Artificial intelligence makes inroads to workplaces

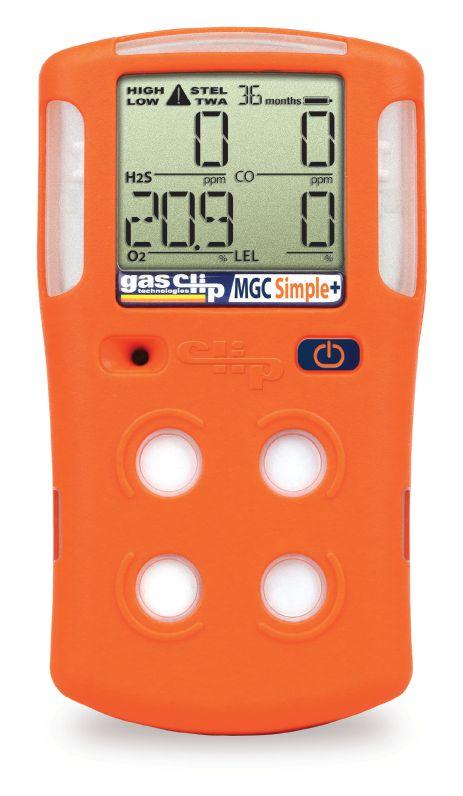

Detects H2S, CO, O2 & LEL combustible gases continuously for 36 months

No charging required... EVER

Calibration not necessary

No sensor or battery replacement

Artificial intelligence (AI) is poised to make its presence felt in many industries. Will AI boost workplace safety, or are we wading into unchartered waters?

BY DANNY KUCHARSKY

Speaking the same language as the C-Suite is the first step to getting workplacesafety issues come under the radar of enterprise risk management system.

GLYN JONES

British Columbia wildfires prompt state of

Saskatchewan launches campaign against healthcare violence; Ontario concludes cancer-claims review; Nova Scotia releases injury figures; and more.

among oil workers; and more.

The increasing volume of electronic waste driving the rise of worker-injury rates in

and waste-management facilities calls for better protective measures.

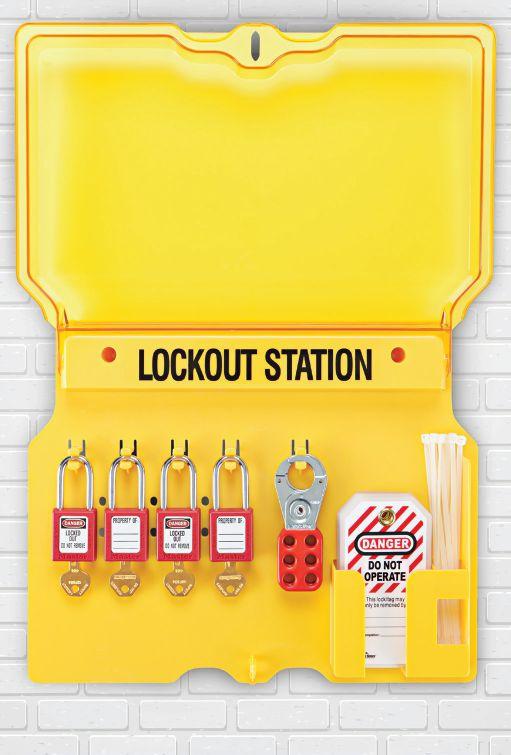

Compliance with proper lockout procedures and program documentation is key to preventing the inadvertent release of hazardous energy.

An

from

Alberta farm workers will have similar rights and protections as other workers in Canada when final industry-specific technical rules governing farms take effect on December 1. Bill 6: Enhanced Protection for Farm and Ranch Workers Act is, in many respects, a victory as it extended safety protections to Alberta’ waged, nonfamily farm and ranch workers who have remained outside the folds of oh&s law for the longest time ever.

But a closer look at the technical rules suggests back-pedalling that smacks of caving in to pressure from the farming community, which has been vocal about their opposition to the bill since it took effect on January 1, 2016.

Consider the following technical rules: Alberta farm workers should follow manufacturer’s specifications of old or existing equipment if available to identify safety hazards and observe proper maintenance and operational procedures; workers can be raised or lowered in front-end loader buckets if no other option is available; and seat belts should be used wherever possible.

It is hard to imagine similar exceptions being made to other regulated industries, in particular the discretionary approach to seat-belt use. And that begs the question: why is the farming industry seemingly treated with kid gloves?

The answers are as varied as they are complex. Farming is personal and a way of life passed down through generations. It is also a communal affair: kids are often roped in to undertake light farming duties and neighbours also help out. As such, any attempt to introduce regulatory enforcement in a tightly-knit, family-owned business is likely to be deemed intrusive and met with resistance.

Secondly, the rural and remote location of farms, which are often extensions of farmers’ private residences, likely contribute to their sense of autonomy and independence. Industry constraints like tight margins, high overheads and depressed commodity prices, coupled with Mother Nature’s unpredictability, can lead to the perception of safety regulations as an undue burden. In other words, Bill 6 is more than just another piece of legislation — it heralds a cultural shift that is not welcomed by the very people that the well-intended law seeks to protect.

Striking a balance between ensuring farm safety and preserving farming’s unique way of life has not been an easy feat for Alberta’s regulators. But make no mistake: farms are dangerous places in which to work and live. According to non-profit organization, The Farm Safety Centre in Raymond, Alberta, agriculture is Canada’s third most hazardous industry. Machine runovers (42 per cent) and drowning (15 per cent) are the most predominant causes of farm-related fatalities involving children aged fourteen and under. I know a farmer in Saskatchewan who lost her child back in the ‘50s when he got buried by snow that fell from the roof of a barn. Half a century down the road, the boy continues to be addressed lovingly as “Little George.”

The unique way of life on farms and ranches, while worthy of preservation within reasonable limits, should not trump health and safety. Statistics on farmrelated injuries and fatalities demonstrate that safety oversight is necessary and way overdue. Teething problems aside, Bill 6 will channel resources and lead to heightened awareness that will ultimately benefit farmers and ranchers alike.

Vol. 34, No. 5 SEPTEMBER/OCTOBER 2018

EDITOR JEAN LIAN 416-510-5115 jlian@ohscanada.com

ART DIRECTOR MARK RYAN

ACCOUNT COORDINATOR CHERYL FISHER 416-510-5194 cfisher@annexbusinessmedia.com

CIRCULATION MANAGER JAY DOSHI 416-442-5600 EXT 5124 jdoshi@annexbusinessmedia.com

PUBLISHER PETER BOXER 416-510-5102 pboxer@ohscanada.com

GROUP PUBLISHER PAUL GROSSINGER pgrossinger@annexbusinessmedia.com

PRESIDENT & CEO MIKE FREDERICKS

EDITORIAL ADVISORY BOARD MEMBERS

DAVID IRETON, Safety Professional, Brampton, Ont.

AL JOHNSON, Vice President, Prevention Services WorkSafeBC, Richmond, B.C.

JANE LEMKE, Program Manager, OHN Certification Program, Mohawk College, Hamilton, Ont.

DON MITCHELL, Safety Consultant, Mississauga, Ont.

MICHELE PARENT, National Manager, Risk Management and Health and Wellness, Standard Life, Montreal, Que.

TERRY RYAN, Workers’ Compensation and Safety Consultant, TRC Group Inc., Mississauga, Ont.

DON SAYERS, Principal Consultant, Don Sayers & Associates, Hanwell, N.B.

DAVID SHANE, National Director, Health and Safety, Canada Post Corporation, Ottawa, Ont.

HENRY SKJERVEN, President, The Skjerven Cattle Company Ltd., Wynyard, Sask.

PETER STRAHLENDORF, Assistant Professor, School of Environmental Health,Ryerson Polytechnic University, Toronto, Ont.

JONATHAN TYSON, Association of Canadian Ergonomists/Association canadienne d’ergonomie, North Bay, Ont.

Printed in Canada

ISSN 0827-4576 (Print)

ISSN 1923-4279 (Digital)

PUBLICATION MAIL AGREEMENT #40065710

CIRCULATION

asingh@annexbusinessmedia.com

Tel: 416-510-5189

Fax: 416-510-6875 or 416-442-2191

Mail: 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

SUBSCRIPTION RATES

Published six times per year – Jan/Feb, Mar/Apr, May/Jun, Jul/Aug, Sep/Oct, Nov/Dec

Canada $98/yr plus tax

USA $98/yr

Foreign $161.50

Occasionally, OHS Canada will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Office privacy@annexbusinessmedia.com

Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2018 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

900,000

The number of federal workers in Canada affected by the revamp of the federal labour code focusing on work-life balance and precarious workers.

Source: Employment and Social Development Canada

$70,000

Fine issued to an Ontario firm on September 7 over an injury sustained by a worker while riding in a scooptram’s bucket.

Source: Ontario Ministry of Labour

92.5%

1. Webpage on Weed: WorkSafeBC has created a new webpage to help employers and employees prepare for cannabis legalization. The webpage provides information about the effects of substance-use impairment and the responsibilities of workers and employers in managing impairment.

Source: WorkSafeBC

2. Free Training: As part of the Career Safety Education program, Saskatchewan youth aged 14 to 21 will have free access to WorkSafe Saskatchewan’s Mental Health: Health and Wellness Strategies, an online course that imparts skills on coping with stress.

Source: Saskatchewan Safety Council

3. To the Rescue: Tahoe Canada mine rescuers from Timmins West and Bell Creek mines will compete at the 11th International Mines Rescue Competition in Ekaterinburg, Russia from September 22 to 29. The Ontario team, which is one of two Canadian teams, will compete against 28 teams representing 12 nations at the biennial event.

Source: Workplace Safety North

4. Safety Superstars: WorkSafeNB will recognize superstars in workplace safety at its annual Safety Star Awards on October 5 in Fredericton. The Health and Safety Leader Award recognizes a leader within an organization who has positively influenced safety culture, while the Health and Safety Champion Award recognizes an employee who goes above and beyond to ensure safety on the job for themselves and others.

Source: ServiceNL

Percentage of school buses in Newfoundland and Labrador that passed mandatory inspections conducted from January to May.

44%

Percentage of allowed lost-time claims in Ontario in 2017 due to sprains and strains.

Source: Workplace Safety and Insurance Board

Source: WorkSafeNB

5. Feedback Sought: The Workers Compensation Board of Prince Edward Island is requesting feedback on proposed changes to the Workers Compensation Act to provide presumptive coverage for firefighters with cancer and heart injuries. Comments can be submitted through an online feedback form by September 16.

Source: Workers’ Compensation Board of Prince Edward Island

A series of gas explosions on September 13 injured at least 10 people and ignited fires in some 39 homes in three communities north of Boston. Entire neighbourhoods had to evacuate as crews scrambled to fight the flames and shut off the gas.

Source: The Associated Press

360°

FEDERAL — The Transportation Safety Board of Canada (TSB) published its latest annual statistics on reported occurrences in the aviation, marine, rail and pipeline transportation on August 22.

In 2017/18, the TSB launched 54 investigations and issued 66 investigation reports, which represented a 50 per cent increase in the number of investigations compared to 2016/17. The average time to complete an investigation was 503 days, compared to 569 days in 2016/17 and the five-year average of 527 days. This reduction in average time reflects the TSB’s efforts at streamlining and modernizing its tools and processes.

“It really has been a busy year,” TSB Chair Kathy Fox says in a statement. “None of these accomplishments would be possible without the substantial efforts of our staff. Their knowledge, expertise, and dedication are what makes the difference when it comes to advancing safety for all of us, from coast to coast to coast.”

TSB carried out 69 outreach activities across the country in the four modes

of transportation to share safety messages and lessons learned from investigations. It also assisted the board in reviewing progress made on recommendations that had been outstanding for more than 10 years. Since 1990, the board has made 594 recommendations, almost 80 per cent of which have led to positive change.

WHITEHORSE — The final report of an independent inspection of the Whitehorse Correctional Centre (WCC) has yielded 40 recommendations on how to improve the delivery of programs and services and better serve inmates with mental wellness needs.

In a statement issued on August 15, the Yukon government says it has undertaken preliminary work to implement the recommendations. An implementation working group is being formed with representation from First Nations governments and justice-system partners to provide the insight required to ensure the recommendations are acted on.

“We are committed to improving the

FEDERAL — The Transportation Safety Board of Canada (TSB) released on August 9 the findings of its investigation on the forced landing of an aircraft in Calgary.

On 25 April 2018, Super T Aviation Piper PA-31-350 Navajo Chieftain departed Medicine Hat Airport in Alberta on an instrument flight rules flight plan with two flight crew members and four passengers on board for a scheduled charter flight to Calgary International Airport. A descent was initiated when the aircraft was approximately 20 nautical miles southeast of the Calgary airport.

Just prior to landing, the crew contacted the arrival controller about the loss of its right fuel pump. Moments later, the flight crew transmitted a Mayday call. Recognizing that the aircraft was not going to make it to the airfield, the flight crew attempted an emergency landing on the northbound lanes of 36 Street N.E. when its right wing contacted a light standard on the right side of the road, shearing off a part of the wing. There were no injuries to those onboard the aircraft nor to people on the ground.

Whitehorse Correctional Centre with a focus on mental health and addiction treatment services,” says Minister of Justice Tracy-Anne McPhee, who called for an inspection at the Whitehorse Correctional Centre in September 2017 to identify areas where the government can improve policies and practices that have an impact on inmates’ mental health, including those related to placement, treatment and available programs

The inspector, David Loukidelis, presented his final report to the Deputy Minister of Justice on May 15 after examining the facility and conducting interviews with First Nations and community members. The final inspection report provided a slew of recommendations in four areas: mental-health services, segregation and separate confinement practices; First Nations programming and services; governance; and administration.

RICHMOND — WorkSafeBC declared a state of emergency on August 22 to ensure a coordinated response to wild-

According to the TSB report, the air operator’s standard operating procedures (SOP) did not include any guidance information on fuel monitoring or management. The captain and first officer used different methods to manage and monitor fuel consumption throughout the flight. When fuelmanagement SOPs are not in place, fuel starvation can occur even if there is sufficient fuel remaining on board the aircraft to complete the planned flight.

Following the incident, the aircraft made several changes to its SOPs and normal procedures checklist for the aircraft, including adding to the company’s SOPs the following: guidance on procedures for accepting runway changes; more detail on aircraft-evacuation procedures; and enhanced procedures on preparing passengers for an emergency landing.

The training syllabus for new crew members and the company’s emergency response plan has also been amended, and an industry-supplied course on fatigue management and human factors has been scheduled.

fires across the province.

The agency provided resources to help British Columbia employers understand the potential hazards and outline measures that can minimize worker exposure during the wildfire season. For workers who work outside, recommendations for reducing exposure to wildfire smoke include reducing the amount of time spent outdoors and staying indoors with the windows closed. Use of a properly fit-tested, certified N95 halfface respirator is highly recommended.

For indoor workplaces, employers can reduce the amount of smoke entering their building by inspecting the HVAC system to ensure that it is working properly. Temporary reduction of the intake of outdoor air should only be done in consultation with a qualified HVAC technician or ventilation engineer. Indoor particle levels in small areas can also be lowered by using individual portable air cleaners equipped with high-efficiency particulate air filters or electrostatic precipitators.

BLAINE LAKE — A company in Blaine Lake, Saskatchewan was fined $1,400 on September 6 for failing to provide records requested by an employmentstandards officer.

The numbered company, operating as Blaine Lake Gas Plus Creta Pizza, was fined under The Saskatchewan Employment Act after pleading guilty to charges stemming from employmentstandards complaints about unpaid wages received between September 28 and December 27, 2016. One additional charge against the company and two charges against the director of the company were withdrawn.

A statement from Labour Relations and Workplace Safety in Regina says records were not provided to the employment standards officer when they were requested. The officer determined that employees were owed nearly $600 in unpaid wages. That amount has since

been paid to the workers.

In the past year, the employment standards division at Labour Relations and Workplace Safety recovered more than $2.1 million in unpaid wages.

SASKATOON — A Saskatchewan company was fined $70,000 on August 22 over a worker injury last year.

The charges stem from an incident that took place on January 30, 2017 in Saskatoon where a worker employed by Wright Construction Western Inc. sustained a serious hip injury after the scissor lift that the worker was unloading from a flatbed trailer drove off the ramp and overturned.

The company was fined $50,000 plus a surcharge of $20,000 after pleading guilty to one count under occupational health and safety regulations in Saskatoon Provincial Court. One additional charge was stayed.

PRINCE ALBERT — A Saskatchewan company was fined $4,900 on September 6 over an incident that led to serious injuries to a worker.

The offence took place on June 2, 2017 near Wakaw, Saskatchewan, according to Labour Relations and Workplace Safety in Regina. A worker employed by Bradley Davidson-Vermette of Prince Albert was removing debris from a conveyor belt when the conveyor system started up, causing the worker to fall approximately four metres. The worker suffered broken bones in his arm, pelvis and hip as well as fractured his ribs and spine.

The company pleaded guilty to failing to ensure that neither the operator nor any other worker will be endangered by starting the machine.

REGINA — Saskatchewan Association for Safe Workplaces in Health (SASWH) launched a campaign on August 24 to increase awareness of violence in the healthcare sector.

The Campaign for Change, #IWillReport, is a collaborative effort with frontline healthcare workers, senior leaders and system partners. The campaign showcases a video docu-

menting personal experiences with violence that healthcare providers in the province have encountered.

“The unfortunate reality is that occurrences of violence and aggression are experienced by many frontline healthcare workers,” Sandra Cripps, chief executive officer of SASWH in Regina, says in a statement. “The participants in this video have represented the issue very well, signalling the call to action of #IWillReport any and all occurrences of violence or aggression.”

Saskatchewan’s healthcare sector continues to experience the highest number of claims reported than all other industries, according to statistics from Saskatchewan Workers’ Compensation Board. The underreporting of violent incidents in the healthcare industry is attributed to the perception that workplace aggression is part of the job. Currently, some healthcare facilities are struggling with a lack of appropriate controls to address the risk of violence.

The campaign seeks to increase the reporting of violence to build a stronger safety culture and promote the adoption of effective violence-prevention initiatives. Increased reporting will also enable more targeted and timely interventions, the statement notes.

WINNIPEG — Manitoba Agriculture is urging farmers, farm families, employees and motorists to keep safety a top priority when harvest is underway across much of the province.

According to a statement from the Manitoba government on August 17, farmers and their employees should take extra precautions when driving past or near slow-moving farm equipment and be respectful of other drivers as long lineups of slow-moving vehicles can cause frustration. It is important to ensure that all lights are working and adjusted properly before moving farm equipment on public roads.

Awareness of height, length and weight restrictions on farm vehicles and when permits may be required is necessary, as well as recognizing the risks associated with fatigue when driving or handling other tasks. Regular inspection and maintenance of farm equipment and creating a separate and supervised play area for children on the farm are important too, the statement adds.

TORONTO — Home furnishings retail store chain IKEA Canada Ltd. in Toronto was fined $55,000 on August 23 over a worker injury last year.

An employee working as a cart retriever was directing a row of 43 nested flatbed shopping trolleys into a cart corral from the front while a co-worker pushed from the rear on February 25, 2017. As the worker was walking directly in front of the row of trolleys as it went down a narrow hallway, the trolleys accelerated and struck the worker, pinning him against a wall and resulted in a critical injury.

According to a court bulletin from Ontario’s Ministry of Labour, the worker had not been provided with sufficient precautions, safeguards or protective clothing to ensure that the movement of trolleys did not pose a danger to workers. Ikea was fined after it pleaded guilty to flouting Section 25(1)(c) of the Occupational Health and Safety Act and Section 45(a) of the Industrial Establishments Regulation (Regulation 851)

PETERBOROUGH — The conclusion of a review of past cancer claims among former General Electric (GE) workers in Peterborough, Ontario saw the acceptance of 71 claims that had previously been denied. The previous decision was upheld in a further 105 claims with four others being abandoned.

According to a Workplace Safety and Insurance Board (WSIB) statement on August 1, cancer diagnoses among Peterborough’s former GE workers were first noted in the 1990s. Toxic chemicals, many of which were known carcinogens, were used at the plant between 1945 and 2000.

Last September, the WSIB created a dedicated review team comprising occupational-disease adjudicators, occupational hygienists and physician experts to look at 233 claims that had previously been denied. The team reviewed each claim individually to apply any new evidence as well as up-

dated scientific research that linked chemical exposure to particular diseases.

“Peterborough families were looking for answers and closure,” says Armando Fatigati, WSIB’s vice president of complex claims. “People brought forward new information and wanted to know that all of the evidence and latest scientific research was considered. We are confident these decisions reflect the most updated scientific research and all the available evidence.”

Reviewers also located the next of kin in eight claims that had previously been abandoned. Next of kin were not found in the remaining 45 previously abandoned claims.

SAINT JOHN — A recent investigation into an incident involving powered mobile equipment in New Brunswick highlighted the importance of rollover protective structures (ROPS) and seat-belt use.

According to a statement from WorkSafeNB issued on August 17, an excavator was moving down a hill in winter when it started to slide. As the tracks hit the raised frozen ground, the momentum of the excavator, combined with the position of the counterweight, caused the excavator to roll over.

Fortunately, the excavator was equipped with both ROPS

Congratulations to the following OHS professionals who have recently been granted the Canadian Registered Safety Professional (CRSP)® Professionnel en sécurité agréé du Canada (PSAC)® designation.

Shady Gamal Shalaby Abdalla CRSP

Cameron Adam CRSP

Shaun Angus CRSP

David Austin CRSP

Tonia Avery CRSP

Holly Baird-Jones CRSP

Stacia Baldwin CRSP

Frederick Barnes CRSP

Andrew Benn CRSP

Catherine Bernard CRSP

Jason Bezaire CRSP

Christina Boncheff CRSP

Carl Bonello CRSP

Dustin Brears CRSP

Danielle Brown CRSP

Kevin Brown CRSP

Matthew Brown CRSP

Randi Brown CRSP

Leanne-Grace Buzon CRSP

Craig Carter CRSP

Jovell Carter CRSP

Mireille Cartier CRSP

Robert Carver CRSP

Catherine Chauder CRSP

Jason Chevrier CRSP

Patrick Choukalos CRSP

Jeff Clare CRSP

Mary Reid Clarkson CRSP

B.Garth Cobb CRSP

Lee Cole CRSP

Andrew Crowther CRSP

Glenn Adam Cummings CRSP

Kumud Deka CRSP

Timothy Ebbinghaus CRSP

Michele Frasier CRSP

Dean Gamblewest CRSP

Rachel Garibaldi CRSP

Caroline Gebel CRSP

Emma Gibson CRSP

Harold Gold CRSP

Chris Halter CRSP

Christopher Hansel CRSP

Randy Hart CRSP

Andrew Hearn CRSP

Ravi Hookoom CRSP

Ammar Hussain CRSP

Trevor James CRSP

Conrad Ray Kilba CRSP

Darlene Konynenbelt CRSP

Samuel Kujembola CRSP

Brock Lafosse CRSP

Sara Lambie CRSP

Julia Shu Ki Lok CRSP

Jamie Lundrigan CRSP

Jared Mackinnon CRSP

Taylor Mawson CRSP

Justin McConville CRSP

Glen McIntosh CRSP

Robert McLellan CRSP

Mariorafols (Mario) Menezes CRSP

Alan Metzler CRSP

Dani Miller CRSP

Chloe Minors CRSP

Claire Mocock CRSP

Terrance Morin CRSP

Deborah Moskal CRSP

Nathan Netelenbos CRSP

Darcy Newman CRSP

Larissa Orlowski CRSP

Shannon Paiement CRSP

Melanie Patterson CRSP

Amit Rajhans CRSP

Martin Ralph CRSP

Melissa Rozon CRSP

Jocelyn Seaman CRSP

Chad Selk CRSP

William Sharpe CRSP

Michal Siembab CRSP

Sarah St. Cyr CRSP

Dustin Symon CRSP

Wilma Santos Torres CRSP

Andreea Trif CRSP

Jessica Tucker CRSP

Christopher Twitchett CRSP

Nicole Vargas CRSP

Laura Vekved CRSP

Henry Verschoof CRSP

Danielle Wardstrom CRSP

Duncan Webb CRSP

Brendan Webster CRSP

Christian Weth CRSP

Caitlin Williams CRSP

Ho Shan Ulrica Wong CRSP

that act as a protective box around the driver, and a falling objects protective structure, or metal mesh sheets wrapped around the powered mobile equipment where the operator sits to protect him from branches, rocks and other falling objects. The operator was not hurt due to the equipment having proper ROPS, combined with seat-belt use.

“We want to remind New Brunswick workers and employers of the priceless value of these protective measures,” WorkSafefNB cautions.

Precautionary measures that can be taken include providing training on the safe operation on slopes in different weather conditions and proper position of the boom, arm and counterweight. Seat belt must be worn at all times when operating powered mobile equipment, the statement adds.

FREDERICTON — Two police officers were among four people killed in a shooting at an apartment in New Brunswick on August 10. Constable Lawrence Robert Costello, 45 and Constable Sara Mae Helen Burns, 43, were killed when they were responding to a call at the apartment that morning. One woman and a man from Fredericton were also killed.

New Brunswick RCMP’s Major Crime Unit is assisting in the homicide investigation and seeking the public’s help with photos or video footage depicting what happened on the day

of the incident. Police has arrested a 48-year-old Fredericton man who remains in custody.

Manitoba Premier Brian Pallister expressed his “deepest condolences to the families of each of the victims and, in particular, the families of the two fallen officers.”

HALIFAX — Workplace injury continues to affect workers, employers and families in Nova Scotia despite progress over the long term, according to the Workers’ Compensation Board (WCB) of Nova Scotia’s Community Report for the first quarter of 2018.

“Our results this quarter speak to the need for continued focus on injury prevention and better support for safe and timely return to work,” says Stuart MacLean, the WCB’s chief executive officer.

There were 1,331 time-loss injuries from January to March, down slightly from the same period in 2017 when there were 1,342 injuries. The injury rate for the first quarter, which is calculated as the number of injuries per 100 WCB-covered workers, remains unchanged at 1.76 — same as the rate at the end of 2017. Three people in the province were killed between January and March, according to a WCB statement issued on August 14.

Workers who get hurt on the job are taking longer to return to work than in recent years. The composite duration index, which measures how long injured workers are off the job, is 120 days at the end of the first quarter — up from 117 days at the end of 2017. Employees in health and social services experienced more injuries than any other sector in the first quarter, usually while assisting or moving people in long-term care or home-care settings. There were 389 time loss claims in these sectors between January and March — three times more than the number of injuries reported by any other industry.

The WCB is improving the way it delivers its services by replacing its aging claims and assessment systems with the industry leading Guidewire software platform, with a launch planned for early next year. More than 5,500 workers have registered for online service so far, and tens of thousands of secure messages and documents have been shared digitally.

“Part of how we are helping to reduce the impact of injury is by making it easier for workers and employers to do business with us,” MacLean says. “We are investing in better tools and faster processes so that we can provide more convenient online service options.”

HALIFAX — Six key findings have emerged from stakeholder consultations by the Workers’ Compensation Board (WCB) of Nova Scotia to gather feedback on developing regulations for post-traumatic stress disorder (PTSD) presumption for frontline and emergency-response workers.

“The purpose of this conversation was to develop principles, criteria and indicators that could be used to inform decisions about the next level of definitions and to guide future decisions about the designation of other occupations,” says the Report on a Stakeholder Conversation released on August 14.

At the directive of Nova Scotia’s Department of Labour and Advanced Education, the WCB hired an independent consulting firm, Landry & Associates, to facilitate the consultation process that engaged some 120 stakeholder representing more than 60 organizations in the province from May 22 to June 19. Six key themes transcending stakeholder lines that have emerged from the consultations are as follows:

i) Workers, employers and the WCB have a shared duty to support frontline and emergency-response workers by building and maintaining the resilience required to sustain mental wellness and well-being. This can be achieved by acknowledging that PTSD is one of a spectrum of stress responses and conditions through which a worker passes before their condition escalates to PTSD and ensuring that workers receive treatment and support as early as possible before their conditions escalate to become PTSD.

ii) Employment as frontline or emergency-response workers will involve frequent and persistent, direct and/or indirect exposure to violent and traumatic situations;

iii) Authorized diagnosticians qualified to make an objective, accurate and thorough diagnosis should be accessible to workers;

iv) The vast majority of participants have greatest confidence in and prefer diagnoses and treatment plans provided by psychiatrists and psychologists, assuming that the WCB can arrange this within 30 days;

v) Regulators should err on the side of flexibility when determining time frames for eligibility for presumption; and vi) There are a wide range of views with respect to the principles that people feel should be applied to select the effective date for the presumption and, by extension, to what the effective date for the presumption should be.

CHARLOTTETOWN — The Workers Compensation Board (WCB) of Prince Edward Island has approved in principle a new policy on medical cannabis as a treatment option for work-related injuries or diseases and is seeking feedback on the draft policy by September 2.

“Medical evidence supporting the effectiveness of cannabis treatment is emerging,” the WCB says in a statement. The proposed policy, which is based on current research and prescribing guidelines for physicians, “will be reviewed regularly to ensure that it aligns with accepted medical practices and the growing body of medical evidence related to cannabis treatment.”

Currently, approval of medical cannabis is considered only under exceptional circumstances as set out in WCB policy, Medications (POL-120). The proposed new policy provides further explanation of the criteria for the approval of medical cannabis to facilitate the WCB’s provision of appropriate medical aid in a responsible and costeffective manner, as well as increase understanding among injured workers, employers, healthcare providers and other stakeholders.

The proposed policy also sets out specific circumstances, criteria and conditions under which medical cannabis may be approved as a treatment for work-related injuries or diseases, including the following: specific injuries, diseases and symptoms for which medi-

cal cannabis may be approved; allowable quantity, price, route and chemical composition of medical cannabis; criteria for trial approval of medical cannabis; safeguards to ensure that risks are assessed and monitored; expectations related to prescribing protocols; and conditions under which approval may be suspended or discontinued.

ST. JOHN’S — Workplace safety and compensation issues in the fishery, hospitality and fabrication industries were the subject of a discussion between Sherry Gambin-Walsh, Minister of Service NL and Minister Responsible for WorkplaceNL and Fish Food and Allied Workers (FFAW) Industrial/Retail/Offshore Council in Gander on August 6.

“The lost-time injury rate in fish processing is more than double the provincial rate,” Gambin-Walsh says. “Working together, we can find solutions to the many health and safety challenges found in fish processing plants throughout the province.”

FFAW-Unifor president Keith Sullivan says safe and healthy workplaces is a priority for its members. “Fish processing continues to lag behind other sectors when it comes to significant, long-term safety issues. We appreciate the opportunity to engage directly with Minister Gambin-Walsh and look forward to continuing to work with her and WorkplaceNL.”

Follow us on Twitter @OHSCanada

So, what’s on your mind?

Ever wonder what other oh&s types are thinking about? Find out by making our website poll at www.ohscanada.com a regular stop.

wildfires

By Jean Lian

Women in Ontario’s education sector are four to six times more likely than their male counterparts to require time off work due to physical assaults at work, according to a study by Toronto-based Institute for Work and Health (IWH) published in August.

The study drew on two population-based sources of data: one was the number of lost-time claims due to assaults accepted by Ontario’s Workplace Safety and Insurance Board between 2002 and 2015, and the other was the number of emergency-room visits due to assaults at work across all Ontario hospitals from 2004 to 2014.

“When it comes to workplace violence, our research suggests that the differing risks among men and women depend on sector and type of violence,” says Dr. Peter Smith, associate scientific director with IWH and principal investigator of the research project.

lence of a sexual nature.

“You cannot look at workplace violence without considering sex and gender differences,” Dr. Smith says. “These differences influence who is more likely to commit violence, who is more likely to work in occupations and industries where violence is highest, and the type of violence experienced.”

Deviation from the altitude restrictions has been identified as the cause for a mid-air collision between two flying-school aircraft last year.

“Our research also found that the rates of workplace violence among men and women are changing over time, with both workers’ compensation and emergency-department data suggesting that workplace violence is increasing among women overall, but remaining stable among men.”

The study also shows that men in Ontario’s health-care sector are almost twice as likely as female workers to have lost-time workers’ compensation claims due to assaults, but the yearly number of cases is declining more sharply among men than women. As a result, the gender gap in workplaceviolence risk is narrowing among healthcare workers. Outside the healthcare and education sectors, workplace-violence risks are similar for both men and women.

Although workplace-violence prevention efforts have tended to focus on healthcare workers, the risk of experiencing violence has been rising for over a decade among women in education, surpassing risk levels for both men and women in health care, Dr. Smith notes.

Findings in this study support those in a related Canadawide study, also led by Dr. Smith and published online in July. Based on Statistics Canada’s General Social Surveys focusing on victimization with a total sample of about 30,000 working respondents, the study found that women are 60 per cent more likely than men to experience some type of self-reported workplace violence. As well, women are four times more likely than men to experience workplace vio-

According to an investigation report the Transportation Safety Board (TSB) of Canada released on September 5, the fatal collision occurred over St-Bruno-de-Montarville, Quebec on March 17, 2017. A Cessna 152 (C-GPNP), operated by a licenced pilot undergoing commercial training at Cargair Ltd., was returning to St-Hubert airport in Montreal from a training flight. At the same time, another Cessna 152 (CFGOI), operated by a student pilot of Cargair Ltd., was leaving the airport for a training flight in a local training area.

The two aircraft collided around noon less than two nautical miles from the airport. One of the aircraft struck the roof of the mall and seriously injured its pilot. The C-FGOI aircraft, which fell in a parking lot, was destroyed, killing the student pilot. Both pilots were international students enrolled in flight training whose first language was neither English nor French, although both had their English-language proficiency assessed as operational, meaning they met the minimum international proficiency level acceptable for radiotelephony communication.

The investigation determined that the pilot of C-GPNP descended 100 feet below his altitude restriction of 1,600 feet while attempting to troubleshoot a radio-communication issue. For reasons unknown, the student pilot of CFGOI climbed 400 feet above his altitude restriction of 1,100 feet and collided with the other aircraft from below.

The investigation also found that the density and variety of operations conducted at St-Hubert Airport increase the complexity of air-traffic control. The varying levels of flying skills and language proficiency among student pilots of the four local flying schools add to this complexity.

The investigation found that Transport Canada’s oversight of aviation language proficiency testing (ALPT) is limited to administrative verifications. As such, it is not possible to assess whether and to what extent designated examiners administer the ALPT program in a manner that ensures validity, reliability and standardization nationally.

Following the incident, Transport Canada published a

Civil Aviation Safety alert recommending that flight-training units ensure that student pilots have been awarded an operational level of language proficiency in accordance with the language-proficiency scale set out in the personnel-licensing standards prior to their first solo flight.

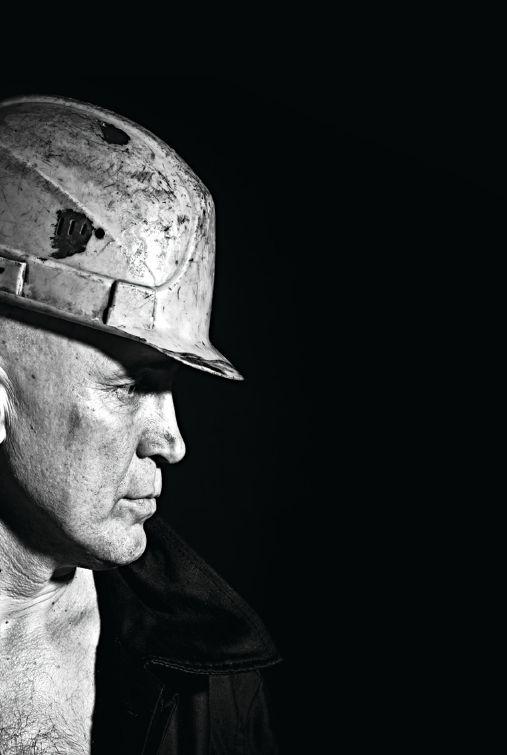

Oil and gas workers have some of the highest hearing-loss rates of any industry, according to a safety bulletin that WorkSafeBC issued on August 22.

Hearing-test data collected by British Columbia employers in the oil and gas drilling sector over five years reveal a steady rise in hearing loss among oil and gas workers in the province. Almost all oil and gas workers are exposed to hazardous noise levels, and the percentage of workers showing signs of noise-induced hearing loss (NIHL) has increased by 12 per cent from 33 per cent in 2012 to 45 per cent in 2017.

By comparison, 13 per cent of workers in all other noisy industries tested positive for NIHL in 2017. Out of the 294 oil and gas drilling workers with NIHL, 65 per cent (194) were under the age of 35.

While the percentage of workers with NIHL has increased in the drilling sector, the percentage of workers who reported wearing a hearing protection device has also risen from 94 to 98 per cent, with a heavy reliance on foam earplugs, the bulletin notes.

“There are a number of reasons why workers may be diagnosed with NIHL even though they are wearing some form of hearing protection,” says Sasha Brown, an occupational audiologist with WorkSafeBC. “The earplugs or earmuffs might be the wrong size, inserted or worn incorrectly, not worn for long enough, or they may not be providing enough protection for the duration and intensity of noise exposure.”

Employers can prevent NIHL by ensuring that at-risk workers wear sufficient hearing protection that fits and they understand how to properly wear it. Rotating workers to different positions so that they spend less time in noisy environments and identifying potential engineering controls to reduce noise-exposure risk are recommended.

At-risk workers should have their hearing tested and be informed of their hearing-test results. It is also essential that workers, who are responsible for taking part in their employer’s hearing-loss prevention program, understand how loud their working environment is and how long they are working in it. Since 2006 there have been more than 41,000 accepted claims for NIHL in British Columbia.

The Workers’ Safety and Compensation Commission (WSCC) has responded to recommendations made by the Office of the Chief Coroner of the Northwest Territories following its investigation into a workplace fatality near Inuvik, Northwest Territories on June 28, 2016. David John Vinnicombe, a 19-year-old Australian, was working for Allen Services & Contracting Ltd. when a piece of heavy equipment he was operating rolled and killed him.

The Commission released their responses to the recommendations on July 31. Among the recommendations is the call for coordination with safety partners to develop a public-education campaign to promote the Powered Mobile Equipment (PME) Code of Practice, with emphasis on ensuring proactive workplace-safety cultures and explaining how employers can implement programs to assess and document worker qualifications and competencies.

WSCC supports the recommendation that employers engage independent third-party firms to audit and review their safety programs regularly. For employers who do not have a recognized third-party audit, WSCC’s safety officers can review their programs and recommend improvements.

Additionally, a mandatory employer-safety incentive program called Safe Advantage measures the effectiveness of larger employers and rewards those with proven practices pertaining to health and safety, return to work or claims management and low claims experience costs. Employers who fall short of standards will pay penalties.

The report also calls for commissioning a study to review the efficacy of the use of both safety equipment and communication devices designed to lessen the chance of injury or death and increase the survivability of heavy-equipment operators in the event of a collision or roll over. Ideally this would include, but not be limited to, a feasibility study of built-in inclinometer gauges with audible and visual alerts and two-way radios.

According to WSCC, it has carried out research on the legislation and safe-work practices in place across Canada and determined that there are currently no jurisdictions where inclinometers gauges are required or considered standard safe-work practice.

“The current legislative requirements in the Northwest Territories are consistent with standard practice across Canada, which requires roll-over protective structures and the use of seat belts or other restraints,” the statement says. “The WSCC does not have the authority to direct the use of safety equipment other than equipment listed in legislation and does not intend to recommend revision to the legislation to add additional equipment requirements at this time.

Follow us on Twitter @OHSCanada

Jean Lian is editor of ohs canada.

BY DANNY KUCHARSKY

In 1942, science-fiction writer Isaac Asimov set out three laws of robotics, one of which says that “a robot may not injure a human being or, through inaction, allow a human being to come to harm.” Artificial intelligence (AI) and robotics have been a part of science fiction for decades, but it is now coming closer to making major inroads in workplaces across Canada.

While AI and robotics are becoming workplace realities, the jury is still out on the impact they will have on the workplace. The term AI refers to the use of artificial means to replicate human thinking and predictive abilities. Machines with AI capabilities can use data and data analysis to learn, make predictions and improve their performances over time. Robots, which were initially built to carry out simple work tasks, are increasingly using AI to think and execute complex tasks.

“There is a huge advantage of using robotics to eliminate unsafe work,” says Shalaleh Rismani, chief innovation officer at Generation R Consulting in Vancouver. But questions have to be asked: Will they make people’s jobs safer or replace them? And will people whose jobs are replaced be retrained for other work?

“It seems like a lot of companies are quite excited about analytics, and I agree that there is a lot of potential there,” Rismani suggests. “But it is unclear that companies know how it is actually going to be helping them.”

The general public might already be well-acquainted with AI, which is used in self-driving cars, but applications are increasingly seen in a number of industries as well. In construction, Triax Technologies Inc. in Norwalk, Connecticut, makes the Spot-r Clip, a wearable device that improves injury-response times through detecting falls by construction workers and sending immediate email or text notifications to supervisors, including information on who fell and where, as well as the height at which the fall occurred.

Fastbrick Robotics, an Australia-based company that develops digital construction technology solutions, has developed Hadrian X, a bricklaying robot that can complete a house in two days. And United States-based DroneDeploy provides a cloud software platform for commercial drones that can survey construction sites, eliminating the need for workers to access dangerous areas.

In the transportation sector, airlines have jumped on the bandwagon by deploying AI in chatbots that respond to common passenger questions and use facial recognition to verify identities for luggage and boarding. Air carriers are using algorithms to predict passenger behaviour and reduce overbooking by analyzing historical passenger data, weather patterns and time of the day.

The growing footprint of AI also has implications for the fleet industry. Tesla’s Semi, a fully electric semi-truck equipped with second-generation, semi-autonomous tech-

nology, is scheduled to go into production next year. The company claims the technology will boost transportation safety since human error is responsible for many of the estimated 4,000 deaths annually in truck-related collisions in the United States. Tesla says the autopilot system will help avoid collisions, but drivers will still need to be alert and be prepared to take action at any time while using it.

According to Silicon Valley company Starsky Robotics, it will be possible to put drivers behind a screen in an office instead of in the cab of the Semi. In February, Starsky completed an 11-kilometre driverless trip in Florida without having a human being in the truck.

Promising and potentially far reaching as AI and robotics can be, an incident with Tesla’s semi-autonomous vehicles is a reminder that this budding technology has some ways to go. In May 2016, a man was killed in Florida when his Tesla Model S crashed and went under the trailer of an 18-wheel trailer in Williston, Florida while the autopilot was activated. It appeared that the car’s radar, camera and sensors had misinterpreted the high ride height of the trailer as an overhead road sign. Tesla explained that the trailer’s white colour against a brightly lit sky also made it difficult to see the truck.

Commenting on the 2016 Tesla incident, Adam Jarvis, vice-president of policy and research at Global Advantage Consulting Group in Ottawa, says computers that use AI will be better than humans “at most of the things we do” and help reduce the number of workplace accidents, but will not eradicate them. “That is going to be why you want those machines,” Jarvis says.

oversees the safe installation and operation of the province’s technical systems and equipment like electrical or gas systems, new buildings and Vancouver’s SkyTrain. It is using AI to enhance the prioritization of resources by predicting with greater accuracy where high hazards can be found.

“By introducing more sophisticated machine autonomy in the risk-assessment process, we aim to find more highhazard sites while operating under the same level of resources,” says Soyean Kim, leader, research and analytics at Technical Safety B.C. in Vancouver.

The organization began using a computer algorithm a few years ago to predict where high hazards may be and has since developed new models for the algorithm, using machine-learning computer programs that input new data and use statistical analysis to think for themselves. “The result is that we have seen it adapt even more quickly to reflect emerging risks,” Kim says.

“Artificial intelligence can be used properly or improperly, and it is a very fine line.”

The incident also highlights the risk of over-relying on technology and letting human control and judgement take a back seat, Jarvis cautions. “Ultimately, the machines are not going to be perfect — at least not for a very long time.”

Global Advantage, which has expertise in ecosystem mapping, consulting and analysis, is examining the adoption rates of AI technology in Canada’s natural resources sector. “For our clients, AI has sort of become a buzzword in the last little while,” Jarvis says.

For natural resources companies, robotics can remove people entirely from hazardous situations. Robots are already taking over some of the most dangerous jobs, such as defusing bombs, while welding robots have replaced humans on automated assembly lines and along with that, their exposure to fumes, heat and noise.

“If you don’t have to send people into dangerous situations because you can send a robot, that keeps people a lot safer,” Jarvis says.

AI can also monitor employees who work in risky conditions by keeping track of their vital signs. “Rather than waiting for somebody to scream or [for] their heart to stop, you can see when a pattern is happening that looks like imminent danger,” Jarvis explains.

Technical Safety B.C. is an independent organization that

While AI does not make the work that employees do safer, it enables safety officers to better identify areas where regulated work may be done in an unsafe manner so that risky practices can be rectified before an incident occurs. For example, tests showed that the algorithm’s prediction of high-hazard electrical sites improved by 80 per cent. Machine-learning technology also reduces the number of top-priority inspections significantly, freeing up safety officers’ time that can be used to visit other sites.

Apart from occupational-safety applications, AI is also making inroads into the human mind. One tool that leverages on AI to give companies insight into the mental and physiological health of their staff is Receptiviti. The development of this software service stems from the realization that large organizations are ill equipped to understand whether the work environment is healthy.

“Oftentimes, it takes an event to happen for them to realize that things weren’t as good as they hoped,” says Jonathan Kreindler, chief executive officer of Receptiviti in Toronto.

Organizations traditionally use engagement surveys to understand their workforces’ general health and assess their employment-satisfaction level. But these tools can be fraught with bias and make it challenging for employers to get an accurate picture of their workforce’s mental well-being. “Employees are scared to speak out and to share what is going on because they fear retribution,” Kreindler says.

Instead of conducting surveys, Receptiviti uses language analytics to understand the states of mind of groups of people within a company and look for indicators that they are under pressure or stressed out. “It is kind of the next generation of human capital analytics,” Kreindler says of Receptiviti, which is used by leading banks in North America and technology firms alike. “People who are under a great deal of duress use function words very differently than people who are under less duress.”

By tapping into email systems, the platform scans

through communications flowing within the organization, looking at thousands of combinations of words to decipher patterns in different categories of function words.

“We are not looking at what people are saying. We are actually looking at the way people are saying what they are saying,” Kreindler explains, adding that the platform is built to analyze data in such a way that no human reads that content. “In that way, we are protecting the anonymity and confidentiality of all of that data.”

Receptiviti works only with organizations that have the permission of their employees to conduct this sort of analytics. “When you work in a bank, part of your employment contract states that you don’t own your computer, your email and you give up the rights to the content you are creating in those emails,” he clarifies.

By using AI for predictive modelling, it can help employers uncover broader trends, such as increasing stress levels in groups of people and comparing stress levels within departments. “This is not a Big Brother kind of monitoring of individuals. What we are doing, at an aggregate level, is trying to understand the health of the workforce.”

Organizations have the responsibility to be transparent about its code of ethics and the operating parameters surrounding the use of AI. “Any organization that is using such technology needs to figure out how they can be self-policing and using it in ways that it was intended,” Kreindler adds. Companies that develop these technologies also have the responsibility to ensure that controls are in place to prevent misuse or abuse.

“Artificial intelligence can be used properly or improperly, and it is a very fine line. If the technology is developed properly, ethically and responsibly, there can be a great deal of benefit,” Kreindler suggests.

Throughout history, ethical conundrums have always accompanied technological advancements, and AI is no exception. For Kishan Dial, partner of risk assurance services at PwC (PricewaterhouseCoopers) Canada in Toronto, the risks of introducing AI are generally not being managed as they should be in Canada. The main reason, he says, is a lack of understanding of the impact that changes — like the introduction of AI — have on people.

Risk in Review 2018, a report by PwC Canada, found that most Canadian organizations are investing in emerging technologies such as AI, but nearly half (46 per cent) of them see the lack of properly skilled teams as a barrier to the benefits of digital innovations. It will also take some time before AI and other technologies make a significant difference in workplaces.

According to the report, only 15 to 25 per cent of Canadian organizations say robotics, AI and intelligent-process automation will have an impact on their organizations within the next three years, while 67 per cent of Canadian chief executive officers indicate that changes in technology will disrupt their businesses in the next five years, compared to 84 per cent among respondents in the United States.

“Canadian organizations are risk averse when it comes to innovation, and that includes adopting things like AI and big data,” Dial says.

Canada may be leading in fundamental research on AI, but “when it comes to companies developing the technology into commercial applications, we lag [behind] other countries by a long shot,” says Jarvis, who observes that Canadian natural resource companies typically do not want to be pioneers on the blazing trail of implementing AI. “We will be the second or maybe the third, but let someone else go first.

Because when you go first, you tend to incur the most costs and most risk.”

He cites as an example the fact that Australia has been using autonomous vehicles in mining for ten years — something that Canada has yet to do. “We have the companies, we have the technology, the capacity available to us; we are just not using it.”

But Rismani, whose company explores the social and ethical challenges that AI and robotics pose to clients, says there may be good reason why Canadian companies are comparatively more conservative when it comes to adopting AI. “You don’t want your company to implement something and after that, something happens and you have a really poor reputation, or employees start quitting on you because you have changed their jobs in a way that they are not happy with.”

Jarvis is doubtful that the growing presence of AI will place workers at greater risk of harm. “There is always the odd chance that somebody makes a programming mistake and it screws up, but the point is the machine is supposed to be better than the human.”

To address the concern of malfunctioning AI as a workplace hazard, Generation R developed an AI ethics roadmap for Technical Safety B.C., highlighting issues that organizations implementing AI need to be aware of. These include the potential that algorithms could misjudge risks, or overlook the essential roles that human experience and logic play in making decisions.

“Part of the issue is a lack of full understanding of AI,” Jarvis says. “We need to exercise a certain amount of caution, but not out of fear.” He advises employers to prepare themselves for this next wave by not being afraid of it, but by hiring people who are educated about it and training employees about AI and how it can be applied at work. Adopting a flexible mindset will also work to the advantage of safety professionals and employers.

The benefits from AI will take ongoing tweaking and work, Kim says. Employers should recognize that not everyone will immediately see AI as a benefit and be aware of the need for phased-in development.

“Recent reports in the media of rogue algorithms show us that left unmonitored, machine learning can recreate and reinforce biases and cause undue harm,” Kim adds. “We see AI as a tool to augment safety officers’ expertise, logic and intuition — not as a replacement to their knowledge. When used responsibly as a tool with clear guidelines and objectives, AI should not pose any particular threats.”

For Dial, the organizations that he works with are moving into AI to reduce human error. For these firms, he recommends that they focus on the workforce of the future and invest in the right skill sets to enable the people who are going to use AI drive efficiency out of it. Organizations also need to understand the cultural changes that will be brought in as a result of adopting AI and ensure that employees are on board with this change.

“Data analytics and AI need to be part of how we do business in the future,” Dial says.

Follow us on Twitter @OHSCanada

Danny Kucharsky is a writer in Montreal.

By Glyn Jones

If you have ever travelled to a country where you do not speak the local language, you may be familiar with blank stares of incomprehension when you talk to people. It can feel the same when safety professionals communicate with people in the C-Suite of their organizations. “Safety” terminology, like “days without a lost-time injury” and “safety first”, tend to get the same blank stares as someone speaking English on the streets of Zagreb or Ankara.

Like foreign travel, it helps to speak the language of the people you meet. So what is the language of senior management executives? Money.

For safety professionals, it may seem wrong to talk in such terms, but getting the resources needed to make workplace-safety improvements is what it is all about. Many safety professionals feel under-resourced without the staff, budget or management support to make the changes they want. Many are engaged in a workplace version of the carnival game “Whack-a-Mole,” solving one issue only to find that another has popped up.

This does not leave much time for long-term planning. As a result, safety professionals focus on immediate causes of lost-time incidents, well aware that the organization is exposed to significant risks if there is a serious injury or fatality on the job.

But what they may not realize is that the organization likely already has a well-oiled machine for evaluating, tracking and dealing with risks. Those risks include changes in commodity prices that affect their raw material costs, currency risks affecting purchasing and sales in other countries and risks from flooding, fires and storms.

Risks that a company recognizes are factored into the Enterprise Risk Management (ERM) system, which is a business strategy that identifies, assesses and prepares for any dangers, risks and other potentials for disaster that may interfere with an organization’s operations, investments and earnings. Most large companies have a committee of the board that is responsible for managing the risks that fall

under that umbrella. As a result, senior leadership demands — and gets — current, hard information on the risks they deem important.

But workplace health and safety issues often do not come under enterprise risk. As a result, occupational-safety concerns are not factored into decisions and have limited access to financial support. This can be attributed primarily to the difference in language between management and oh&s professionals who are fluent in their own language, but expressions such as “lost-time incident” may go right over the heads of many senior executives who focus on areas such as finance, accounting and production.

As well, the C-Suite talks in terms of hard numbers. Safety professionals may have their own numbers — tracking injuries and lost time due to incidents — but they do not generally have a good handle on the financial costs incurred due to workplace accidents.

To cite a recent example, the health and safety director for a large municipality was well aware that the municipality was in a penalty position with the workers’ compensation board (WCB), which resulted in some significant costs. But he did not have a detailed understanding of the drivers that were pushing those costs higher.

A closer examination revealed that some factors contributing to the WCB penalty position lies in the municipality’s custodial staff, the majority of which were well over 50 and were prone to injury when executing their normal duties, such as lifting and reaching. This translated into a higher frequency of time off work and longer recovery times due to strain-related injuries.

Another contributing factor was that the municipality was paying its staff $2 per hour below market rates for custodial work. This meant that younger, fitter workers tended to stay away, and the only people available were older workers who could not compete for other higher-paid jobs. The lower rate of pay also meant that these employees needed a second job to make ends meet. As a result of them working long hours, fatigue became a factor in increasing their workplace-injury rate.

The lack of knowledge about costs associated with workplace incidents is not unique to safety professionals. In the C-Suite, WCB claims tend to be perceived as an unpredictable and unmanageable expense. But the truth is that about half of WCB costs can often be controlled, and it is becoming easier to track those costs — even in the smallest organizations — due to the increasing availability of accounting, human resources and other informationtechnology-management systems that can be configured to provide the data needed.

If there is an injury that warrants an investigation, it is possible to track the time of the workers and supervisors who were pulled off the job to help with the investigation, including the extra hours and overtime paid to keep production going during the investigation. And those costs can be significant. From this, safety professionals can determine the savings to the company if those job-injury costs were not incurred.

onstrating that there are hard, quantifiable costs to unresolved health and safety issues and showing how those costs can be managed. Not only will this give safety professionals a better chance at getting the required resources and support they need from senior management, but also opens the way for safety issues to be considered along with traditional risks that fall under ERM.

“Inclusion under the ERM umbrella is the key to having risk factors followed and acted upon.”

Armed with this information, safety professionals will be in a better position to get the attention of top management, which is inherently interested in reducing costs, and propose ideas on how to increase revenue through cost savings that will have an immediate impact on the bottom line. Being fluent in the language of the C-Suite means dem-

Currently, the aspects of ERM that are best recognized and managed by corporations include financial, operational, strategic and environmental risks. Inclusion under the ERM umbrella is the key to having risk factors followed and acted upon by the board, which asks pointed questions about how those risks are being managed, and staff are directed to provide a steady stream of data about those risks.

In other words, ERM-covered risks become part of the organization’s “dashboard” of issues that are held front and centre. Most importantly, ERM-covered risks will receive funding and support from management and other departments within the organization.

Follow us on Twitter @OHSCanada

Glyn Jones is a partner at oh&s consulting company, EHS Partnerships Ltd. in Calgary.

2018 Volunteer of the Year Announcement

Tom Welton, Director General Prevention Services, Workplace Safety North has been a CRSP since 1992 and an active volunteer with the BCRSP since 2004.

Tom has more than 30 years experience as a health and safety professional in the forestry, pulp and paper industry and has held numerous positions, originally with the Ontario Forestry Safe Workplace Association, which became Workplace Safety North in 2010. Tom is a graduate of the Lakehead University Forestry diploma program, and the Ryerson University Occupational Health and Safety Certificate Program.

In 2004, Tom joined the BCRSP Governing Board as a Governor and served a two year term. Since 2006 Tom has served as Chair of the Regional Screening Centre for the Ontario Near North region, and he also serves as the BCRSP Regional Communications Liaison (RCL) for Ontario North. He was recently appointed as the Chair of the BCRSP Communications/RCL Committee. Tom extends his volunteer time beyond BCRSP and also serves as a board member of the local YMCA, is an active member of the North Bay community and enjoys instructing downhill skiing for disabled youth.

The Board of Canadian Registered Safety Professionals (BCRSP) Volunteer of the Year program was initiated in 2001 in conjunction with its 25th anniversary and the United Nation’s “Year of the Volunteer”. The BCRSP is a public interest, ISO 17024 (Certification of Persons) accredited and ISO 9001 (Quality Management System) certified, self-regulating, self-governing federally incorporated organization established in 1976 for the purpose of certifying occupational health and safety professionals. The Canadian Registered Safety Professional (CRSP)®/Professionnel en sécurité agréé du Canada (PSAC)® certification is considered a benchmark in the OHS profession and the certification of choice for OHS professionals in Canada.

info@bcrsp.ca, www.bcrsp.ca

“R” FOR RECYCLING: Technology changes at a breakneck pace. For consumers, keeping up with technological changes often means upgrading their smartphones and buying new laptops with a higher computing power. As we look forward to new devices, what often escapes our mind is that our old gadgets end up in landfills or get recycled as electronic waste, or e-waste, which is a source of numerous toxic chemicals, metals and organic compounds that present a health risk to employees in recycling facilities.

A GROWING MOUNTAIN: Increasing digitization has boosted the amount of e-waste significantly. According to Statistics Canada, the amount of diverted electronic waste nearly tripled from just over 24,000 tons to slightly more than 71,000 tons between 2008 and 2012.

E-waste covers a gamut of electronic devices that include computers and its paraphernalia, personal items like mobile phones and cameras, household appliances such as television and lamps and office equipment that include printers and scanners. According to a study published in 2016 by Harvard T.H. Chan School of Public Health in Boston, Massachusetts, metals present in electronic devices encompass cadmium, lead, mercury and nickel, while organic chemical compounds of concern include flame retardants and polychlorinated biphenyls.

When electronics are burned, chemicals like polychlorinated dibenzop-dioxins and dibenzofurans may be generated. Disassembling, shredding and compacting e-waste also create fine dust like cadmium and berrylium which, when inhaled or swallowed, are toxic to human health, states a fact sheet on working safely with e-waste recycling from the California Department of Public Health (CDPH).

HUMAN TOLL: The growing volume of e-waste is reflected in rising worker-injury rates from recycling and waste-management workplaces. The injury rate increased by almost 13 per cent from 2010 to 2011 for industrial workers involved in these activities, according to Workplace Safety and Insurance Board in Toronto.

And the health toll stemming from these hazards is serious. Lead dust from cathode-ray tubes, batteries and older printed circuit boards can cause anemia, kidney damage and high blood pressure. Mercury vapour from switches, thermostats and fluorescent tubes can damage the nerves and the brain as well as trigger birth defects, while flameretardant dusts from plastic cases and parts are associated with thyroid hormone problems, the CDPH fact sheet notes. Exposure to chemical hazards aside, other dangers in-

clude the use of cranes and other lifting devices that could result in workers being struck by equipment or waste loads and improper material-handling practices that cause musculoskeletal disorders, Ontario’s Ministry of Labour notes.

Uneven surfaces or spills could lead to slips, trips and falls, while unguarded equipment and failure to lock out equipment for maintenance or inspection could lead to lacerations, amputations and crushing injuries.

REALITY BITES: A recent study out of the United States speaks to the hazards that e-waste workers face.

The Health Hazard Evaluation Program, which investigates possible health hazards in workplaces under the United States’ Occupational Safety and Health Act of 1970, received a request from an electronic-scrap-recycling facility. A total of five visits were made between 2012 and 2013 to examine employee exposures to workplace contaminants.

A report, published in 2014 by the United States’ Centers for Disease Control and Prevention and the National Institute for Occupational Safety and Health, indicated that employees’ blood lead levels ranged up to 13.7 micrograms per deciliter of blood. A level of 10 or higher is considered high, and two employees had blood lead levels above 10. One employee was overexposed to lead in air, while two were over-

exposed to airborne cadmium. Lead was also found on the clothing and skin of workers and on surfaces.

Workers were also overexposed to noise and engaged in work involving repetitive motion in awkward positions. On the positive side, results showed that blood and urine cadmium levels were below current occupational exposure limits (OELs), no mercury was detected in urine samples and silica concentrations in the air were well below OELs.

ON ALL FRONTS: Addressing hazards in e-waste recycling facilities requires a multi-pronged approach to occupational hygiene. The following measures listed in the CDPH fact sheet, grouped according to the type of operational hazard, can be implemented:

i) Dust: Processing e-waste create fine dust that can affect workers’ health. Depending on what is in the dust, even small amounts can be toxic. The following are some ways to control the generation of toxic dust:

• Set aside a clean eating area to prevent the inadvertent ingestion of toxic substances;

• Provide uniforms, smocks or coveralls and shoes that employees can wear during work hours;

• Make showers and changing and handwashing facilities available onsite, including separate lockers for workers to keep their street clothes and shoes away from their contaminated work clothes;

• Give workers tools to manually dissemble and remove cathode ray tubes and flat screens before shredding to minimize the release of toxic materials;

• Provide HEPA-filtered vacuums or wet mops for cleaning lead or cadmium-containing dust; and

• Measure dust levels in the air when it contains lead or cadmium. Employers must also provide local-exhaust ventilation to reduce dust at the source and provide personal protective equipment like respirators.

ii) Cuts and lacerations: Many electronic components have sharp edges or fragments that can cause injuries. Employers should provide safety eyewear, cut-resistant gloves and arm guards to workers who disassemble, sort, shred and handle glass. If a co-worker is using a hammer, mallet or grinder for disassembly, use a face shield for extra protection.

iii) Noise: Hearing loss due to noise from hammering, drilling or using power tools can be prevented. Reduce workplace noise by minimizing vibration of the work table by placing a layer of plywood or rubber matting on the table. Other measures include measuring full-shift exposures for all workers to determine who to include in a hearing-conservation program, establishing a hearing-conservation program for workers with average exposure at or above 85 decibels and providing ear protection devices or rotating workers out of noisy areas. Conducting a noise-monitoring program and hearing tests for employees are also recommended.

iv) Muscle Injuries: Electronic waste can be heavy and difficult to handle. To prevent muscle strain and injury caused by repetitive motions, adopt simple ergonomic measures, such as providing material-handling aids like dollies, hand trucks, lifters and turntables. Grip-enhancing gloves help to minimize the amount of force used by workers to grip tools and materials, while adjustable work tables and tool-suspension equipment can prevent lifting or repetitive strain injuries.

PROTECT THYSELF: Workers should practice good housekeeping by keeping their work areas clean. They should also avoid eating or smoking while handling e-waste, observe good hand hygiene before drinking or eating and as far as possible, shower at the workplace and change into clean clothes before heading home. Workers also have the right to see the results of air-monitoring tests and request their employer to test their blood lead level. A respirator must be worn each time they clean up broken cathode ray tube glass and other dusty tasks, and they should perform a seal check each time they put on a respirator.

Follow us on Twitter @OHSCanada

By Jean Lian

De-energizing machines prior to conducting maintenance work is key to ensuring worker safety, but failure to do so continues to cause injuries and fatalities in workplaces. In 2013, 17 per cent or 2,737 of all orders issued by Ontario’s Ministry of Labour inspectors were for machine guarding and lockout violations. In 2012, machine guarding and lockout was one of the top 10 most frequently issued orders by the provincial labour ministry.

Lockout/tagout keeps employees safe by making a machinery inoperable, but just shutting down or disconnecting an equipment is not enough. According to Mauriah Lamia, content and social-media manager for Accuform in Brooksville, Florida, a program consisting of energy-control procedures, employee training and periodic inspections must be in place to prevent accidental equipment start-up that could injure workers.

John Teece, senior product manager of safety with The Master Lock Company in Milwaukee, Wisconsin, agrees. “Whenever there is a source of hazardous energy — it could be an originating or residual source — there needs to be a hazardous-energy control plan.”

sonnel must be trained on locking out each piece of equipment, and their knowledge of the lockout/tagout process should be audited periodically. As for affected employees, “they don’t need to be trained to the extent of an authorized employee does, but they need to understand that a lockout is taking place and the signs of lockout,” he adds.