No matter how challenging your needs, BKT is with you offering a wide range of OTR tires specifically designed for the toughest operating conditions: from mining to construction sites.

Sturdy and resistant, reliable and safe, able to combine comfort and high performance. BKT is with you, even when work gets tough.

For nearly 20 years, Darren Neil has been building up a solid reputation for his company, Darren Neil and Sons Excavating Inc.

8 The power of partnership

Building relationships takes centre stage at Forward Summit 2022.

18 Ring of Fire

Talks about massive mining road are picking up.

21 A Canadian first

Calgary recycling firm invests in state-of-the-art soil refuse facility.

24 An all-in-one system

Trimble’s next gen 3D Paving Control System for Asphalt Compactors.

28 BCSSGA helps build back B.C.

The BCSSGA leadership took on a vital role, managing communications during the disaster between industry and government.

Calling all aggregate producers!

Did you recently complete an interesting project upgrading a pit or quarry? Did you recently enhance an aspect of your operations through a change in how you manage a department? I would love to hear all about! Better yet, send me a proposal to present at Quarry Tech, Rock to Road’s live educational forums taking place coast to coast this year in Halifax and Calgary.

In addition to a host of industry experts already lined up to speak about how to enhance your operations through the latest technologies (full speaker agenda will be available on September 1), I’m interested in hearing from producers about a variety of issues from tackling supply chains to managing labour shortages, sky-high fuel prices and safety during the COVID-19 coronavirus pandemic. Let’s face it, there’s been no shortage of challenges for the aggregate industry these past few years. If you’re interested in presenting on how you’re navigating any of these hurdles, reach out and connect with me.

For the technology providers that haven’t yet sent a proposal, there are still a few spots left to present, so make sure to send me your proposal!

Presentation proposals are also being accepted for the following topics:

• The future of autonomous vehicles;

• The latest in crushing and screening technologies with case studies showing how they are lowering costs/increasing production;

• Blasting operation best pracitces;

• Tips for reducing dust and noise in pits and quarries;

• The latest in washing technologies with case studies showing how they are improving operations and water conservation;

• The latest hybrid and electric equipment for reducing fuel consumption; and

• Preventative maintenance solutions.

Quarry Tech is a one-day workshop focused on the latest technologies and techniques for optimizing quarry and pit operations.

This one-day event exclusively for quarry and pit owners and operators will offer attendees case studies and panel sessions presented by industry experts covering a wide variety of topics.

Quarry Tech Halifax will take place on October 13 at the Alt Hotel Halifax Airport.

Quarry Tech Calgary will take place on October 18 at the Radisson Hotel & Conference Centre Calgary Airport.

Deadline for all presentation proposals is August 29, 2022. Speakers selected to present at both forums will be notified by August 31, 2022.

Any questions regarding presentation proposals can be sent to Rock to Road editor Andrew Snook at: asnook@annexweb.com.

Looking to sponsor our Quarry Tech forums? For sponsorship information, you can contact: Laura Goodwin at: lgoodwin@annexbusinessmedia.com. For more information or to register, visit: www.quarrytech.ca.

Hope to see you in Calgary or Halifax in 2022!

@RocktoRoad

With decades of proven experience as a premier asphalt plant manufacturer with a reputation for building high-quality equipment, supported by world-class service, Astec is the ideal partner to our asphalt plant customers. We provide single source accountability by delivering a full range of services, including planning, manufacturing, setup, startup, and service. Astec maintains large parts inventories and has capabilities to manufacture custom parts when needed.

Scan QR code to see Astec’s full line of Asphalt Plant Products.

Volvo Construction Equipment (Volvo CE) recently became the first manufacturer to deliver a construction machine built using fossil-free steel to a customer.

The A30G articulated hauler built using fossil-free steel was handed over by president of Volvo CE Melker Jernberg to long-standing customer NCC on June 1, 2022 at a ceremony hosted by LeadIt – the Leadership Group for Industry Transition – in conjunction with the United Nations environmental meeting Stockholm +50.

The move comes just nine months after the company unveiled the world’s first vehicle concept using fossilfree steel, as part of the testing of the implementation in an ordinary production setup. While commercial introduction is expected to be gradual with selected customers, this first handover is an important milestone in the Group’s

ambition to drive industry transformation towards global climate goals. The A30G is produced at Volvo CE’s Braås facility in Sweden, using the existing manufacturing process, with fossil-free steel from Swedish steel company SSAB.

“We are sure that to succeed in decarbonizing the construction industry, actors in the value chain will need to

collaborate and act. Thanks to our strong partnerships with other driven and forward-thinking companies, we are now able to lead the change towards fossil-free construction and be the first to deliver a machine built using fossil-free steel to a customer. Turning commitments into actions is key to building the world we want to live in,” Jernberg said.

As part of its Science-Based Targets commitment, Volvo CE is set to achieve net-zero greenhouse gas emissions by 2040. Alongside the electrification of its machines, the company recognizes the importance of reducing its carbon footprint across its entire value chain. This includes the raw materials used in its products, of which steel is a major component. The production using fossilfree steel in Volvo CE’s machines and components will be gradual and depend on aspects such as steel availability.

On July 4, 2022, Frontline Machinery acquired Chieftain Equipment and its aggregate processing equipment lineup.

Founded in 1991, Chieftain Equipment is a well-established and widely respected aggregate equipment dealer based in the Edmonton region representing the Astec Group of Companies (for Astec’s static and mobile crushing and screening, material handling, washing, and classifying product lines), Sandvik mobile crushers and screens, Vale Industries, and more.

Consistent with Frontline’s expansion and service strategy, this strategic acquisition increases Frontline Machinery’s infrastructure and personnel, allowing for continued growth in the province of Alberta and the ability to better serve existing customers in the region.

“Over its existence of over 30 years, Chieftain Equipment has developed a deep heritage and strong market share in the aggregate industry,” said Daryl Todd, president of Frontline Machinery. “Their highly experienced, knowledgeable, and dedicated team has supported their growth, helping build a reputation of trust and transparency. Together we are well-positioned to expand and look forward to delivering a consistent, high-quality customer experience.”

By combining and leveraging Frontline’s and Chieftain’s strengths, abilities, and relationships, Frontline Machinery expects to drive aggressive growth. The company plans to ramp up regional operational and service capabilities through a significant increase in parts, service department capacities, and the equipment rental and sales fleet. At the same time, they will add additional resources and investments where necessary.

“We are excited to become a part of the Frontline family,” said Willie Thompson of Chieftain Equipment. “They understand the needs of our customers and share a common vision and mindset. We are confident that Frontline will continue to enhance and develop what we have built over the last three decades while supporting the uptime and productivity of existing Chieftain customers.”

Rock to Road magazine is circulated free of charge to qualified individuals holding management and supervisory positions with companies engaged in the aggregate, roadbuilding, ready-mix concrete and asphalt production industry in Canada. The Publisher reserves the right to determine qualification.

At

BY ANDREW Snook

> The Forward Summit 2022, in association with the Canadian Council of Aboriginal Business, featured a panel that focused on the value of true partnerships between industry and Indigenous communities.

The panel, “The Power of Partnership Beyond the Project,” focused on the long-term partnerships involved in two projects: a collaboration between Whitecap Dakota First Nation and SaskTel to bring access to fibre-optic broadband service to the community of Whitecap Dakota First Nation in Whitecap, Sask.; and the Taza development project, a massive First Nations redevelopment project on 1,200 acres of Tsuut’ina Nation land in the Calgary area involving a partnership between the Nation and real estate developer Canderel to build a major commercial development.

The session was moderated by Tim Coldwell of Chandos Construction. The speakers were Councillor Frank Royal of Whitecap Dakota First Nation; Colleen Cameron, Indigenous business development, Sasktel; Dan Van Leeuwen, managing director of development for Taza Development Corp; and

Your ability to turn virgin material and waste product into high quality aggregates requires equipment with unmatched power and precision. From reducing shot rock to sizing and shaping fine sand, we design and manufacture the most versatile and efficient crushers. Not sure what you need? Let our experts partner with you to apply the ideal solution.

See our full line of crushing equipment

the table had to realize that, and had to be willing to put up that that risk, while we put up the land as our own equity investment,” he said. “Being able to have that type of partnership where we both equally took on the risk, and we really took on the rewards was extremely important.”

The Tsuut’ina Nation also wanted to ensure that the development wasn't a typical development you would see in Calgary or Edmonton or downtown Toronto.

“We wanted it to really speak that you’re on Nation land. This is a First Nation development and it's not just about painting beads and feathers on the side of the building, but it actually integrates the culture, the tradition, and the ability for the Nation to have that ownership and have its members working there, both on a short- and long-term basis.”

Van Leeuwen says too often developers look at developing on First Nations land come in with the wrong approach.

“I think a lot of other developers look at developing on First Nations as we'll come in, show you what to do, tell you what to do, and if we make money, we'll share some. I think that's a flawed beginning and a flawed start,” he said.

Van Leeuwen says Canderel took the approach from the very beginning that things had to be set up equally.

“And then from that point forward, you start to say to yourself, ‘Well, what does equal vision and equal opportunity mean?’ You know, the Nation has a tremendous value in their land. We, as a company, have a tremendous access to capital. How can you bring those things together to create an equal benefit?” he said.

Bryce Starlight, vice-president of development, Taza Development Corp.

The first questions posed by Coldwell was, “How did you develop a vision for what you want it to achieve for the project, and what checks and balances or governance did you put in place?”

The first speaker to answer was Starlight, the Tsuut’ina Nation’s representative leading the long-term economic development mandate for the Taza development project.

“When we first went out to the market looking for partners for land development, we were focused mostly

on true partnership, genuine partnership,” he said. “What we didn't want to do was engage with a developer who was going to have us sit in the backseat while they did all the driving and gave all the directions. We wanted to actually actively participate in the design, the development, the creation of that vision, and then also the ownership on a longterm basis.”

Starlight added that one of the major impediments for many First Nations looking to take on larger infrastructure projects is a lack of access to free capital.

“So, the partner that we brought to

Van Leeuwen said the benefits from the project need to come back to the Nation for a long-term reward.

“The idea is not to pull the money off this project so that it leaves the community. The idea is to make sure that this partnership truly is an inclusion,” he said. “We have a saying together at Tsuut’ina, and it's more than just together in terms of Tsuut’ina and Canderel. We want to see everybody locally, regionally and further, not only come to get a benefit from being on the Nation, but also benefit back to the Nation for the long term. Our partnership, its first term is 40 years. I think if there's any

at Repurpose Aggregates (Joppatowne, MD)

September 22nd 2022

8am - 4pm

In partnership with our customer, Repurpose Aggregates, we are excited to host an Open House event this September.

Experience our industry-leading solutions live in action at one of our newest C, D & E waste recycling wash plants in the United States.

Join our experts for a live plant tour, real-time equipment demonstrations and networking with our CDE experts.

Don’t miss this opportunity to see our most innovative solutions in situ.

REGISTER HERE

Scan this QR code to register for the Open House today!

*Please note registration is required to attend this event.

developers in the room, they would call us crazy. But we said, let's set this out to have a long-term vision. That is what is making the partnership run well. It's governed by a board of equal Tsuut’ina and Canderel. We have a dispute mechanism that we could put in, but we've never had a dispute because we've set it up on that basis.”

Councillor Royal said the collaboration between Whitecap Dakota First Nation and SaskTel was vital for the future development of the Nation for the casino and resort, residential development, as well as the development of new twin arenas. He added that having a strong internet infrastructure for business, and community was needed throughout the COVID-19 coronavirus pandemic.

“Before the pandemic we were having monthly Elders lunches. During COVID, we turned to Zoom with the Elders and bought them all iPads,” he said, adding that the internet infrastructure was also vital for e-Learning.

SaskTel’s Cameron said that the company’s executive supporting the project acknowledged early on that it needed to have a core group of people who are Indigenous and who understood Indigenous and First Nations communities.

“As a result, we've been able to create and develop some amazing partnerships and have that long-term vision and that strategy together with our customers and the communities,” she said.

The relationship between Sasktel and Whitecap Dakota First Nation has been developing over the past 20 years.

About 15 years ago, the Nation built a cell tower with Sasktel as part of its long-term vision for economic growth. The internet infrastructure was another major step for achieving the Nation’s long-term growth, which also includes a golf course, hotel and a sub-development.

“But in order to have all that, they needed to have some infrastructure. And that partnership went together in terms of having that dialogue, we at SaskTel ensuring that we follow their vision, and we have those checks and marks in balance that we could identify and work with them and bring that construction to the community,” Cameron said, adding that now all community members have access to fibre-optic broadband service technology, which creates opportunities for the Elders and the youth.

The recent developments at the Nation have resulted in about 800 jobs between the casino, golf course and hotel, and more potential jobs could be created through the development of the twin arenas, a spa resort and future residential projects.

“In order to get investment, Sasktel and government recognized that there were investment opportunities for this project. More jobs mean better quality of life for our members,” said Councillor Royal.

Coldwell also asked the panel about risk management.

“Any partnership has risks that are inherent to the partnership. How did you get them out on the table and start to have adult conversations about them?” he asked the speakers.

Starlight said ensuring that the Tsuut’ina Nation was directly involved in the project was key for mitigating risk while removing politics from the overall business decisions.

“Not to say that we don't work with Chief and Council on a regular basis, but when it comes to the actual investment decisions, the way that we're actually developing, and the speed of how we're developing, we really had to ensure that it was moving at the speed of business,” he said. “What I've seen killed more deals than not is time. You delay too long, or the market changes, and all of a sudden, the project just goes out the window because you just weren't quick enough. So, for us being able to have that transparency, where Chief and Council representatives sit on the board, but at the same time aren't bound by the overall Chief and Council body to make that decision is extremely beneficial.”

Starlight added that updates were regularly offered to the community to ensure the project remains aligned with the community’s vision.

“What this helps us to do is survive leadership changes. Changes in Chief and Council, changes in administration even, where it can be very individually based a lot of times. Where someone's mandate or priority may kibosh an entire development project, if you're not careful,” he said.

The Nation also ensured that it had equal representation at a senior level.

“That's where my role comes in, where we're not just talking about a developer who's acting as a third party to a board of directors that's represented by the Nation. But you actually have someone who's got boots on the ground, who's getting their hands dirty, and actually taking part of the active development on a day-to-day basis,” Starlight said.

While the fibre-optic broadband service collaboration between Whitecap Dakota First Nation and SaskTel experienced a few “hiccups,” the Nation had someone in place that communicated with the community and Council about any concerns and questions that came up.

“People wanted to know when they were going to be hooked up, so we had that person communicate, and as of last year, everybody is hooked up. And, of course, manage the problems and expectations, and it went pretty smooth. So, that was a good project for us,” said Councillor Royal.

Additional highlights from the 2022 Forward Summit included panels on the Power of Procurement: Indigenous Inclusion in all Aspects of Supply Chain Across Industry; Leading the Way: Inspirational Indigenous Women and Perspectives on the Current Economic Landscape; The Ethics of Indigenous Engagement; and Growing Partnerships through Sustainable Forest Management.

The summit also featured 16 breakout sessions, which each focused on economic growth opportunities and challenges for a specific industry and demographic; more than 40 exhibits; Elders and Chiefs who shared their wisdom and hopes for the future with the Forward Summit audience; Indigenous artisans who put their unique creations on full display; and the Opening Night Reception co-hosted by Northeastern Alberta Business Aboriginal Association (NAABA), and the Silent Auction which raised over $6,000 CDN for The Legacy of Hope Foundation.

For more information, visit www.forwardsummit.ca.

HAZEMAG Roller Screens are proving their worth around the world with outstanding, dependable performance. The latest generation are engineered and designed to ensure application success, flexibility, highly reduced maintenance and field proven reliability. One of the largest, most modern cement plants in the world looked to HAZEMAG to solve their application concern. Commissioned in April, 2011, the HAZEMAG wobbler feeder (2,600 ton/hour) has processed well over 60 million tons of material without a single downtime incident.

HAZEMAG USA INC.

P.O. BOX 1064 Uniontown, PA 15401

Phone: 724.439.3512

Fax: 724.439.3514

E-mail: info@hazemag.com

HAZEMAG CANADA INC.

1 Marconi Court, Unit #10 Bolton, ON L7E 1E2

Phone: 905.857.9623

Fax: 905.857.3025

E-mail: info@hazemag.ca

Savings in energy and operational costs

A high degree of operational flexibility

Compact, low-profile design

Excellent performance under difficult raw material conditions – “high amounts of moisture and clays”

High efficiency / performance in removing the finer fractions from the feed stream

VARIOwobbler® – the ability to adjust the gap setting at the touch of a button

Exclusive “chain link” system that ensures trouble free operation

Exclusive “form fit” shaft design for reduced operating costs and excellent service life

Highly reduced maintenance. Nothing on the market comes close!

Field proven dependability and success

BY ANDREW Snook

> For nearly 20 years, Darren Neil has been building up a solid reputation for his company, Darren Neil and Sons Excavating Inc., in the Collingwood/Wasaga Beach, Ont. area. This popular area for residents of the Greater Toronto Area to spend their weekends and summer vacations has been Darren’s home his entire life. His company services everything within a few hundred kilometres around the Collingwood area, and its focus has evolved and grown over the past 19 years. Darren started his construction company in 2003 focusing on excavating, then soon after, aggregate haulage and float service, but then added custom crushing into the mix in 2015 to create a niche business within the aggregates sector.

Darren Neil and Sons Excavating performs a variety of work including earthmoving, excavating, trucking, grading, and snow removal in the wintertime. The company also performs site demolition and recycling in the Collingwood, Wasaga Beach, Stayner and Elmvale areas. The company’s custom crushing

services has been evolving as well.

“We’ve been trying to progress on our custom crushing and cater to not just recycling but gravel crushing operations as well. Now we’re close to a fifty-fifty split,” Darren says while chatting at a customer’s pit in the Feversham, Ont. area.

Demand for Darren Neil and Sons Excavating’s custom crushing services has increased enough for Darren to expand his fleet annually. He recently purchased a Lippmann-Milwaukee 4800 Closed-Circuit Plant, as well as another McCloskey International R155 screener, a J50 jaw crusher, and additional stackers and support equipment through Ault Equipment.

The sharply rising cost of fuel made Darren think hard about what equipment should be his latest investments.

“With the cost of fuel, we added a Lippmann 4800 plant to try and conserve fuel,” he says, adding that the 4800 plant has one diesel-powered generator, while the rest of the unit runs off electricity. “It feeds our electric stackers as well, so we have less fuel cost and less maintenance.”

The Lippmann-Milwaukee 4800 was also chosen because it’s less likely to encounter parts shortages, Darren says.

“With the Lippmann we went old school because it has less electronics and sensors,” he says, adding that sensors have been the most difficult parts to replace on equipment throughout the COVID-19 coronavirus pandemic. “The old technology is tried and true, but the new equipment attracts new employees, so you have the good and the bad with both. Safetywise the new equipment is superior.”

Darren likes the fact that Lippmann-Milwaukee and McCloskey products can both be purchased and supported by one dealer.

His fleet is a sea of green with McCloskey International crushing equipment making up the majority of his gear. This includes an I34R impact crusher, an I44 v3 impact crusher, two R155 screeners, an S130 triple-deck screener, five ST80 wheeled stackers, and an old 412 portable trommel screen.

He also uses Komatsu WA480, WA320, PC350, PC210 and CASE 1121, 821, CX240, CX210 wheel loaders and excavators for feeding his crushing and screening fleet, and breaking concrete and rock. His hammer of choice is built locally in the BTI brand.

Darren really likes that the McCloskey International plant is nearby in Keene, Ont.

“Good people, and only three hours away to the factory if you really need something, they are there to help,” he says.

While Darren Neil and Sons Excavating has been very busy servicing its clients’ pits, as well as providing all of its other services, the company has also expanded to include producing its own aggregate during slower days.

“I purchased an additional pit last year and now we have two, one in Orr Lake and another in Singhampton,” Darren says. His future plans include the purchase of a fully electric fixed plant. Darren is in the process of researching his options to find the best solution for his business. He is also busy getting his two sons, Brett and Braeden, familiar with his operations. Currently, his eldest son works in the excavation and trucking divisions of his company, while his youngest is busy working in the crushing operations.

“Both are capable, well rounded and will be good leaders in the future,” he says.

The first year of the COVID-19 coronavirus pandemic had the most significant

impact on Darren’s production, but fortunately that didn’t last long.

“At the start everybody put on the brakes, but soon after realized we needed to keep moving,” he says, adding that these days it’s business as usual in terms of demand. In the case of recycled products, the demand is growing quickly. “People are trying to produce more recycled products due to the high cost of virgin aggregate. The recycled products are high quality. We can make spec products all day long. As long as you can make spec with it, why not do it and save money and be more sustainable.”

As with most aggregate producers, one area where the pandemic has affected production is within Darren’s supply chain.

“You can’t get parts so it’s hard to stay on schedule. You can’t plan ahead because you don’t know when the parts will come in,” he says.

Another area where the pandemic hasn’t helped matters is within the skilled labour pool, which was already experiencing significant shortfalls across the entire construction sector.

Darren Neil and Sons Excavating currently employs 35 to 40 people across its operations and it has been incredibly challenging to fill roles to grow the business further.

“The people are not available. It’s very hard to get them, whether its truck drivers, machine operators or crushing staff,” Darren says. “You pay top dollar, treat them well, and hope they stick around. We really put our heart and soul into encouraging young people to come out. We are a family-run business and if you work here, you’re part of the family.”

Darren says his current staff are the company’s best advertisers in terms of finding new people.

“Our existing staff have been great at helping bring in new staff, so that’s excellent,” he says. “It also makes me feel good that they recommended others to come work with them, it shows they like it here,” he says.

Having a family run and family supported business is important to Darren and he looks forward to continuing to grow his business in the Collingwood and surrounding area for the next generation.

BY GRANT cameron

> Discussion about an all-season access road to the Ring of Fire mining area northeast of Thunder Bay is heating up now that Ontario's PCs have been re-elected.

With Premier Doug Ford and the party firmly in control of Ontario's economic levers for another term, it looks all but certain that the thoroughfare, dubbed the Corridor to Prosperity, will get the green light.

If there was any doubt, Ford put it firmly to rest on the campaign trail and later during his election night victory speech. During a campaign stop May 7 in Sault Ste. Marie, the premier reaffirmed his commitment.

“We're working side by side with Indigenous communities in true partnership and investing a billion dollars to build an all-season road to the Ring of Fire,” he told party faithful. “This road will be an absolute game-changer. It'll be a corridor to prosperity that will connect communities, families and businesses throughout the north.”

In 2021 alone, the government invested $641 million to expand and repair northern Ontario highways which created al-

most 4,500 jobs in the north, the premier noted, but the road to the Ring of Fire is most important.

“It will help create thousands of new mining jobs and bring countless benefits and opportunities for Indigenous communities, including easier access to everyday goods that most of us take for granted like groceries, fuel, health care and water,” he said. “Unlocking the Ring of Fire will be an enormous [opportunity] for the North.”

Minerals from the area will make Ontario a resource powerhouse, he said, and as the province works towards being the North American leader in electric vehicle production and building new EV battery facilities and securing new investments from the auto companies, the resources have never been more important.

“I want the minerals extracted here in the north, the clean steel produced here at Algoma, to be a critical part of the EV supply chain we're building right here in Ontario, and we can only do this by all working together.”

Ford reiterated his support for the road in his election night victory remarks.

“Thank you for sharing in a vision for our great province, sharing in a dream of a bright and prosperous future in an era of unprecedented growth and opportunity,” he said to a roar of applause. “So, if you're a miner in the North who's out of work, I want you to know that we're building that road to the Ring of Fire.”

Ontario has the critical minerals that the entire world is after, he said, and the province has the capital, technology, ingenuity and most importantly the vision to build the road to the Ring of Fire and make it happen.

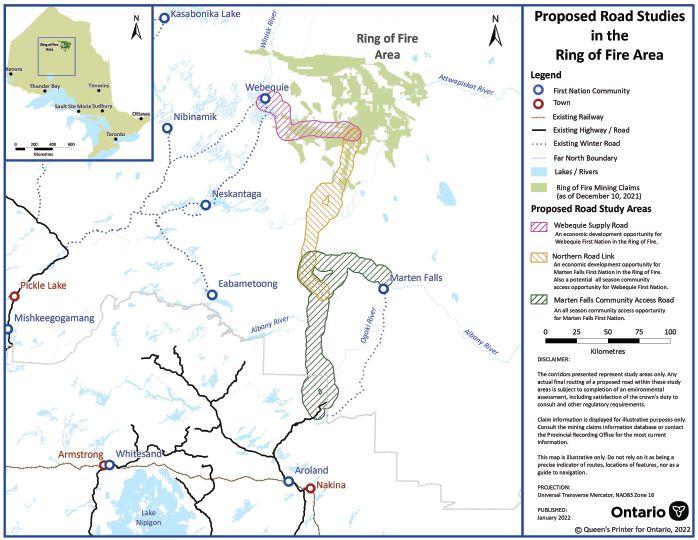

The Ring of Fire is about 500 kilometres to the north and east of Thunder Bay and about 300 kilometres from the nearest paved road. It covers an area of about 5,000 square kilometres, much of it wetlands, and is one of the most promising development opportunities for critical minerals in the province.

Some of the largest mineral deposits in Canadian history have been found in the area. The region has the potential to yield $60 billion in minerals and the deposits are substantial enough to support mining operations for a century.

The Ring of Fire deposit includes chro-

The Ring of Fire covers an area of about 5,000 square kilometres, much of it wetlands, and is one of the most promising development opportunities for critical minerals in the province.

mite, cobalt, nickel, copper and platinum – minerals which will play a role in batteries for the future of low- and zero-emission vehicles and transportation.

Developing the area is important because it will create jobs, generate revenue, bring prosperity to communities across the north, including First Nation communities, and lead to more infrastructure being built.

The road, actually a series of three interconnected thoroughfares, is critical to the development of the region as ice roads have been failing recently and the window for trucking in goods has been limited to two or three weeks. The three road projects will create a north-south corridor connecting the Ring of Fire area to the provincial highway network.

Exploration activity is underway in the area. As of January 2022, there were about 26,167 active mining claims held by 15 companies and individuals, covering approximately 4,972 square kilometres. Mining activity in the area is also ramping up with a new lithium development project, Island Gold Mine's third shaft expansion, and IAMGOLD's Côté Gold Project set to open in 2023.

According to Ontario Mining Association president Chris Hodgson, the Ring of Fire is home to some of the most significant mineral deposits in the world and provides Ontario with a natural advantage when it comes to producing

the materials required to build the electric vehicles and economy of the future.

“We are now seeing significant progress being made to ensure that these resources are safely extracted and connected to the world markets,” he said. “The benefits of these investments to this region is hard to overstate, and will bring good jobs and economic opportunities to the communities of Northern Ontario.”

Three separate links will be joined together to form the road and provide a corridor that will run for nearly 300 kilometres from Aroland Community Access Road in the south to Webequie First Nation and Ring of Fire developments in the north.

The three areas being studied are, at this stage, known as the Marten Falls Community Access Road in the south, Northern Road Link in the middle, and Webequie Supply Road in the north.

Proposed access route studies are being led by Marten Falls First Nation and Webequie First Nation. They are leading environmental assessments for their individual proposed all-season road projects, and are co-proponents for the planning and development of the proposed Northern Road Link.

Presently, the study areas are identified for environmental assessments only and do not reflect any final routing.

Last year, the province approved terms of reference for the Marten Falls Community Access Road and Webequie Supply Road. The two projects are in the late stages of environmental assessments.

The two First Nations communities also recently announced that they will be submitting terms of reference for the proposed environmental assessment for the Northern Road Link.

"This proposed road is the final piece of critical road infrastructure needed to ensure reliable, all-season road access to potential mining sites in the Ring of Fire and connect both First Nations communities to Ontario’s highway network," the province said in a news release.

The province has committed close to $1 billion to support critical legacy infrastructure, such as the planning and construction of the road network. The plan is also supported by a Critical Minerals Strategy and $2 million in 2022–23 and $3 million in 2023–24 to create a Critical

Minerals Innovation Fund.

“Our partnership sets a new precedence in the region on Indigenous proponency,” said Chief Bruce Achneepineskum of the Marten Falls First Nation. “As we prepare to submit the terms of reference for the Northern Road Link project, it is important to remember why we are here and what this represents. We are leading the Northern Road Link because the project is in our traditional territory and we are exercising our right to self-determination. This represents a potentially bright future for our future generations, for our neighbours, and for the region.”

“Webequie First Nation is proud of this important milestone in our collaboration with Marten Falls First Nation,” said Chief Cornelius Wabasse of the

Webequie First Nation. “The NRL project is an Indigenous-led environmental assessment, which integrates Indigenousprinciples with the provincial process. We look forward to discussing the NRL project with our Indigenous neighbours and key stakeholders.”

While the campaign rhetoric indicated the Tories will move ahead with the Ring of Fire, Ford made his intentions clear in unveiling his new, 30-person cabinet in June.

Northern Development and Mines was split into two portfolios and former Timmins mayor and mining industry executive George Pirie was pegged as Ontario Minister of Mines, with a special mandate to develop the Ring of Fire.

BY ANDREW Snook

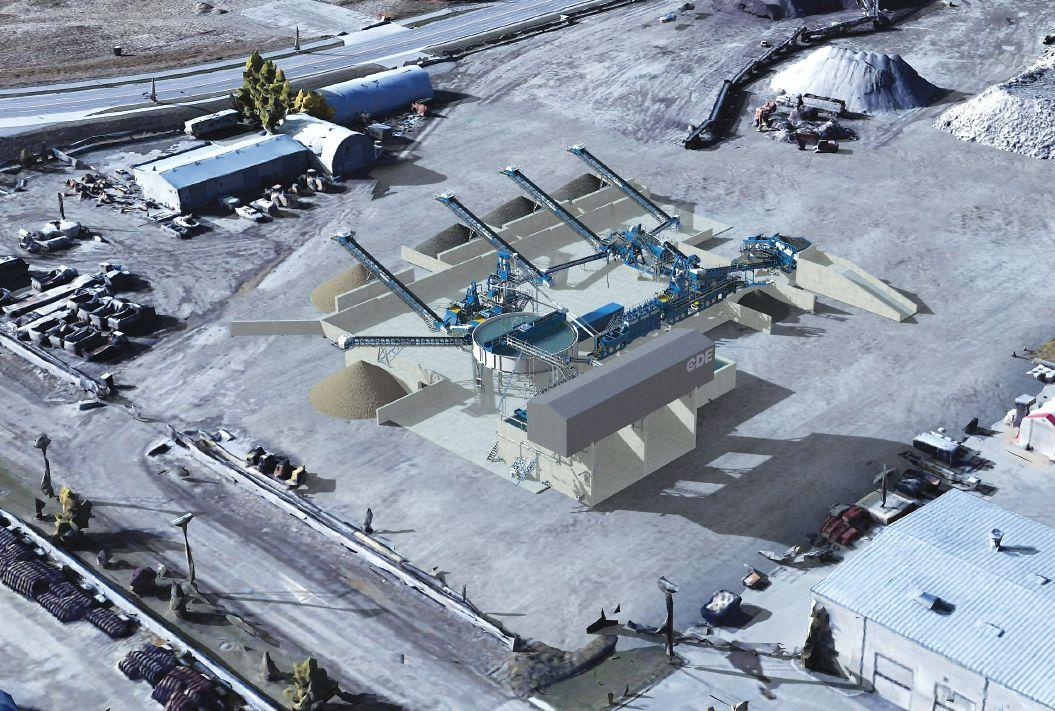

> Thanks to a multi-million-dollar grant, Calgary Aggregate Recycling Inc. is constructing Canada’s first soil refuse facility.

The Indigenous-owned, southeast Calgary recycler firm for concrete, asphalt and aggregate products was awarded an $8-million investment from Emissions Reduction Alberta (ERA) to build the facility.

The company, which has been in operation for more than 30 years, produces a wide of variety of recycled products including 25-mm recycled asphalt, 25-mm and 80-mm recycled concrete, recycled drain concrete, 25 mm and 80 mm gravel, bank pit run and clean fill. The addition of the soil refuse facility will give the company the ability to divert more than 510,000 tons of soil from landfills. It is estimated that the facility will be able to reduce carbon emissions in Alberta by 22,567 tons annually.

“At Calgary Aggregate, our mission is to reduce the cost of construction – socially, environmentally and economically,” Calgary Aggregate Recycling president Travis Powell recently stated. “With the support from ERA and the Government of Alberta, we are pleased to construct Calgary’s first C&D waste

recycling plant to disrupt the out-of-date practices in the construction industry with economical and viable solutions to position Alberta as a leader in sustainable and responsible construction.”

The heart of the soil refuse facility is designed and engineered by CDE. The wet processing industry experts have already commissioned two similar plants in the U.S. in New York State in 2020 and in Maryland in 2022.

“We are privileged to work alongside Calgary Aggregate Recycling Inc. to deliver a major C&D waste recycling system of its kind in Canada,” stated CDE’s business development manager for Canada, Adrian Convery. “The resulting solution will represent all that we strive for in pursuit of a circular economy, facilitating the diversion of vast tonnages of material from landfill, transforming them into high-grade recycled sand and aggregates for the construction industry, while simultaneously restoring land for future use and driving down CO2 emissions.”

In total, the facility is expected to have the annual capacity to recycle up to 600,000 tons of excavated material with some of the recycled product re-entering the construction industry as premium recycled sand and aggregate products.

The company’s initial interest in a soil refuse facility stemmed from a reoccurring problem it was trying to solve.

“Well, I would say the biggest thing was that we were running into issues with our contracting business on where we could get rid of contaminated soil, economically, and efficiently,” Powell explains to Rock to Road. “Landfills, namely the City of Calgary landfill, they don't want this type of material. So, they've raised the price so high that it's just not feasible to go there. And, you know, other municipal landfills are filling up so fast that we're having to truck further and further away. You know, it seems like every year, currently, we're tracking over 300 miles round trip for disposal of soil. And to us, it just didn't make sense anymore. So, we figured we had to look for a solution and we came across CDE’s technology… and that's kind of where we started to look and eventually made the investment towards.”

Calgary Aggregate Recycling then applied for the grant to help fund the new facility through the ERA, which Powell says was a very important part of the company’s investment.

“They had a challenge called the Shovel-Ready Challenge, and we were looking at this technology before and we thought, you know, in probably three, four years, we would make an investment into it. It's a sizable investment for smaller construction business like ours. So, we applied for the Shovel-Ready Challenge on the prem-

ise of emissions reduction, the shortening of the travel distance to dispose of this material, and then also, on the new virgin aggregate that's getting imported into the city all the time,” Powell says. “We tackled the transportation distances on both those products, and we found that we had sizable emissions reductions. So, we applied through Emissions Reductions Alberta for this grant, and they awarded us 50 per cent of our investment for this new facility.”

Powell says the market for recycled concrete, as well as the market for processing contaminated soil in the regions his company services are all fairly high.

“The recycled market is pretty strong on our other products like our recycled concrete or recycled asphalt, we have fairly good demand,” Powell says. “There is no market yet in in our area for recycled sand or recycled stone, so we're going to be the first into it. But we think that it'll go well. Our materials going to meet Tier 1 Residential or Agricultural guidelines, which means it can be used in any construction project, whether it's residential, commercial or industrial. We're optimistic it will displace a lot of a lot of dispersion aggregate mining.”

The focus on processing contaminated soils comes from old, contaminated sites that are in the process of being reclaimed or require reclamation.

“There’s lot of old brownfield activities throughout history. So it could be, you know, we have a site that we've just dealt with recently that was a leather tannery 100 years ago. There's contamination from old dry cleaners, old gas stations, old metal working shops. As the city grows, the industrial parks of the 1900s are now urban cores. As they get redeveloped and condo buildings go in there, then you have to reclaim that material. That's what's driving a lot of it, the redevelopment of our downtown core.”

Powell is very grateful to the Province of Alberta and the ERA for its investment in the company’s growth and a more sustainable Alberta.

“We're pretty fortunate to have a forward-thinking provincial government that is helping small companies like ours make these sizable investments into our future,” he says.

Calgary Aggregate Recycling’s soil refuse facility is expected to complete construction in the fall of 2022.

BY ANDREW Snook

> Trimble recently released its Trimble Roadworks Paving Control Platform for Asphalt Compactors. This system differs greatly from previous versions, as it is designed to standardize Trimble’s compaction offerings, explains Devin Laubhan, paving product manager for Trimble.

"With the Trimble Roadworks compaction system, what we’re trying to do when it comes to compaction as a whole, within machine control and Trimble, is standardize what we're what we're offering for compaction,” he says. “What that means is in our legacy systems for asphalt and soil and landfill, there were quite a few different base kits, configurations, options, licensing requirements. What we've tried to do with Roadworks, both on the Earthworks soil compaction side and Roadworks with the asphalt compaction side, is really standardized kitting, licensing, and features to make it more portable amongst contractors who have different machines within their fleet.”

Laubhan says that some contractors have asphalt compactors and soil compactors across their fleet, so Trimble is making it

JOIN US

HALIFAX, NS – OCTOBER 13TH, 2022

CALGARY, AB – OCTOBER 18TH, 2022

Rock to Road is excited to announce that Quarry Tech is back live and in person in 2022! These popular one-day forums focused on the optimization of quarry and pit operations will be coming back to Calgary and Halifax this fall.

Quarry Tech is an exclusive event for quarry and pit owners and operators that will offer attendees case studies and panel sessions presented by industry experts covering a wide variety of key industry-specific topics.

The call for proposals to present at both Quarry Tech forums will be opening soon!

easier for the end user to have a standard kitting offering and standard licensing options.

“Then we don't necessarily care what that machine type is,” he says. “Now, there are going to be specific features for each machine type that are applicable to them, but we hope that this makes it easier for contractors to share equipment across their fleet and still get the best results they can possibly get from using the technology.”

To make the system as user-friendly as possible, it leverages the highly intuitive Android-based Trimble Roadworks software. This is also designed to help shorten training times and decrease downtime for operators already familiar with the Roadworks user interface. Trimble stated that with the proper hardware and software configurations, the new system is flexible and can support a variety of jobsite needs and specifications.

When it comes to asphalt compaction, a lot of the features that have been there previously in Trimble’s prior compaction systems are still there pursuant to what contractors look for when it comes to the data that they need to collect and map with these compactors, Laubhan says.

“The big three in my mind are mapping, pass counts and mapping temperature of the asphalt mat under the machine,” he adds. “Also, CMV mapping or surface stiffness mapping, if that is ei-

ther applicable to the job or something the contractor wants to collect. The nice thing about the new platform is with our larger display, we're able to configure the system to see multiple things at once on the display versus, in the past, only being able to see one plan view that shows pass count and then some other text items. With the new system, we're able to let users configure the screen so that they can see things like pass count temperature, CMV, all at the same time on the same screen. It gives them a quick glance, to know you know if they're if they're influencing compaction and meeting their compaction metrics.”

The system, like Trimble’s previous systems, is tailored to be customizable based on the goals of each individual contractor.

“The bare minimum offering for the system would be pass count. You get pass count as the core feature for Roadworks or Earthworks Compaction. Everything after that is an add-on. So, even temperature mapping is an add-on. CMV mapping is an add-on. If you don't need CMV mapping, if you don't need to actually collect that data, we don't require you to install the sensor on the machine that collects that data,” Laubhan explains. “The other big thing really that we've changed with Roadworks from our previous systems are customizable licensing. And what that means is, if you don't need a specific feature of the system, we're not going to

charge you for it in the software. So, if all you need is to go out into the field and do some basic compaction mapping –where you want to collect pass count and temperature – we have what we call a ‘core license’ for the compaction platform that allows you to do just that. We're not charging you to use something like a 3D design in the field. You don't have to use Trimble Business Center design software. You don't have to use any sort of post-processing data analytics in our Works Manager or Works OS post compaction processing software. But we can add on licensing for those features that a contractor may require. This is where the wider power of the Trimble connected site offering is truly leveraged, but it’s not required for every job or every machine.”

Kevin Garcia, general manager for Trimble Civil Specialty Solutions, says that Trimble Roadworks’ Paving Control Platform is a particularly important release because DOTs and private owners are building technology requirements into their RFPs more and more frequently.

“The Trimble Roadworks platform is specifically designed to be easy to learn and use. Variable pricing helps make this platform even more accessible and levels the playing field for contractors of all types and sizes,” Garcia says.

For more information, visit: heavyindustry.trimble.com/roadworks-asphalt.

> SEPTEMBER 18-20

BCRB Fall Conference Kelowna, B.C. roadbuilders.bc.ca

> SEPTEMBER 23-25

CANS AGM

Cardigan, P.E.I. cans.ns.ca

> OCTOBER 3-5 SC&RA Crane & Rigging Workshop

Dallas, Texas scranet.org

> OCTOBER 13

Quarry Tech

Halifax, N.S. quarrytech.ca

> OCTOBER 18

Quarry Tech Calgary, Alta. quarrytech.ca

> OCTOBER 24-30 Bauma Germany bauma.de

> DECEMBER 1-3 BCRB AGM

Victoria, B.C roadbuilders.bc.ca

2023

> JANUARY 16-19 World of Concrete

Las Vegas, Nev. worldofconcrete.com

> MARCH 14-18 CONEXPOCON/AGG

Las Vegas, Nev. conexpoconagg.com

cdeglobal.com/us 682-350-0300

www.deere.ca/en/parts-andservice/connected-support/

BY ANDREW Snook

> When the flooding disaster hit in November 2021, destroying communities, washing out roads and trapping residents in some areas of B.C.’s Southern Interior, the B.C. Stone, Sand and Gravel Association’s (BCSSGA) membership sprang into action to help however, and wherever, it could.

The BCSSGA leadership took on a role as well, managing communications during the disaster between industry and government. There were some interesting outcomes that stemmed from the discussions the association had with regulators and Emergency Management BC.

“Part of the role the association played was really as a conduit for messaging to membership from government, pushing out that messaging, and then relaying what we're hearing from members back mostly to the Ministry of Energy and Mines, because people had a lot of questions about their permits and what they were and were not allowed to do in an emergency situation, because we've got hours of work, processing demands, trucking routes, and other things to manage,” says Derek Holmes, executive director for the BCSSGA. “And so, we

were helping people get through how to submit emergency authorization requests and notices of departure, and things like that. There was really good communication with the Ministry.”

That communication was especially important for B.C.’s Ministry of Transportation when it came to managing the roads that were damaged or entirely washed away.

“No one at the Ministry of Transportation, or Emergency Management BC, really knew where all the pits were. The Ministry of Transportation knew where their pits are, but the private ones, they really had no sense of that information. There was a lot of grabbing material wherever they could,” Holmes says.

To aid the Ministry of Transportation and Emergency Management BC in the future, BCSSGA put a list together of all the pits in different areas, so Emergency Management BC had the information readily accessible for the next time a disaster strikes.

“So next time they've got all of these different sources plotted out, and they can pick the best source for the job,” Holmes says. “You spend all this time permitting these sources and then disaster comes up and they kind of grab stuff from everywhere, and there's all these unintentional consequences of borrowing material where it really shouldn't be mined when there's perfectly good sources close by."

To make matters worse, the Sumas River dyke was breached in Abbotsford. Fortunately, BCSSGA’s local membership quickly organized to help manage the disaster.

“All of the BCSSGA producer members on Sumas Mountain set up a group where they set up correspondence with the local residents, setup road use with the City of Abbotsford and Emergency Management BC, so the association had appropriate truck routes set up, and so there would be coordination between the pits, so that only producers would move materials so they would leave trucking lanes open for a steady flow of trucks going up to the dike,” Holmes says. "Once it did reopen, it reopened on a very phased approach so that there was a slow ramp up, and coordinated different routes to all the quarries that kind of went through residential neighborhoods, school zones and things like that. So, we set up flaggers in those locations to make sure everything

was done safely and there was public confidence that the trucks were being managed appropriately."

Holmes add that the BC Roadbuilders Association did a great job as well through the emergencies.

"With their membership and it mobilizing, getting set there, that really felt like everybody's coming together," he says.

Holmes says the Ministry of Energy and Mines has been a great partner through all of the disaster work.

“They've been really accommodating when it comes to folks and their permits and operating schedules. There were very few questions asked when it came

to allowing people to purchase from their permits to just get done what needed to get done,” he says, adding that work to replace Highway 8 is still ongoing. “There are many kilometres of that highway there are still missing. So, a number of pits are still running under emergency authorization in that corridor and outside of Merritt."

As part of the rebuilding of Highway 8, the Ministry of Transportation is taking a hard look at its options for moving sections of the highway onto higher ground to prevent a similar catastrophe if similar flooding were to occur in the future, Holmes adds.

When the imminent resignation of Alberta Premier Jason Kenney occurs in October, Alberta will swear in the province’s eighth premier in 16 years. Out of the first seven heads of government in this era, only Rachel Notley will have completed a full four-year term from swearing in to standing for re-election.

Alberta’s age of dynastic premiers like Earnest Manning, Peter Lougheed, or Ralph Klein has ended. All of these premiers served over three terms or more in office. That kind of dominance over their party and the province seems impossible in this province today.

Also, the next UCP Premier will face the electorate at some point between October and the end of May 2023. Pundits claim that re-election is far from a certainty. The NDP’s Rachel Notley’s hold on her own party leadership is far more secure, and pundits claim that she’ll have a chance at winning back the Premier’s seat.

In the balance of this frequent upheaval is Alberta’s aggregate industry. Long-standing issues have been unaddressed to a greater or lesser extent by many of these Premiers. Whoever takes over the Government of Alberta, and for however long, will inherit several challenges to the aggregate industry and their ability to serve Albertans’ needs.

Long timelines for environmental permitting have been a problem for decades. While Alberta’s aggregate industry is not looking for deregulation, the application routinely will take years. It has a massive impact on the economic viability of new pits and the projects and communities they are meant to serve.

The outgoing government made a concentrated and somewhat successful push to clear backlogs in 2020. Currently, a long-term attempt to digitize the application process is underway. Whatever gains in applications wait times that have been made are severely offset by a severe lack of usability.

Occupational health and safety rules for aggregate pits are largely lumped in with conventional mines. These rules are adequate for mining but aren’t compatible with much smaller aggregate operations. Incompatible equipment rules are a particularly expensive by-product of this incompatibility.

ASGA has been attempting to get aggregate-spe-

cific OH&S rules for several years and participated in intensive consultations in 2020. The industry is still waiting to see what will come of that consultation.

Reform to the Community Aggregate Payment Levy (CAPL) policy is now 16 years in the making. CAPL is the funding program when the aggregate industry provides funding to municipalities to offset the industry’s impact, but the funds have disappeared into general revenues. While we have better lines of communications are in place with representatives of municipal government, little progress has been made.

Infrastructure funding from the province remains in long-term jeopardy, especially outside of Alberta’s two large cities. The previous NDP government made investments to boost the then-slumping economy but decreased it in their final budget.

Subsequently, the UCP threatened to sharply cut it further in the “McKinnon Report,” claiming that Alberta spent too much maintaining infrastructure when compared to other provinces. Initially, they moved to cut transfers from the province to smaller municipalities.

They backed away from that course when COVID-19 hampered economic recovery, and stimulus was badly needed. However, the last budget suggests they may return to austerity in infrastructure spending, despite posting budget surpluses fuelled by oil and natural gas revenues.

The aggregate industry, along with other resource industries, have struggled for attention and concern from the last several Alberta premiers. The contrast becomes apparent when compared to the responsiveness of neighbouring B.C. (with an NDP government) or Saskatchewan (with a conservative government). The roller coaster of the oil industry often overwhelms the Alberta government’s attention.

ASGA has made progress in garnering attention with cabinet ministers and MLA’s by making their needs known early in their tenures, not replying on non-political staff to brief ministers on their needs, and clearly communicating the consequences of government inaction.

John Ashton is the executive director of the Alberta Sand & Gravel Association.

VÖGELE SUPER 1700-3i / SUPER 1703-3i

VÖGELE SUPER 2000-3i / SUPER 2003-3i

The number one on the global market presents the “Dash 3” paver generation for the North American market. The 8-foot SUPER 1700-3i track and SUPER 1703-3i wheel and the 10-foot SUPER 2000-3i track and SUPER 2003-3i wheel pavers are available with an unparalleled range of screed offerings including front and rear-mounted vibratory screeds to high-compaction screeds. The new pavers include the intuitive ErgoPlus 3 operating system along with a few enhancements including VÖGELE EcoPlus and PaveDock Assistant.

www.wirtgen-group.com