website: www.worksafebc.com/en •

Alexandra Skinner is a manager of government and media relations with WorkSafeBC.

By Ellen Cools

As more and more governments look to renewable resources to help combat climate change and reach net-zero emissions, researchers continue to explore the potential benefits of woodbased bioenergy.

For Canada’s northern and remote communities, which have long relied on imported fossil fuels for heat and power, bioenergy represents an opportunity not only for clean, renewable energy, but also for more community leadership.

A new study from Natural Resources Canada (NRCan) – Greenhouse gas mitigation potential of replacing diesel fuel with wood-based bioenergy in an artic Indigenous community: A pilot study in Fort McPherson, Canada, by Jennifer Buss, Nicolas Mansuy, Jérôme Laganière, and Daniel Persson – confirms that replacing diesel fuel with biomass such as wood pellets and local chips can help mitigate greenhouse gas (GHG) emissions in northern remote communities while also providing socioeconomic benefits.

The study is part of an ongoing project that Mansuy and his colleagues began in 2019, and will continue for another two years. The project examines the opportunities and challenges for community-based bioenergy development in northern Indigenous communities.

The communities they are working with have received funding from the federal government’s Clean Energy for Rural and Remote Communities: BioHeat, Demonstration and Deployment Program. Some of them have already installed boilers and are transitioning to bioenergy, while others are looking at solutions for steady supply of biomass.

“There is a lot of interest for renewables energy globally right now and bioenergy can play a critical role, especially in Canada where we have so much biomass available,” Mansuy says. “But, we

realize for remote communities in the North, it’s more challenging because of the complexity of the supply chain and the long transport distances.”

Mansuy and his colleagues’ recent study specifically examined the GHG mitigation potential of wood-based bioenergy in northern remote communities. A life cycle assessment-based model was developed for Fort McPherson, N.W.T., to estimate potential GHG emission reductions achieved by switching from diesel generators to wood-based bioenergy.

Mansuy and his colleagues chose Fort McPherson as the pilot project for two reasons: First, the community has a significant amount of local biomass available. NRCan was able to collaborate with the community as well as the Canadian Wood Fibre Centre and FPInnovations.

Secondly, the community is 100 kilometres north of the Arctic Circle, making

Fort McPherson among the most extreme locations in Canada for bioenergy development, Mansuy says. “The idea was that if we see some success here in terms of GHG mitigation, that means we can probably have more GHG mitigation for communities in the south.”

The community also has a growing energy demand – using 310,000 GJ annually – and high energy costs. Fort McPherson’s goal is to replace its diesel generators with a combined heat and power (CHP) wood-based bioenergy system. In 2013, the community received an 85-kW boiler, which it used to provide heat for two buildings. The community also has a wood marshalling yard and tent shelter to store and process biomass.

As part of the study, the researchers tested using wood chips from willow locally harvested near Fort McPherson as well as trucking wood pellets from La Crete Sawmills in La Crete, Alta., nearly 3,000 km from the community.

Despite being above the Arctic Circle, Fort McPherson has a forested area next to the Peel River, part of the Gwich’in Settlement Area. “Despite the latitude, the forest here seems quite productive, but we are still conducting surveys to assess its longterm potential and sustainability,” Mansuy says.

The study also accounted for transportation distances, biomass boiler efficiency and emission factors, including the fuel used to transport the wood pellets. The transportation distance for the local supply chain to the biomass boiler was just 3.3 kilometres, although the researchers also modelled the GHG emissions savings based on a distance of 50 kilometres to account for future harvesting operations further from Fort McPherson. The transportation distance for the imported La Crete pellets is 2,900 kilometres.

The researchers ultimately found that replacing diesel fuel with wood-based bioenergy resulted in GHG emissions savings of 26,623 to 32,155 tonnes of CO2 per year over 100 years using local willow wood chips, and savings of 11,331 to 29,741 tonnes of CO2 with imported wood pellets.

Based on this model, Fort McPherson could see GHG benefits using local wood chips within zero to 20 years. With imported wood pellets, the community would see GHG benefits within two years (with a boiler conversion efficiency of 90 per cent) to 37 years (with an efficiency of 65 per cent). The range in numbers is based on the conversion efficiency of the biomass boiler, either at 90 per cent or 65 per cent.

These findings have several implications for Fort McPherson because of the community’s immediate need to create local jobs and revenue, Mansuy says. “By investing in the local supply chain, you can create jobs and involve the people, create revenue locally, and you have more control over the whole project. This is very important, especially for the Indigenous leadership.”

But, to ensure remote, northern communities can take advantage of the environmental and socioeconomic benefits of bioenergy, some challenges will need to be addressed.

Developing sustainable practices is key to minimizing the impacts on the ecosystem and securing sustainable biomass supply chains. In addition, having boilers that can accept different types of feedstock, for example, will help provide greater flexibility for communities. It’s also important to have good quality feedstock so communities don’t need to spend time and money cleaning the biomass before it goes into the boiler, Mansuy says.

Canada has not enjoyed a strong domestic market for wood pellets and wood chips. Mansuy and his colleagues are also working to understand the business ecosystem and the issues the industry faces.

“I had a Canadian company call me, they said they do a lot of business in the U.S., but asked why not in Canada? We need to understand why, and what are the barriers. Is it because of the lack of investment, the complexity of the supply chains, the competition with fossil fuels or other renewables?” Mansuy asks. “Right now, we are conducting interviews with companies to hear their perspectives about that.”

Logistical infrastructure challenges along the supply chain also

need to be addressed. “Sometimes we hear that bioenergy is simple because, this is Canada, we have forests everywhere, it’s just a matter of shipping biomass. But, if we’re talking about the North its different. When you need to truck for thousands of kilometres on gravel or ice roads, you have to make sure you can ship the feedstock when needed, cost effectively, in every season.

“In the previous study, we asked communities about the main barriers they face, and the lack of infrastructure was one of them,” he continues. “The climate in the North is also really harsh on infrastructure, but also the logistics, for example, to store the pellets or chips because you need to maintain a constant moisture level so you need the proper equipment. All this must be taken into account at the beginning of the project development.”

To address some of these issues, NRCan is looking at developing guidelines for investing in a biomass system. The guidelines will include a checklist to ensure they have access to biomass and the supply chain is viable economically and sustainable for the long-term, Mansuy explains. “And we want to combine this with Indigenous knowledge and local expertise as well, just to make sure that the bioenergy project is integrated with the existing values and uses and doesn’t create more pressure on the landscape.

“It’s very important that the communities have the say and the vision of how the landscape is managed for different values, including biomass harvesting and bioenergy.” • 371, Boulevard des Chutes Bureau #102 Québec, QC, G1E 3G1 1-800-463-4862

Ferdinand Blvd. Unit 4 Dieppe, NB, E1A 7G1 1-800-931-9611

The story of a man with a plan... for a zoo, and its poo

By Anthony Capkun

Chartered financial analyst Daniel Bida did not set out to become a developer of biogas plants. “It was a bit of a personal evolution for me,” he says. Prior to founding ZooShare, he worked in the finance industry as an analyst for the global utility sector.

“I didn’t know anything about how power generation worked, or how the regulated electricity industry worked,” Bida admits. “But I learned about the business of utilities, and I’ve always cared deeply about nature and the environment. As a result, I have always been drawn to renewables – without really much knowledge of how they actually worked.”

“And I was feeling unfulfilled in my job and wanted to find something more meaningful,” he recounts. “Maybe I could be an entrepreneur; maybe I could work for myself.”

Around this time, the Toronto Zoo had some dreams of its own.

“The Toronto Zoo Biogas Project was, actually, a long time in the making,” says Bida. Somewhere around 2003 – before he came into the picture – the Toronto Zoo got a grant to investigate the feasibility of building a biogas plant that would digest zoo manure and create energy.

That feasibility study must have concluded the conditions weren’t right for committing to such a project, and the idea stalled.

Fast-forward to 2010, Bida says, “and at this point, there was a renewable power buying program in Ontario, offering 20year contracts for various renewable energy, including biogas.”

That changed everything, so the zoo issued an RFP to build a 2-MW to 5-MW biogas plant at the site of its compost facility, which would sell power to the grid

and provide heat to the zoo – not to mention fertilizer for the zoo and the general market. The plant also had to achieve these goals “in an odor-free manner” which, if you consider the volume of food waste needed to produce that amount of power, would have been extremely difficult to achieve.

“When the zoo’s larger project didn’t materialize, I took the opportunity to present to them my vision for the project,” Bida says. “And that was how the ZooShare Biogas Cooperative came about. I assembled a team and we put a proposal in to the zoo to build a 500-kW community-owned biogas plant.”

The group presented it to the zoo as a community project whereby most of the capital would come from the general public, e.g. zoo visitors and members, people who have some connection to the zoo, or maybe just people who live nearby.

“And the zoo was keen to go ahead with developing a project that would turn what was previously a cost – manure management

– into a source of revenue,” he says.

While ZooShare’s proposal was markedly different from the first RFP, it would generate lease fees and power – and process manure, too – so the zoo decided to proceed with Bida’s concept. In late 2010, the zoo’s board gave approval to sign a Memorandum of Understanding (MOU) with Bida’s group.

The ZooShare Co-op was the counterparty to that MOU. It would raise funds from its membership to contribute capital in the project.

We were not selling shares to our members; as a non-profit, there’s no equity to sell in the organization. So we raised capital from our membership through community bonds,” Bida explains. “We did a number of issuances over the years; basically, as we reached major milestones – and the level of risk declined and our need for capital for the next phase increased – we would do another round of bond sales.”

“We had some early funders who took

the most risk when there really wasn’t very much in place,” he says, admitting, “Securing debt for a project like this is very difficult, primarily because you need long-term waste supply contracts.”

Eventually, ZooShare realized it had to sell equity in the project to strengthen its financial foundation and get the project built. It was at that point that the project was separated into its own entity, and a new Limited Partnership was formed, with EnerForge as the equity partner.

(EnerForge is a wholly owned subsidiary of Oshawa Power & Utilities Corp., which, up until Spring 2020, was known as Oshawa PUC Energy Services.)

Thus, in November 2019, officials and dignitaries gathered to celebrate the strategic partnership that, according to the press release, would make “significant greenhouse gas reductions a reality at the Toronto Zoo.”

Work could get underway to build the project that would convert 2,000 tonnes of zoo manure – plus some 15,000 tonnes of food waste from grocery stores, restaurants and other businesses around the Greater Toronto Area – into enough renewable energy to

symbolic of Canada’s newly emerging green economy, where structurally different organizations interplay in unique ways to generate sustainable bottom lines for all involved,” said Ivano Labricciosa, president and CEO of EnerForge. “Our team is proud to bring our expertise in

months later. “It was their concept, their belief in this particular renewable initiative [...] but didn’t have the funds to push the project over the finish line.”

He continued: “We realized this particular project is right up our alley in terms of being able to do renewables and show

™

AVAILABLE IN SIZES UP TO DN800 (32 INCHES)

The pandemic struck a few months after that partnership announcement but, despite all of the challenges that resulted from COVID, project development proceeded. And, in April 2021, the Toronto Zoo Biogas Project was declared officially online.

“The difficult thing in any project is that you start with your assumptions and projections – how you think things are going to happen – then you get to reality, and things are a little bit different,” Bida says.

Over the course of this project, he learned a lot about both manure and food waste – probably more than he ever thought possible. For example, he learned early on that a project of this scale might be difficult and that food waste was going to have to be a key input to make it work.

Biogas is an industry where economies of scale play heavily into overall project economics, Bida explains. “A project like ours, which processes 15,000 tonnes of food waste a year, is actually small for a food waste anaerobic digestion project.”

That said, it generates the equivalent of enough power for approximately 250 homes.

“Many of the Ontario digester projects that exist are primarily digesting liquid dairy manure along with food waste, or other agricultural waste streams,” he points out. “ZooShare is no different in that we’re digesting a blend of manure and food waste, but the manure we’re digesting is actually solid and quite dry, due to all the bedding material.”

On a volume basis, about 10 per cent of what goes in the digester comes from the zoo, and the rest is commercial food waste. Manure represents food that has already been eaten, and so its energy yield is much lower than food waste that “hasn’t been eaten yet”.

Looking at it from strictly biogas-production perspective, the zoo’s materials account for about five per cent of the biogas produced. Which helps explain why ZooShare relies on commercial food waste “to feed the anaerobic digester, which generates the gas and, ultimately, the electricity”.

Food waste, too, can be of low quality,

but for a different reason. ZooShare’s digester includes contaminant removal systems to sort out things like plastic or – believe it or not – bones and other materials which tend to build up in the digester over time or can end up in the digestate. “This way we don’t end up reducing the available capacity of our digestion tanks with a build-up of contaminants.”

The pandemic definitely impacted ZooShare’s operations, but perhaps not in the way you would think. Because the biogas plant relies heavily on commercial food waste, all the lockdowns and restrictions on restaurants, conferences, event venues, etc., severely curtailed ZooShare’s anticipated feedstock.

“We were negotiating with one waste management company for 10,000 tonnes of food waste per year – about two-thirds of our food waste needs,” Bida recalls. “By the time we got to signing a contract, we were in the middle of the pandemic, and they could only contractually commit to 1,500 tonnes per year.”

“I think a lot of what I’m saying here is not unusual for a new biogas plant,” Bida muses. “None of what actually happened over the first six months of operation surprises me in the least; every new operation goes through some challenges.”

Despite the challenges – alongside a very steep learning curve – Bida is very proud of the Toronto Zoo Biogas Project.

“We faced a number of delays and an almost endless number of challenges; so I took the lumps, because I really wanted to cross the finish line,” says Bida, who continues to pursue projects that can integrate as much local waste and local capital as possible, so that the overall impact of the project – environmentally and economically – can be maximized.

“At the end of the day, it’s very gratifying to envision something, put it on your back and cross the finish line with it. Yes, it can be tiring and stressful. And certainly I didn’t count on it taking 10 years!” •

It gives me great pleasure to invite you to join us at the Wood Pellet Association of Canada’s 2022 Annual Conference and to announce that we will be meeting in person once again! The conference will take place at the Marriott Pinnacle Hotel in Vancouver from September 1921, followed by a tour to B.C.’s North Coast.

Your attendance at this year’s conference will provide valuable input as we discuss the future of our sector and our important role domestically, nationally and globally. The fact is, the time has come for Canada’s wood pellet sector to harness our collective energy and take centre stage in the bioeconomy conversation. That’s why our conference theme this year is The Power of Pellets: Unlocking a World of Possibilities.

Today, our sector has earned national and international respect for the important role wood pellets play in tackling climate change globally while providing responsible, renewable clean energy both domestically and nationally. But that’s just the beginning for our sector.

Canadian wood pellets offer a world of possibilities not only to meet greenhouse gas emissions targets, but also to opening doors to the bioeconomy with innovative solutions and new products that will support the transition to a greener, more sustainable world.

The conference will bring together thought leaders and experts from across the world to inspire and challenge our sector to discuss:

• The endless possibilities for wood pellets and what the future holds for our sector;

• Local heroes who are making their communities stronger by investing in the wood pellet sector;

• The need to set the record straight when it comes to the importance of wood biomass and healthy forests;

• The role of biomass in climate change mitigation: the science, the opportunities and the challenges;

• Making our industry safer through innovation; and

• A thought-provoking keynote address that will leave us inspired to seize the opportunities ahead.

I’d like to express my gratitude to our sponsors who do so much to make our event possible.

• Biomass Energy Lab

• Bruks Siwertell

• Brunette Machinery

• CPM Global

• Fink Machine Inc.

• FWS Group of Companies

• Airex Énergie Inc.

• Canadian National Railway

• VETS Group

• Firefly Ab

• Biomass Engineering & Equipment

• Drax

• MoistTech

• MoistTech Corp.

• Prodesa North America

• Amandus Kahl

• stela Laxhuber GmbH

• Hargassner Ges mbH

• SGS Canada Inc.

• TSI Inc.

• Andritz

• Wellons Canada

It’s not too late to be a conference sponsor this year, so please reach out to Rebecca Lewis at rlewis@annexbusinessmedia.com.

We look forward to welcoming more than 200 government officials, customers, NGOs, forest companies and pellet producers and representatives from across the pellet and wood biomass supply chain at this year’s conference. This attendance confirms that the conference has gained an international reputation as an important vehicle to share perspectives ideas and build on the momentum of our sector. Join us as we prepare to take the next step in the evolution of wood pellets. We look forward to seeing you there!

All the best,

Gordon Murray Executive Director Wood Pellet Association of Canada

SEPTEMBER 19-21, 2022, Marriott Pinnacle Hotel, Vancouver, B.C.

MONDAY, SEPT 19, 2022 PRE-CONFERENCE

8:45 a.m. to 4:45 p.m. Golf Tournament – Mayfair Lakes Golf and Country Club

9:00 a.m. to 3:30 p.m.

Workshop: ENplus Training for Quality Managers – Marriott Pinnacle Hotel; UBC Biomass Lab

6:00 p.m. to 9:30 p.m.

Opening Reception Marriott Pinnacle Hotel

TUESDAY, SEPT 20, 2022 CONFERENCE DAY 1

7:30 a.m. to 8:30 a.m.

Breakfast and Registration

8:30 a.m. to 8:50 a.m.

Session 1: Unlocking the World of Pellets

Moderator: Gordon Murray, Executive Director, WPAC

Vaughan Bassett, President, WPAC

Sr. Representative, Natural Resources Canada

8:50 a.m. to 10:15 a.m.

Session 2: The Gateway to New Possibilities

Moderator: Gordon Murray, Executive Director, WPAC

Wood Pellets as a Foundation of a Low Carbon Economy – Jamie Stephen, Managing Director, TorchLight Bioresources

Advancing British Columbia’s Bioeconomy – Ministry of Forests Innovation, Bioeconomy and Indigenous Opportunities Branch

Industry and Government: Responding to the Challenge – Jamie Stephen, TorchLight Bioresources; Vaughan Bassett, Drax; Gregg Koehler, Premium Pellet Ltd.; Representative Ministry of Forests Innovation, Bioeconomy and Indigenous Opportunities Branch

10:15 a.m. to 10:45 a.m.

Coffee Break – Networking in exhibition area

10:45 a.m. to 12:05 p.m.

Session 3: Stronger Communities and Local Economic Development

Moderator: Gregg Koehler, Sales Manager, Premium Pellet Ltd.

Skeena Bioenergy and Kitsumkalum Economic Development Group: Working Together in Northwest BC – Roger Keery, President, Skeena Sawmills Ltd.; Diane Collins, General Manager, Kitsumkalum Economic Development Group

Bioheat Strategy for Atlantic Canada – Jonathan Levesque, General Manager, Biomass Solutions Biomasse

Eliminating Furnace Oil to Reduce GHG Emissions from Nova Scotia Government Buildings – Paula Cook, Senior Energy Engineer, Public Works, Government of Nova Scotia

12:05 p.m. to 1:30 p.m.

Lunch and Networking in Exhibition Area

1:30 p.m. to 2:40 p.m.

Session 4: Setting the Record Straight

Moderator: Diane Nicholls, Vice-President, Sustainability, Drax

What Do We Stand For? – Karen Brandt, Senior Consultant, Brandt Strategy Inc.

The Art of the Possible – Philippe Theriault, General Manager, Tsi Del Del Enterprises

Advancing Wildfire Resiliency and Utilization in British Columbia –Steve Kozuki, Executive Director, Forest Enhancement Society of BC

2:40 p.m. to 3:10 p.m.

Coffee Break – Networking in exhibition area

3:10 p.m. to 4:50 p.m.

Session 5: Biomass and Climate Change Mitigation

Moderator: Jamie Stephen, Managing Director, TorchLight Bioresources

Sustainable Forest Management Contributions to Climate Change Mitigation – Gary Bull, Professor Faculty of Forestry, University of British Columbia

Carbon Sequestration in Managed Forests and Dispelling the Myth of Carbon Debt – William Strauss, President, FutureMetrics

On the Path to Becoming a Negative Emissions Company: BECCS – Drax

5:00 p.m. to 7:00 p.m.

Director of Research and Technical

WEDNESDAY, SEPT 21, 2022

7:30 a.m. to 8:30 a.m.

8:30 a.m. to 9:50 a.m. –– Bill Laturnus, Senior Council

Manager, Fike Canada – Kayleigh Rayner-Brown, Principal, Obex Risk

10:00 a.m. to 10:30 a.m. – Networking in 10:30 a.m. to 11:30 a.m.

President, WPAC

11:30 a.m. to 11:40 a.m.

Summary and Wrap-up – Vaughan

Amandus Kahl GMBH & Co. KG (Sarj Equipment, Canada)

Balcan

Bulldog Bag Ltd.

Certified Labs

Möllers North America Inc.

Nvenia

Polypro Solutions

Premier Tech Chronos

Rethceif Packaging

Silvana Import Trading Inc.

Trinity Packaging

DIES

Amandus Kahl GMBH & Co. KG (Sarj Equipment, Canada)

Certified Labs

CPM Global Biomass Group

Dorssers Inc.

La Meccanica Srl Di Reffo

Münch-Edelstahl GMBH

Salmatec GMBH

Silvana Import Trading Inc.

Amandus Kahl GMBH & Co. KG (Sarj Equipment, Canada)

Andritz Group

Anhydro Inc. (Spx Flow Technology)

Baker-Rullman

Buettner Energy And Drying Systems

North America, LLC

Certified Labs

Dieffenbacher North America, Inc.

Earth Care Products, Inc.

Energy Unlimited Inc.

GEA Canada

Münch-Edelstahl GMBH

Player Design, Inc.

Saimatec Engineering

Siempelkamp Energy Systems GMBH

Silvana Import Trading Inc.

Solagen Inc.

Stela Laxhuber GMBH

Thompson Dehydrating

TSI Dryers

Uzelac Industries Inc.

SERVICES

Andritz Group

Biomass Engineering & Equipment

Buskirk Engineering

Deltech

Dieffenbacher North America, Inc.

Earth Care Products, Inc.

Energy Unlimited Inc.

Law-Marot-Milpro Inc.

Mid-South Engineering Stolberg Group

Process And Storage Solutions

Solagen Inc.

TS Manufacturing

FIRE/SPARK

SUPPRESSION

Airplus Industrial

Allied Blower

Amandus Kahl GBMH & Co. KG

(Sarj Equipment, Canada)

Clarke’s Industries, Inc.

Concept-Air

CV Technology, Inc.

Fagus GreCon, Inc

Fenwal-Iep Technologies

Fike Corporation

Firefly Ab

Flamex, Inc.

Rodrigue Métal Ltée

Silvana Import Trading Inc.

Amandus Kahl GMBH & Co. KG

(Sarj Equipment, Canada)

Andritz Group

Bruks Siwertell

Brunette Machinery Company Inc.

Buskirk Engineering

Certified Labs

CPM Bliss Industries, LLC

CPM Global Biomass Group

CSE Bliss Manufacturing LLC

Dieffenbacher North America, Inc.

Gemco Energy

Jeffrey Rader – Terra Source

La Meccanica Srl Di Reffo

Law-Marot-Milpro Inc.

Münch-Edelstahl GMBH

Schutte Hammermill

Silvana Import Trading Inc.

HANDLING EQUIPMENT

Biomass Engineering & Equipment

Bruks Siwertell

Law-Marot-Milpro Inc.

S. Huot

LUBRICANTS

Sinto

MOISTURE ANALYZERS

Döescher Microwave System GMBH

Fagus GreCon, Inc.

MoistTech Corp.

Tews Of America Corp.

PELLET MILLS

Amandus Kahl GMBH & Co. KG (Sarj Equipment, Canada)

Andritz Group

Buskirk Engineering

Certified Labs

CPM Bliss Industries, LLC

CPM Global Biomass Group

La Meccanica Srl Di Reffo

Münch-Edelstahl GMBH

Pelleting Technology Netherlands

Salmatec GMBH

Silvana Import Trading Inc.

PNEUMATIC CONVEYING

Allied Blower

Amandus Kahl GMBH & Co. KG

(Sarj Equipment, Canada)

Baum Pneumatics Inc.

Certified Labs

Clarke’s Industries, Inc.

Concept-Air

Continental Conveyors

Coperion K-Tron

Fox Venturi

Jeffrey Rader – Terra Source

Koger Air Corporation

Rodrigue Métal Ltée

Silvana Import Trading Inc.

Walinga

PORTS

Port Metro Vancouver

Port Of Belledune

Port Of Halifax

Port Of Montreal

Port Of Quebec

Port Of Trois-Riviéres

Port Saguenay

QUALITY CONTROL EQUIPMENT & SERVICES

Amandus Kahl GMBH & Co. KG (Sarj Equipment, Canada)

Biomass Energy Lab

Domo-System Technologies

Electromatic Equipment Company Inc.

Fagus GreCon, Inc.

Münch-Edelstahl GMBH

Silvana Import Trading

Timber Products Inspection

Twin Ports Testing Inc.

SCREENS & COOLERS

Amandus Kahl GMBH & Co. KG (Sarj Equipment, Canada)

Andritz Group

Baum Pneumatics Inc.

BM&M Screening Solutions

Bruks Siwertell

Brunette Machinery Company Inc.

Buskirk Engineering

Certified Labs

CPM Bliss Manufacturing, LLC

CPM Global Biomass Group

CSE Bliss Manufacturing, LLC

Dieffenbacher North America, Inc.

Jeffrey Rader – Terra Source

La Meccanica Srl Di Reffo

Law-Marot-Milpro Inc.

Münch-Edelstahl GMBH

Pelleting Technology Netherlands

Silvana Import Trading Inc.

TRUCK DUMPERS

Airoflex Equipment

B.I.D Canada Ltd.

Bruks Siwertell

Phelps Industrial

Wolf Material Handling Systems

AIROFLEX EQUIPMENT

www.airoflex.com

563-264-8066

BAUM PNEUMATICS INC.

www.baumpneumatics.com

604-945-4507

AIRPLUS INDUSTRIAL

www.airplusindustrial.ca

1 (866) 291-6855

AIRPLUS Industrial is a leading and integrated provider for industrial clean-air solutions and compressed-air applications in Western Canada. With 30+ years experience in dust, mist and fume collection plus compressed-air applications in industrial sectors, we bring strong relationships with equipment manufacturers and expert service experience to our customers.

ALLIED BLOWER

www.alliedblower.com

604-930-7000

AMANDUS KAHL GMBH & CO. KG (SARJ EQUIPMENT, CANADA)

www.akahl.de

905 806 6837

AMANDUS KAHL is one of the leading manufacturers of plants for conditioning feed, food, biomass, wood, straw, waste tyres, sewage sludge, plastics scrap as well as domestic and industrial waste. From the small individual press to industrial pelleting plant: We realise all the desired sizes. Construction of heavy machinery pays off: Our plants are characterised by a high operational safety and availability also for continuous operation. The main machines as pan grinder mills, belt driers, pelleting presses and coolers, are produced in our factory at Reinbek near Hamburg - made in Germany. We also offer consultation and assistance from the start of the project until after-sales service.

ANDRITZ GROUP

www.andritz.com 457-216-0300

ANHYDRO INC. (SPX FLOW TECHNOLOGY)

www.spx.com/en/anhydro/ 704-752-4400

BAKER-RULLMAN

www.baker-rullman.com 920-261-8107

BALCAN

www.balcan.com 1-877-422-5226

Untitled-10 1

A proud high pressure supplier to Canada’s newest and cleanest dust collection “turnkey” system which consists of containment and a multicone dust collection system that does not require the use of large baghouses. We provide, repair, modify, maintain, and monitor services to existing high pressure conveying systems for dust collection equipment.

CERTIFIED LABS www.certifiedlabs.com 905-691-0492

CLARKE’S INDUSTRIES, INC. www.clarkes-ind.com 541-343-3395

B.I.D CANADA LTD.

www.bidcanadaltd.com (506) 328-4381

DelTech has a proven, long-standing reputation for designing and manufacturing continuous/ batch kilns, biomass-fuelled energy system technologies, and pellet plant manufacturing. We provide specialized start-to-finish energy solutions for the entire forestry sector.

BIOMASS ENERGY LAB www.biomassenergylab.com 218-461-2579

BIOMASS ENGINEERING & EQUIPMENT www.biomassengineeringequipment.com 317-522-0864

BM&M SCREENING SOLUTIONS www.bmandm.com 1-800-663-0323

BRUKS SIWERTELL www.bruks-siwertell.com 770-849-0100

BRUNETTE MACHINERY COMPANY INC. www.brunettemc.com 604-522-3977

BULLDOG BAG LTD. www.bulldogbag.com 1-800-665-1944

BUSKIRK ENGINEERING www.buskirkeng.com 260-622-5550

BUETTNER ENERGY AND DRYING SYSTEMS NORTH AMERICA, LLC www.buettner-energy-dryer.com (704) 910-0162

CONCEPT-AIR www.concept-air.ca 1-866-644-0041

Successful solutions for aspiration systems and industrial processes. Our dust collectors are designed to efficiently treat a variety of particle types. We offer a turnkey service that meets the most demanding standards in the industry!

COPERION K-TRON www.coperion.com 785-825-1611

Untitled-10 1

CONTINENTAL CONVEYORS www.continentalconveyor.ca 418-338-4682

Continental provides a full range of mechanical bulk handling and storage equipment including en-masse chain conveyors, screw conveyors, belt conveyors, disc screens as well as storage and reclaim solutions. Robust designs coupled with over 50 years of wood industry and related experience assures quality conveying systems for pellet, biomass, fuel, and wood processing industries. Contact us to see how we can help you move your bulk materials.

CPM BLISS INDUSTRIES, LLC

www.bliss-industries.com 580-765-7787

CPM GLOBAL BIOMASS GROUP www.cpm.net 1-800-428-0846

CSE BLISS MANUFACTURING LLC www.csebliss.com 580-749-4895

CV TECHNOLOGY, INC. www.cvtechnology.com 561-694-9588

DELTECH www.deltech.ca 1-800-736-7733

DIEFFENBACHER NORTH AMERICA, INC www.dieffenbacher.com 519-979-6937

2022-07-19 9:22 AM

DÖESCHER MICROWAVE SYSTEM GMBH

www.moisturemeter.eu 510-420-1716

DOMO-SYSTEM TECHNOLOGIES

www.domosystem.fr

+33(0)1 45 87 22 99

DORSSERS INC.

www.dorssers.com

519-676-8113

EARTH CARE PRODUCTS, INC.

www.ecpisystems.com 620-331-0090

ELECTROMATIC EQUIPMENT COMPANY INC

www.checkline.com 1-800-645-4330

ENERGY UNLIMITED INC.

www.energyunlimitedinc.com

608-935-9119

FAGUS GRECON, INC

www.Fagus-GreCon.us

704-912-0000

Fagus GreCon the leader in Spark Detection and Extinguishing Systems for 40+ years, helps eliminate early causes of fires and explosions. InfraRed sensors detect sparks/embers and then automatically trigger countermeasures.

FENWAL-IEP TECHNOLOGIES

www.ieptechnologies.com 855-793-8407

FIKE CORPORATION

www.fike.com

800-363-8116

FIREFLY AB

www.firefly.se

+46 (0)8 449 25 00

FLAMEX, INC.

www.sparkdetection.com 336-299-2933

FLAMEX is a leading North American supplier of customized industrial process fire prevention systems and equipment. We have 40 plus years of experience and numerous installations in the wood pellet industry.

FOX VENTURI

www.foxvalve.com 973-328-1011

GEA CANADA

www.gea.com 819-477-7444

GEMCO ENERGY

www.agicogroup.com

0086-372-5965148

JEFFREY RADER – TERRA SOURCE

www.terrasource.com 514-822-2660

KOGER AIR CORPORATION

www.kogerair.com

800-368-2096

LA MECCANICA SRL DI REFFO

www.lameccanica.it +39 049 941 9000

LAW-MAROT-MILPRO INC.

www.lmmequip.com

800-461-6276

Law-Marot-Milpro is a leading North American manufacturer of pellet cooling, pellet cleaning and material handling equipment. Our sturdy equipment has been in operations for over 50 years across North America.

MID-SOUTH ENGINEERING STOLBERG GROUP www.mseco.com/stolberg 604-273-1915

MOISTTECH CORP

www.moisttech.com 941-727-1800

Insensitive to material variations such as particle size, material height & color, MoistTech moisture sensors provide continuous, reliable readings with zero maintenance and a one-time calibration with a non-drift optical design allowing operational personnel to confidently make immediate process adjustments based on real-time measurements.

MÖLLERS NORTH AMERICA INC.

www.mollersna.com 616-942-6504

MÜNCH-EDELSTAHL GMBH

www.muench-edelstahl-gmbh.de/en +49 02103 58996

NVENIA www.nvenia.com 763-231-0100

PELLETING TECHNOLOGY NETHERLANDS www.ptn.nl +31 (0)73 54 984 72

PHELPS INDUSTRIAL www.phelpsindustries.com 501-375-1141

PLAYER DESIGN, INC. www.playerdesign.net 207-764-6811

POLYPRO SOLUTIONS www.polyprosolutions.ca 514-730-2433

PORT METRO VANCOUVER www.portmetrovancouver.com 604-665-9000

PORT OF BELLEDUNE www.portofbelledune.ca 506-522-1200

PORT OF HALIFAX www.portofhalifax.ca 902-426-8222

PORT OF MONTREAL www.port-montreal.com 514-283-7011

PORT OF QUEBEC www.portquebec.ca 418-648-3640

PORT OF TROIS-RIVIÉRES www.porttr.com 819-378-2887

PORT SAGUENAY www.portsaguenay.ca 418-697-0250

PREMIER TECH CHRONOS www.ptchronos.com 418-868-8324

Among the largest packaging equipment manufacturers in the world, Premier Tech commits to creating sustainable solutions that improve the efficiency of manufacturing facilities in the nutrition, industrial, agricultural and organics market sectors.

PRIMARY PACKAGING

www.primarypackaging.com

800-774-2247

PRINCE RUPERT PORT AUTHORITY

www.rupertport.com 250-627-8899

PROCESS AND STORAGE SOLUTIONS

www.processandstorage.com

256-638-1838

RETHCEIF PACKAGING

www.rethceif.com

866-298-1876

RODRIGUE MÉTAL LTÉE

www.rodriguemetal.com 418-839-0400 ext. 231

Rodrigue Metal Ltd is a leader in the design, manufacture and installation of Dust Collecting Systems for biomass and pellet plants. Since 1964, we have installed more than 500 Dust Collecting Systems in the Wood Processing Industry.

S. HUOT

www.shuot.com

418-681-0291

For more than fifty years, S. Huot Inc. has been a leader in designing and manufacturing Biomass Handling Conveyors for wood pellet plants in North America. We also offer Turn-Key services for all our equipment.

SAIMATEC ENGINEERING

www.saimatec.fi +358-40 0252326

SALMATEC GMBH

www.salmatec.de/en 49 4172 98 97-0

For almost 50 years, SALMATEC produces and develops cutting edge pelleting equipment. In addition to our MAXIMA pelletizers, we build dies and rollers in any size and configuration - all Made in Germany.

SCHUTTE HAMMERMILL

www.hammermills.com 800.447.4634

SIEMPELKAMP ENERGY SYSTEMS GMBH www.siempelkamp.com 770-424-4141

SILVANA IMPORT TRADING INC.

www.silvanatrading.com 514-939-3523

TSI DRYERS www.tsi-inc.net 425-771-1190