FEATURES

FEATURES

Byron Loeppky discusses the importance of automation for Friesens

GAMUT

5 News, People, Installs

8 Calendar

NEW PRODUCTS

16 Erwin Busselot Five tech innovations 12 6 22 16

ISSN 1481 9287. PrintAction is published 10 times per year by Annex Business Media. Canada Post Publications Mail Agreement No. 40065710. Return undeliverable Canadian addresses to: Circulation Department, 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1. No part of the editorial content in this publication may be reprinted without the publisher’s written permission. © 2022 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of this publication. Printed in Canada.

18 Introducing new solutions from Tilia Labs, Ricoh, Xaar, Hubergroup, and Roland DGA

SPOTLIGHT

22 Loredo Rucchin, founder and CEO, Jukebox

COLUMNS

FROM THE EDITOR

4 Nithya Caleb Globally, we’re growing!

INSIDER

8 Bob Dale and Manraj Matharu Great expectations

CHRONICLE

10 Nick Howard Alva and his newspaper

TECHNOLOGY REPORT

According to Mordor Intelligence’s report, “Commercial Printing Market – Growth, Trends, COVID-19 Impact, and Forecasts (2022 – 2027),” the global commercial printing market, which was valued at USD 411.99 billion in 2020, is projected to be worth USD 472.35 billion by 2026, registering a CAGR of 2.24 per cent during 2021 – 2026.

472.35 billion

The global commercial printing market is projected to be worth USD 472.35 billion by 2026, according to Mordor Intelligence.

Technological proliferation, along with the growth of new applications, is behind this surge in demand for commercial printing services. The report highlights “the need for short-run production for a wide range of applications is increasing rapidly for commercially printed materials, such as books, direct mail, brochures, and catalogs.” The report’s authors expect 72 per cent of corporations to utilize direct mail campaigns, as they are relatively inexpensive and effective.

Another factor is the increased demand for promotional materials from retail, food, and beverage industries. The report mentions a recent Adobe poll of 1,250 U.S. consumers that found printbased ads are garnering increased consumer attention.

The introduction of eco-friendly practices, such as using plant-based inks and recycled or FSC-certified paper, is also a driver of growth.

It looks like “the printing industry is finding its post pandemic feet,” as Erwin Busselot, business innovation and solutions director, Graphic Communications Group, Ricoh Europe, aptly said.

According to WhatTheyThink’s Printing Outlook 2022 report, the revenues of 17 per cent of the print businesses that were surveyed had risen more than 25 per cent compared to 2020, and 78 per cent of print service providers saw an increase in their 2021 revenues compared to 2020.

A whopping 71 per cent of the respondents reported having hiring plans for 2022.The top positions being sought this year are postpress/binding/finishing staff and press operators.

The top challenges for respondents are “consumables and supplies pricing” (56 per cent) and “pricing” (41 per cent).

While “improving economic conditions” is the top opportunity, cited by 40 per cent of respondents, it is down 10 percentage points, while the pre-pandemic number one—“customers outsourcing more work to us”—is back to 37 per cent.

Almost one-fourth (23 per cent) of survey respondents are not planning to make investments in 2022. Top items for those planning on spending are binding/finishing equipment and highspeed production inkjet equipment.

Busselot believes “hardware developments have increased automation, quality, and productivity to help PSPs increase their capacity, improve quality, and expand their services” to offer more short runs and bespoke products. Further, companies are trying to automate every step of the printing process, “from order intake and complex campaign management to efficient production planning, and dispatch.”

Workflow assessments and research by Keypoint Intelligence have shown “improving job onboarding processes and leveraging optimization techniques in prepress can have positive impacts.”

“Capturing the customer request and content are the two primary tasks to onboard a print job that should be structured and digitized, perhaps through an online request for quote tool or web-to-print solution. As for optimization, improving the composition and quality of files (in addition to using ink optimization software) provides annual savings in consumables and labour costs,” said Eva Padula, senior consulting editor at Keypoint Intelligence.

Padula believes the increased levels of automation indicate some print service providers will be ready for the next shift in automation that enables smart print manufacturing.

“There is a progressive order before PSPs can reach semi-to-fully autonomous printing by the end of this decade.

However, print service providers that are automating their work now are bound to reap financial rewards in the future. Keep that in mind, as you navigate the rest of 2021.

Reader Service

Print and digital subscription inquiries or changes, please contact

NITHYA CALEB Editor ncaleb@annexbusinessmedia.com

Barbara Adelt, Audience Development Manager

Tel: 416-510-5184

Fax: 416-510-6875

Email: badelt@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor

Nithya Caleb ncaleb@annexbusinessmedia.com 437-220-3039

Contributing writers

Bob Dale, Manraj Matharu, Nick Howard, and Erwin Busselot

Media Sales Manager

Kim Barton kbarton@annexbusinessmedia.com 416-510-5246

Media Designer

Lisa Zambri lzambri@annexbusinessmedia.com

Account Coordinator Alice Chen achen@annexbusinessmedia.com 416-510-5217

Group Publisher/VP Sales

Martin McAnulty mmcanulty@annexbusinessmedia.com

COO Scott Jamieson sjamieson@annexbusinessmedia.com

Subscription rates

For a 1 year

subscription (10 issues): Canada — $43.00 +Tax Canada 2 year — $70.50 +Tax United States —$98.00

Other foreign —$191.00

All prices in CAD funds

Mailing address

Annex Business Media 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1 Tel: 416-442-5600 Fax: 416-442-2230

Occasionally, PrintAction will mail information on behalf of industry related groups whose products and services we believe could be of interest to you. If you prefer not to receive this information, please contact our Audience Development in any of the four ways listed above.

Annex Business Media Privacy Officer Privacy@annexbusinessmedia.com 800-668-2384

PrintAction is printed by Annex Business Media Printing on Creator Gloss 80lb text and Creator Silk 70lb text available from Spicers Canada.

ISSN 1481 9287

Mail Agreement No. 40065710

March/April 2022 | Vol. 61, No. 2 printaction.com

An employee-owned company in Altona, Man., Friesens Corporation achieved a record $100 million in sales for the first time. The company had one of their best years in over a decade, thanks to really strong performance in their book division and the subsidiary company, FriesenPress.

The increase in demand is the result of strong retail sales of printed books. The shortage of supply is a result of limited book manufacturing capacity in North America and major disruptions to global supply chains. All of these positioned Friesens as a desirable print partner for Canadian and American publishers.

Harling Distribution Inc., a provider of data-driven mail, fulfillment and distribution services, acquires Datex Services of Richmond, B.C. Founded in 1969, Datex has served the B.C. marketplace with a full suite of mailing services for over 50 years. Stormer Yttri, president at Datex, Perry Jongsma, VP-operations, and Adrian Bartel, data technician, will be joining the Hemlock Harling team to support and expand their roster of customers.

Canadian printer Cober has increased print on demand revenue by 20 per cent, just 18 months after signing up to the Infigo web-to-print platform. By integrating Infigo with

Cober’s MIS, Tharstern, as well as their internal workflow, automation, payment and shipping systems, the company can now receive orders, take payments, manufacture and ship orders, all with minimal human intervention.

Affiliates of Chatham Asset Management acquire R.R. Donnelley & Sons Company (RRD) for $10.85 per share in cash. The acquisition was previously announced on December 14, 2021, and RRD stockholders approved the transaction at a special meeting of stockholders held on February 23, 2022. Upon completion of the transaction, RRD’s common stock ceased trading on the New York Stock Exchange. Thomas J. Quinlan has assumed the role of president and CEO of RRD.

Kodak has taken over the exclusive distribution of Presteligence’s NewsXtreme Cloud Workflow and My News 360 editorial content management software in the United States and Canada. NewsXtreme Cloud Workflow offers intelligent file routing, PDF preflight and auto-correction, colour calibrated hardcopy and softproofing, automated

page pairing and imposition, and ink optimization. My News 360 is a content management and multi-channel publishing platform that allows publishers to create and distribute multimedia content quickly and accurately to any media outlet or channel including website, social media, apps, and print.

The Hershey Company in collaboration with HP has been leveraging the power of digital printing technology to transform its iconic chocolate bar packaging into a celebration of women. Now in its third year, the #HerShe campaign uses Hershey’s Milk Chocolate Bar packaging, that was printed on a HP Indigo 20000 digital press, to help make ‘invisible women, visible’ by supporting gender equality through a global movement that celebrates female achievements in science, business, sports, activism, and music. This year, the bars will also feature a QR code that will open consumers’ eyes to the many contributions of women.

Global Graphics Software has been granted a US patent for “Systems and methods for printer density compensation and stability” by the United States Patent and Trademark Office. The patent relates to the technology which underlies PrintFlat, Global Graphics’ software that improves uniformity and

removes unwanted banding from inkjet output, enabling digital production of a wide range of products including wide-format graphics, laminates, flooring and decor, and packaging.

Agfa, Kodak, Zünd, and Durst win European Digital Press Association (EDP) awards Agfa’s printing solutions that won awards this year are the Jeti Tauro H3300 UHS LED, the InterioJet 3300, and the Alussa leather printing ink.

Kodak earned the prestigious industry accolade in the “Industrial Print & Finishing Solutions – Best Folding Carton Solution” category for its Kodak Ascend.

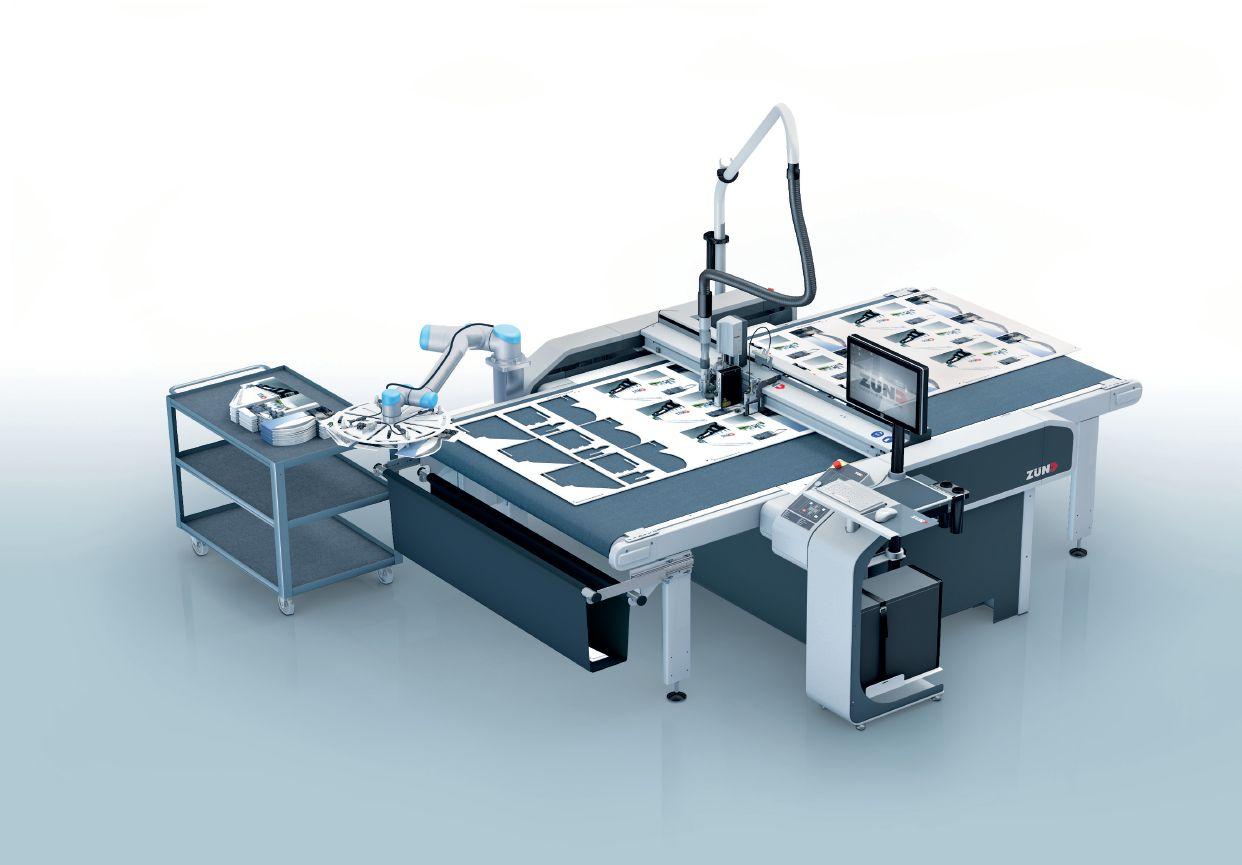

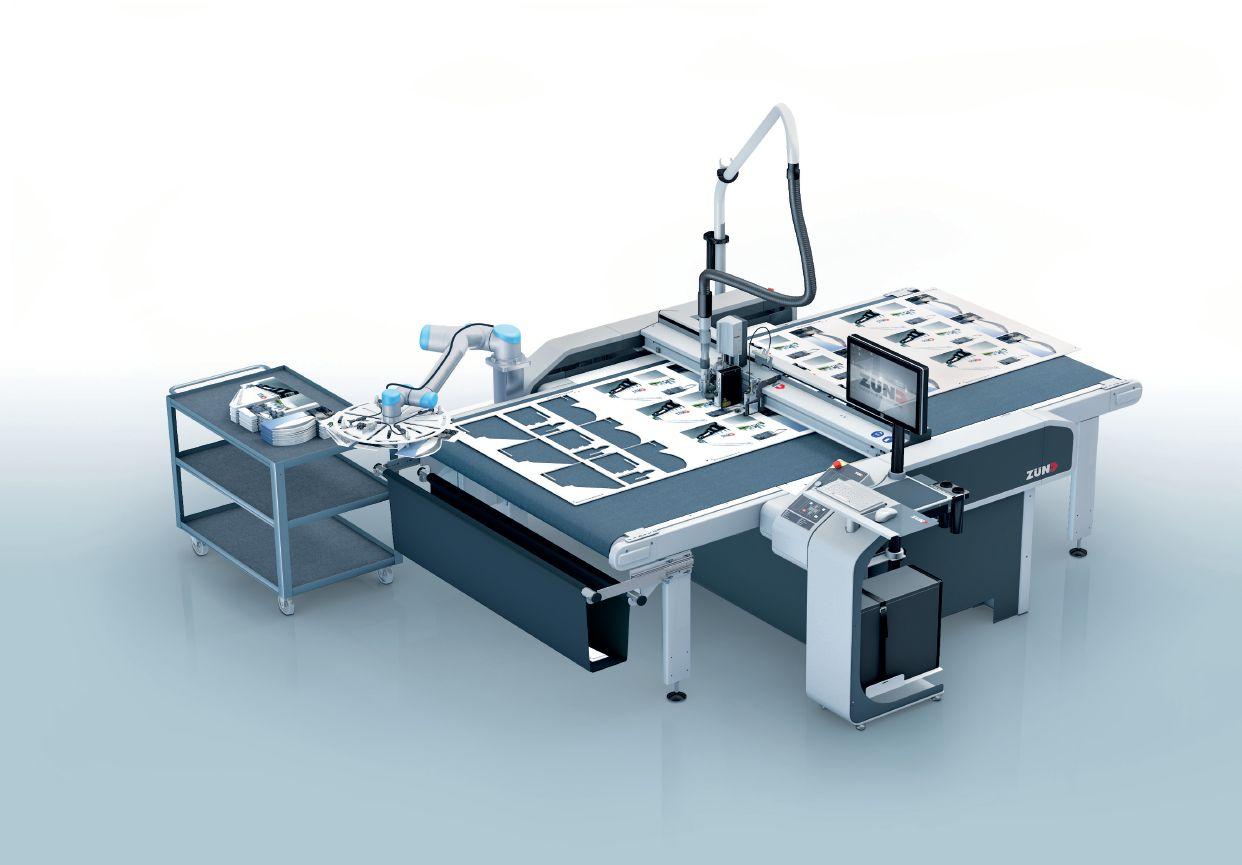

The EDP jury declared Zünd’s PrimeCenter the “Best Workflow Solution”, while the Pick&Place Interface Option and the Visualizing Option were recognized as “Best in Robotics” and “Best Print

Support Tool,” respectively.

Durst was able to win for its flagships, the P5 Tex iSub and P5 350 HS. For the jury, the P5Tex iSub is the best roll-to-roll textile printing system with an integrated inline finishing unit. The P5 350 HS hybrid printing system was able to assert itself as the best UV printing system for corrugated packaging.

Ricoh Pro VC70000 earns Fogra certification. It is the only market available continuous feed inkjet press to hold the Fogra Validation Printing System (VPS) certification. Fogra VPS assesses if systems that produce a hard copy validation print, directly from digital data, conform to the ISO 12647-8 standard.

The Mitchell Group promotes Gregory Wong as vice-president of operations. He was previously the director of digital operations. Wong brings a strong pre-media, workflow, and operations background to the role and will oversee the entire group’s’ operations with a focus on excellence and workflow.

Rochester Software Solutions expands its business development team. Bobby Pierce joins RSA as director, business development, in the east US region. Pierce comes to RSA with demonstrated success in enterprise software, hardware and services developed from over 20 years in the printing industry. Recently, Pierce was a national channel manager at Ricoh Corporation. Prior to that, he spent 16 years with Xerox supporting production workflow solutions.

The largest commercial printer on Vancouver Island, British Columbia, Digital Direct Printing recently installed two Polar N 78 Plus cutters from Heidelberg.

Connecting for Results (CFR) appoints Mark Phillips to the newly created position of vice-president, corporate development, CFR, and sales development, Techstream.

An expert in automation implementation, Phillips has extensive experience in the printing industry. He has held a number of senior management positions, from sales to business direction, in both private and international organizations. An early adopter of digital printing, he has helped to successfully implement inkjet technology, advanced MIS, and ERP integration, while managing customer relationships and increasing cost savings with technology. In his role with CFR, Phillips will be responsible for developing corporate partnerships and overseeing sales development for the Techstream procurement automation software.

Durst North America appoints Philip Hampson as its national sales representative in Canada. Philip Hampson brings a wealth of experience as a veteran in the printing industry. He has previously served in several national sales roles supporting various print markets.

Standard Finishing Systems appoints Shaun Hunt as the director of technical services. After 36 years at Ricoh, Hunt joined the Standard Finishing team in May 2021 as the technical services operations manager. After proving himself to be a great addition to the technical team, Standard’s executive committee promoted him to director of technical services.

Ontario-based Print2Go recently installed a Duplo DDC-810, which allows the company to expand its horizon and deliver personalized printing experience.

AMP Digital, a Montreal-based family-owned business specializing in large-format printing and digital cutting, has installed a new flatbed printer from Agfa, the Jeti Mira 2732 LED.

April 11-13, 2022

Inkjet Summit Austin, Texas

April 20-21, 2022

Visual Graphics Industry Grand Rendezvous Laval, Que.

April 26-29, 2022

Durst Expo 2022: Label Brixen, Italy

May 01-04, 2022

Printing United Alliance annual Continuous Improvement Conference Scottsdale, Ariz.

May 31-June 03, 2022

FESPA Global Print Expo Messe Berlin, Germany

May 25, 2022

Printovation Canada Vaughan, Ont.

June 02-June 03, 2022

2022 Supporting Women in Trades Conference St.John’s, N.L.

All industries are facing staffing challenges, but the graphic arts sector has, for many years, found it challenging to attract young talent.

1⁄3

Approximately ⅓ of the survey respondents felt the industry is larger and more technologically advanced than they assumed as a student.

By Bob Dale and Manraj Matharu

The graphic arts sector has, for many years, found it challenging to attract young talent. For many decades, a key source of recruitment has been the Ryerson Graphic Communications Management (GCM) program in Toronto.We reached out to a few grads to get their first impressions of the industry after some months on the job. We asked about how prepared they were, what they like about their work, and how has their impression of the industry changed.

First though, why did the students we interviewed choose this industry? The feedback suggests that most students chose the GCM program for design and/or marketing career opportunities. While we may lament that design is only a sliver of the industry and marketing is a separate beast, we can look to industry guru Frank Romano for insights. During a recent vlog, he reminds us that at one time, printing was a regular course in most technology-focused high schools and colleges throughout North America. That number has dwindled, and the schools with printing-related courses focus on the creative and prepress aspects of graphic arts. The focus is on preparing files for use by output technology. This has become a theoretical exercise since most schools cannot afford the output technologies, such as toner, inkjet and wide format, that are used in the in-

A survey of a pool of new grads reveals freshers find the printing industry more technically advanced than they thought. Sadly, the salary didn’t meet most of their expectations.

dustry. Gone are the days of using a simple multi-lith press to teach generations.

It was interesting that other key reasons included ‘community’ and packaging. We presume by ‘community’ students chose the GCM program because other like-minded students were interested in it.

All graduates believe they were well prepared for the industry, but almost half indicated their perception of the industry has changed. Approximately ⅓ felt the industry is larger and more technologically advanced than they assumed. While the initial impressions of some entering the industry has improved, more work is needed to help others see the advancements in the industry.

The graduates interviewed secured positions like co-ordinator, junior marketing, design and press operator. The majority were in design or marketing roles. These roles do not appear to be reflective of the positions in a typical commercial print operation, but these are the jobs graduates sought. Most of the graduates reported they are enjoying their first position in the industry. Almost everyone

reported that ‘the people’ were the best part of the job. A close second was the ‘environment’.

Almost half of the respondents plan to stay with their current firm for only one year, while almost one-thirds indicated two years.

What would they change? Almost 60 per cent believe they should be paid more and almost 30 per cent would like increased participation in strategy and design decisions. It appears that entry-level positions are not meeting students’ expectations. Another key factor may be that many of the participants indicated they are employed in design roles. Junior design roles are not in high demand, and there is a lot of competition for these jobs.

There is a lot of work to do to attract young talent to the industry, and from this small survey, we can see that there is also a lot of work required to improve retention of people entering the industry.

Bob Dale is vice-president and Manraj Matharu is marketing administrator of Connecting for Results. They can be reached at info@connectingforresults.com.

Free Business Cards are only valid if they are ordered for your own business (Not valid if you are not the

One of the brightest minds of the modern era began his work life as a printer

By Nick Howard

In 1859, a leg of the Grand Trunk Railway ran between the cities of Port Huron and Detroit, Mich. Onboard an old springless boxcar, 12-year-old Alva set up his small shop to print The Weekly Herald newspaper. The paper sold for three cents a copy. Alva was an inquisitive lad, and had been homeschooled by his mother in Port Huron.

His father was born in Nova Scotia. He later relocated to the village of Vienna in southwestern Ontario. In 1837, Alva’s father was embroiled in the Upper Canada Rebellion and was forced to flee to Ohio in the United States, where Alva was born.

As a child, Alva became fascinated with the world of science and would spend countless hours preparing various chemical experiments at home. An incessant need for money to support his expensive hobby drew him into the world of printing. Alva reckoned that a newspaper with space for people who rode or worked on the railroad to advertise in had the makings of a lucrative business. Even by late 19th-century standards, his equipment was rather sparse. Three hundred pounds of used lead type was soon purchased from the Detroit Free Press while a crude hand-crank proof press, capable of printing a 12

x 16-in. sheet, was scrounged along with inks, a type stick, and paper. The whole shop fit into a corner of an old boxcar that was once used as a smoking compartment.

Opportunity is missed by most people because it is dressed in overalls and looks like work. –Thomas Alva Edison

Getting started wasn’t easy. Alva cut a deal with the railway company. After composing the paper, he’d be kept busy printing the couple-ofhundred papers while bouncing along the railway track to and from Port Huron and Detroit. Stories of the people who worked in the railway found themselves in print along with small advertisements, timetables, and gossip. One such ad offered “office copying presses,” an early and only way to make copies from a typographic form. At such a young age, Alva often added his own “Op-ed” philosophy: “Reason, justice, and equity never had weight enough on the face of the earth to govern the councils of men.”

Even though he was busy, Alva found time to conduct chemical experiments. One day, a bottle of phosphorus, one of the many ingredients that had accumulated in his shop, fell down. The acid quickly set the boxcar on fire. Thankfully, the conductor saw the smoke and managed to put out the fire. However, he tossed all of Alva’s print shop materials and chemicals out of the train in anger. He also gave Alva a good thrashing, which included boxing his ears, before forcing him out of the train. It has been suggested the beating may have resulted in lifelong deafness.

Reports indicate that after his rapid expulsion, Alva drudged back along the tracks to search for, and retrieve, his possessions; including all of the eight- and 12-point types used to print the Herald. Despite this setback, the paper continued.

Reason, justice, and equity never had weight enough on the face of the earth to govern the councils of men.

– Thomas Alva Edison

By the age of 13, Alva was said to be earning $50-per week ($1,700 in today’s money) from his paper, in addition to sales of everything from candy to vegetables. In contrast, at 12, I was too busy watching Heckle & Jeckl cartoons and getting into mischief. Serendipity would intervene soon.

In 1862, Alva saved the life of a toddler whose father was a station agent in the railway office of Mount Clemens, Mich. Grateful to Alva, the child’s father offered to train him as a telegraph operator. Alva soon found himself out of the newspaper business and holding a new position in the telegraph office of the Grand Trunk Railway in Stratford, Ont.

By the age of 13, Thomas Alva Edison was said to be earning $50 (approx. $1,700 in today’s money) a week.

The telegraph was revolutionizing communication, and by the age of 19, Alva was working for Western Union in Louisville, Ky.

Although captivated with Samuel Morse’s telegraph, he continued with his chemical experiments until the day a bottle of sulfuric acid spilled onto the floor. The liquid wicked through the floorboards onto his boss’s desk below. This resulted in another quick dismissal.

Perhaps no one could have anticipated what was in store for this young man who simply couldn’t stop experimenting. Alva then moved to New York City. A parade of inventions began hatching in his lab in Menlo Park, N.J.

been talking about Thomas Alva Edison, “the Wizard of Menlo Park,” a boy genius with minimal homeschooling and a constant desire to discover something new. How ironic that just a few years after Edison left Stratford, another inventor, Alexander Graham Bell, would make the first telephone call in the town of Brantford (Ont.), which was only an hour away?

It is worth remembering Edison began his professional journey as a printer. Who said the best and brightest minds don’t have ink in their blood?

He would soon be recognized as one of the world’s greatest inventors, credited with discovering the light bulb, phonograph, and power generation technologies that have reshaped early 20th century. I’m sure you’ve guessed by now that I’ve

, a partner in Howard Graphic Equipment and Howard Iron Works, is a printing historian, consultant and Certified Appraiser of capital equipment. nick@howardgraphicequipment.com

Loeppky

By Nithya Caleb

In the early 1990s, Friesens, Altona, Man., was one of the first printing companies to use a robot at the back of a binding line. While it ended up being a cumbersome process and not cost-effective, the initiative points to the importance of automation for Friesens.

“We had massive gates around it [robot]. It took up a lot of space. Even then, the attempt was to find ways to have more automation. We realized it is got to be a core part of what we do and how we think,” recalls Byron Loeppky, senior vice-president of books, Friesens.

Automation has certainly become more real for Friesens. Currently, they have four cobots on their bind-

ing lines. According to Loeppky, these cobots are more intuitive, easier to train, and don’t require big cages. The software is better too. Changes can be made easily. Friesens is planning to add one more cobot this year.

“We typically would have one or two people at the back of the line stacking up books, placing them in cartons, and then on a skid. Now, a label is applied, and the cartons are stacked on a skid without human intervention. Then someone picks up the skid once it is full,” explained Loeppky.

The introduction of cobots has

helped Friesens, an employee-owned company, address some of the labour challenges that are afflicting the print industry. The industry is struggling to fill in minimum-wage positions requiring manual labour.The cobots are enabling Friesens to move their employees from these labour-intensive, less-skilled positions to more skilled jobs.

“It’s not a scary conversation with our staff. Staff are not concerned they will not have a job tomorrow. Their jobs may change. Automation is creating new opportunities for them inside the company. It also allows for opportunities for increased compensation. Automation at Friesens is not causing anyone to

lose their jobs. It is just trying to address a labour challenge that we have as we grow. Automation is creating new opportunities for staff. This is good news both for us as a business, for our customers and even for our employees,” says Loeppky.

Loeppky agrees automation requires capital investment, but it may not be expensive in the long run.

“It is expensive, and it’s also not so. For example, if we focus on the areas where we have a large amount of turnover, which is always at the lower end of the pay scale, we have an opportunity to do well there be-

senior vice-president of books,

cause we run shifts six days a week/24 hours a day. If you replace one or two people on four shifts, you are now actually replacing five to eight, and that number looks much more appealing very quickly. Since we’re a multi-shift operation, our payback can be relatively quick. Certainly, it becomes more challenging for one-shift operations,” Loeppky explains.

Historically an offset company, Friesens is making bigger bets and investments in digital technologies as it better understands where the tech fits into its marketplace. It recently installed a new HP 50000, a four-toner based press offering high-quality prints on lower run lengths. Friesens has also bought new finishing systems. Capitol investment is key for Friesens. The company believes the only way to stay alive as a business is by reinvesting in it. Before the pandemic hit, the company had invested $30 million over a three-year period.

Automation at Friesens is not causing anyone to lose their jobs. It is just trying to address a labour challenge that we have as we grow. Automation is creating new opportunities for staff.

The biggest challenge for Friesens or any other company interested in automating operations is the variety and newness of vendors. Many traditional vendors for book manufacturers are still developing their expertise in this part of their business, which then introduces new vendors and new possibilities.

“In the next five years, I certainly could see that we might have 15 to 20 cobots in our facility doing more of the manual tasks. We will have a lot more automation that is taking us from a roll to a finished book with fewer people than we are using today. We are planning for this to happen. This way, we’ll be able to get become a much more efficient business.”

By Erwin Busselot

Demand for greater digitization, sustainability, productivity, and automation is driving evolution in the $760.6 billion global printing industry. It is also being reshaped by the impact of the Coronavirus. New business and buying models have emerged.

This is according to Smithers’

Ten-Year Forecast of Disruptive Technologies in Print report.1 It assessed the market potential for more than 20 innovations in the print industry through to 2031 and identified a number of highly influential trends. Five stood out to me.

Smithers reported the focus will be on developing digital systems to print on packaging substrates, such as corrugated board, folding cartons, and flexible plastics, as well as integrated digital finishing. Other

1 Visit www.smithers.com/services/market-reports/printing/ten-yearforecast-disruptive-technologies-in-print.

Reliable, customizable workflow automation–from prepress to dispatch

Semi- to fully automated/robotic load/off-load, pick&place

opportunities in packaging and beyond will come from the wider use of inkjet in direct-to-pack and direct-to-object application.

Presses will need to handle and print at high quality on a new generation of flexible paper, biopolymer, and monomaterial plastic stocks. For consumables, the emphasis will be ink sets that incorpor-

$760.6 billion

The global printing industry is worth $760.6 billion.

ate more natural, sustainable ingredients.

Wider automation and digitization of commercial and packaging print workflows will present significant opportunities for printers. As a result, there will be increased innovation in robotic handling and the installation of the first generation of co-operative worker-robotic systems, or ‘cobots’.

Print-specific AI software solutions will grow and deployed by press manufacturers to automate a variety of labour-intensive and time-consuming tasks.

Over time, AI carefully measures the results of each task, noting differences in results and methods, and gradually, intelligently and automatically improving the system’s overall performance.

Digitization will be enhanced by the

Presses will need to handle and print at high quality on a new generation of flexible paper, biopolymer, and monomaterial plastic stocks.

wider rollout of 5G connectivity, and, by the end of the decade, 6G telephony networks. Other advances that could be levered include commercial accessibility to quantum computing power via the cloud. These trends are all in various stages of evolution. Some are long established and already part of our everyday production landscape. Others are being explored and are in the process of opening up greater opportunities for printers.

Erwin Busselot is the business innovations and solutions director, Graphic Communications Group, Ricoh Europe.

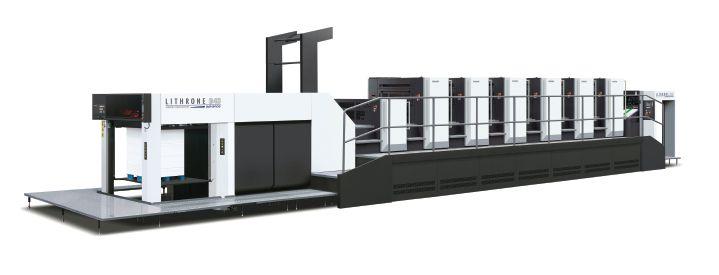

Serving the US market for nearly a decade, RM Machinery (RMM) proudly brings our expertise to Canada’s printing industry. We deliver the highest quality sheetfed o set, digital inkjet, and flexo printing presses by partnering with the finest manufacturers in the industry.

RMM is the premier distributor in Canada for Mitsubishi, RMGT, and Miyakoshi printing presses; Böttcher rollers, blankets, and chemistry; Standard Horizon finishing systems; GEW UV curing systems and TOYO inks.

For years, Mitsubishi set the superior technology standard for Canadian printers. Today, RM Machinery returns that innovation to Canada, but with an even higher standard: Ryobi Mitsubishi Graphic Technology (RMGT).

We are stable, local, and o er the best-in-class technology. We maintain an ample supply of parts, and for as long as you own one of our supported presses, you are guaranteed ongoing service and support programs that are among the best in the industry.

RM Machinery Inc.

905-238-9797 • 1-855-RMGT-123

5250 Satellite Drive, Unit 9

Mississauga, ON L4W 5G5 www.rmmc.ca

Equipping North America to print.

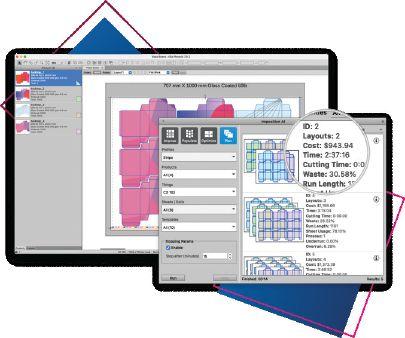

Tilia Phoenix Version 8 offers enhanced functionality designed to accelerate productivity and provide new levels of connectivity.

Tilia Labs releases Phoenix Version 8.0 Tilia Labs, developer of plan-

ning, imposition, and artificial intelligent (AI) software solutions announces the latest re-

lease of its industry-leading technology, Tilia Phoenix. Developed for all print sectors including packaging, labels, commercial, and wide-format printing, Tilia Phoenix is an AI-driven planning and imposition system shown to measurably improve print job efficiency, production, and profitability.

Supported by customer requests and industry feedback, Tilia Phoenix Version 8 includes new features and enhanced functionality designed to advance the user experience, accelerate productivity, provide new levels of connectivity, and introduce the software into new markets.

Ricoh launches its first plant-based ink

Ricoh’s plant-based ink is the first-of-its-kind for mainstream graphics and packaging print. The ink is a derivative of the

oil-based ink created for the decor printing sector as part of Ricoh’s collaboration with German equipment manufacturer Olbrich. The ink has been developed to deliver excellent rub resistance and set-off performance for corrugated brown and white boards, as well as carton board.

The print heads are easier to clean and less likely to clog as

Ricoh launches its first plant-based ink for mainstream graphics and packaging print.

releases a new ultrasonic self-cleaning mode called Sure Flow to clear and prevent nozzle blockages.

‘open time’ is much longer. This helps enhance jetting reliability, performance, and printhead life. Low ink consumption is also enabled as the same optical density is achievable using 50 per cent less ink.

Xaar has launched Sure Flow, its new ultrasonic self-cleaning mode, which is designed to help users keep their print at its very best.

Sure Flow enables users to clear and prevent nozzle blockages without the need to remove the printhead, maximizing operational print time for opti-

mum productivity. Enabled by software, users simply activate the mode as required by adjusting the settings and loading a command file. This drives each channel to work at maximum power and frequency to create ultrasonic waves that produce controlled vibrations of the channel walls without pausing production or the need to remove the printhead.

Press speeds of up to 20,000 sheets per hour are now possible in packaging and commercial printing, but they often lead to a critical ink-water bal-

ance. At the same time, job volumes are getting smaller, so a stable production with fast control response is important. To meet these changing market requirements, Hubergroup Print Solutions has now launched Perfect-Dry-Fix, a fountain solution additive that is suitable for conventional and UV offset printing.

Perfect-Dry-Fix is specially designed for fast printing. Even at high press speeds, the solution ensures fast control behaviour, good wetting of the non-image area, fast plate free-running, and stable production printing behaviour.

Roland DGA releases its third-generation inkjets – the

TrueVIS VG3 and SG3 series. The VG3 and SG3 printer/ cutters are suitable for a wide range of applications, including signs and banners, window graphics, labels, decals, floor graphics, vehicle graphics, interior decor, and heat transfer apparel. In addition to enabling users to optimize production, they offer dynamic ink configurations, exact colour targeting, and unsurpassed printand-cut accuracy.

“The VG3 Series models are designed to satisfy the most demanding print professionals, while the SG3 Series puts TrueVIS performance, versatility, and dependability within reach of start-up and growing print businesses,” said Daniel Valade, Roland DGA product manager of digital print.

Experienced (3+years) narrow Flexo Press Operator required for day shift operation in Scarborough. Responsible for the setup and teardown of press for each job. Conducts inspections during the run to ensure colour consistency and takes corrective measures when out of specification. Completes required records for job tracking, stock, ink reconciliation and efficiency measurements. Maintains a clean and safe work area. Schedule: 8hr shift; Monday – Friday. Benefits: competitive hourly rates; extended health care.

Interested candidates should contact the General Manager at FlexoPartners with your resume @ hr@flexopartners.ca

Loredo Rucchin is CEO and founder of Jukebox that has offices Vancouver and Toronto. With his team of expert printers and skillful designers, Rucchin (now in his mid-40s) aims to inspire, celebrate creativity, and equip customers with unique, trend-setting products. Jukebox offers offset printing, book publishing, screen printing, spot UV, letterpress, and sticker printing.

What is the state of the print industry today, in your opinion?

LR: The last few years have brought the print industry to its knees, leaving it in a grim, unfavourable state. The industry is at a turning point.We are in a make-or-break situation, and for many businesses, this volatile period will break them.

Inventory and supply chain issues are at the forefront of the problem. In a competitive industry like the print industry, many companies cannot simply push up their prices or tell customers to wait. It is all about ‘printing on demand.’ If your company cannot do that, a customer will find someone who can.

We also need to factor in the longterm impact of rising fuel prices and how it will affect the everyday cost of business. If your company relies on vendors and suppliers that transport goods or uses a delivery service to assist in daily operations, you will see an increase in service fees. Additionally, the cost of labour will rise. At the end of the day, customers will bear the brunt by paying more for print products and services.

Lastly, with the escalating war in Ukraine, we will see global inflation, shortages, and uncertainties across all industries. There will be a substantial rise in debt as people try to keep up with price hikes and disruption to regular economic activity.

What attracted you to the print industry?

LR: For a long time, everyone offered the same products and basic paper, so it was easy to get into the industry and quickly become profitable. Today, the print industry has plenty of untapped sectors, and I see an opportunity to grow and thrive within those spaces. With the constant shifting in the print industry, there has been a lot of uncertainty.

But for forward-thinking, agile, and adaptive individuals, there is much opportunity and success to be found.

How can the industry attract more young people?

LR: The answer is simple: Hire young people! Jukebox is powered by a team of young professionals who drive our production and customer support teams. Currently, 75 per cent of our employees are between 20 and 30 years old.

In such a competitive landscape, how can printers win more sales?

75 per cent of Jukebox’s employees are between 20 and 30 years old.

LR: You need to appeal to an international market. Many print companies rely solely on local business, and by doing this, they are limiting themselves from international sales opportunities. Appealing to the global market immediately increases the chance for more sales. It is as easy as ensuring your website and staff can handle international online orders. Also, invest in a diverse range of machinery as it allows you to offer a broader range of products, which will enable you to generate more sales. Lastly, ensure your website is powered by Amazon Web Service along with SAP technology.

What are some of the biggest opportunities in the print industry?

LR: The most significant opportunity in the print industry is to scale your business by investing in reliable machinery that is always operational. You can add considerable value to the production and quality of the products by adding a digital press to your workflow. Some printers allow you to create textured and raised effects to print on thick stocks including synthetics and paper boards up to 22 pt, which will open up new business opportunities.

What do you think is the most exciting thing about print today?

LR: Each day comes with its own challenges, but more importantly, new opportunities, products, and technology. One of the most exciting products to come out of our workshop at Jukebox is our perfect bound books. As a business, we can now assist writers, photographers, and other creatives to publish books and magazines with ease.

Rucchin’s responses were edited for length. For more Q&A Spotlight interviews, please visit www.printaction.com/profile.

CANADA IS

Commercial, trade, packaging, and label print company owners and managers, technical representatives, consultants, graphic designers and researchers.

“Learn

One-day event limited to 10 sponsor exhibitors. Networking opportunities with a targeted audience -your potential clients!