Re-thinking road safety

What will “safe” mean in the age of autonomous vehicles?

Reliable Gas Detection

At Gas Clip Technologies, we believe that quality and budget-friendly should go hand-in-hand, which is why we create top-of-the-line gas detection solutions that have a low cost of ownership. Each detector is compliance-based and designed to withstand the roughest treatment in the harshest environments.

All of our products are available through distributors worldwide.

Scan to visit our website!

UPCOMING E VENTS

ASSP Safety Congress & Expo (Aug. 7 - 9): Booth #900

VPPPA Safety+ Symposium (Aug. 26 - 27): Booth #810

NSC Safety Congress & Expo (Sept. 16 - 18): Booth #1328

BRANDI COWEN

BY JAMES CARELESS

BY JAMES CARELESS

BRANDI COWEN

From the Editor

By Brandi Cowen, Editor

May you live in interesting times…

Hello there! My name is Brandi Cowen, and I’m your new editor of OHS Canada. It’s great to meet you!

By the time you read this, I’ll have been in the role for just over three months. I’ll have had the pleasure of emailing back and forth with many of you, speaking with some of you via phone and video calls, and even meeting a few of you in person.

I’ll also have been horrified to learn how many workers are killed or i njured on the job each year. According to the Association of Workers’ Compensation Boards of Canada, there were 993 workplace fatalities in this country in 2022 (the latest year for which complete data is available). That same year, there were nearly 349,000 lost time claims due to injury or disease.

By the time you read this, I’ll have shed a few tears thinking about the lives lost and those forever changed by a split second in someone’s workday. But enough about me.

OHS Canada is all about you – the dedicated occupational health and safety professionals working tirelessly to bring workplace injury and fatality statistics as close to zero as possible.

EDITORIAL ADVISORY BOARD

You’ve recently faced unprece dented situation after unprecedented situation, and you’ve risen to the challenge every time. After a global pandemic, worldwide PPE shortages, record-breaking wildfires and heat domes, polar vortexes and snowpocalypses, to say nothing of atmospheric rivers, it’s understandable if you feel like you’ve seen it all – and maybe you have.

These pages are a place to share what works, and what doesn’t, with your peers so everyone can benefit from a safer workplace.

But it’s far more likely that the coming years will bring new challenges. Some may seem ripped straight from a Hollywood blockbuster (here’s looking at you, COVID-19), while others may be so mundane that no one outside your field takes notice. Whatever the future brings, we’ll face it together.

These pages are a place to share what works, and what doesn’t, w ith your peers so everyone can benefit from a safer workplace. In between issues, we’ll take these crucial conversations online, sharing

Paula Campkin: chief safety officer, Energy Safety Canada

Marty Dol: president and founder, HASCO Health & Safety Canada

Uyen Vu: director of communications, Institute of Work & Health

Natalie Oree: prevention consultant, SAFE Work Manitoba

David Powers: EHS director (Atlantic), Sysco Canada

best practices on the OHS Canada website and exchanging ideas via social media. This is how we’ll learn to make our workplaces safer. How we’ll save more workers from suffering the pain of a workplace injury. How we’ll spare more families and friends the grief of losing a loved one.

Never hesitate to reach out with your stories. I want to hear about your wins, your losses, and the lessons you’ve learned from both. My cell is always on, and my inbox is always open. (You can find my contact info listed in the masthead on the right-hand side of this page.)

And if you don’t think of yourself as a writer or a storyteller, that’s okay. Because I am a writer, and your stories are the ones I’m here to tell. Put me to work and let’s help more people head home safely at the end of the day.

P.S. If you want to learn from the very best of the best, join us for the OHS Canada Honours awards gala in Toronto on Sept. 26. We’re bringing leaders from across the co untry together to celebrate the best occupational health and safety practices in the country. You can find all the details at www.ohshonours.com.

Richard Quenneville: senior director of corporate services, T. Harris Environmental Management

Maureen Shaw: lecturer and presenter

Dylan Short: managing director, The Redlands Group

email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR

Brandi Cowen 437-770-4370 bcowen@annexbusinessmedia.com

MEDIA DESIGNER

Graham Jeffrey

ACCOUNT CO-ORDINATOR

Cheryl Fisher 416-510-5194 cfisher@annexbusinessmedia.com

AUDIENCE DEVELOPMENT MANAGER Barbara Adelt 416-510-5184 badelt@annexbusinessmedia.com

BRAND SALES MANAGER Silvana Maiolo smaiolo@annexbusinessmedia.com

SENIOR PUBLISHER

Paul Burton pburton@annexbusinessmedia.com

GROUP PUBLISHER Anne Beswick abeswick@annexbusinessmedia.com

CEO Scott Jamieson sjamieson@annexbusinessmedia.com

Printed in Canada

ISSN 0827-4576 (Print) ISSN 1923-4279 (Digital) PUBLICATION MAIL AGREEMENT #40065710

SUBSCRIPTION RATES

Published four times per year –Winter, Spring, Summer, Fall Canada $70/yr plus tax USA $98/yr CDN Foreign $162/yr CDN Single copy $19 CDN

Occasionally, OHS Canada will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Business Media Privacy Office privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2024 Annex Business Media All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Quebec offering free legal counsel to victims of workplace harassment and sexual violence

Quebec has announced $2.4 million over four years to cover the legal expenses for people who file claims of psychological harassment or sexual violence in the workplace.

Labour Minister Jean Boulet made the announcement on June 20 alongside Sophie Gagnon, head of the non-profit legal organization Juripop, which will receive the funding.

Boulet says the money will help the organization’s lawyers give free legal services to about 300 people per year.

To be eligible for funding, people will have to file a complaint with the province’s workplace safety board.

“This measure will play an essential role in improving access to justice for victims, in addition to benefitting all parties concerned by strengthening procedural fairness in the handling of complaints of sexual harassment,” Gagnon said.

The announcement comes after the province adopted Bill 42, the Act to Prevent and Fight Psychological Harassment and Sexual Violence in the Workplace, earlier this year to better protect employees.

A committee of three professors recommended the funding envelope, saying that complainants did not have sufficient personalized support to be properly represented in their claims before the workplace safety board.

- With files from The Canadian Press

300

BCRSP and CRBOH streamline path to certification by both bodies

The Board of Canadian Registered Safety Professionals (BCRSP) has ratified a memorandum of understanding (MOU) with the Canadian Registration Board of Occupational Hygienists (CRBOH), giving certificants of either body alternative routes to achieve dual certification.

Holders of a BCRSP certification will now be able to apply for certification under a streamlined process with the CRBOH, and similarly, holders of a CRBOH certification will be able to apply for certification under a streamlined process with the BCRSP, making the route to the examinations for both organizations more straightforward.

The MOU details the specific requirements and eligibility and outlines that individuals who are currently certified by one organization and subsequently obtain a certification from the other

organization within their continuous professional development cycle will be awarded full requalification credits under the respective processes.

“This agreement is an important step towards greater collaboration in Canada between two highly recognized certification boards and is an important benefit for certificants to have a streamlined avenue to obtain certification,” said Paul Belair, BCRSP chair.

“This partnership is important because it strengthens our commitment to raising professional standards and boosting the collaboration between occupational hygiene and safety professionals,” added Matt Brewer, president of CRBOH. “Together, we’re aiming to create a safer, healthier work environment across Canada, which will benefit both our members and the communities we serve.”

Number of victims of workplace harassment and sexual violence who will be able to access free legal services in Quebec per year

Amendments to SK’s Workers’ Compensation Act coming in October

On Oct. 1, amendments to Saskatchewan’s Workers’ Compensation Act, 2013 will come into force, including the expansion of occupational disease coverage to include six additional forms of cancer (penile, pancreatic, thyroid, soft tissue sarcoma, mesothelioma and laryngeal) for firefighters.

The amendments also include:

• Updating the privacy provisions to: (1) mirror The Health Information Protection Act; (2) provide for administrative penalties if a privacy breach occurs; and (3) simplify the process for releasing information during reconsideration or review of a decision on compensation claims;

• Requiring appeal tribunal decisions with rationale to be published;

• Covering the expenses associated with transporting a deceased worker’s body to the usual residence outside Canada;

• Providing compensation to a worker’s dependent children when the worker passes away from a non-work-related injury while on compensation, no matter the length of time on compensation;

• Simplifying the medical review panel process;

• Increasing the permanent functional impairment award over a four-year period and indexing afterward; and

• Indexing the independence allowance.

On Jan. 1, 2025, the amended definition of “worker” will remove executive officers and include secondary and postsecondary students in recognized programs..

WorkSafeBC recommends changes to improve crane safety

WorkSafeBC says the risks associated with cranes in B.C. are increasing as more cranes are in operation than ever before, and this work is taking place on increasingly complex, multi-employer worksites.

400

Approximate number of tower cranes operating in British Columbia.

In 2021, a tower crane collapse in Kelowna took the lives of five workers, and earlier this year, several crane-related incidents occurred, including a fatal incident at the Oakridge Park worksite that claimed the life of a worker.

In March of this year, WorkSafeBC brought together 130 crane-sector stakeholders, including labour representatives, tower crane operators, employers, prime contractors, rental companies, and the BC Association for Crane Safety, to identify and address gaps in crane safety.

“Following a comprehensive review of crane safety, and informed by stakeholder input and feedback, we’ve developed a risk-reduction strategy with recommendations aimed at further improving tower crane safety in B.C.,” said Todd McDonald, head of prevention services for WorkSafeBC.

Key recommendations include:

• Review the existing crane operator certification program to ensure it supports safe work.

• Explore how to improve the

training and skills of supervisors, riggers and workers involved in the assembly, operation, disassembly or repositioning of cranes.

• Review options for employers responsible for the assembly, operation, disassembly or repositioning of tower cranes, including registration and licensing.

• Increase the staffing and capacity of WorkSafeBC’s specialized crane inspection team.

• Develop new regulations to address the frequency of tower crane inspections.

• Review and update the province’s Occupational Health and Safety Regulation — including regulations related to cranes and rigging — to ensure they meet the needs of increasingly complex worksites.

• Ensure the BC Association for Crane Safety is equipped to service and support workers and employers in the sector.

WorkSafeBC is also continuing to implement changes already underway as part of its crane safety initiative, which aims to identify and eliminate unsafe work practices and equipment hazards that have the potential to cause death, serious injury and/or catastrophic equipment failure.

Workplace Safety North confirms Parent as new president and CEO

Mike Parent, CRSP, CSP, has been confirmed president and chief executive officer of Workplace Safety North (WSN) by the organization’s board of directors. He stepped into the role on an interim basis in September 2023.

With a background as a paramedic, miner, mine rescue volunteer, and mining health and safety manager, Parent brings a wealth of experience to his new role. He has been a pivotal figure at WSN since 2015, serving as vice-president of health and safety services, and interim president and CEO.

Parent’s extensive tenure within Ontario’s prevention system has cemented his reputation as a collaborative leader dedicated to health and safety advocacy. He aims to enhance the WSN legacy by spearheading a strategic plan that continues to ensure the well-being of every worker.

“I entered the health and safety field to make a difference,” Parent said in a media release. “Now, as president and CEO, I have the chance to impact safety on a provincial scale.”

During his time as a senior leader, Parent led a team of mining health and safety consultants, trainers, and specialists. His industry expertise is set to drive innovation in the provincial mine rescue program, as well as in the development of health and safety products, training programs,

and outreach initiatives for Ontario’s mining and forest products sectors.

“We are delighted to welcome Mike as the new president and CEO of Workplace Safety North and Ontario Mine Rescue,” said Lydia Renton, chair of WSN’s board of directors, in a media release. “Mike’s proven track record in occupational health and safety, coupled with his strategic vision and leadership skills, make him the ideal choice to lead our organization into the future.”

Ontario’s health and safety landscape is evolving, with a renewed focus on proactive research aimed at reducing workplace risks.

“WSN health and safety specialists and mine rescue officers are dedicated to helping companies assess risks, prepare for emergencies, and comply with legislative requirements,” Parent said. “Our vision remains that every worker returns home safe and healthy at the end of each workday.”

WSN is an independent not-for-profit and one of four sector-based health and safety associations in Ontario. Headquartered in northern Ontario, WSN oversees the provincial mine rescue program and delivers ministry-approved workplace health and safety training and services across the mining and forest products industries.

Mike Parent, CRSP, CSP

Stockyard fined $325,000 after one worker killed and another injured

On May 14, Spiritwood Stockyards (1984) Ltd. pleaded guilty in Spiritwood Provincial Court to two violations of The Occupational Health and Safety Regulations, 2020

The company was fined for contravening subsection 7-6 (1) of the regulations (being an employer fail where there is a risk of injury to the head of a worker to provide approved industrial protective headwear and require a worker to use it, resulting in the serious injury of a worker), as well as contravening subsection 9-2 (2) of the regulations (being an employer fail to ensure that workers use a fall protection system at a temporary or permanent work area if a worker may fall three metres or more; or there is a possibility of injury if a worker falls less than three metres, resulting in the death of a worker).

The Court imposed a total fine of $232,142.86 with a surcharge of $92,857.14, for a total amount of $325,000.

Five other charges were withdrawn.

The charges stemmed from two separate incidents that occurred near Spiritwood, Sask. The first occurred on Nov. 11, 2021, where a worker was struck by a gate and seriously injured while attempting to load bulls onto a trailer.

The second incident occurred on Jan. 26, 2022, where a worker was fatally injured while attempting to clear snow off a roof when the worker fell through a fiberglass skylight.

Construction company, supervisor, fined $546K for worker fatality

Volker Stevin Contracting Ltd., and supervisor Michael O’Neill have been fined a total of $546,000, following the death of a worker in 2019.

On Oct. 2, 2019, the worker was fatally injured while working in a storm drain in Airdrie, Alta., when they were run over by a work truck operated by another worker.

The company, being an employer, was found guilty of contravening:

Number of charges

Spiritwood Stockyards pleaded guilty to after one worker was killed and another injured in separate incidents, just three months apart.

• Section 3(1)(a)(i) of the Occupational Health and Safety (OHS) Act, for failure to ensure the health and safety of a worker engaged in the work of that employer, by failing to ensure their worker was not beyond the range of powered mobile equipment, a company truck, while performing work.

• Section 258(1)(a) of the OHS Code, where the movement of a part of powered mobile equipment, a company truck, created a danger to their worker, permitted the worker to remain within range of the part.

Volker Stevin Contracting Ltd. was fined $420,000 for the contravention of section 3(1)(a)(i) of the OHS Act and $60,000 for the contravention of section 258(1)(a) of the OHS Code.

The total fine was $480,000, inclusive of a 20 per cent victim fine surcharge.

All other charges against Volker Stevin Contracting Ltd. were withdrawn or conditionally stayed.

O’Neill was found guilty of contravening:

• Section 4(a)(ii) of the OHS Act, being a supervisor, failure to take all precautions necessary to protect the health and safety of a worker under his supervision by driving over the worker with a company vehicle while distracted.

• Section 258(1)(b) of the OHS Code, being an operator, and where the movement of a part of powered mobile equipment, a company truck, created a danger to a worker, moved the equipment where the worker was exposed to the danger.

O’Neill was fined $60,000 for the contravention of section 4(a) (ii) of the OHS Act and $6,000 for the contravention of section 258(1) (b) of the OHS Code.

The total fine was $66,000 inclusive of the 20 per cent victim fine surcharge.

All other charges against O’Neill were withdrawn or conditionally stayed.

Additional charges against a third worker were withdrawn.

Construction company fined $80,000 after two workers injured

Amico Contractors Inc. has been fined $80,000 after two workers were injured falling from a work platform.

The company pleaded guilty to failing to ensure that the platform was constructed and installed to support the weight of the workers, as required by section 134(1)(a) of Regulation 213/91, contrary to section 25(1)(c) of Ontario’s Occupational Health and Safety Act

On July 25, 2022, two workers were setting precast stairs and landings in stair shafts at a construction project in LaSalle, Ont. To complete the task, they built a work platform and braced it inside the stair shaft.

Shortly after the two workers climbed onto the platform to complete their work on the stairs, the platform fell with both of them on it, causing injuries.

A Ministry of Labour, Immigration, Training and Skills Development inspection revealed the workers did not construct or install the platform to support all loads to which it was likely to be subjected.

Construction company, director fined $117,500 after worker fatally injured

A small construction company and its director have been fined $117,500 after pleading guilty to violations of the Occupational Health and Safety Act in an Ontario court.

The fine comes after a March 2022 incident that fatally injured an employee working on a roof without guardrail protection or appropriate fall protection equipment.

By failing to ensure the worker was protected by means of fall protection, VanHeughten Contractors Inc. failed, as an employer, to ensure that the measures and procedures prescribed under section 26.1(2) of Regulation 213/91 were carried out in the workplace, contrary to section 25(1)(c) of the Occupational Health and Safety Act

The company was fined $85,000.

Kyle VanHeughten failed, as a director of the company, to take all reasonable care to ensure the corporation complied with section 26.1(2) of Regulation 213/91 contrary to Section 32(a) of the Act. He was fined $32,500.

The court also imposed a 25 per cent victim fine surcharge, as required by the Provincial Offences Act The surcharge is credited to a special provincial government fund to assist victims of crime.

On March 4, 2022, four workers were installing wooden roof trusses on a construction project in Aylmer, Ont. The trusses were being installed on top of framed walls. No guardrail protection was present, nor were any of the workers wearing any other method of prescribed fall protection equipment, or protective headwear.

One worker was standing on a two-by-four inch wood strapping while nailing wood with a cordless framing nailer. The strapping broke and the worker fell 5.08 meters from the roof and was struck by the nailer, causing fatal injuries.

Mental Health

By Bill Howatt

Preventing workplace mental harm begins by asking questions

What percentage of your workforce is at risk of workplace mental harm?

Before answering this question, you must understand mental harm. Workplace mental harm may not be permanent but could impact an employee’s judgment or behaviour. It can be likened to an injured ankle that is sprained, not broken. The person can continue walking with treatment and support while the ankle heals.

Employers must understand that an employee feeling overwhelmed by unrealistic expectations can lead to psychological injury, which prevents them from performing their daily functions and compromises their effectiveness. At that point, they will benefit from seeing a mental health professional who can assess their impairment and disability.

H ow much stress do your employees experience daily?

A n estimated 57 per cent of American and Canadian workers feel stressed. When I discuss workplace mental health with a CEO, we talk about how psychological safety can support and drive productivity, protect tacit knowledge, reduce lost time and promote organizational resiliency and sustainability. The conversation eventually gets to employees’ experiences, but I have found focusing on the outcomes and tangible financial benefits of investing in workplace mental health is helpful.

E mployers who are genuinely concerned about employee burnout and job stress can ensure that support programs are in place for

employees’ mental health. However, such programs tend to focus on employees, not the root causes of their stress.

Using evidencebased, anonymous workplace assessments can help employers determine what may be protecting workers from mental harm or putting them at risk.

M icheal Leiter and Christina Maslach, two leading global experts in workplace burnout, report that burnout is a response to chronic job stress. They suggest that burnout is akin to the proverbial canary in the coal mine, meaning that when employees experience burnout, it is prudent to look beyond the individuals to their environment and the root cause of their stress.

P roviding employees with a resiliency or mental fitness program, a resiliency mental health app, or access to an employee assistance program can be helpful when implemented with a thoughtful workplace mental health program. Unfortunately, employers too often focus on tactics and fail to address the root cause, which may be how work is organized and managed.

For example, employees who

work in a command-and-control culture and live in fear will likely never feel comfortable and constantly experience stress. This mental state increases their risk of mental harm and injury.

H ow employers can protect employees from mental harm and psychological injury

My advice to employers is that impact requires a system approach. I often use a fish tank analogy to make the point that maintaining a clean tank is critical to the fish’s health. A guiding principle for mitigating employees’ risk of mental harm, such as workplace stress and burnout, is promoting a two-way accountability approach where employees and employers create a workplace for employees to flourish.

The following four-step model begins by asking workers and leaders what they are experiencing. It is beneficial to understand current risks, factors contributing to risk,

Dr. Bill Howatt is the Ottawa-based president of Howatt HR Consulting.

Mental Health

and the percentage of the workforce languishing and flourishing, as well as to search for evidence of programs doing what they should be doing. The critical lesson for anyone facilitating workplace mental health is that activity does not necessarily mean the outcome is being achieved. Buying a Stairmaster is of little value if it is not used regularly.

1 Obtain a workforce mental harm risk profile — Obtaining a baseline using a simple tool like the Q15 Mental Health Harm Risk Profile can help employees and employers understand the mental health harm risk based on employees’ experiences over the past 30 days. This risk profile asks employees how they are doing and provides them with feedback and recommendations. The higher the mental health harm risk profile, the higher the likelihood that employees may experience mental or psychological injuries that can increase workers’ compensation and other disability claims. This risk profile can help employers understand employees’ experiences that can increase their risk of burnout and other stress-related concerns like isolation, loneliness and maladaptive coping. It can take time to change a system, so it is prudent to encourage employees to engage in help-seeking behaviours to mitigate the risk of disability claims.

2. Discover what issues or factors create drains — Ask employees to share their workplace experiences to help reveal psychosocial factors that are chargers and drains. When choosing a workplace assessment, employers should be clear on what outputs they want to know about. Research shows that it is helpful to understand psychosocial

The critical lesson for anyone facilitating workplace mental health is that activity does not necessarily mean the outcome is being achieved. Buying a Stairmaster is of little value if it is not used regularly.

factors and hazards and how psychologically safe leaders and teams are. OHS risks such as bullying and harassment, the value of existing programs, and how employees perceive that they are resilient and flourishing should also be discerned. Using evidence-based, anonymous workplace assessments can help employers determine what may be protecting workers from mental harm or putting them at risk. The challenge with many workplaces is not what they are doing. How they are doing it often creates strain and stress.

3 Inquire about what can be done and how to support employees’ experience — Asking employees this question helps employers understand through a workforce lens what they think could improve the employee experience. Though workplace mental health committees can provide inputs, they often are limited to a few voices. Employers can take a qualitative approach by arranging focus groups where employees feel safe sharing ideas and opinions. These groups dig into employees’ experiences and seek solutions. For example, if the first question found many employees are at risk of mental harm and the second confirmed workload is a significant drain, leveraging a work redesign would look for what could be done to reduce workload stress, perhaps by eliminating useless meetings or allowing

more flexibility for employees to work from home.

Focus groups encourage listening, asking open-ended questions and engaging employees in conversations to create solutions and ideas that may not otherwise be considered. Based on the data collected from all three questions, this step aims to determine what actions can be taken to prevent mental harm, ensure mental health supports are accessible and in place, and guide operational decisions that can influence the employee experience regarding what is being done and how. For example, the data collected may highlight the benefits of challenging a policy or red tape that can free up mental energy.

4. Build and launch a workplace mental health game plan — The first three steps increase awareness and accountability. This step moves from ideas and discussion to action. Regardless of the plan, provide for resistance and build a workplace mental health scorecard to measure output via a Plan-Do-Check-Act approach. Workplace mental health game plans promote accountability, learning and habits. I use what I learned from my dad: a stove has four burners, so you can only have so many pots cooking at once. I have taken this into my consulting and coach employers that less is more. It is better to do a few things well that achieve impact. One challenge often not considered in implementing workplace mental health game plans is they are designed to work in an organization that likely already has many things going on. Hence, creating space for impact requires being realistic and accepting that changing habits is a process, not an event.

The Canadian Centre for Occupational Health and

The Canadian Centre for Occupational Health and Safety (CCOHS) promotes the total well-being – physical, psychosocial, and mental health – of workers in Canada by providing information, advice, education, and management systems and solutions that support the prevention of injury and illness. Visit www.ccohs.ca for more safety tips.

Be prepared with a plan for outdoor workers

Outdoor workers are exposed to unique and, at times, unpredictable hazards, including extreme weather conditions, poor air quality, and bug bites. Having a summer health and safety plan can help reduce the risk of injuries and illnesses.

A comprehensive plan should consider risk factors during routine work, such as working in the heat, as well as unexpected circumstances, like a sudden storm. By taking inventory of the possible hazards workers may face outdoors and putting precautions in place, you can anticipate and be prepared for a healthy summer for all.

Develop a summer safety plan

S tart by reviewing how outdoor hazards are managed in your workplace. Check the legislation in your jurisdiction to make sure your organization is meeting its responsibilities.

Next, conduct risk assessments for any work done outdoors. Inspect jobsites to identify potential hazards, evaluate the level of risk to workers, and determine measures to eliminate or lower the risk and keep workers safe. It’s also good practice to review past incident reports to pinpoint issues that need to be addressed.

Talk about concerns with workers and health and safety committee members and representatives and encourage them to share their experiences and input. After all, health and safety is a shared responsibility among employers, management and workers. To create a safer outdoor work environment, you’ll need everyone’s feedback, support, and participation.

Providing access to drinking water and encouraging breaks in areas where workers can cool down can help reduce the risk of heat-related illnesses and injuries.

Take measures to reduce risk

Then it’s time to introduce measures that reduce risk of workplace harm. The most effective way is to eliminate a hazard altogether or to substitute it with a safer alternative. However, when it comes to outdoor hazards, like sun exposure, this isn’t always possible. Instead, ensure the worker stays hydrated and use measures that separate the worker from the hazard, like providing shaded areas on the jobsite. Also, share information about possible hazards to raise awareness and encourage prevention practices.

Include information on outdoor health and safety in new hire orientations, training, and “crew talks” before a shift. If workers are required to wear personal protective equipment, ensure it is appropriate for the

job and work conditions, in good working condition, and that they know how to wear it properly.

W hen sharing your plan with workers, communicate in clear, plain language and avoid using jargon or technical terms without a clear explanation. This will make sure everyone understands important health and safety guidance.

Ultraviolet rays from the sun

Even on cloudy days, the sun’s ultraviolet (UV) radiation can cause premature skin aging, sun burns, skin cancer, and eye damage. Layering on personal sun protection is a must for workers to reduce the risk of sun harm.

Workers should wear lightweight, long-sleeved shirts and pants in sun-resistant fabric,

UV-rated sunglasses, and a widebrimmed hat that covers the head, face, ears and neck. A backflap or visor can also be added to hard hats.

A broad-spectrum, waterproof sunscreen and lip balm with a sun protection factor (SPF) of at least 30 should be applied every two hours and after sweating. Workers should also seek shade as much as possible under trees or canopies and structures on the jobsite.

Understanding the UV index, which measures the strength of the sun’s UV rays, can help determine the level of risk to workers daily, and what precautions to take to lower the risk. The higher the UV index, the greater the need for precautions, so check the local UV index forecast when scheduling outdoor work. Where possible, schedule less strenuous tasks between 11 a.m. to 3 p.m., when UV radiation is at its strongest.

Extreme heat and humidity

Direct sun also puts workers at risk of heat stress. And with global warming caused by climate change, extreme heat events are becoming more frequent.

The body aims to maintain a constant internal temperature of 37 C at all times. In hot weather, the body produces sweat, which cools the body as it evaporates. As the humidity or moisture content of the air increases, sweat does not evaporate as readily and under these circumstances, the body temperature rises and may cause illness. Heat stress occurs when a worker’s heart rate and core body temperature rise. It can lead to heat rash or prickly heat, heat cramps, heat exhaustion, heat stroke and even death.

Providing access to drinking water and encouraging breaks in areas where workers can cool down can help reduce risk.

Employers can also supply cooling wear to workers, such as vests, neck

Include information on outdoor health and safety in new hire orientations, training, and “crew talks” before a shift.

shades and headwear with built-in cooling mechanisms.

During extreme heat events, check on workers for any irregular behaviour and know the warning signs of heat stress. Symptoms can include muscle cramps, fainting, nausea, extreme thirst, and weakness.

E xtreme heat can also cause severe weather events, such as lightning storms. Since there is no safe place to be outdoors during lightning, ensure workers are trained to avoid areas that conduct electricity and to seek safe shelter in a storm. As with any emergency response, pre-planning, including the provision of first aid and medical care for affected workers, is key to reducing risk in the face of extreme weather conditions.

Poor air quality

S oaring temperatures also increase air pollution levels and the potential for wildfire events, both of which put workers at risk of harmful exposures. In fact, air pollution coupled with the sun’s UV rays creates a chemical called ground-level ozone, which is harmful to breathe.

Poor air quality can cause chronic health issues such as respiratory disease, heart disease, and allergies. It can also heighten symptoms in those with underlying health issues, like breathing or heart problems, so ensure you have accommodations in place to protect these workers when air quality is poor.

Ch eck local air quality index reports and avoid or limit outdoor work during instances of poor air quality. When this is not possible, provide fit-tested respirators to filter out harmful particulates.

Bug bites and animal-to-human disease

Working outdoors also means sharing a jobsite with insects and wildlife. When infected with viruses or bacteria, these creatures can spread pathogens to humans, causing illnesses like West Nile virus, Lyme disease, rabies, and bird flu.

Workers should perform their duties upwind of animals, practic e proper hand hygiene, regularly disinfect objects and equipment, and wear dedicated clothing and footwear that is regularly washed.

Removing sources of stagnant water from a jobsite, where mosquitos may breed, and cutting down vegetation where ticks tend to live, can reduce the risk of mosquito- and tickborne diseases.

To avoid insect bites, workers should also wear light-coloured, long-sleeved shirts, pants tucked into socks, and closed toe shoes.

Providing insect repellent containing DEET or i caridin, or permethrin-treated clothing, can also help to repel insects.

Tying back hair and doing a thorough tick check can help to further prevent tick-borne diseases. Should a worker get bitten by a tick, carefully remove it as soon as possible. In some cases, you may need to report the exposure to your local public health authority.

A safer outdoor work environment

Take the time to review and evaluate the effectiveness of your summer health and safety plan. Walk through jobsites to observe hazards, put precautions in place, analyze any incidents or near-misses, and introduce workplace inspections and refresher training.

Follow these steps and you’ll be prepared for any health and safety hazards that may come your way this summer.

CSA Group

CSA Group is a global organization dedicated to safety, social good and sustainability. It is a leader in standards development and in testing, inspection and certification around the world, including Canada, the U.S.A., Europe and Asia. CSA Group’s mandate is to hold the future to a higher standard.

Adapting first aid standards for modern work environments

Accidents and illnesses can happen at any time, in any work environment. For this reason, first aid kits and first aid training are crucial in Canadian workplaces. They help make workers feel safe and comfortable, help to prevent further harm, and can sometimes be the difference between life and death.

It’s important that first aid standards are updated regularly to align with leading practices in first aid training and to address the evolving needs of Canada’s diverse work environments.

C SA Group’s Candace Sellar, manager of health and safety strategic initiatives – standards, shares details on the most recent changes in two new editions of CSA Group’s standards on first aid training and first aid kits for the workplace.

What are the key changes in the new editions of CSA Group’s first aid standards compared to the previous versions?

CSA Z1210:24, First aid training for the workplace – Curriculum and quality management for training agencies is the second edition of this standard and introduces several significant changes aimed at enhancing the clarity and comprehensiveness of the standard. One of the updates outlines the components of workplace first aid training courses, specifying the requirements of each training level. Additionally, new guidelines detail the requirements for training agencies to recertify many workplace first aiders.

CSA Z1220:24 First aid kits in the workplace has also been updated. This second edition includes the addition of organizational and worker roles and responsibilities, a revision of first aid kit content requirements, and the separation of optional first aid kit contents into specialized and additional items.

How are work environments changing and what impact does this have on first aid?

Today’s workplaces are evolving and becoming more complex, requiring workplace first aid to adapt. Changes in the physical environment due to climate change, such as extreme weather and a rise in

vector-borne and zoonotic diseases, as well as the rise of remote and hybrid work settings, affect how first aid is delivered. The structure of work is also shifting, with an increasing number of lone workers without immediate access to other first aiders, as well as more gig, freelance, and contract workers, potentially leading to longer hours and fatigue-related hazards. The workforce is diversifying, with multi-generational teams and an increasing number of new Canadians bringing varied language, cultural, and religious needs.

A key occupational health and safety (OHS) activity for any organization to undertake is to

First aid kits in the workplace can help to prevent further harm and may even be the difference between life and death.

continually assess and improve first aid programs by understanding how the changes noted above are impacting their workplaces, along with the make-up of their worker populations, and to conduct these assessments in consultation with their workers. It is important to avoid a “one and done” approach and instead understand how the shifting complexities of the environment could impact first aid plans, supplies, equipment, and training needs.

In what ways do the new standards address the diverse needs of a modern workforce, including considerations for equity, diversity, inclusion, and accessibility (EDIA)?

When planning for a modern workforce and first aid needs, organizations should consider a variety of factors. These include workers that are aging, have disabilities, are neurodiverse, are new to the workforce, and/or are new to Canada. This is relevant for both those being trained in first aid and those who might receive first aid.

The 2024 edition of CSA Z1210 highlights the need for training providers to recognize and respect diversity among learners. This includes considering learners’ backgrounds, first aid experience, age, neurological conditions, language fluency, cultural differences, and communication styles. Accessibility needs are also addressed in the workplace first aid training program design.

The standard also emphasizes effective communication and addresses barriers that may arise, such as when an injured or ill worker speaks a different language or has a disability requiring alternative communication methods. Additionally, it underscores the importance of understanding the principle of consent.

It is important to avoid a “one and done” approach and instead understand how the shifting complexities of the environment could impact first aid plans, supplies, equipment, and training needs.

temperatures due to a changing climate, the 2024 edition of CSA Z1220 has now made it a requirement that all levels of first aid kits contain emergency blankets.

Is the implementation of first aid standards mandatory across all workplaces in Canada?

Training providers must consider learners’ backgrounds, first aid experience, age, neurological conditions, language fluency, and cultural differences, as well as communication styles.

The 2024 edition of CSA Z1220 includes the potential necessity of naloxone hydrochloride in certain workplaces, particularly where there may be a higher risk of opioid use. It is listed as an example of an additional or specialized supply for first aid kits, requiring specialty first aid training or an optional add-on to a first aid training program. The standard also now references different forms of glucose instead of specifying glucose tablets, ensuring inclusivity for locations where glucose tablets may not be available or practical.

How do the updated first aid standards account for the effects of climate change, such as increased heat stress or natural disasters, on workplace safety?

CSA Z1210:24 recognizes that first aiders may find themselves in complex response settings, such as those brought about by climate change, and must be prepared with the appropriate knowledge, skill, and self-efficacy to respond in such scenarios. It also requires the first aider to have awareness of the principles of hazard identification, risk assessment, control processes, and implementation within the workplace. This is critical when a first aider finds themselves in an evolving emergency, not only for the optimal delivery of first aid, but also for their personal protection.

In addition, recognizing that many lone and/or remote workers have greater exposure to extreme

D evelopment of the new 2024 editions of CSA Z1210 and CSA Z1220 was made possible, in part, by the financial support of the Canadian Association of Administrators of Labour Legislation – Occupational Safety and Health (CAALL-OSH). Whether the 2024 editions will be considered for referencing in regulation will be determined by each respective jurisdiction. Currently, first aid regulations vary geographically, so the best approach is to confirm legislative requirements with the appropriate jurisdiction.

What CSA Group resources are available to help organizations and individuals implement first aid in the workplace?

C SA Group offers free standards support tools for a variety of our OHS standards, including first aid kits. Helpful tools include an illustrated guide for creating and maintaining first aid kits, a checklist for inspecting kits and ensuring they meet the standard’s requirements, and an eight-step guide to support workplace emergency readiness. Additionally, CSA Group’s new report, “First Aid Training and CPR Skills Retention,” reviews the effectiveness of initial and refresher training for CPR skills. These free resources can help organizations enhance their workplace safety programs and better prepare employees for emergencies. To find the full suite of support tools, visit https://www.csagroup. org/store/standards-support-tools/ occupational-health-and-safety.

The future is driverless

By Brandi Cowen

Remember the first time you slid into the driver’s seat and wrapped your hands around the steering wheel with the intent to drive somewhere? Maybe you were bursting with the excitement of finally gaining some of the freedoms older siblings or friends enjoyed, or you were confident you’d handle the family vehicle like a pro in no time.

During those earliest drives, most of us understand that driving is a responsibility – one that can and will be taken away if we don’t obey the rules, exercise caution, and use good judgment behind the wheel. Our teachers, whether helpful family members or trained professionals, try to instill good habits that will keep us safe.

Then we start to gain confidence and get more comfortable. Maybe those good habits slip a little. A shoulder check before changing lanes becomes a glance at the blind spot warning indicator in the side mirror. The speedometer creeps further above the speed limit because traffic is light, and you know speed traps are rare on a particular stretch of road. Over time, our experience behind the wheel can breed complacency.

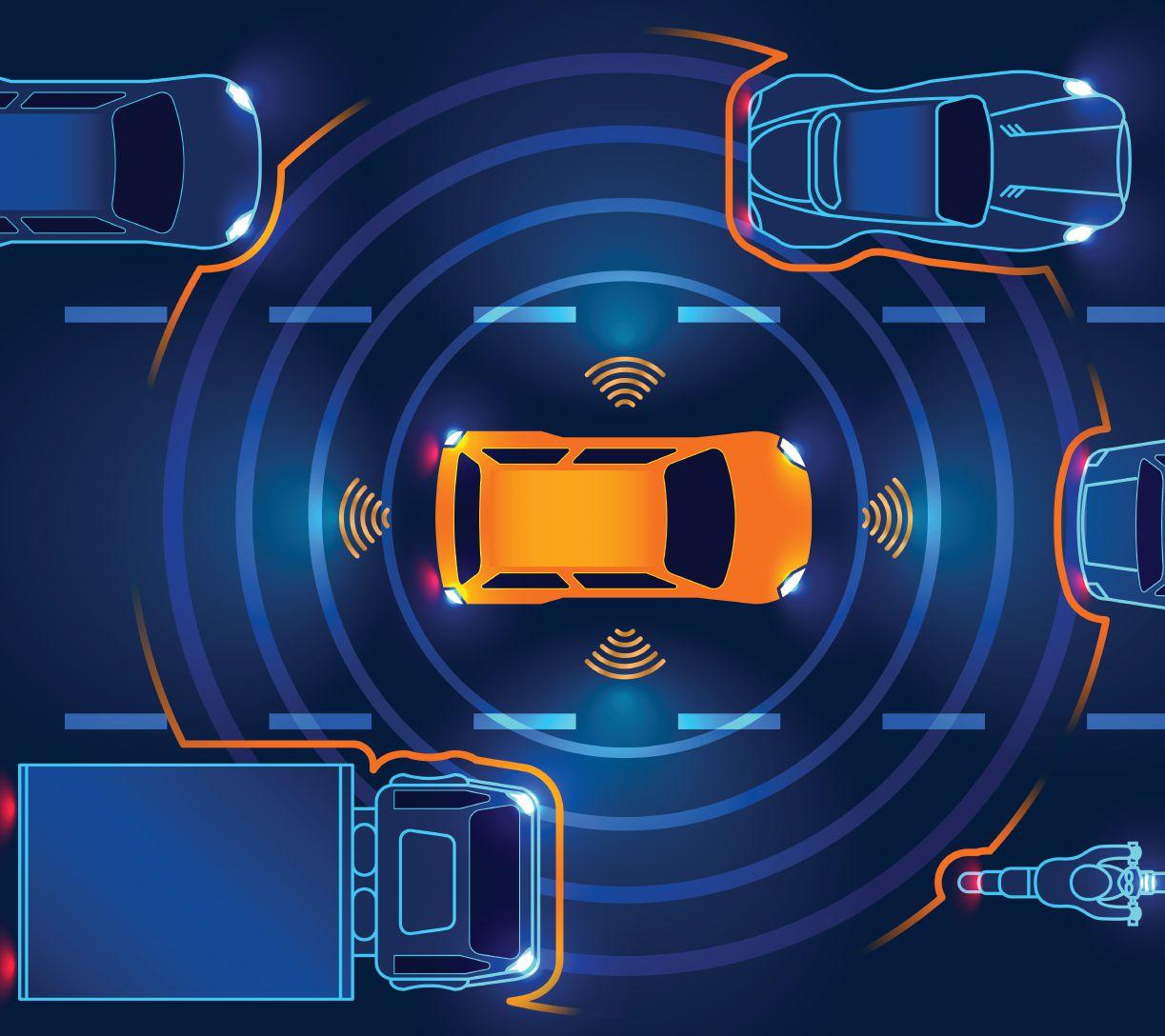

Can autonomous technology save us from ourselves?

Driver behaviour contributes to about 86 per cent of collisions causing injury or death on Canada’s roadways, according to Transport Canada’s National Collision Database. In a country that recorded 1,931 motor vehicle fatalities in 2022 (the last year for which complete data is available), that means about 1,660 deaths were caused by human error. This begs the question: can autonomous technology make our roads safer?

“It’s not a simple task,” says Amir Khajepour, a professor in the Faculty of Engineering at the University of Waterloo. “With driving, what’s happening has infinite scenarios, so how are we going to make sure that the vehicle and control systems you have can safely detect [conditions] and then go through all the scenarios safely?”

When humans are behind the wheel, they take in hundreds of details every second and predict what’s likely to happen next. If the driver’s side door of a parked car opens into an oncoming cyclist, a human driver can anticipate that the cyclist will most likely swerve into traffic to avoid colliding with that door and then respond

accordingly. The cyclist’s behaviour is more challenging for an autonomous vehicle to predict, and the challenge grows as the vehicle’s operating environment becomes more crowded.

“People know that humans cause accidents, make mistakes, but they expect technology to be perfect.”

To help autonomous vehicles become better at predicting outcomes, researchers are outfitting them with multi-sensory equipment. There’s lidar (light detection and ranging) and radar (radio detection and ranging) to scan the environment and report back, sonar (sound navigation and ranging) to detect objects and navigate, GPS to geolocate and navigate, inertial measurement units to monitor the vehicle’s physical movements, and a variety of cameras to help the vehicle visualize its environment and interpret data such as signs and traffic lights.

“ We mix these together because each of them has strengths, and when you put them together, it generates more accurate information about the environment,” says Khajepour. “We’re also using a lot of predictions on the movement of objects, whether that’s a pedestrian or a vehicle or a bicycle. Based on those predictions, we’re able to make [the autonomous vehicles] safer and more predictable.”

But even the best technology has limitations.

“All hardware and all software fail occasionally, and there’s also what we call ‘edge cases’ or unusual situations,” says Barrie Kirk, president of the Canadian Automated Vehicle Initiative (CAVI). “[In April] in the States there was a robo-taxi that got into a collision because it was confused by another car being towed backwards. That hadn’t been put into its programming.”

Helping autonomous vehicles respond appropriately in

these situations will go a long way toward ushering in the age of fully autonomous driving in Canada.

What we mean when we talk about autonomous driving

The Society of Automotive Engineers (SAE) has adopted a standard classification system to indicate the degree of automation a vehicle offers (see page 20). At level zero, an active and engaged driver is required to operate the vehicle at all times. At level five, the vehicle can drive itself everywhere with no human interaction required beyond setting a destination.

Many vehicles on the road today offer technologies that place them somewhere between level zero and level two. That means these vehicles still rely on their drivers to be attentive and engaged behind the wheel – and organizations with employees whose duties put them behind the wheel rely on the driver’s competencies, too.

For now, anyway.

In recent years, higher-level autonomous vehicles have debuted on our roads via pilot projects. In January 2022, Loblaw Companies Limited partnered with Gatik, an autonomous middle-mile logistics company, to trial a fleet of autonomous box trucks. The trucks safely completed more than 150,000 autonomous deliveries from a Loblaw distribution facility to five nearby retail locations in the Greater Toronto Area with a back-up driver on board. After establishing a track record of 100 per cent safety along these fixed, repetitive routes, the companies pulled the drivers from the trucks and completed Canada’s first driverless delivery in October 2022.

Driver behaviour is a contributing factor in about 86 per cent of collisions causing injury or death on Canada’s roadways.

Safety looms large in the future of AVs

For every success story, there’s a cautionary tale. In May, the National Highway Traffic Safety Administration in the United States announced it would investigate the automated driving system developed by Amazon’s self-driving robo-taxi, Zoox. The investigation stemmed from two incidents in which the vehicles braked suddenly and were rear-ended by motorists.

“ The paradox is that in the long run, self-driving vehicles will be safer than human-driven vehicles,” Kirk says. “But we’re not there yet.”

He stresses the need to think critically about how we define the term “safety” in the context of autonomous vehicles.

“ The government says ‘we will make sure that self-driving cars are safe for Canadians’ without really defining what that means. My big concern is people would be forgiven for thinking that the government will keep them totally safe and that will not be the case. People know that humans cause accidents, make mistakes, but they expect technology to be perfect.”

Managing expectations around the safety of AVs will be critical going forward. Kirk points to the United Kingdom’s Automated Vehicles Act, which became law in May, as a model for legislators to consider in devising Canada’s AV framework.

“ The [United Kingdom’s] AV bill is very explicit and says that we can expect self-driving passenger cars to be as safe as – and probably even safer than – a competent, good human driver,” Kirk explains.

In its announcement of the new law, which sets the stage for AVs to hit the road as early as 2026, the U.K. government stressed “the law will require self-driving vehicles to achieve a level of safety at least as high as careful and competent human drivers, as well as meeting rigorous safety checks before being allowed onto roads. Therefore, in the future, deaths and injuries from drink driving, speeding, tiredness and inattention could be drastically reduced.”

Here at home, much work remains to create a comprehensive framework for widespread adoption of autonomous vehicles.

In recent years, autonomous vehicles have debuted on Canadian roads via pilot projects.

At the federal level, the government is responsible for regulating the manufacture and import of motor vehicles, as well as safety components. This includes regulating cybersecurity.

“ Transport Canada has issued a number of documents, from guidelines for testing autonomous driving systems to safety frameworks that are aimed at advancing and moving the dial on autonomous vehicles,” says Edona Vila, a partner at the law firm BLG and a member of the firm’s Autonomous Vehicles Group. “But we haven’t yet seen a concerted effort like the U.K. framework.”

Then there are the provincial and territorial levels to consider. These levels of government bear the responsibility for traffic laws, regulating drivers and insurance liability.

“ What we need is the provinces and the feds moving concurrently with an overarching goal of aligning those regulatory frameworks in a consistent fashion so that you don’t have inconsistencies between regulatory frameworks and between provinces to allow for the full-scale deployment of these vehicles,” Vila adds.

Considerations for employers

“Employment law tends to be a bit more reactive than proactive… Employment law is regulated provincially and so provinces tend to copycat one another,”

says Noah Burshtein, a senior associate at BLG who specializes in labour and employment law.

He notes that under provincial and territorial occupational health and safety legislation, employers have a general duty to provide a safe working environment to the extent possible. This responsibility won’t change with the adoption of AVs.

“In Ontario, the Workplace Safety and Insurance Board has been studying this issue – they’re going to have to think about how rates and coverage and workplace injuries will be examined in the context of autonomous technology,” Burshtein adds.

He notes employers must also ensure that any AV program they roll out meets their obligations under local accessibility laws. “Employees will not be able to be excluded from jobs involving nonaccessible AV technology.”

The adoption of AVs will also impact discipline and performance management. After all, humans can’t be held to the same standard as machines; human workers get tired and need breaks.

Thinking beyond highways and byways

Though we still have a long way to go before AVs appear on Canadian roads en masse, some industries are already putting autonomous technology to work on job sites.

IAMGOLD’s Cote Gold deposit in north-

The six stages of autonomous vehicles

Level

0: No automation

The human driver performs all aspects of the dynamic driving tasks.

Level 1: Driver assistance

The vehicle’s driver assistance features support the driver with either steering or acceleration/deceleration under specific conditions. The human driver is expected to perform all remaining aspects of the dynamic driving task, including monitoring and responding to the driving environment.

Level 2: Partial automation

The vehicle’s driver assistance features support the driver with both steering and acceleration/deceleration under specific conditions. The human driver is still expected to perform all remaining aspects of the dynamic driving task, including monitoring and responding to the driving environment.

Source: Transport Canada

eastern Ontario is slated to begin commercial operations this year. When it reaches full production, it will be mined by 23 autonomous haul trucks, two electric shovels, three front-end loaders and six autonomous drills, and supported by a variety of other equipment. The fleet will operate inside an autonomous operating zone; staff access will be restricted to qualified and necessary personnel to maximize safety and control of operating conditions.

Meanwhile, in the forestry sector, FPInnovations has been working to adopt autonomous vehicle technologies for several years. The company’s first test took place at its Tolko OSB mill in Meadow Lake, Sask., in 2019, when a level-four autonomous truck made empty and partially-loaded trips between a loading point and the delivery dock in a contained area of the mill yard.

Autonomous equipment is also being used on farms, in warehouses and manufacturing facilities, and at countless other job sites across the country.

As autonomous technology becomes more widespread and more humans grow accustomed to co-existing with it, setting realistic expectations about the safety of the technology will remain crucial.

“The technology will be better, but never perfect,” Kirk says. “Everybody – all stakeholders, government, industry people like myself – need to help better manage expectations.”

Level 3: Conditional automation

The vehicle’s automated driving system (ADS) features perform all aspects of the dynamic driving task, including monitoring and responding to the driving environment under specific conditions. The human driver must be alert and ready to perform the dynamic driving task when the system requests the human driver to intervene.

Level 4: High automation

The ADS-equipped vehicle performs all aspects of the dynamic driving task, including monitoring and responding to the driving environment, under specific conditions. The vehicle is designed to respond safely without human action to all situations, including when it reaches the limits of its operating environment.

Level 5: Full automation

The ADS-equipped vehicle performs all aspects of the dynamic driving task, including monitoring and responding to the driving environment, in all conditions.

Safety Leadership

By Wayne Arondus

Strategies from safety leaders

Safety at work requires an ongoing dedication to continuous learning and improvement. Despite the resolve of even the best leaders, complacency creeps in. To challenge this, we need to commit to honest self-reflection and critical evaluation.

B usiness leaders who succeed in building strong safety cultures understand that the key is not individual excellence, but the collective actions of their entire team. Their success depends on the degree to which they influence and inspire others to place value and priority on health and safety.

O ver the last few months, we had the opportunity to connect with three finalists for the prestigious Soaring Eagle Leadership Award. Lesli Bradley, Jaime Pacreu, and Brent McCrea are three very different leaders who have mastered this ability to inspire and nurture effective safety cultures in their organizations

In detailed interviews with all three, they shared approaches and strategies they have adopted to build a dynamic environment of continuous improvement in their businesses.

Accountability and audit drive safety culture at SunRype

Bradley, president of Kelowna, B.C.’s SunRype Products, a division of A. Lassonde, cultivates a resilient safety culture to equip her employees to

adapt to unforeseen circumstances. In a large subsidiary of an even larger food and beverage manufacturer, leadership through accountability and process is critical.

Leaders who make time to learn from each other are better equipped to foster growth and resilience within their own organizations and communities.

“Our people are the most valuable asset of any organization,” Bradley says. “Our role as a health and safety leader is vital in shaping the culture. It is about being accountable and ensuring the tone from the top reflects the importance of health and safety to all people at all levels of the organization.”

O ne crucial way Bradley accomplishes this at SunRype is through the Occupational Safety Standard of Excellence (OSSE) certification. Audits help SunRype identify where they can improve their safety programs. Their joint health and safety committee uses the audit findings to determine action plans for the coming year.

Those action plans are an essential part of the foundation of the next year’s business objectives.

Values and knowledge sharing promote empathy at Kerry Canada Knowledge sharing among leaders also promotes empathy

and broader perspectives. Pacreu, plant manager at Kerry Canada’s plant in Delta, B.C., explains that he aims to make safety a core value for his team, not a priority. It is a mantra he regularly speaks and demonstrates by his actions, and as a result, his leadership team and staff embrace the mindset.

“If we make safety our value, it’s going to always be there. Today, we are prioritizing production. Tomorrow, we might have a quality issue that we need to address. And the next day, we might need to look at our costs. Our priorities change, but safety must always be the same.”

Inspired by the impact on their own safety performance, Kerry’s Delta plant leaders are now sharing their successes and best practices with the company’s other locations.

At McCrea’s Welding, knowledge sharing and connection influence safety in a company and a community

Understanding diverse leadership styles and experiences enhances a leader’s ability to connect with and motivate a diverse team; shared learning helps leaders navigate challenges more effectively.

I n Campbell River, B.C., McCrea, owner of McCrea’s Welding Ltd., demonstrates this every day.

He shares his personal safety experience and knowledge with customers, contractors, and other local businesses to strengthen safety programs

across the supply chain and around his tight-knit community.

“ We were able to take our procedures and policies down to a local company to share with them our process stepby-step, helping them develop their own safety,” McCrea says. “We also helped them make a film to use to train their staff in the future.”

McCrea’s mentorship not only of staff but of others in his community eventually garnered him the prestigious Soaring Eagle Leadership Award, recognizing the small business owner for exemplary and inspiring leadership that includes a commitment to health and safety.

Whether you are a smalltown business owner or an executive in a multimilliondollar business, the importance of building a supportive network where knowledge and wisdom are freely exchanged cannot be understated. Your network becomes a source of mentorship and guidance that is particularly valuable during crises or periods of rapid growth or uncertainty.

U ltimately, leaders who make time to learn from each other are better equipped to foster growth and resilience within their own organizations and communities.

Leaders who set a precedent for continuous development create an environment where everyone, regardless of position, feels empowered to contribute to a safer workplace and healthier culture

Wayne Arondus is the chief operating officer of the Manufacturing Safety Alliance of B.C.

Coping with extreme heat on the job

By James Careless

As the world gets hotter, so do the job sites people are working on. This is why coping with extreme summertime heat is more important than ever for outdoor workers and their employers; too much heat can literally kill you.

Unfortunately, many of today’s heat management rules are inadequate because they apply the same standards to everybody. “Moreover, these guidelines fail to provide direction on the safe, maximum work time before heat-mitigation controls should be employed (e.g., rest breaks, cooling) during hot weather or extreme heat events,” says Glen Kenny, professor of physiology and director of human and environmental physiology research at the University of Ottawa.

To address this problem, Kenny has been “conducting day-long work simulation trials to define, for the first time, initial safe work times (time required to achieve a predefined core temperature of 38C or 38.5C for unacclimated and acclimated workers respectively) for young and older men and women to ensure that all workers are protected and not just young men,” he said. “Further, we are conducting work to refine the use of work rest allocations that considers individual factors that can limit a person’s capacity to dissipate heat such as age and sex of the worker.”

As detailed in an October 2018 American Journal of Industrial Medicine article, ‘Occupational heat stress management: Does one size fit all?’, which Kenny co-authored with

The resistance of any worker to heat stress varies based on how many days this stress has been experienced at work.

Sean R. Notley and Andreas D. Flouris, “applying a generalized ‘one size fits all’ exposure limit for all workers does not consider the extensive individual variation in heat strain and the subsequent risk of heat-related injury associated with a given heat stress.”

In other words, extreme heat guidelines that are sufficient to protect young healthy men could place men of other ages and fitness, and women in general at greater risk of experiencing heat-related injury or even death.

Moreover, the resistance of any worker to heat stress varies based on how many days this stress has been experienced at work. “If you take a worker that just had a long weekend off and they come to work on Tuesday well rested, that’s great: They probably have their normal ability to thermoregulate,” says Kenny. “When they then work in extreme heat over consecutive days, that ongoing exposure is essentially going to cause deterioration in their body’s ability to dissipate heat. This means current

exposure limits that would safely protect them on Monday are not going to be providing the same level of protection on Friday.”

Occupational health and safety managers need to take steps today to help workers and their managers deal with on-the-job extreme heat. What follows is a brief look at the very real threats posed by extreme heat events and what can be done to mitigate them.

What are extreme heat events?

When a summer day becomes brutally hot, it tends to be described as an ‘extreme heat event.’ According to André Gauvin, an occupational hygienist with Occupational Health Clinics for Ontario Workers (OHCOW), “Anything with a humidex above 45 is an extreme heat event. So when the outdoor temperature is over 32 degrees Celsius with a relative humidity above 60 per cent, you’re getting very close to that 45 humidex.”

This being said, defining what constitutes an extreme heat event

“depends on various factors, including geographical location, which affects acclimatization and climate norms, as well as individual vulnerability,” says Jordan Clark, senior policy associate with Duke University’s Nicholas Institute for Energy, Environment & Sustainability. “This is why we generally look at comprehensive indices that account for multiple factors affecting heat stress. One of the most effective measures is the Wet Bulb Globe Temperature (WBGT) index. This index takes into account not just air temperature, but also humidity, wind speed, and solar radiation. These factors combined give us a more accurate picture of how the human body experiences heat stress.”

A range of heat-related illnesses

Although the illnesses caused by too much exposure to extreme heat vary, they all have one thing in common. “At their core, heat-related illnesses arise from the body’s inability to dissipate internal metabolic heat generation effectively,” Clark says. “When the rate of heat production exceeds the body’s capacity to lose heat through sweating and other mechanisms, core body temperature rises, leading to various heat-related conditions. It’s important to distinguish between classic heat illness [caused by being in extreme heat] and exertional heat illness [caused by working in extreme heat], though symptoms can overlap.”

When it comes to heat-related illnesses, “heat stroke is obviously the most severe,” says Gauvin. Caused by the body’s core temperature rising above normal to 40C or higher, heat stroke occurs when the body’s thermoregulatory responses (such as perspiration) cannot cool it adequately in extreme heat. Symptoms include: fatigue; high body temperature; hot, red, dry or damp skin; confusion; loss of consciousness; and a fast/strong pulse.

As cited by Jordan, other heat-related illnesses to watch for include:

• Heat cramps: Caused by an electrolyte imbalance due to excessive sweating, symptoms include painful muscle spasms usually in the legs, arms, or abdomen, plus heavy perspiration.

• H eat exhaustion: Brought on by excessive loss of water and salt, usually through sweating. Signs to watch for include heavy sweating, dizziness, headache, fast and weak pulse, thirst, irritability, and nausea.

• Heat rash: Caused by blocked sweat glands. Heat rash presents as small, red blister clusters on the neck, chest, and groin, or within elbow creases.

• Exertional heat illness: The result of performing strenuous activities in hot conditions. Symptoms can include excessive fatigue, hyperventilation, vomiting, physical collapse, confusion, and, in severe cases, multi-organ failure.

Coping strategies

The best way to cope with extreme heat events is to not work in these conditions. Failing that, workers should be dressed in clothes that breathe; wear wide-brimmed ventilated hats, UV-protective sunglasses, and personal cooling vests; drink plenty of water and electrolyte-enhanced beverages to replace lost salts; apply cool, damp cloths to pulse points at the neck, wrists and

temples; and be shaded from direct sunlight with access to outdoor misting fans for cooling.

“ When possible, schedule strenuous activities during cooler parts of the day; take regular breaks in cool, shaded areas; and work in pairs to monitor each other for signs of heat stress,” says Clark. Should signs of heat-related illness occur, the worker should go to a cooler location for an extended period of time until completely recovered. Medical help should be sought if there is any cause for concern whatsoever.

Again, workers of different ages, sexes, and fitness levels can be more vulnerable to extreme heat than others, so err on the side of caution. And though it is possible for workers to acclimatize to working in hot conditions over time, extended exposures can actually erode the body’s ability to cope — so don’t rely on ‘getting used to the heat’ as a coping strategy.

The bottom line: Extreme heat is becoming a fact of life on outdoor job sites across Canada. Dealing with it proactively and constructively is good for worker health, and thus good for business as well.

Glen Kenny is conducting work simulation trials to define safe work times for men and women of all ages.

How to safely execute rescues at height

By James Careless

Even with the best training, personal protective equipment (PPE), and responsible operational procedures, accidents do occur when people fall while working at height. In cases where the person cannot recover themselves, safe and effective response by others on the job site is essential.

“ Workers who fall and become suspended in their fall arrest harness need to be rescued immediately,” says Mathew MacLeod, senior technical specialist in occupational health and safety with the Canadian Centre for Occupational Health and

Safety (CCOHS). “Suspension trauma can occur if they’re left hanging for too long, which happens due to blood pooling in the lower body, reducing the amount of oxygen available to the brain. The worker may also have sustained an injury from the actual fall, require medical attention, and could be unconscious.”

Creating an effective ‘working at heights’ rescue plan

Because working at heights can be inherently dangerous, health and safety managers need to devise and implement a rescue plan before an incident happens.

To create an effective rescue plan, “involve qu alified individuals competent in rescue at heights,

including those doing the work,” MacLeod says. “Make sure the plan is specific for the job you are planning for, considering the hazards, location, tasks being performed, environmental conditions, how and where a worker could fall and the type of rescue that would be needed, among other factors. You’ll also need to identify the hazards associated with the rescue and how a rescue will be initiated to ensure the plan is appropriate and the required equipment is available and maintained.”

That’s not all: An effective working at heights rescue plan will need to be designed for quick yet safe deployment, and backed by first aid training for rescuers, along with provisions to access outside medical aid fast. “The quickest route to the

hospital should be mapped out,” MacLeod says. “In locations far from a hospital, additional measures may be needed to ensure a worker can receive appropriate medical attention, if required.”

PPE for rescuers, communications procedures, and step-by-step rescue procedures need to be included in the rescue plan. The types of PPE required will depend on the hazards and risks associated with anticipated rescue scenarios, as will the communications and rescue procedures selected.

“Common personal protective equipment could include fall protection equipment, head protection, eye protection, high-visibility apparel, gloves, or safety footwear,” MacLeod says. “A first-aid kit and rescue equipment and accessories will also be required. You also need to identify the most effective means of communication. This may include using radios, cell phones, headsets, always maintaining direct voice communication or other means.”

Assess the risks accurately

The dangers associated with rescues at height can be properly identified by accurate risk assessments before, during, and after such rescues have taken place. The goal is to assess the risks as accurately as possible in the planning stage — with constant updates to the plan over time — then cope with unexpected risks during the actual rescue and incorporate the ‘lessons learned’ from that response into the rescue plan for next time.

“ Dev eloping a systematic and comprehensive method for identifying hazards and assessing risk is essential,” MacLeod says. “The team responsible for developing the rescue plan needs to identify all hazards that may cause harm to workers during the initial work and a potential rescue. Hazards that can

The skills that height rescuers require are many and daunting, which is why regular training is so important.

cause damage to equipment or infrastructure, including any damage that could impact the rescue, also need to be identified.”

Train the rescue team repeatedly

Creating a rescue at heights plan is one thing. Making it work in practice is another. Achieving this second goal requires choosing rescuers with the right experience, and then training them repeatedly to keep their skills – including first aid and CPR – fresh.

12,600

The skills that height rescuers require are many and daunting, which is why regular training is so important. “Methods may include ladder rescue, elevating work platform rescue, using the lifeline to retrieve the worker, rescuers rappelling down to retrieve the worker, pulling a worker from an area below, using emergency equipment to reach the worker such as a crane basket, rope rescue, and other methods,” MacLeod says. “Always ensure any equipment required to perform the rescue successfully has been inspected and maintained and can be accessed immediately in the event of a rescue.”