A look into the products, technologies and solutions shaping the market

A look into the products, technologies and solutions shaping the market

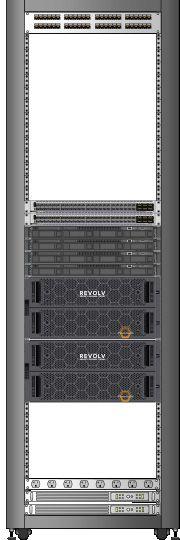

Specifying and installing large-scale video surveillance systems can be a daunting task. The last few years or so we have heard more about Hyperconverged Infrastructure (HCI), and more recently, Hybrid Hyperconverged Infrastructure (hHCI) has also come into play. Traditional HCI has many benefits, but with that comes extensive training, multiple software components and a hefty price tag which can be out of reach for many customers in the security industry.

Hybrid Hyperconverged Infrastructure takes traditional HCI and allows connection to an external SAN storage. This provides ultimate flexibility options for future expansion as you can expand the networking and compute separate from to the storage. Separate servers, storage networks and storage arrays are replaced with a single hybrid hyperconverged solution to create an easily scalable system with a smaller footprint.

What’s the difference between traditional HCI and Hybrid HCI?

Traditional HCI combines storage, compute, and virtualization in each unit (node). The storage across the nodes is added to a redundant storage pool which provides resiliency of node failures. With a hybrid hyperconverged infrastructure, you no longer have to choose between a SAN or an HCI appliance, you can have them both. This way, the capacity of existing hyperconverged nodes can be expanded on-line by connecting to an external SAN, without needing to shut down the clustered array of nodes, adding more storage or purchasing more nodes.

Simplify product monitoring by reducing the number of points of reference. BCD International’s REVOLV Hybrid

HCI (the only hybrid HCI on the market) achieves this by reducing the number of graphical user interfaces, or GUI’s, you interact with on a daily basis while monitoring the system. For example, BCD has recently developed the Harmonize Conductor iDRAC plug-in, which integrates with the core Genetec Security Center platform. This enables visibility of any faults from the storage solution within the Genetec GUI. This also gives the added advantage of only having one GUI for the operator to monitor, maintain, and react to when critical server infrastructure issues may arise. Overall, the advantages are less install time, less training and lesser chance of an operator missing an issue.

BCD International also recently released its Harmonize Conductor VMware plug-in for Genetec’s Security Center. This custom integration simplifies the user experience by introducing virtual machine monitoring within the Security Center platform. Many surveillance partners are not VMware certified and could be concerned about potential training required. Although the installation engineers will need to work within VMware, BCD has automated a significant amount of the VMware functionality behind the software, so you don’t need to be a certified VMware engineer to install and maintain the products. The amount of time spent on the VMware side can be learned within half a day’s training. Plus, step-by-step guides are sent out covering this process with every order. BCD also has certified engineers and support team ready to assist.

In the words of Albert Einstein, “Genius is making complex ideas simple, not making simple ideas complex.”

To learn more about BCD International and Hybrid HCI, contact revolv@bcdinc.com or visit bcdinc.com/revolv

DEEPSTOR LITE

nitial hHCI deployments begin with 3 Nodes + 1 SAN with RAID 6 protection

DEEPSTOR

4 or more compute nodes combined with 1 SAN utilizing RAID 6

DEEPSTOR+

4 or more compute nodes combined with 2 SANS that are mirrored. Data is written to each SAN simultaneously and each individual SAN is protected with RAID 6 I

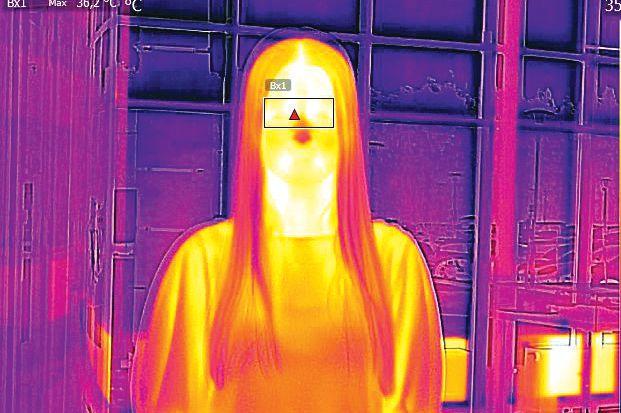

Thermal-based technology solutions have become part of the new normal as businesses look to re-open safely

By Alanna Fairey

In a world that now requires people to social distance and monitor their temperature, thermal solutions have become a technology staple.

Dave Bursell, vice-president of business development and product management at FLIR, says that the company has seen an exponential increase in demand for their thermal temperature solutions. “It’s really hard to say what that new normal will look like, but this much we do know — this technology will be a part of it,” Bursell says. “We’re preparing for that and making sure that we can meet the needs of the different workplaces.”

Sharing that the company began offering thermal temperature solutions after the SARS outbreak back in 2003, Bursell says that FLIR’s thermal temperature solutions include the FLIR Exx-Series, FLIR T500 Series and A400-A700.

“The thermal imaging has a software on the camera itself called Screen ESP mode which enables that portable handheld camera to do screening, and it has auto detection,” Bursell explains.

If the temperature of the skin is above average, then the individual may be selected for additional screening. Bursell says that identifying individuals with elevated body temperature can help reduce or dramatically slow the spread of viruses and infections.

“We introduce things like facial detection, which is detecting that there’s a face there, and then we can really concentrate the measurement on the corner of the eye,” Bursell explains. “Research has shown that that’s the best place to relate skin temperature to core body temperature.”

Bursell notes that FLIR’s thermal temperature solution technologies have seen substantial acceleration in sectors such as manufacturing and warehousing facilities,

as well as distribution centres and “essentially any place where you have people gathering and coming to work, and you have a fairly large population of workers.

“We are seeing the technology being utilized now as a pre-screening method, again to ensure worker safety and health,” Bursell adds.

Another sector that has recently begun to utilize thermal temperature technologies is airports. Back in June, the Government of Canada announced that temperature screenings are mandatory for all passengers on international or transborder flights travelling to Canada prior to boarding at their point of departure.

It is not just passengers who will have to be screened — it was also announced that all employees and personnel that enter or work in the restricted area of the airport and screened through a Canadian Air Transport Security Authority point will be subject to temperature screening procedures by CATSA personnel.

According to an official statement from

“I do think it is definitely a shield in your arsenal that you want to have, along with your questionnaires, along with your sanitization, along with your physical distancing.”

— Jason Haelzle, GHD

Transport Canada, a phased approach has been taken in order to implement temperature screening. The approach is as follows:

Phase 1: On July 9, all air operators were required to conduct temperature screenings of all passengers travelling to Canada prior to departure from international or transborder points of departure.

Phase 2: On July 30, temperature screening stations were placed in the departure section of the four major airports that are currently identified for international travel (Montreal, Toronto, Calgary, Vancouver).

Phase 3: By September 2020, temperature screening stations will be in place in the departure sections of the next 11 busiest airports in Canada (St. John’s, Halifax, Quebec City, Ottawa, Toronto –Billy Bishop, Winnipeg, Regina, Saskatoon, Edmonton, Kelowna, Victoria).

“Temperature screening can be conducted with a variety of technologies, from handheld digital infrared thermometers to sophisticated contactless thermal camera-based systems that can automatically screen a high volume of travellers in queues and manage any privacy concerns,” Transport Canada said in a prepared statement. “The implementation of measures would not prescribe a single type of equipment to use.”

A representative from Transport Canada also shared that they have established technology performance standards for equipment that adheres to industry standards. This approach was taken to ensure that the thermal temperature equipment should operate as expected during temperature screening for accuracy, according to the statement.

When Toyota Motor Manufacturing Canada Inc. (TMMC) began preparation for the reopening of its Cambridge and Woodstock, Ont. plants, the automaker sought the help of GHD, a global engineering firm based in Waterloo, Ont., for recommended thermal temperature solutions.

“I don’t know any other manufacturer or business that has

taken the full scale approach that Toyota has taken,” says GHD vice-president Jason Haelzle. “They move mountains to make sure that their staff and team members are safe.”

Haelzle shares that just 11 hours after GHD had an initial meeting with TMMC, his team had to deploy to the site for a pilot of Hikvision temperature thermal screening monitors. “It was quite impressive to see the resources that are deployed, and the rapid response that Toyota did,” Haelzle says.

The installation of the Hikvision thermal imaging solutions helped to establish new safety procedures and protocols, says Haelzle.

TMMC employees are now mandated to fill out a daily questionnaire to determine if anything from a health perspective has changed. Once the questionnaire is completed, each person’s temperature is checked using thermal cameras, which has a high throughput, according to Haelzle.

“If there’s a high-level alert, it triggers and makes a sound so that you are aware of it,” Haelzle explains. “Then you can pull the individual aside for a secondary screening questionnaire.”

Looking ahead at the new normal, Haelzle believes that as more and more businesses start to reopen, thermal temperature screening solutions will be a popular solution. He notes that businesses in other sectors have also implemented similar technology.

“Some businesses are having employees do it, whether it’s at home on their own and they can register their own data,” says Haelzle. “There are probably 50 cameras at different businesses that have been sold and more cameras are going in continuously.”

While thermal temperature technologies have played an essential role in the country’s reopening, Bursell stresses that thermal imaging technology does not explicitly detect COVID-19 and urges the public to continue to remain vigilant and practice good hygiene and social distancing.

“All thermal imaging can do is detect an elevated skin temperature. Keeping that in mind and understanding that is important to be clear,” Bursell stresses.

“We want to make sure that that message is clear that [thermal imaging] does not detect a virus or a fever.”

While Haelzle also agrees that thermal temperature technologies are not the sole solution to dealing with COVID-19, he believes that they do contribute in a meaningful way, and will continue to do so as the province slowly reopens.

“I do think it is definitely a shield in your arsenal that you want to have, along with your questionnaires, along with your sanitization, along with your physical distancing,” Haelzle concludes. “I think it is definitely a necessary step.”

Do you know how your

cameras are made? You probably should.

By Aaron Saks, Sr. Product and Technical Training Manager at Hanwha Techwin America

IP security cameras are by their very nature connected to the internet either directly, or through a network. That’s what allows users to access them remotely, to check in on their business, and what lets dealers to easily update device software remotely. But this feature can also be a problem. When not secured properly, devices in the so-called Internet of Things (IoT) can be accessed remotely by just about anyone, not just those with whom you want to share access. And that’s a big problem for our industry.

Since a product is only as good as the hardware and software inside it, examining how something is built can give us rapid insight into its potential vulnerabilities and overall cyber worthiness. The NDAA (National Defense Authorization Act) ban is particularly focused on the subject of component sourcing for security devices. What is inside that device that could be exploited? Where did it come from? What do we know about the manufacturing process? These are all important questions about the manufacturing supply chain that need to be considered by anyone who cares about cybersecurity.

The easiest way to reassure customers that your system is compliant and cybersecure is to make everything yourself. However, that’s not always practical for many companies who rely on 3rd parties to supply critical components that they themselves do not manufacture. It’s also true that not every part, (resistors, transistors, and more) has a cyber aspect that can be exploited. So, worrying or restricting products over individual piece parts is unnecessary. There are, however, many OEM and re-labeled products on the market in which companies utilize external 3rd party technology in the form of processing chips, codec modules, network interface components, and more to perform certain complex tasks that could potentially be exploited.

This is where knowledge of the supply chain and manufacturing process becomes so crucial. It might be very difficult to get information about a company’s supply chain and processes since it may not be seen as an asset or selling point to disclose such data. When in doubt, try and find a manufacturer who creates and assembles as much the technology ‘in house’ as

possible. An ‘end-to-end’ solution will include not just the manufacturing and sourcing of trusted parts, but also the final assembly, QC and logistics. A reputable manufacturer should manage the entire product lifecycle including updates and fixes. Any reasonable vendor should be willing to divulge where they source their parts, where their products are made and how they are tested, otherwise they may not be in full compliance with things like the NDAA.

If a company tells you its products are cybersecure, should you just believe them? It’s important to look for independent verification. Until recently, there hasn’t been any internation ally recognized standard for cybersecurity for IoT products such as security cameras and supporting devices and software. The UL CAP (UL Cybersecurity Assurance Program) is a newer certification service designed to help organizations manage their cybersecurity risks and validate their cybersecu rity capabilities to the marketplace. Products that achieve UL CAP certification go through rigorous testing and have had their processes vetted by an independent, respected agency. Choosing a product with UL CAP certification should pro vide end users with additional peace of mind.

It has never been more important for systems integrators and procurement departments to be fully aware of the risks associated with decisions based solely on price, without tak ing into consideration any possible cybersecurity weaknesses or vulnerabilities. When shown how easy it is to hack into some of the low-cost security hardware that is widely available on the market, people understand first-hand, the perils that poor procurement choices can cause. In the event that these purchases have already been made, it’s important to evaluate the vulnerabilities and assess the risks through an analysis of the product, and by performing a penetration test. Once the evaluation is complete, every effort should be made to mitigate the important risks identified and, if necessary, replace the devices at risk with ones that come with a trusted design and manufacturing process.

For more information please contact: Johnell Johnson | Marketing Communications Manager Hanwha Techwin America

500 Frank W. Burr Blvd. Suite 43 Teaneck, NJ 07666

C: 404-210-9116 • j.johnson@hanwha.com l Hanwhasecurity.com

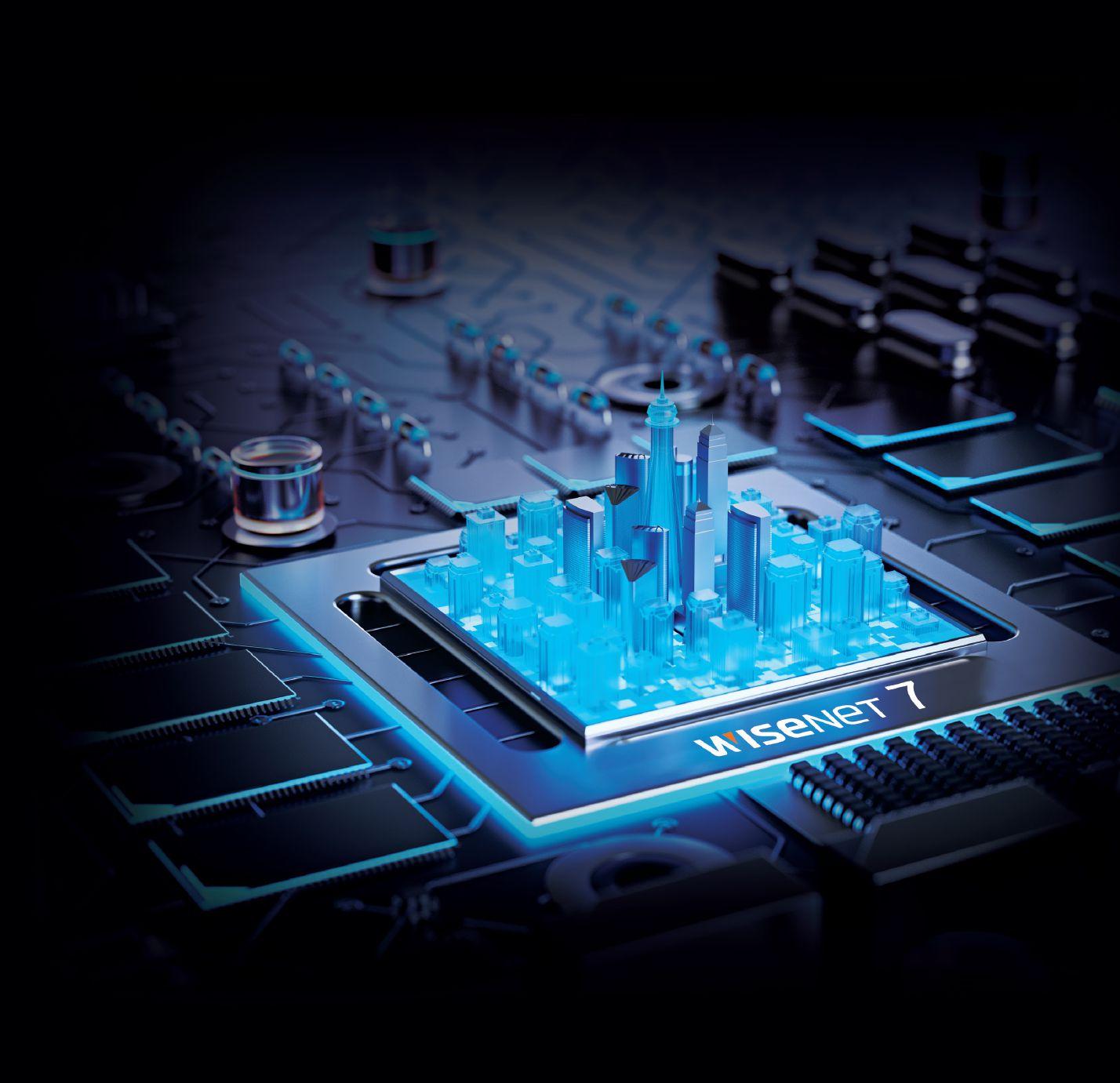

At the heart of Hanwha Techwin’s new product development is the Wisenet 7 System on Chip (SoC). Designed in-house and built in Korea, Wisenet 7 is our most technology-intensive and feature-rich chipset. From its enhanced image quality and total cybersecurity to unprecedented user convenience and operational efficiency, Wisenet 7 delivers end-to-end intelligent video surveillance capabilities today…and tomorrow.

© 2020 Hanwha Techwin America, Inc. HanwhaSecurity.com

Specialty cameras that are different from the typical range can address specific surveillance needs

Most people are familiar with the common camera types. Box, bullet, dome and turret cameras are all popular choices. These four form factors will meet the needs of almost any application, but there are niche cases where a different type of camera could be a better choice.

Specialized cameras are nothing new, yet many integrators avoid them either because they are outside of their comfort zone, or because they have had a negative experience with them in the past. Familiarizing yourself with these cameras and understanding their limitations is key to delivering the best surveillance solutions.

Fisheye cameras have been around a long time, but their popularity is gradually increasing as de-warping software becomes more common. Fisheye cameras use a single wide-angle lens to provide a circular, 360° view. They work particularly well in small, indoor spaces where detail is not as important as the ability to track activity throughout a scene. Fisheye cameras do not work well for scenes where great detail is required or where lighting is poor.

Their image sensors are required to capture an enormous field of view. This leads to the most common mistake when specifying these cameras, which is not understanding the impact this has on the camera’s range. For large spaces or areas where objects will be at a great distance, fisheye cameras are not the right choice.

Panoramic cameras are another type of camera that can achieve 360° coverage, but they are typically more expensive than fisheyes. For that extra cost, you get a camera that overcomes many of the shortfalls associated with fisheyes. Panoramic cameras are very good at capturing details and can perform well in low-light environments. Panoramic cameras are typically made up

of anywhere from two to four image sensors inside a single housing. Sometimes these sensors are fixed in place to provide complete 180° or 360° coverage.

In other cases, panoramic cameras allow users to reposition each sensor and customize the coverage area. Panoramic cameras have the added benefit of requiring only one network cable, whereas integrators looking to achieve the same coverage with multiple cameras would need to use multiple cables which can quickly increase costs. The major downside of panoramic cameras is the upfront cost, though this is usually offset by operational savings in the end.

Covert cameras are probably the most famous of specialty cameras, but their uses are not always as nefarious as some might think. Covert cameras have found their place in applications where traditional cameras would be obtrusive or simply would not fit.

ATMs are a popular application for covert cameras, where the device needs to be discrete while only inches away from a customer’s face. Another popular application for covert cameras is where finishes or

architectural design would be disturbed by traditional surveillance cameras.

In these cases, using a camera that can be hidden or at least blend into the environment can provide the surveillance required without taking away from the aesthetic of a carefully designed space. Due to their size, covert cameras lack features like vari-focal lenses or IR illuminators. Because of this, they are not good for large scenes and should never be used in low-light applications.

It can be difficult to know when specialty cameras are required or when traditional cameras are a better choice. As manufacturers expand their specialty camera product lines, end users will become more aware of them and start asking for them specifically.

In the meantime, it is up to the integrators to challenge themselves to learn and apply these cameras as part of their solutions. In most cases, a traditional camera will still get the job done, but switching to a specialty camera can take a project to the next level.

Colin

Bodbyl is the chief technology officer of Stealth Monitoring (www. stealthmonitoring.com).

By Neil Sutton

Almost any successful security integration project could rightly be called the solution to a puzzle. The task before Fibertel was taking pieces from different puzzles and placing them together such that they appeared to all come from the same box and form the same picture.

Edmonton-based Fibertel Communications Canada is SP&T News’ Integrator of the Year 2020, an annual award sponsored by Anixter Canada. Fibertel was named for the award by SP&T News’ editorial advisory board based on a nomination that detailed an integration project for client the Alberta Investment Management Corp. (AIMCo), specifically, HSBC Bank Place in downtown Edmonton.

Multiple contractors, including general contractor PCL Construction, Western Electrical, engineering consultant Smith + Andersen, and HVAC specialist Automatic Controls, came on to handle the project. Fibertel was brought on board by Western Electrical to fulfill the security component.

The 18-storey HSBC building, owned by AIMCo and run by property management firm Epic Investment Services, was stripped down to its concrete bones and rebuilt a-new as a smart building.

Fibertel was responsible for installing a variety of systems including an access control system from Gallagher, 120 Bluetooth-enabled HID Global card readers, 120 Hanwha Techwin video surveillance cameras, a video management system from Pelco, an intercom and mass notification system from Commend and a ThyssenKrupp Destination Dispatch elevator system. The install also included network and structured cabling, and more than 200 intrusion devices and 18 intrusion panels. The solution was spread across 18 communication rooms, one per floor; the building-wide intercom system was also integrated with the elevator dispatch system.

One of the major challenges ahead of Fibertel was integrating

the entire security system through a Building Management System (BMS) supplied by Schneider and installed by Automatic Controls. Coaxing these systems into talking to one another is where Fibertel truly earned its stripes, according to special project manager Tyson McCann.

“There’s nothing typical about this project,” he says. “When you start to get into what we did with the building automation, the BMS… it’s truly a unified system. Not only do you have the typical things that a building automation system is managing, like the lighting and the heating, etc., but now you’ve folded in the access control, the cameras, the scheduling of the doors — who

has access to what floors at what times. It’s all being done through the BMS. In my experience, I don’t know of any other building that has something of this magnitude in place.”

“Typically the BMS, and various other components — the ThyssenKrupp, the access control, the video surveillance — they work best typically on their own,” adds lead project manager Eddison Sambury. “So we had to take various manufacturers that may not necessarily be aligned and have the various components mesh. We had to be that contractor, that expert, to figure out solutions to make those manufacturers align.”

Sambury, who coined the aforementioned puzzle pieces from different boxes

“In my experience, I don’t know of any other building that has something of this magnitude in place.”

—Tyson McCann, Fibertel

analogy, says, “We had to make different pieces … fit and look as one.”

For McCann, it became an exercise in machine linguistics — like trying to get a fax machine to talk to a computer via a scanner, he says. “There’s very many companies that can install access control or install cameras. The real work begins when you try to have these different software platforms communicate with each other when they don’t natively do it already and having it work seamlessly.”

The HSBC building’s owner, AIMCo, is also its largest single tenant, occupying floors nine through 16 with an option to also move in to the eighth, should their expansion require it. Epic, as the property management company, is responsible for the day-to-day operations on site. Security had to be satisfied to the wishes of both companies, which essentially resulted in two end users, two sets of requirements and two timelines.

“We had to coordinate with AIMCo, but at the same time, we had the property management team, which is Epic, which took ownership of the rest of the building — the parkade, the main floor and various other tenant floors up to the eighth,” explains Sambury. “We had to ensure that their requirements were met, so that when the tenants moved in, there aren’t any difficulties for the tenants to mesh into the system that we installed.”

Serving two clients created some pressure, notes McCann, especially when one tenant needed the elevators to be available by a particular date. That deadline required a complex integration linking the access control system to the elevator system. “The way the access control system wanted to communicate to the elevator control sys-

tem, they weren’t even able to talk to the same communication protocol, so we needed to put translation in there, which ended up resulting in a third-party system to have that translation occur between the two platforms,” he says.

But tight timelines are not unusual for projects of this scope, he adds. “Ultimately the client has their requirements, and they’re shifting requirements. That can occur. It’s our job to make sure we hit those targets that are set for us.”

The complexity of the integration, combined with the flexibility required to meet multiple customer demands meant a high degree of collaboration formed between all of the contractors engaged with the project, says Sambury.

“To make things work, and make them work according to the customer’s requests, we had to spend a lot of time talking with the engineer, talking with Automatic Controls, ThyssenKrupp, even down to the door hardware contractor,” he says. “There were a lot of components that, on a typical project, we may not be as involved as we were, but with this HSBC job, we were in and amongst every discussion that was happening on that site.”

The bulk of the project was completed by November 2019 — at which point tenants were able to move into the building on an ongoing basis. An unforeseen complication, and one that affected construction projects and office buildings globally, was the pandemic. By the time COVID-19 began to disrupt Canadian organizations, Fibertel was fortunate to be at the tail end of the HSBC project, but there were still a few issues to contend with.

“One of the larger things I’ve seen happen since COVID is there’s been some sporadic challenges with the supply chain,” says McCann. “We would have unknown lead times, but it wouldn’t be across the board. Sometimes things are showing up right on time and other times there’s a random shortage of different materials.

“It didn’t really affect this project too much, because at this point, we already had the materials in place. It was just making sure that we have the right people, that we are able to maintain contact and continue to talk

to them and collaborate with them to make sure that we’re finishing it off properly.”

Sambury says the unusual situation created by COVID-19 required some shifts be rescheduled, so workers on-site could operate in isolation or socially distanced from one another. Likewise, collaboration with project partners had to move online and the teams embraced Zoom calls rather than face-to-face meetings to continue to communicate.

The building system, as developed and installed, also allows technicians to work on systems remotely, enabling quick diagnoses and faster troubleshooting.

“I always recommend providing us the ability to remote in, because that’s your first line of defence,” says McCann. “When anything goes wrong on a system, the first thing I want to see happen is have an analyst go in and see what they can see. Because very often, that’s going to help you get to the root cause of what’s going wrong on site.”

Both major stakeholders in this endeavor came away satisfied with the work as well as the dedication the Fibertel team demonstrated.

“They were willing to work with us and spend so much time making sure that everything was just the way it needed to be so that it worked with our IT group and facilities group and with the building group,”

says Lisette Goyette, facilities coordinator, AIMCo, and one of the building’s regular tenants. “There were just a lot of moving pieces. In my opinion, they stick-handled it really well.”

“They were excellent communicators,” adds Kevin Humphrys, general manager, Epic. “The team that they had here on the ground knew how to manage the project, but what was very useful to the property management group was their ability to communicate in layman’s terms what was happening … so we can communicate that to our stakeholders.”

Goyette says that Fibertel senior security technician Andrew Mathiesen was particularly attentive to AIMCo’s needs. “We would not have gotten this job done without his expertise.”

She recalls a recent situation when she had an issue with a card reader. “Andrew called me back right away and walked me through it. They’re very customer service focused.”

The Fibertel team had to be flexible throughout the process, says Sambury, serving the building’s stakeholders while translating their vision of a smart building into reality. “I always credit the team we have here. I was very happy that we were able to bring the team members together to come up with a design that could mesh the various systems together. It was truthfully and honestly a full team endeavor.”