•A RASTECH SPONSOR SHOWCASE•

INNOVATION FROM THE GROUND UP

www.rastechmagazine.com

Reader Service

Print and digital subscription inquiries or changes, please contact

Angelita Potal, Audience Development Manager

Tel: 416-510-5113

Email:

apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Account Coordinator/Sales

Catherine Giles

416-510-5232

cgilesh@annexbusinessmedia.com

Guest Editor

Mari-Len De Guzman mdeguzman@mastheadmedia.ca

Account Manager

Morgen Balch 519-429-5183 mbalch@annexbusinessmedia.com

Associate Publisher

Jeremy Thain 250-474-3982 jthain@annexbusinessmedia.com

Group Publisher Anne Beswick 416-410-5248 abeswick@annexbusinessmedia.com

Audience Manager

Urszula Grzyb 416- 510-5180 ugrzyb@annexbusinessmedia.com

CEO Scott Jamieson sjamieson@annexbusinessmedia.com

Printed in Canada

SUBSCRIPTION

RAStech is published as a supplement to Hatchery International and Aquaculture North America.

Occasionally, RAStech will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Office privacy@annexbusinessmedia.com Tel: 800.668.2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2025 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Made possible with the support of

Welcome to the fourth edition of Solutions in RAS, RAStech’s annual resource guide produced in collaboration with our trusted brand partners in the recirculating aquaculture systems (RAS) sector. As always, the information in these pages is aimed at helping you and your RAS team raise healthy fish in the most efficient and cost-effective way.

In this year’s edition we welcome RAS technology providers from Finland, Canada, Denmark, Norway and the USA. These companies give valuable insights into solutions that use AI to improve fish farm efficiencies, modular RAS design, improvements in water treatment technologies, fish handling, and more.

In our popular Executive Insights section (pages 16 & 17), we’ve posed the question “How can innovations in RAS technology drive more sustainable farming practices while ensuring long-term, economic viability for producers?” You’ll see that it has generated quite the variety of responses from this year’s sponsors.

Here at Annex Business Media, we strive to provide great content for our industry readers, and to help connect them with providers of the latest products and technology for their markets. Over the past few years, Solutions In RAS has proven to be a highly useful publication for land-based aquaculture professionals. We collaborate directly with the technology providers to give them a voice and a platform to not only share their expertise, but also showcase their thought-leadership. Long may this continue.

In fact, we encourage new technology providers to get in touch with us about participating in next year’s edition, so that they too can showcase their solutions, demonstrate their expertise and offer their insights in this special annual publication. We’re always on the look-out for new solutions which can help advance the land-based aquaculture sector as it continues to develop.

Enjoy this edition and I look forward to catching up with many of you at this year’s RASTECH 2025 conference & trade fair in San Diego.

Thanks for your continued support of our media.

Jeremy Thain

Associate Publisher - Aquaculture Division

Annex Business Media jthain@annexbusinessmedia.com

6-7

Flow-through to full RAS: Water reuse strategies in land-based aquaculture

8-9

Don’t go with the flow: 4 key lessons in RAS wastewater treatment

MERCK / 10-11

Promoting fish health and welfare through innovation

ARVOTEC /12

Smart feed: Precision farming solutions for sustainable RAS

Innovating for growth. FREA Solutions’ new growout module touts high energy efficiency, with flexible expansion capabilities

Reshaping sustainable production through artificial intelligence

Revolutionizing RAS: Onsite oxygen production, secure storage with OxyMax

Norwegian Helland Silosystem eyes North American expansion

Think tank: Designing for scale and sustainability

In the evolving world of land-based aquaculture, selecting the right water reuse strategy is a critical decision that impacts cost, risk and operational complexity. As discussions around recirculating aquaculture systems (RAS) and hybrid flow-through systems gain momentum, understanding their nuances is key to making informed decisions. KC Hosler, Chief Technology Officer of PR Aqua, a RAS engineering and solutions provider based in Nanaimo, B.C., sheds light on this complex topic.

He points out that rather than distinct technologies, these systems exist on a continuum of water use strategies. On the far left of that spectrum are fully open or “flow-through” systems and on the far right are fully closed or “zero -exchange” RAS.

“I think it’s important to understand how you actually find your spot on that spectrum and how you pick the right solution for any given application,” Hosler says. “Generally speaking, as you move from the left side to the right side, your water use is going to decrease while your operational complexity will increase.”

When considering a land-based aquaculture system, the choice isn’t simply between RAS and hybrid flow-through.

“These three terms — flow-through, partial reuse (or hybrid flowthrough) and RAS — are just different parts of the same continuum of water use strategies,” Hosler explains. “As you move from fully open to

fully closed systems, you’re adding additional technology components to reduce the amount of influent water used.”

Each step toward reduced water usage comes with trade-offs. While lowering water use decreases reliance on influent quality and reduces the risk of pathogen introduction, it simultaneously increases operational complexity, capital costs and the potential for mechanical failures.

“Finding the right solution along that spectrum is a matter of balance,” says Hosler. “It requires understanding the farm owner’s priorities, site conditions and risk tolerance.”

This continuum approach helps operators avoid a one-size-fits-all mentality. The degree of water reuse implemented must align with the available resources, local regulations and the species being farmed. Some species, for example, can tolerate higher concentrations of metabolic byproducts better than others, making them more suited to systems with higher water reuse rates.

Water flow in any aquaculture system serves two primary functions: delivering oxygen to fish and carrying away metabolic byproducts. As water reuse increases, additional treatment technologies must be introduced to maintain water quality.

“Generally speaking, as you start to reduce your water flow, the first limitation you’ll encounter is oxygen availability,” Hosler explains. “So,

you add a technology to supplement oxygen. But as you keep reducing water use, carbon dioxide starts accumulating, requiring aeration treatments. The next limiting factor is particulate, requiring the addition of solids removal. Then ammonia becomes limiting, which leads to the introduction of biofiltration.”

This stepwise addition of treatment technologies continues until a system reaches a near-closed state. However, a completely closed system is rarely practical due to the high energy and maintenance costs required to manage every water chemistry parameter without water exchange, Hosler notes.

Additionally, increasing complexity means operators must have a greater level of technical expertise to manage and troubleshoot their systems. “The more technology you integrate, the more training and experience your team needs to keep everything running smoothly,” Hosler says. “A highly automated system might require fewer staff but demands specialists to oversee operations.”

Much of the current industry conversation revolves around hybrid flow-through systems, often presented as an alternative to RAS.

But Hosler cautions against viewing them as fundamentally different technologies.

“Hybrid flow-through, also called partial reuse, has been used for decades,” he points out. “It’s not new technology; it’s just being applied at a larger scale now.”

In hybrid flow-through systems, key treatments such as oxygenation and aeration allow for a significant reduction in water use — typically reusing 30 to 70 per cent of the total flow. However, since biofiltration is not typically included, ammonia levels are still controlled by water exchange rather than treatment.

“This strategy works best when you have near-perfect influent water quality and temperature,” says Hosler. “You’re still dependent on what’s coming into the facility, and it’s difficult to modify those conditions because of the large water volumes involved.”

Hybrid systems are often attractive due to their relative simplicity and lower upfront costs compared to full RAS. However, the reliance on influent water quality can be a limiting factor, particularly in regions where water resources are constrained or regulations impose strict discharge limitations. Additionally, seasonal variations in water temperature and chemistry can introduce unpredictability, requiring additional management strategies.

RAS takes water reuse a step further by incorporating biofiltration and additional treatments to allow for even lower water exchange rates. However, Hosler emphasizes that RAS itself covers a broad spectrum of solutions.

“RAS can mean anything from a partial reuse system with a biofilter to highly complex setups managing nitrate, heavy metals and phosphorus,” he explains. “Even within RAS, the level of water reuse and treatment complexity varies widely.”

One of the key benefits of RAS is the ability to control water quality more precisely, making it particularly beneficial for high-value species or locations with limited water availability. It also allows for biosecurity measures that can reduce the risk of disease transmission, a critical factor for commercial aquaculture operations.

However, these advantages come with tradeoffs. RAS requires significant capital investment and may have higher energy consumption. Additionally, biological filtration systems require careful management to maintain the necessary bacterial populations for effective

waste processing. With increased operational complexity, the risk of mechanical or electrical failure increases as does the risk of operator error.

“It’s not just about installing the technology; it’s about having the expertise to run it effectively day in and day out,” Hosler stresses.

The decision between hybrid flow-through and RAS isn’t about choosing one superior technology over another — it’s about identifying the right balance for a given site, the production goals, and the related risk profile.

“We always recommend doing no more than necessary to achieve the desired outcome,” Hosler advises. “Why introduce more complexity and cost than required? The key is to understand your limitations — whether it’s water availability, discharge regulations or environmental conditions — and then pick a water use strategy and design that efficiently overcomes them.”

Operators should also consider long-term scalability when making infrastructure investments. A system that works well for a smallscale operation might become a bottleneck as production increases.

“Planning for future expansion from the start can save a lot of time and money down the road,” Hosler notes.

As the aquaculture industry continues to evolve, thoughtful application of water reuse strategies will be critical to ensuring sustainable and economically viable land-based aquaculture production. By understanding the nuances of different system designs, operators can make informed choices that align with their resources, goals and long-term success.

Through decades of experience delivering successful RAS projects, PR Aqua can help producers navigate the technical and economic aspects of their RAS journey.

Understanding the range of land-based technology solutions for operational and economic efficiency.

Wastewater treatment is a crucial yet often overlooked component of recirculating aquaculture systems (RAS). And yet, it may be one of the most important investments in RAS, critical to both ensuring the health of the system and the species that grow in them, and to the producer’s bottomline as regulatory and environmental risks carry financial consequences.

As the aquaculture industry continues to grow, understanding and properly managing wastewater treatment becomes increasingly important for successful operations, says Trevor Gent, director of engineered solutions at Alumichem, a global wastewater treatment solutions provider headquartered in Denmark and with offices in Canada, USA, Brazil, Belgium, UK and Ghana.

With decades of experience providing water treatment solutions for multiple industries, Alumichem is leveraging lessons learned to provide not just technology but the knowledge to help RAS producers optimize their water treatment systems.

Here are four essential lessons learned from years of experience building RAS wastewater treatment.

Unlike traditional wastewater treatment plants that operate in relatively steady states, RAS facilities experience significant variations in their waste output. These fluctuations occur naturally as fish grow from hatchery to harvest size, creating a cyclical pattern of increasing and decreasing waste volumes.

“The thing about a traditional wastewater plant is they run relatively in a steady state,” explains Gent. “If you’re talking about an industrial facility, oil and gas plant, textile plant, they turn on and run under constant conditions. Whereas in a RAS facility, you’re starting with hatchery and growing to a certain size and then you take the entire mass and send it out and start over again.”

The wastewater treatment system needs to be able to manage these fluctuations effectively, and these changes don’t happen overnight.

“Because what we treat is ultimately excess food and fish feces in a RAS wastewater treatment system.” And the volume of waste gets bigger as the fish grows bigger.

“RAS facilities are inherently dynamic,” Gent notes. “It’s really important to understand that those fluctuations can impact how the system operates and that you have to be prepared for those changes.”

The variable nature of RAS operations demands flexible wastewater treatment systems. Single-equipment solutions often fall short when managing the ups and downs of waste production. Instead, successful systems incorporate redundancy and adaptability in their design.

As Gent explains, “If you just build a system with a single piece of equipment and a single dewatering process, it gets very hard to manage those ups and downs. A lot of wastewater treatment is based on retention time or holding time through the process.”

Flexibility can take many forms, from multiple treatment units to adjustable retention times. This adaptability ensures the system can handle varying loads while maintaining treatment efficiency. The goal is to create a system

that can scale up or down as needed, accommodating the natural fluctuations in biomass without compromising treatment quality.

One of the costliest mistakes in RAS facility planning is treating wastewater management as a secondary consideration.

“We get brought in after the fact a lot of times because we’re not the most expensive part of the process,” Gent explains.

Often, producers are so focused on their ultimate goal of producing fish and building the systems that produce the fish and leave the wastewater treatment aspect as an afterthought.

This oversight can lead to significant challenges. “A lot of times we get brought in and they say, ‘Well, this is the size of the building you can have,’ versus, ‘What size of building do you need?’ And so we end up having to design around a building versus designing the right system,” Gent points out.

Bringing in all the engineering pieces, including wastewater treatment, early in the planning process helps producers build a better system that can meet not just production goals but satisfy environmental regulations, both now and into the future.

“Environmental permitting is an ever-changing beast,” Gent says. “So planning for now and planning for the future are really important. Don’t bring us in late. Bring us in

on the forefront so that we can think through what can come.”

While it might be tempting to outsource wastewater treatment entirely, successful RAS facilities understand the importance of maintaining ownership and knowledge of their treatment systems.

Gent shares an insight from a client: “When we first bought the plant with you guys, we had no idea what this meant, what this entailed. We’re now informed buyers. We know what we want, what to think about and look for.”

Being an informed operator means understanding the full scope of the operation and having a dedicated team or person operating the wastewater treatment system.

“That doesn’t mean they have to be there 24 hours a day, seven days a week. But you have to make sure that you have people on your team that are going to get trained, that are going to listen to the training, be interested in the training and execute on what it is,” Gent says.

As environmental regulations continue to evolve, staying ahead of compliance requirements while maintaining operational efficiency becomes increasingly crucial. Alumichem approaches this challenge through a twopronged strategy of innovation and practical adaptation.

“The beauty of wastewater is the contaminants are pretty well known at this point,” Gent explains. “It’s not a matter of what the contaminants are, it’s what the government wants us to do with those contaminants.”

The company’s innovation team continuously works on improving treatment efficiency and reducing system footprints. Automation is playing an increasingly important role in modern wastewater treatment.

“We’re starting to execute on solutions for clients where we’re using new control mechanisms, allowing us to better synchronize equipment operation with chemical adjustments, leading to improved efficiency and performance,” Gent notes.

Alumichem offers a comprehensive approach to water treatment, customized to meet client’s specific objectives and the regulatory environment in which they operate.

CONTACT INFO

Trevor Gent

tge@alumichem.com

www.alumichem.com

The aquaculture industry faces increasing pressure to adopt sustainable practices while ensuring the highest standards of fish welfare. With the rising global demand for seafood and heightened scrutiny over environmental impacts, producers are shifting towards land-based aquaculture and recirculating aquaculture systems (RAS). These controlled environments offer improved biosecurity, waste management and resource efficiency, positioning them as a critical solution for the industry’s future.

While RAS provides several advantages for producers, it also comes with some unique challenges, particularly in disease prevention, water quality management and operational efficiency.

Merck Animal Health is at the forefront of this paradigm shift, delivering comprehensive solutions that integrate biopharmaceutical innovation with advanced technology to support sustainable aquaculture. Through its Aqua division, the company provides cutting-edge fish health, identification and welfare solutions that help producers navigate the complexities of modern aquaculture. By combining veterinary medicines, vaccines and smart technology, Merck Animal Health empowers fish farmers to enhance efficiency, reduce environmental impact, and ensure the long-term viability of their operations across North America.

Merck Animal Health is committed to addressing some of the most pressing challenges in aquaculture. “We work collaboratively with fish farmers to improve fish health and welfare across various species,” says Ryan Vasak, customer manager for the North America Aqua Business Unit of Merck Animal Health. “Our solutions span biologics, pharmaceuticals and technology, all designed to support sustainable growth in the industry.”

One of the standout aspects of Merck Animal Health’s approach is

its integration of biopharmaceutical products with advanced technology. The company offers a comprehensive suite of veterinary medicines and vaccines for species including salmon, trout, catfish, tilapia, and marine fish such as yellowtail and sea bass. These medical innovations are complemented by industry-leading technological solutions that improve fish handling, traceability and overall welfare.

Over the past six years, the company has significantly expanded its technology portfolio, bringing leading brands such as Vaki, Biomark and Falcon Biomass under its umbrella. This allows Merck Animal Health to provide a range of diversified solutions to aquaculture producers, from real-time monitoring and automation to vaccines and disease management.

A pioneer in ‘smart’ fish handling equipment and real-time monitoring technology, the Vaki brand is one of only few technologies that offer a fully integrated pumping, grading and counting system. Merck Animal Health’s continuous innovation in the development and manufacturing of Vaki equipment, technology and the SmartFlow System has enabled customers to access key insights from data, facilitating planning and decision making.

“The Vaki SmartFlow system sets a new industry standard, giving customers critical data insights while enhancing automation and efficiency,” explains Vasak. “This technology ensures that fish welfare remains a priority while also improving productivity.”

Similarly, the Biomark portfolio of identification systems and PIT tag technology allows producers to track and catalog fish throughout their lifecycle.

“With Biomark products, aquaculture operations can implement robust broodstock management and traceability measures, ensuring high

standards of sustainability and resource management,” Vasak adds.

Another revolutionary technology, Falcon Biomass, is already gaining momentum in land-based aquaculture in Europe and Chile. Falcon Biomass uses vision technology to monitor fish, capturing images and using this image data to estimate the average weight, growth and size distribution of the fish in the tank.

By integrating these advanced solutions, aquaculture producers can achieve better growth rates, reduce waste and improve economic viability.

Merck Animal Health’s growth strategy includes targeted acquisitions that expand its aquaculture capabilities.

“Our acquisition strategy positions Merck Animal Health to provide a comprehensive approach to promote fish health, welfare and sustainability in aquaculture, conservation and fisheries within the aqua industry,” Vasak explains.

Their acquisition of Elanco’s aqua business in July 2024 strengthened the company’s vaccine and treatment portfolio, adding innovative solutions such as CLYNAV, a DNA-based vaccine for Atlantic salmon, and IMVIXA, an anti-parasitic sea lice treatment. Elanco’s comprehensive portfolio included vaccines, antiparasitic treatments, water supplements and nutrition.

Similarly, the acquisition of the Vaki business in late 2019 broadened Merck Animal Health’s aquaculture portfolio by expanding into complementary fish farming and conservation areas to generate outcomes with precision farming and fish welfare solutions.

These acquisitions have also enabled the company to offer a more integrated approach to disease management, combining vaccination programs with data-driven monitoring to

help producers identify and mitigate potential health risks before they become significant problems.

AquaCare 365 is another platform by which Merck Animal Health helps support fish farmers. It’s a training and development initiative that enhances operational efficiency and fish welfare practices. The program includes industry expert-led training modules, quizzes and certifications, ensuring that aquaculture professionals have access to the latest best practices.

“Merck Animal Health is committed to advancing fish health and welfare, which is essential for the long-term success of our customers’ operations,” says Tim Kniffen, technical services veterinarian in the North America Aqua Business Unit of Merck Animal Health. Feedback on the program has been overwhelmingly positive, with some companies incorporating it into their onboarding processes, Vasak adds.

“It’s a fantastic way to ensure that new staff understand the values and expectations of their company,” Vasak adds.

Aqua Care365 not only improves staff training but also helps standardize best practices across aquaculture facilities. The program covers essential topics such as water quality management, disease prevention, biosecurity and proper fish handling techniques, ensuring that all personnel are well-equipped to contribute to a thriving, sustainable aquaculture operation.

“As a former hatchery manager, I see huge benefit in offering staff training and development opportunities. I certainly would have offered Aqua Care365 to my staff had it been around when I was more active in fish culture,” Vasak says.

As the aquaculture industry continues to evolve, Merck Animal Health remains at the forefront, combining scientific expertise with advanced technology to support sustainable and responsible fish farming. Whether through vaccines, real-time monitoring, or traceability solutions, the company is shaping the future of aquaculture with a commitment to innovation and fish welfare.

“Our mission is to provide aquaculture producers with the tools they need to succeed while prioritizing the health and well-being of the fish they raise,” says Vasak. “By integrating biopharmaceutical solutions with cuttingedge technology, we’re helping build a more sustainable future for the industry.”

Looking ahead, Merck Animal Health is poised to continue to drive innovation through research and development, ensuring that fish farmers have access to the latest advancements in disease prevention, aquaculture technology and data-driven decision-making. With a holistic approach to fish health and welfare, the company is setting new standards for a more efficient and sustainable aquaculture industry.

A comprehensive suite of solutions from pharmaceutical to technology, helping producers optimize fish health and improve efficiency.

Ryan Vasak

ryan.vasak@merck.com

www.merck-animal-health.com

As the adoption of recirculating aquaculture systems (RAS) continues to expand, the need for precise, efficient and automated solutions that support these operations becomes increasingly critical. Finland-based Arvo-Tec, a leading innovator in aquaculture technology, provides state-of-theart feeding and solutions tailored to the unique demands of RAS farms. By integrating advanced automation and data-driven insights, Arvo-Tec empowers fish farmers to optimize production while minimizing waste and environmental impact.

At the heart of every successful RAS operation is efficient feed management. Feed accounts for the largest operational cost in aquaculture, and optimizing its delivery is crucial for both sustainability and profitability. Arvo-Tec’s automated feeding systems ensure the right amount of nutrition is given at the right time, reducing waste and promoting optimal growth rates. These intelligent systems minimize labour-intensive feeding routines, enabling farmers to focus on strategic farm management.

The TD2000 is a high-precision feeding system designed for con-

tinuous, even distribution of feed, ensuring that fish receive consistent nutrition throughout their lifecycle. This system allows for customizable feeding schedules and adapts to different species’ requirements, maximizing feed utilization and minimizing waste. Arvo-Tec Mobile Feeder is ideal for farms requiring flexibility in feed delivery, allowing multiple feed types to be distributed efficiently across different tanks with a single feeder unit. It utilizes a fast-charging and automatic refill station to deliver high-capacity feeding with high level of control of speed, dosing and spread.

Maintaining ideal water quality and fish health is paramount in RAS farming. Arvo-Tec’s own monitoring and control systems, including the WOLF control and ArvoPRO online, provide real-time data on critical parameters such as oxygen levels, temperature and feeding behavior. By integrating these insights into farm operations, producers can make informed decisions that enhance fish welfare and improve overall productivity. The systems can also integrate seamlessly with existing third-party monitoring tools on the market for ease of adoption.

The WOLF control system con-

management software for accurate reporting on feed usage and fish growth.

Arvo-Tec’s solutions reduce dependency on manual labour. Automated feeding and monitoring decrease the need for constant human supervision, freeing up time for farmers to focus on expansion and business development. By streamlining daily operations, farms can scale efficiently without significantly increasing labour costs.

This suite of solutions provide comprehensive feed logistics for RAS producers, enabling gentle and efficient feed handling from truck to tank, and everything in-between.

tinuously tracks key environmental variables, alerting farmers to potential issues before they become critical. This proactive approach minimizes stress on fish populations, reducing the likelihood of disease outbreaks and improving overall stock health. Meanwhile, ArvoPRO acts as a centralized hub, collecting data from various sensors across the facility. This cloudbased system allows farmers to monitor their operations remotely, ensuring optimal conditions and increasing operational efficiency.

One of the key advantages of Arvo-Tec’s technology is its ability to transform raw data into actionable insights. By integrating feeding and monitoring systems with farm management software, producers gain a comprehensive view of their operations.

In large RAS operations, a highly integrated, connected system — from water to feed to waste — can provide rich amounts of data that can provide key metrics for both real-time insights about the fish and the system, but also enable data-driven decision making and predictive analytics modeling. For example, AI enabled camera pellet detection systems can provide multiple data points to a farm

Arvo-Tec’s expertise and innovations make it an ideal partner for RAS operators looking to scale efficiently and sustainably. With a track record of delivering reliable, user-friendly solutions, Arvo-Tec empowers fish farmers to achieve consistent production outcomes while reducing costs and environmental impact.

Arvo-Tec works closely with aquaculture operations to customize solutions that fit their specific needs. Whether a farm requires a tailored feeding strategy, enhanced monitoring capabilities, or data integration support, Arvo-Tec provides end-to-end solutions that enhance productivity and sustainability.

Smart feeding and monitoring solutions that optimize efficiency, reduce waste and support sustainable RAS farming.

CONTACT

Joonas Jääskeläinen Tel +358 20 729 9910 sales@arvotec.fi www.arvotec.fi

FREA Solutions’ new grow-out module touts high energy efficiency, with flexible expansion capabilities

FREA Solutions is testing the commercial scale application of a new grow-out module it developed in response to the market’s increasing demand for larger-sized trout and the trend among salmon producers to grow larger smolt on land.

“The growout module is based on FREA Solutions’ core principles of ‘keeping it simple’ and ‘making it work,’” explained Thorsten Vammen, general manager of FREA Solutions. “All elements of the growout module are based on proven solutions.”

The company developed the new growout module in full commercial scale, and has been put into production in one of its RAS fish farms in Denmark. The system is undergoing modifications to resolve issues that come up during in-house operations, to ensure optimal performance.

Once satisfied that the solution works in commercial scale operation, FREA will begin offering the new grow-out module to customers.

Keeping things simple, supported by extensive operational experience, ensures a high degree of reliability and proven production capability of FREA’s RAS farming solutions.

“You can perform magic in spreadsheets and on drawings, but when it comes to reliability and performance, nothing beats actual operational experience,” Vammen said.

Overall simplicity in all applied solutions greatly reduces financial investment, and results in significant savings on energy, maintenance and repair costs. FREA’s RAS solutions offer low capex and opex profiles unmatched on the market.

Knowledge-sharing is another benefit provided by FREA to its customers, by providing them with all the knowledge gained from pilot commercial testing conducted at FREA’s RAS farms, often resulting in solutions that exceed production expectations.

Like its other RAS solutions, the grow-out module is built with standardized, prefabricated concrete elements. Pre-made and quickly assembled on site, this gives a predictable fast construction time, cuts down on labour cost during installation, and results in greatly reduced construction cost. Using raceways ensures an optimal utilization of land — producing more on the same site, or using less land for the planned production. Moving water in

channels results in minimal underground piping, taking significant complexity and costs out of the construction process. Inexpensive airlifts are used for gentle fish transport within the facility, and for delivery, eliminating the need for fish pumps.

FREA has been operating its own RAS facility without drum filters since 2014. The grow-out module also uses sludge cones and fixed bed biofilters for removal of solids and fine particles. This combination provides a fast and effective way to remove fish feces from production raceways, eliminates the need for drum filters, and provides ease of operation The system also requires very little maintenance and minimal energy consumption for back-washing of biofilters. The absence of drum filters

not only significantly reduces capex but also generates huge savings from low energy consumption and low labour cost since no additional staff is required to maintain and operate the drum filters.

All blowers, electric main panels and other technical installations are placed in one single ‘technical corridor,’ servicing all grow-out modules. The technical corridor is expandable to allow for additional growout modules. It can easily be enlarged to facilitate the additional technical installations for newly added modules. With all electric equipment placed in one single corridor, blowers and other equipment can be interchangeably used between modules. This greatly reduces the need for investing in redundancy equipment.

Water treatment chambers can be installed with a customized number of either moving bed bioreactors (MBBRs) or fixed bed bioreactors (FBBRs). As standard, MBBRs are fitted with a chamber separation grid to ensure optimal circulation of the biomedia and to promote efficient nitrification. All FBBRs are fitted with a fixed bed biofilter in the bottom of the chamber, and CO2 degassing above the biofilter, all within the same water treatment chamber. Combining FBBR with degassing significantly reduces required land footprint, further saving significant construction cost.

From the very beginning, fish transport has been carefully considered and integrated into the layout of the grow-out module solution, using airlifts instead of fish pumps. Many years of in-house operational experience has proven this to be an effective and gentle way to transport fish, and with a minimal impact on growth.

“At FREA we stop feeding just a few hours before grading, and once graded, fish will start eating right after,” Vammen explained. Using airlifts eliminates the need for costly fish pumps (only pipes and a compressor are needed), provides easy operation, requires no maintenance, and uses minimal energy during operation.

The grow-out module blends in naturally with the surrounding terrain. Roof and wall panels can easily be fitted di-

rectly onto the precast concrete modules for better temperature control, and enhanced biosecurity. Manufactured in a controlled environment, the precast concrete elements used in raceways and water treatment sections, ensure consistent high quality and smooth surfaces. This eliminates the need for costly coating and keeps raceways, water channels and water treatment sections free of fouling, greatly reducing the risk of getting off-flavor issues. Servicing all modules from one single technical corridor — and making it accessible without having to enter production or water treatment sections — further ensures optimal biosecurity.

The grow-out module comes with the low energy consumption FREA’s solutions have been well-known for. With water moving in channels by gravity, only lifted 0.8 meter once per recirculation, having no drum filters, and using airlifts instead of fish pumps, FREA’s new grow-out module is one of the most sustainable and energy-efficient RAS solutions in the world.

As of press time, FREA is still in the process of collecting energy consumption figures from the operation of two, fully commercial-scale grow-out modules. However, early indications reveal consumption will likely be below 2 kWh per kg of fish produced (for a production of large trout to approximately 3 kg). The high-quality precast concrete elements provide ample support for a roof structure with energy generating solar panels, further enhancing the sustainability profile of the module solution.

Vammen is urging interested RAS producers and operators to reach out to the company for the validated energy consumption data.

Simple, effective RAS technologies that are tested and proven through real-world applications.

Thorsten Vammen tnv@frea-solutions.com www.frea-solutions.com

How can innovations in RAS technology drive more sustainable farming practices while ensuring long-term, economic viability for producers?

TREVOR GENT

Director, Engineered Solutions,Alumichem

“Innovation in water treatment is key to making land-based aquaculture both sustainable and economically viable. Advanced treatment technologies not only help farms meet strict water discharge limits but also enable the recovery and reuse of valuable nutrients from sludge. By integrating cost-effective wastewater management into aquaculture operations, producers can reduce environmental impact, focus on growing fish, and enhance long-term productivity. As the industry grows, adopting these solutions will be essential for balancing sustainability with profitability, ensuring a resilient future for aquaculture.”

THORSTEN VAMMEN

General Manager, FREA Solutions

“The future of RAS technology lies in modular design, simplified yet well-tested solutions, and a strong focus on reducing both capital and operational costs. Standardized modules allow for rapid, cost-efficient expansion, and minimizes complexity and maintenance. Energy-efficient solutions, such as gravity-fed water movement, airlift technology for fish transport, and the elimination of high-maintenance filtration systems, are driving down energy consumption and improving system reliability. Looking ahead, the integration of AI and machine learning will further optimize fish welfare and performance, enhancing feeding programs, water quality monitoring and overall operational efficiency. As demand for responsible seafood production rises, these innovations ensure a balance between ecological responsibility and long-term economic success for producers worldwide.”

TONY PANTAGES CEO, Octaform

“Sustainability in RAS isn’t just about resource efficiency, it’s also about reducing long-term operational costs. One of the biggest challenges in land-based aquaculture is the ongoing maintenance of tanks, with coatings that require repeated re-application, causing downtime and added expenses. Octaform’s embedded PVC liner provides a permanent solution, eliminating the need for coatings while ensuring a durable, low-maintenance environment. With a 20-year warranty against leaks and corrosion, we’re delivering tanks built to last, supporting both sustainability and the economic viability of producers.”

CEO, WESI Solutions

“We see that RAS was primarily designed and developed as a sustainable way to farm fish. However, maintaining stable water conditions has proven challenging. New innovations and AI will help RAS operations become more efficient and help to keep the whole process under control by enhancing monitoring, optimizing feeding and resource use, and improving fish welfare. As the industry continues to evolve, while navigating labour challenges, incorporating AI will likely become essential for meeting the growing demand for sustainably produced seafood, while maintaining profitability. We believe data management and use of AI technologies will enhance and develop long-term profitability and sustainability in RAS.”

INGE STIAN HELLAND

CEO, Helland SiloSystem

“Our mechanical fish feeding products improve sustainability by optimizing feed usage, reducing waste, lowering energy consumption, and promoting healthier fish. These advantages help farmers reduce costs, minimize environmental impact, and increase productivity, all of which support long-term economic viability.”

STEVEN MCDOUGALL

President and CEO, Benchmark International

“Innovations in RAS technology are not only revolutionizing sustainable farming practices but also ensuring long-term economic viability for producers. Our integrated approach, exemplified by the OxyMax solution, transforms oxygen management by enabling on-site production and secure storage. Our solution offers a level of resilience that not only supports higher stocking densities and improved fish welfare but also minimizes the environmental footprint of traditional oxygen supply methods. By leveraging these innovations, producers can achieve enhanced productivity and operational efficiency while driving sustainability across the industry. In essence, our commitment is to empower aquaculture operators with technology that ensures reliable and cost-effective oxygen management, ultimately fostering a more secure, responsible and profitable future for modern aquaculture.”

JOONAS JÄÄSKELÄINEN

Sales Manager, Arvo-Tec

“As global demand for seafood continues to rise, conventional aquaculture methods face increasing pressure due to resource depletion, environmental concerns and disease outbreaks. Innovative RAS addresses these challenges by significantly reducing water consumption, minimizing waste discharge and improving biosecurity. Automated feeding solutions are a key innovation within RAS, providing precise and frequent feed delivery to optimize the feed conversion ratio and minimize waste. By monitoring fish behavior and environmental parameters in real-time, automated feeders ensure that fish receive the right amount of food at

the optimal times, reducing the risk of overfeeding and maintaining water quality. This precision not only enhances fish growth and health but also reduces operational costs and labor.

For producers, the long-term economic viability of RAS depends on balancing initial capital investments with operational efficiencies. Breakthroughs in cost-effective system design, feed optimization, and species selection can enhance profitability while ensuring environmental responsibility. By continuously innovating, RAS technology has the potential to reshape aquaculture into a more resilient, sustainable, and economically feasible industry.”

RICHIE CARMICHAEL

Associate Director of Sales, North America

Aqua Business Unit, Merck Animal Health “As resources continue to experience unprecedented strain, innovations in RAS technology drive necessary efficiency gains and increased reliability in protein production. These innovations could uniquely position RAS driven aquatic protein production as a long-term, economic and environmentally sustainable source of food for our planet.”

KC HOSLER

Chief Operating & Technical Officer, PR Aqua “Sustainability and economic viability will be achieved through continued development towards standardized modular RAS production systems. Standardization will provide the repeatable performance, predictable cost, and shortened development timelines that are required for investment, and the continuous incremental improvement in operating efficiencies that will drive long-term economic viability. The standard RAS then becomes a base from which innovative technologies may be added to further improve sustainability and farm economics. For example, technologies may be added to valorize RAS by-products (e.g. fish sludge), creating additional revenue streams while contributing to circular economy principles, or to incorporate renewable energy sources (e.g. solar or wind) to reduce reliance on fossil fuels and contribute to a more sustainable energy profile.”

In today’s aquaculture landscape, maintaining optimal oxygen levels isn’t just a technical necessity—it’s the lifeblood of productive fish farming. With rising operational costs and the ever-present risk of power interruptions, aquaculture producers are increasingly seeking reliable, costeffective solutions to secure their oxygen supply.

One solution that’s gaining traction on the market is Benchmark International’s OxyMax solution. This technology is a state-of-the-art system that integrates Oxygen Solutions’ VPSA oxygen concentrators with Fabrum’s ad -

vanced cryogenic cooler and dewar storage for seamless operation.

Traditional oxygen supply methods, often reliant on external deliveries, leave aquaculture operations vulnerable to supply chain disruptions and fluctuating costs. OxyMax turns this model on its head by enabling operators to produce high-purity oxygen onsite.

The heart of the system is the VPSA (Vacuum Pressure Swing Adsorption) oxygen concentrator, engineered to consistently deliver oxygen at

92 to 95 per cent purity. This level of purity ensures that every drop of oxygen meets the high standards necessary for optimal fish health and water quality.

What truly sets the OxyMax solution apart is its seamless integration with Fabrum’s cryogenic cooling technology. Once the VPSA unit generates oxygen, the system channels the gas into the Fabrum cryogenic cooler, which rapidly cools the oxygen down to approximately –183°C. At these ultra-low temperatures, the

oxygen transitions into a liquid state—a transformation that offers two major advantages:

Liquid oxygen takes up significantly less space than its gaseous form, allowing for a more streamlined and secure storage solution in the dewar.

Redundant safety net: By converting and storing oxygen as a liquid, operators create a robust backup that can sustain operations even during a power failure—ensuring that fish yields are never jeopardized by an interruption in oxygen supply.

HIGH-PURITY OUTPUT: The VPSA concentrator consistently produces oxygen at 92 to 95 per cent purity, essential for maintaining optimal aquatic environments.

CRYOGENIC CONVERSION: Fabrum’s cryogenic cooler brings oxygen to –183°C, converting it from gas to liquid almost instantaneously, thereby maximizing storage efficiency.

ENERGY-EFFICIENT OPERATIONS: By leveraging on-site production and storage, OxyMax minimizes the need for frequent deliveries and reduces the operational expenses associated with traditional oxygen procurement.

MODULAR AND SCALABLE: Designed with the aquaculture specialist in mind, the system’s modular architecture allows for scalability, adapting to the needs of small hatcheries or

For aquaculture operators, the OxyMax solution is more than just advanced equipment—it’s a strategic asset. By producing oxygen on-site, fish farmers can:

Achieve significant cost savings: It eliminates recurring expenses associated with external oxygen deliveries and reduces long-term maintenance costs.

Enhance operational continuity: With a liquid oxygen backup in place, the system ensures that even during unexpected power outages, the oxygen supply remains uninterrupted, safeguarding fish health and yield.

Increase overall efficiency: The integrated, self-regulating process simplifies system management, freeing up valuable time and resources for other critical aspects of aquaculture operations.

In the fast-evolving aquaculture industry, the need for reliable, efficient oxygen supply systems has never been greater. The OxyMax solution from Benchmark International is poised to transform how fish farmers manage their oxygen needs, by offering a cuttingedge, cost-effective and resilient system that not only

meets today’s challenges but also paves the way for future innovations in aquaculture.

For aquaculture producers looking to enhance production stability and protect their yields, exploring the OxyMax solution is a step toward a more sustainable and profitable future.

Discover how integrating onsite oxygen production with advanced cryogenic storage can revolutionize your aquaculture operations. Learn more about the OxyMax solution from Benchmark International and take control of your oxygen supply today.

OxyMax empowers fish farmers with onsite oxygen production and liquid backup all in one.

Samson Dirrar samson.dirrar@benchmarkinc.ca

www.bench-int.com

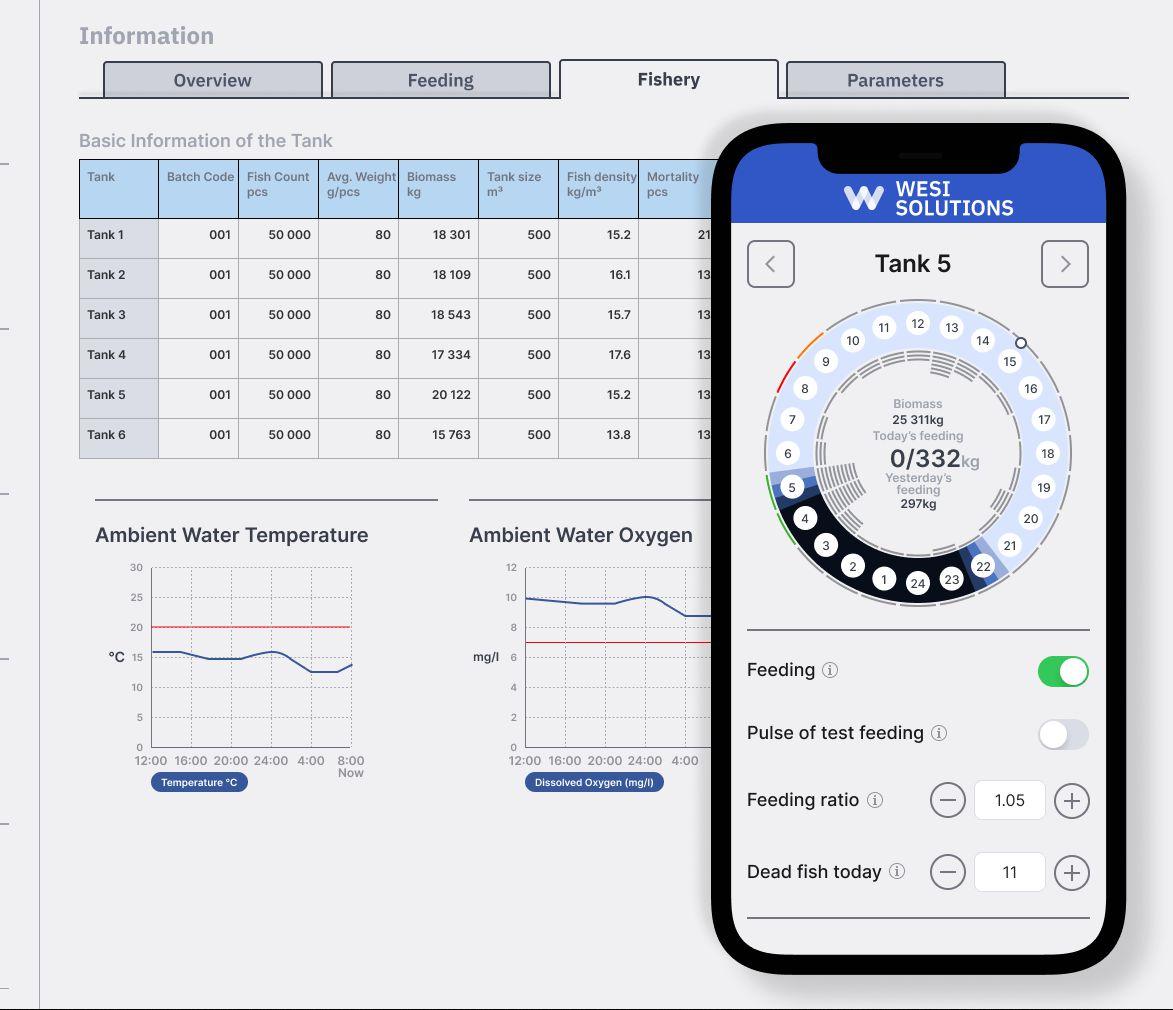

Reshaping sustainable production through artificial intelligence

Recirculating aquaculture systems (RAS) offer a sustainable approach to fish farming, allowing for greater control over environmental conditions while minimizing water use and nutrient discharge. However, maintaining the delicate balance of water quality, optimizing fish health, and ensuring efficient resource use remain ongoing challenges for RAS operators. Even slight deviations in water parameters or feeding patterns can impact fish welfare and farm productivity.

Like many industries, aquaculture producers are increasingly evaluating artificial intelligence (AI) as a key tool for data-driven decision-making and system automation.

AI-driven technologies integrated into RAS operations have delivered game-changing benefits such as improved system monitoring and enhanced feeding efficiency. These innovations also enable predictive management strategies that allow operators to anticipate issues and mitigate risks, accordingly, before

they occur.

Helsinki-based WESI Solutions is among the growing number of AI innovators in the aquaculture space. Through AI-powered monitoring and analytics, the company aims to help fish farmers navigate the complexities of RAS management with greater precision and efficiency.

One of the core advantages of AI in aquaculture is its ability to collect and analyze large volumes of data in real time. Instead of relying solely on manual observations, AI systems continuously track key metrics such as water parameters, fish activity and system performance. According to Mika Seppälä, CEO of WESI Solutions, this allows for more accurate assessments of both short-term fluctuations and long-term trends.

“Where a human can estimate the activi-

ty of fish based on experience or short-term changes, AI allows for precise comparisons of both long- and short-term changes and models formed from previous data,” Seppälä explains.

Processed historical data on short- and longterm changes in fish activity can provide key insights on fish behaviour. When combined with other monitoring data, AI tools can help determine the stress level of the fish, which in turn can affect feeding efficiency and growth, Seppälä notes.

By detecting subtle shifts in environmental conditions, AI systems can help pre-empt issues before they escalate. For example, signals of declining water quality, such as gradual increases in carbon dioxide or imbalances in dissolved oxygen, can be flagged early, allowing for timely corrective actions.

“WESI can prevent collapses in water quality or fish welfare because these actions do not occur quickly, but weak signals have likely been measurable for a longer time,” says Seppälä.

This proactive approach is particularly valuable in large-scale RAS facilities where human monitoring alone may not be sufficient. By continuously assessing multiple data points, AI enables operators to focus on strategic decision-making rather than reactive problem-solving.

Feeding practices in aquaculture have traditionally relied on fixed schedules or manual assessments of fish activity. This approach, while effective to some extent, can lead to inefficiencies, such as overfeeding, which degrades water quality, or underfeeding, which hampers growth. AI-driven feeding systems are now changing this dynamic by adjusting feeding regimens in real time based on fish behavior and environmental factors.

WESI’s system, for instance, monitors fish responses during feeding and adapts the feeding pattern accordingly.

“Feeding can be adjusted both up and down depending on the water parameter and the activity of the fish,” says Seppälä. This adaptability helps optimize feed conversion ratios while minimizing waste. Moreover, in cases where water quality is deteriorating, AI can intervene to reduce feeding rates, preventing further stress on fish and mitigating environmental impact.

Beyond cost and waste reduction, feeding optimization plays a key role in improving the overall health of fish stocks. Overfeeding can lead to uneaten feed accumulating in the system, which puts a load on the water treatment system and stress on the fish. Underfeeding, on the other hand, can result in uneven growth rates and increased competition among fish. AI’s ability to fine-tune feeding schedules ensures that fish receive the right amount of nutrition at the right time.

The aquaculture sector is facing growing scrutiny over its environmental impact. AI’s potential to improve the overall sustainability of seafood production can be a game-changer for the industry, particularly in resource efficiency and waste reduction. One of the most direct applications is in nutrient management, both in terms of feed efficiency and effluent treatment.

“In terms of nutrients, AI can improve feeding results — that is, how efficiently the feed consumed is converted into biomass,” Seppälä explains. By optimizing the feed-to-growth ratio, farms can reduce excess nutrient discharge, which also reduces the volume of effluent in the system.

Beyond feeding optimization, AI is also helping improve water treatment processes. “A functioning effluent treatment system is essential for removing nutrients that have ended up in the water as solids,” Seppälä notes.

Automated monitoring systems can regulate flow rates, oxygenation levels and filtration efficiency, ensuring stable conditions for fish while minimizing resource use. The ability to track and adjust these parameters 24/7 offers a significant advantage in maintaining water quality without excessive manual intervention.

AI can also contribute to reducing a RAS operation’s carbon footprint — or “tail print,” as they are sometimes referred to in the aquaculture context — by optimizing energy use.

RAS facilities rely on pumps, aerators and filtration systems, all of which consume large amounts of electricity. By continuously analyzing system performance, AI can help operators identify inefficiencies and adjust settings to reduce energy consumption without compromising fish welfare.

“All activities that reduce energy consumption, improve feed efficiency and minimize fish mortality contribute to significant reductions in a RAS facility’s carbon footprint — and WESI’s AI solutions help RAS operators achieve all this,” Seppälä says.

As aquaculture expands to meet the increasing global demand for seafood, technological advancements will likely play a central role in shaping the industry’s future. AI-powered systems are expected to become standard in RAS operations, helping farmers improve productivity while addressing sustainability concerns. However, the adoption of these technologies is not without challenges; factors such as cost, system integration and data

management will influence how widely AI solutions are implemented.

Seppälä sees AI as an essential tool for the future of aquaculture. “New innovations and AI will help RAS operations become more efficient by enhancing monitoring, optimizing feeding and resource use, and improving fish welfare,” he says.

While AI is not a silver bullet for all challenges in aquaculture, its ability to enhance decision-making and automate critical processes presents a compelling case for broader adoption. As the technology matures, it will likely become an integral part of sustainable and economically viable fish farming practices.

For RAS producers looking to stay competitive, the integration of AI represents a step toward greater efficiency, resilience and longterm sustainability. While challenges remain, the potential benefits of AI-driven aquaculture systems suggest that this technology will be a cornerstone of the industry’s future evolution.

AI-powered monitoring and analytics system provides data-driven insights in RAS, dramatically improving operational efficiency, fish welfare and system health.

CONTACT INFO

Mika Seppälä mika@wesi.fi www.wesi.fi

Helland Silosystem, a Norwegian family business with a 45-year legacy in aquaculture, is setting its sights on North America as the next frontier for its innovative fish feed handling solutions. With extensive experience in both sea-based and land-based aquaculture, Helland aims to bring its expertise in gentle feed handling and efficient storage solutions to the rapidly growing recirculating aquaculture systems (RAS) market.

“We believe that we can contribute a lot of expertise and knowledge to land-based aquaculture, based on the experience we have gained in Norway,” says Inge Stian Helland, CEO and third-generation leader of the company. “The development happening in the industry is incredibly exciting to be a part of.”

Since 1965, Helland has been designing and manufacturing high-quality silos and feed transport solutions for the agriculture and aquaculture industries. The company offers a diverse range of silos and feed handling equipment designed for aquaculture applications. The equipment is tailored to cover the needs of each individual land-based facility.

Initially specializing in feed storage and transport for oceanbased fish farms, Helland transitioned to serving the land-based aquaculture market as RAS technology gained momentum.

The shift has proven advantageous. “Land-based farming is right up our alley,” Helland explains. “It’s a great environment for us to do installation and provide products.”

Helland’s silos and feed transport systems ensure that fish farmers can efficiently store and distribute feed while maintaining pellet integrity. “Feed is the biggest cost in a fish farm,” Helland notes. “If you have even two per cent breakage in a facility that feeds 50 tons a day, that’s 1,000 kilos of wasted feed daily — who wouldn’t like to reduce this kind of waste?”

To mitigate this, Helland’s equipment is designed for gentle handling, minimizing pellet breakage and ensuring that fish get the highest quality feed. The company even operates a testing facility in Norway where it can simulate a customer’s feed handling process, demonstrating its equipment’s effectiveness in reducing waste.

Beyond feed storage and transport, Helland’s dosing units play a crucial role in feed optimization and fish growth. The company’s specialized distribution systems ensure feed spread across tanks evenly, preventing fish from clustering in certain areas and maximizing feeding efficiency.

“You want the same amount of feed across the tank,” Helland says. “By spreading the fish, you optimize the feeding, ensuring the best possible growth.”

Designed for sustainability and seamless integration

Sustainability is also a major focus for Helland SiloSystem. “We are very aware of the materials we use — no plastics, only durable metals that last,” Helland explains. The company also prioritizes recyclability, ensuring that waste from its production processes is repurposed.

As automation becomes increasingly critical in modern RAS facilities, Helland has ensured its systems integrate seamlessly with various control technologies. “Fish farmers have different experience with feeding and control systems, some fish farmers want to use the latest technology and use water quality parameters, camera technology, or fish behavior analysis to optimize feeding, whilst others rely more on being ‘hands-on’ in the feeding process,” says Helland. “Our system is designed to easily integrate with the breeders’ preferred control system, or already existing control systems.”

With land-based aquaculture on the rise in North Ameri-

ca, Helland SiloSystem sees a prime opportunity to introduce its proven solutions to a new market. The company’s experience in Europe, combined with its deep understanding of feed handling efficiency, positions it as a valuable partner for RAS producers looking to optimize operations and reduce feed waste.

By applying decades of expertise in fish feed handling, Helland Silosystem is set to make a significant impact on North America’s evolving land-based aquaculture industry — delivering precision, sustainability and cost-efficiency to fish farmers looking for an edge in the competitive RAS market.

THE SOLUTION

Proven expertise in high-quality silos and feed transport solutions, backed by 45 years of design and manufacturing experience.

CONTACT

Inge Stian Helland post@helland-silo.no

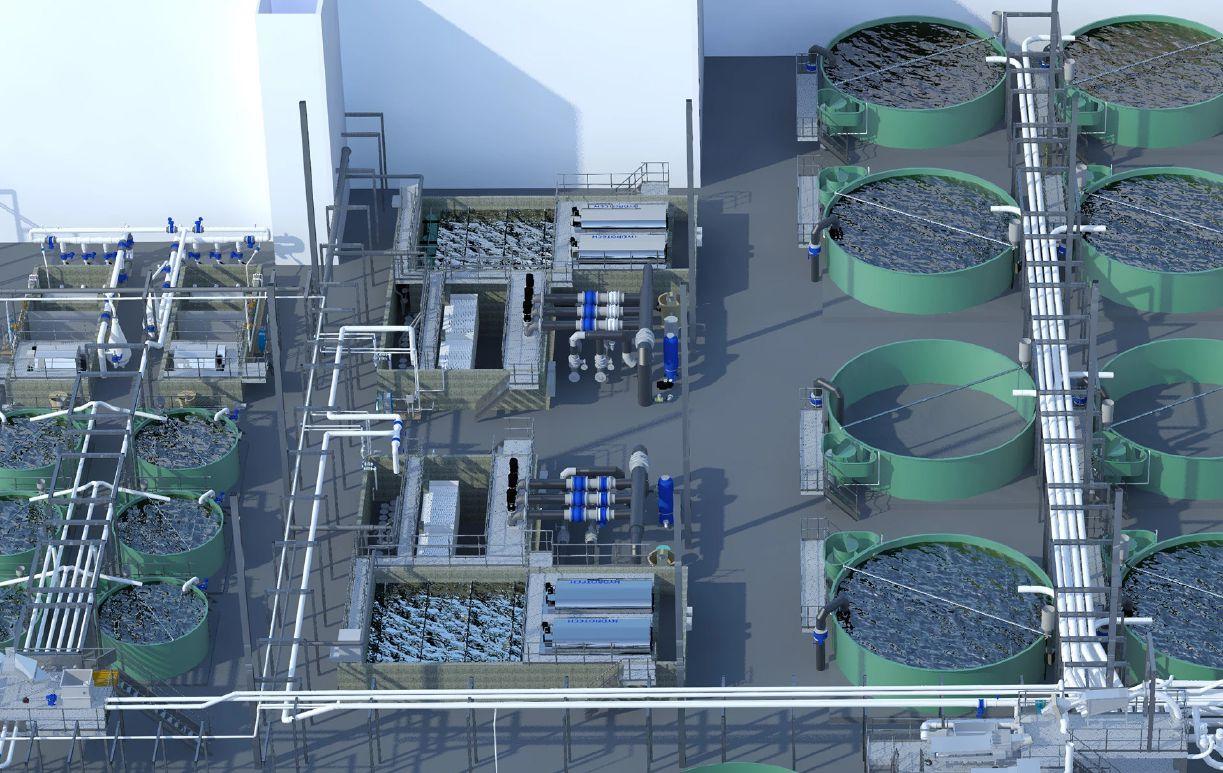

Recirculating aquaculture systems (RAS) have emerged as a key solution in modern fish farming, offering a controlled environment that minimizes water use and mitigates external contamination risks. However, building and maintaining these systems come with their own set of challenges. Tanks must be designed to withstand environmental stressors, accommodate fluctuating production demands, and minimize maintenance efforts over time. The materials and construction methods used in these systems play a crucial role in determining their longevity and sustainability.

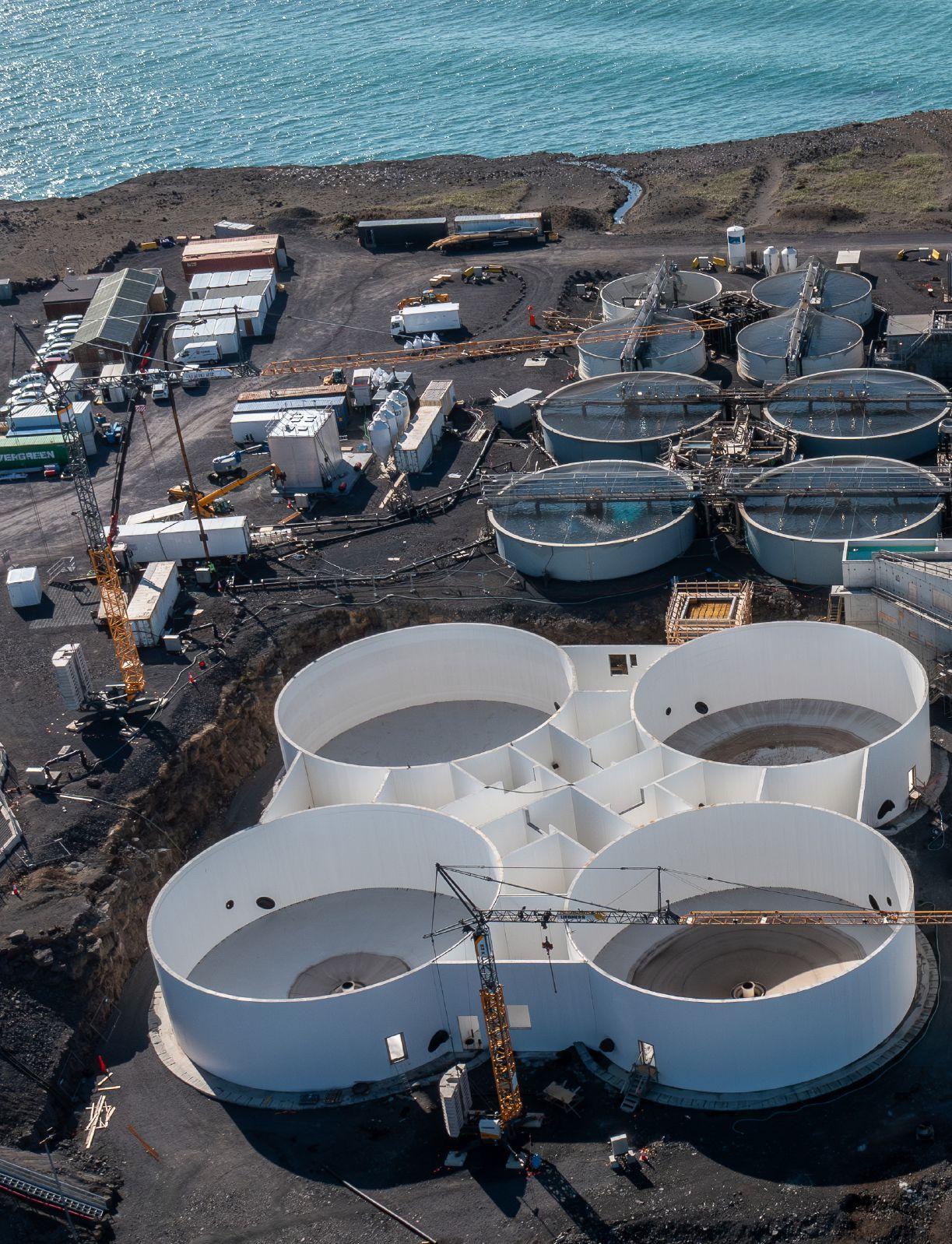

In large-scale RAS projects, producers are adapting new construction methods to improve durability and flexibility. Vancouver-based Octaform, which specializes in integrated PVC-lined concrete forming systems, has been instrumental in these efforts. The ability to accommodate design changes mid-project has become increasingly important, particularly as operations scale up to meet growing demand.

“We’re not just a supplier, we’re a trusted partner,” says Callum Graham, business development manager at Octaform. “We’re servicing some of the largest projects in the world.”

Graham highlights Octaform’s recent involvement in a major aquaculture project in Iceland. “They’re targeting about 50,000 tons of Atlantic salmon,” he explains. Located just south of Reyk-

javik, the facility utilizes seawater sourced from underground wells that has been filtered through layers of lava, creating an optimal environment for fish production.

“It’s a very progressive design-build, so we’ve had to be very agile,” Graham says. “Our dedicated project execution team is assigned to every project, offering a full wrap of services covering production, logistics and field support to assist contractors on-site.”

Sustainability is another key factor shaping RAS infrastructure decisions. Concrete tanks with embedded liners, for instance, have been reported to improve durability and reduce the need for recoating or frequent repairs.

“The most sustainable building is the one that lasts the longest,” says Graham. “Our system embeds a PVC liner into concrete tanks, extending their service life.”

Octaform’s solution is designed to extend the lifespan of concrete structures, ensuring long-term utility and reduced environmental impact. “Our system helps regulate the hydration process during concrete curing, keeping the concrete moist for longer, which ultimately enhances its strength,” Graham says.

This improvement not only prevents degradation over time but also offers a sustainable edge by promising robust infrastructure and low maintenance over decades.

Research into seismic-resistant tank construction has also provided insights into structural integrity improvements. Octaform’s concrete forming system with PVC liner underwent testing at the University of British Columbia to determine if it can protect a reinforced concrete structure against cracking and spalling during a severe earthquake. The tests were conducted by Dr. Carlos Ventura, a global expert in earthquakes and seismic research.

Dynamic loads were performed by placing both a traditional concrete wall and an Octaform wall on shaking tables. The result of the experiment showed the control wall specimen suffered catastrophic failure while Octaform exceeded 250 percent without any significant damage.

Biofilm buildup in tanks is another major concern for RAS producers, affecting fish health and overall yields. Addressing these issues requires materials that facilitate easier cleaning and maintenance while reducing the risk of contamination.

“Biofilm buildup can lead to off-flavor compounds and negatively impacts fish health,” Graham points out. “With our embedded liner, you won’t need to recoat the tanks as you would with some coatings. Just a simple power wash keeps them clean.”

Moreover, Octaform’s PVC liner is certified for potable water use, meaning it meets rigorous standards for water quality.

Retrofitting older tanks to extend their usability offers an alternative to costly demolition and reconstruction efforts. “We’ve saved biogas tanks that were close to failure by reinforcing them with a fresh PVC liner,” Graham notes.

For old concrete tanks, such as in hatcheries or older RAS facilities, that are nearing the end of their service life, this solution could be a game-changer. Octaform’s WallArmor reline solution can extend the life of existing infrastructure.

“Some facilities have tanks over 30 years old, which may not provide the best environment for the fish. With our system, they can extend the lifespan of their infrastructure rather than starting from scratch,” Graham says.

Advancements in materials science, sustainability measures and construction efficiency will all contribute to the evolution of RAS operations, ensuring they remain viable and resilient in an increasingly demanding global market.

THE SOLUTION

PVC-lined concrete forming systems with proven strength and durability. CONTACT Callum Graham callum.graham@octaform. com www.octaform.com

RASTECH SPONSOR SHOWCASE•