AIR

New evidence sheds light on decade-old fatality

THE NEW ORDER

The risks and rewards of flexible work arrangements

WHEN TRAGEDY STRIKES A company’s journey to safety excellence

ARRESTING FALLS

Scaling heights without tumbling down

“A” FOR AMMONIA Tips to protect workers from exposure

Detects H2S, CO, O2 & LEL combustible gases continuously for 36 months

No charging required... EVER

Calibration not necessary

No sensor or battery replacement

Fails

New medical evidence suggesting exposure to toxic gases is prompting a review into

BY JEAN LIAN

Digitization has given rise to flexible work arrangements. How can employers address the rewards and safety challenges associated with the remote office? BY

KELLY PUTTER

Recognizing fall hazards and using proper fall-protection equipment are key to protecting workers who scale heights to get the

BY JEAN LIAN

JEAN LIAN

Legally High

The legalization of recreational marijuana on October 17 has ushered in a new chapter in Canada where a patchwork of jurisdictional laws regulate where and how weed products will be sold and consumed.

The road to legalizing recreational weed has been fraught with controversy. Pro-pot advocates support legalization on the grounds that it will deal a blow to the black market which poses a threat to public safety, set better quality control of weed to prevent overdoses, promote the availability of medical cannabis and reduce gang-related activity stemming from the illegal drug trade. There is also the argument that legalization will normalize the use of cannabis and encourage people to be more open about it, hence facilitating enforcement.

But the concerns associated with legal weed are just as numerous: workplace risks aside, there are adverse physiological effects associated with consuming weed — not to mention the risk of addiction and cannabis as a gateway to hardcore drugs like heroine and prescription opioids.

If Colorado, which legalized marijuana in 2012, is any indication, legitimizing pot use is unlikely to make the black market go away. Colorado’s black market continues to thrive after 2012, due to higher dispensary prices and the continued smuggling of weed grown in the state into other parts of America where the drug remains illegal, according to a CBC article published in May.

For many workplaces, giving the green light to pot is akin to opening a Pandora’s box. Unlike alcohol which has a specific numeric value to measure impairment, no such indicator exists for marijuana. As well, tetrahydrocannabinol (THC) metabolizes differently than alcohol does: THC hits the peak and dissipates quickly, and the level of THC detected in the blood is typically lower than at the time of ingestion. The duration of high for marijuana also depends on the user’s metabolism and consumption method. An individual with a high metabolism will dissipate THC from his or her system more quickly than someone with a low metabolism. Ingesting marijuana produces a slower but more intense high, while inhalation delivers a quick, albeit shortlived euphoria.

Time will tell how the legalization of marijuana will affect Canadian workplaces. Legal weed could influence some companies to adopt a more aggressive stance when implementing fit-for-duty or random-testing policies that, in turn, could give rise to litigation involving disputes over whether a company has reasonable cause to conduct testing, infringed worker rights in the process of enforcing fit-for-duty policies, or inadvertently discriminated against employees who use cannabis as a medicine. In addition to the need for employers to review their fit-for-duty and substance-testing policies, training supervisors and workers to recognize and deal with impairment will also become paramount.

The pot bill is here to stay, but the law is not the only thing that regulates human behaviour. There is a moral compass within us that serves as a guiding force. For me, living with the guilt of hurting someone as a result of my choice to be recreationally impaired is a more effective deterrent than any fine or sentence the law can mete out. Because unlike a jail term that has an expiry date, the conscience is something that I have to live with for the rest of my life.

Jean Lian

Vol. 34, No. 6 NOVEMBER/DECEMBER 2018

EDITOR JEAN LIAN 416-510-5115 jlian@ohscanada.com

ART DIRECTOR MARK RYAN

ACCOUNT COORDINATOR CHERYL FISHER 416-510-5194 cfisher@annexbusinessmedia.com

CIRCULATION MANAGER JAY DOSHI 416-442-5600 EXT 5124 jdoshi@annexbusinessmedia.com

PUBLISHER PETER BOXER 416-510-5102 pboxer@ohscanada.com

GROUP PUBLISHER PAUL GROSSINGER pgrossinger@annexbusinessmedia.com

PRESIDENT & CEO MIKE FREDERICKS

EDITORIAL ADVISORY BOARD MEMBERS

DAVID IRETON, Safety Professional, Brampton, Ont.

AL JOHNSON, Vice President, Prevention Services WorkSafeBC, Richmond, B.C.

JANE LEMKE, Program Manager, OHN Certification Program, Mohawk College, Hamilton, Ont.

DON MITCHELL, Safety Consultant, Mississauga, Ont.

MICHELE PARENT, National Manager, Risk Management and Health and Wellness, Standard Life, Montreal, Que.

TERRY RYAN, Workers’ Compensation and Safety Consultant, TRC Group Inc., Mississauga, Ont.

DON SAYERS, Principal Consultant, Don Sayers & Associates, Hanwell, N.B.

DAVID SHANE, National Director, Health and Safety, Canada Post Corporation, Ottawa, Ont.

HENRY SKJERVEN, President, The Skjerven Cattle Company Ltd., Wynyard, Sask.

PETER STRAHLENDORF, Assistant Professor, School of Environmental Health,Ryerson Polytechnic University, Toronto, Ont.

JONATHAN TYSON, Association of Canadian Ergonomists/Association canadienne d’ergonomie, North Bay, Ont.

Printed in Canada

ISSN 0827-4576 (Print)

ISSN 1923-4279 (Digital)

PUBLICATION MAIL AGREEMENT #40065710

CIRCULATION

asingh@annexbusinessmedia.com

Tel: 416-510-5189

Fax: 416-510-6875 or 416-442-2191

Mail: 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

SUBSCRIPTION RATES

Published six times per year – Jan/Feb, Mar/Apr, May/Jun, Jul/Aug, Sep/Oct, Nov/Dec

Canada $98/yr plus tax

USA $98/yr

Foreign $161.50

Occasionally, OHS Canada will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Office privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2018 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

$6 million

A new safety grant launched on October 15 to help eligible agriculture employers in Alberta comply with new oh&s requirements that took effect on December 1.

Source: Alberta Government

$900,000

Grants set aside for 60 volunteer first-responder organizations in Nova Scotia to purchase safety equipment.

Source: Nova Scotia government

$325,000

Fine meted out to Toronto construction firm Coco Paving Inc. over a fatality at a road-reconstruction project in Markham.

Source: Ontario Ministry of Labour

34%

The percentage of organizations that have updated their substance-abuse policies to manage cannabis at work.

Source: Morneau Shepell

1. Turning the Tide: WorkSafeBC is raising awareness about the importance of wearing personal flotation devices in the commercial fishing industry. Its awareness efforts, announced on November 6, includes a video recounting two incidents involving commercial-fishing workers who were lost at sea.

Source: WorkSafeBC

2. New Appointment: The Workers’ Compensation Board of Alberta has appointed Grace Thostenson as the new chair of the board with effect from October 24. Thostenson has been a member of the WCB board since 2012.

Source: WCB Alberta

3. Pain in the Back: Almost 60 per cent of truck drivers experienced musculoskeletal pain and discomfort. The findings of the Ontario study, released on October 30, found an association between back pain and specific risk factors, including organizational safety climate, risk level, exhaustion, marital status and higher education levels.

Source: University of Waterloo

4. Respect Training Launched: Saskatchewan has launched workplace-respect training for government employees on October 1 to support healthy and inclusive workplaces. The provincial government partnered with Respect Group Inc. to deliver the 90-minute online training course, which will be available to employees for the next four years.

Source: Government of Saskatchewan

5. Support for Mental Health: Employees and managers will have better access to mentalhealth and wellness resources with the opening of the Office of Workplace Mental Health on October 3 by the Nova Scotia Government and General Employees Union (NSGEU) and the Public Service Commission. Three mental-health navigators will be located throughout the province.

SHOOTING RAMPAGE IN HOSPITAL

Source: Government of Nova Scotia

A police officer, a doctor and a pharmacy resident were killed on November 19 when a man involved in a domestic-violence incident went on a shooting rampage at Chicago’s Mercy Hospital. The hospital had its first active-shooter drill a few weeks prior to this incident. About 200 patients were being cared for at the time of the shooting,

Source: ABC News 360°

OH&S UPDATE

BOARD PROBES RUNWAY OVERRUN

FEDERAL — An aircraft with four crew members on board flying in to Halifax from Chicago narrowly avoided an incident when it overran a runway at Stanfield International Airport.

According to a preliminary investigation report from the Transportation Safety Board (TSB) of Canada, a Boeing 747-400 cargo aircraft operated by Sky Lease Cargo came to rest 210 metres off the end of the runway on November 7 after it struck a localizer antenna during the overrun, causing its landing gear to collapse. Crew members sustained minor injuries. It was raining at the time with a strong westerly wind gusting at 33 km/h.

The investigation team conducted an initial examination of the incident site. The flight data recorder, cockpit voice recorder, along with other systems aboard the aircraft that contain flight data have been recovered and sent to Ottawa for analysis. Investigators will conduct interviews with witnesses, air traffic control and airport personnel and review aircraft systems, aircraft-maintenance records, pilot training, qualifications and proficiency records.

Runway overruns are a TSB Watchlist issue. Since 2013, there have been an average of 9 overrun accidents and incidents every year in Canada.

UPDATED WHMIS TAKES EFFECT

WHITEHORSE — Yukon workplaces must comply with the updated Workplace Hazardous Materials Information System (WHMIS) regulations, which apply to workplaces where hazardous materials are used, by December 1.

Employers must provide workers with information on the safe use of hazardous products like solvents, bleach and paint through symbols, labels, information sheets, education and training.

The Yukon regulations were updated in 2015 to align with the revised federal regulations. The three-year transition period gave suppliers of hazardous products and employers time to put all the changes into place.

“These updated regulations are essential to preventing workplace injuries caused by hazardous materials,” Kurt Dieckmann, president and chief executive officer of Yukon Workers’ Com-

REASONS CITED FOR MAN OVERBOARD

FEDERAL — Unsuitable equipment and inadequate work procedures on a general cargo vessel led to the death of a crew member who fell overboard.

According to a Transportation Safety Board of Canada (TSB) report released on November 2, Amazoneborg was docked in the Port of Trois-Rivières, Quebec on September 29, 2017. The third officer was assigned to take the vessel’s draft measurements as part of routine cargo operations. Some time after going to read the draft marks amidships on the seaward side, the third officer was reported missing. The third officer’s body was found eight days later near Champlain, Quebec.

The investigation found that the third officer used a rope ladder to read the seaward draft marks in the middle of the vessel. The ladder, when resting flat against the vessel’s hull, left little room for hand and foot holds. The ladder was rigged to the guardrail in such a way that there was no safe way to access the ladder from the deck. Investigators

pensation Health and Safety Board in Whitehorse, says in a statement.

PROCESS SAFETY TARGETED

RICHMOND — Process safety is the focus of WorkSafeBC’s new initiative to prevent low-frequency, high-consequence events like catastrophic fires, explosions and chemical releases.

The initiative, launched early this year, focuses on sectors that include chemical manufacturing and processing, oil and gas and wood products manufacturing, according to a WorkSafeBC statement released on October 25. By identifying hazards and implementing critical controls to mitigate harm, process safety seeks to prevent the release of hazardous substances that could lead to catastrophic consequences.

The multi-disciplinary WorkSafeBC team comprises prevention officers and managers, engineers, risk analysts and human factors specialists. The team inspected at least 50 employers across the province in the first year of the initiative.

“We are looking at the types of hazards and the risks they pose that are

believe that the third officer fell while climbing over the vessel’s guardrail to use the ladder, or while using the ladder.

Although a permit was required to work overboard on the vessel, there were no instructions or procedures for taking draft measurements in the company or vessel manuals. As well, the investigation found that no one was aware of the third officer’s actions, no fall-protection system or personal flotation device was used and no one was present to initiate emergency response when the third officer went overboard.

Following the occurrence, the vessel’s operator discontinued the use of rope ladders and replaced them with embarkation ladders. The use of a fall protection system, personal flotation device and the presence of second crewmember with access to lifebuoys and a communication system are now required for working overboard. The company also explained the various methods available for taking draft measurements to its crews, the statement adds.

specific to each employer, and how they are managing and controlling those risks,” says Gordon Harkness, manager of risk-analysis unit. “We want employers to manage the risks that are created through their processes.”

In addition to process-safety inspections, two information sessions for employers were held this year in Prince George and Richmond. A third session was scheduled to take place in November in Richmond. “We see process safety as the next logical step in the journey that we’ve been working on with health and safety in the province,” says Budd Phillips, manager of prevention field services.

CAMPAIGN ON IMPAIRMENT LAUNCHED

RICHMOND — WorkSafeBC launched an awareness campaign to educate employers and workers about workplace impairment as the legalization of recreational cannabis took effect on October 17.

“Impairment in the workplace isn’t a new issue in British Columbia, but it has become top of mind as cannabis becomes legal for recreational use,” says Tom Brocklehurst, director of prevention practices and quality for WorkSafeBC. “We are reaching out to employers and workers to remind them that they share responsibility for managing impairment in the workplace.”

Under current oh&s regulations, employers must not allow an impaired worker to perform work activities that could endanger the worker or anyone else or remain at any workplace while the worker’s ability to work safely is impaired. Employers also need to make workers aware of their responsibilities, including ensuring that their ability to work safely is not impaired by alcohol, drugs, or other causes and they show up fit to work and remain so throughout the work day. The supervisor must be notified if workers’ ability to work safely is impaired for any reason.

“The legalization of recreational cannabis provides a good opportunity for employers and workers to be reminded about workplace-safety policies and practices,” says Minister of Labour Harry Bains.

WorkSafeBC advises employers to develop policies and procedures to address occupational impairment. “An impairment policy that takes a fit-to-work approach to impairment can help employers meet their workplace-safety obligations,” Brocklehurst adds.

POTASH COMPANY FINED

SASKATOON — A Saskatchewan company was fined $490,000 on October 31 after pleading guilty to one count under Occupational Health and Safety Regulations

The incident occurred at Agrium Inc.’s mine near Vanscoy on August 21, 2016. A worker was struck in the abdomen by a cable that was not secured when a conveyor belt was started, seriously injuring the worker. Agrium pleaded guilty to failing to provide and maintain a plant, system of work and

working environment to prevent injury and ensure workers’ health and safety. One additional charge was withdrawn.

FIRM PLEADS GUILTY TO FATALITY

MOOSE JAW — A company in Moose Jaw, Saskatchewan, was fined $23,800 after pleading guilty on October 3 to charges stemming from a workplace fatality on June 16, 2017. A worker had fallen from the roof of a house while taking measurements at a worksite in Moose Jaw.

Lorne Tardif, operating as Elite Eavestroughing, pleaded guilty to contravening clause 12(c) of the regulations by failing to provide information, instruction, training and supervision necessary to protect the safety of workers. Two additional charges were withdrawn.

NEW PENALTIES FOR DISTRACTED DRIVING

WINNIPEG — Manitoba drivers will have their short-term roadside licence suspended for using a cellphone or other hand-operated electronic devices while behind the wheel as changes to the Highway Traffic Act and the Drivers and Vehicles Act take effect on November 1.

Drivers will be subject to a three-day roadside licence suspension for the first time a driver is caught using a cellphone

or other hand-operated electronic device, and a seven-day suspension for a subsequent occurrence within 10 years. Suspended drivers must surrender their driver’s licence at the roadside. Officers charging a driver with careless driving will have to notify Manitoba Public Insurance (MPI) immediately to review the driver’s record and determine if further penalties may be required. MPI will also collect a $50 licence reinstatement fee.

“This legislation underscores the seriousness of distracted-driving infractions and enacts stricter penalties for this behaviour,” says Infrastructure Minister Ron Schuler.

Other distracted driving penalties that will come into force include an increase in the fine for using a hand-operated electronic device while driving from $203 to $672 and an increase in demerits for careless driving from two to five points for each infraction.

DIRECTOR FINED FOR FATALITY

TORONTO — A director in Bolton, Ontario was fined $22,000 on November 8 over the death of a worker.

Robert Markle is the sole director of JTF Davco Ltd., a Toronto-based company that fabricates screws from brass and other metal stock. On February 15, 2017, the worker was overseeing the operation of screw machines, one of which was a five-spindle automatic screw machine with an exposed stock reel composed of a bundle of five tubes into which thin 12-foot rods of brass stock were placed. The stock was inserted into the machine to fabricate threaded inserts from the stock.

The stock reel would complete a partial rotation at fixed intervals to accommodate the insertion of bars of brass stock into the machine. The stock reel was held together with two locking collars with five bolts each, the heads of which protruded from the collar. During the shift, the worker sat down on a wooden crate near the exposed stock reel with his back against the bundle. As the stock reel rotated, the exposed bolt heads of one of the collars grabbed the worker’s shirt collar, pulling it into the rotating stock reel. The worker sus-

tained fatal neck compression.

Investigation revealed that the exposed stock reel and locking collars were not protected by a guard or other device to prevent access to moving parts. Markle pleaded guilty to violating section 32(a) of the Occupational Health and Safety Act.

LACK OF GUARD SPURS PENALTY

TORONTO — A baked-goods manufacturer in Ontario was fined $60,000 on October 23 over an incident last year.

On June 13, 2017, an employee of Give and Go Prepared Foods Corporation was emptying large bags of icing sugar into a sugar-sifting machine at the company’s facility in Brampton. An auger in the machine transports the sugar to an industrial mixer, where it is mixed with other ingredients to make cake fondant. The worker accidentally made contact with the auger while reaching down into the machine to move icing sugar towards the auger, resulting in permanent injuries.

The firm pleaded guilty to failing to equip the sugar-sifting machine with a guard to prevent access to the auger.

WORKER HURT BY CULVERT

IIDERTON — An Ontario company that manufactures precast concrete products for the construction industry was fined $75,000 on October 25 over an injury.

According to Ontario’s Ministry of Labour, the incident occurred on August 2, 2017 when two employees of Coldstream Concrete Ltd. were working in a heavy precast yard, moving three-sided concrete culverts from a trailer bed onto the ground by using a gantry straddle crane and spreader beam. One worker operated the crane from the cab, while the other worker was on the ground, rigging culverts to the crane.

The crane operator moved a 23,000-kilogram culvert from the trailer and set it down on the ground. As the co-worker needed to remove a metal date plate attached to the culvert’s bottom, the crane operator raised the culvert so that the co-worker can reach un-

derneath to chisel the date plate away.

In the process of doing so, the worker heard a cracking noise and was knocked to the ground by the culvert, sustaining a permanent injury. An examination of the crane showed that a pin in the roller chain link connecting the crane’s hoist transmission drive socket to the hoist drum socket assembly had failed, causing the hoist drum to rotate freely. The part of the culvert, which had been supported by one end of the crane, fell to the ground.

Coldstream pleaded guilty to failing to ensure a machinery or material that is temporarily elevated is securely blocked to prevent it from falling or moving.

FIRM SENTENCED FOR INJURY

MISSISSAUGA — A manufacturer and packager of aerosol products in Toronto was fined $75,000 on October 18 in connection with an injury last year.

A worker who was on a work placement through Sheridan College in Oakville, Ontario was assigned to a task on a conveyor at the plant owned by K-G Spray-Pak Inc. After completing the task, the worker reached under the conveyor to cut off the ends of the tie straps used to secure hosing. In the process of retrieving the dropped pliers, the worker’s hair got caught in a rotating return shaft on the conveyor’s underside and sustained injuries.

The company pleaded guilty to failing to ensure that maintenance on a machine can be conducted only when it is not operational and any moving part has been stopped.

CONTRACTOR PLEADS GUILTY

WINDSOR — A multi-trade construction contractor in Windsor, Ontario was fined $150,000 on October 12 over a fatality two years ago.

Vollmer Inc. was installing new electrical equipment and cable for a new machinery that was being set up in a Windsor plant on November 3, 2016. A worker, along with a crew, was pulling lengths of heavy electrical cable onto the roof of the plant. The worker,

™ The heart and / Icon, “Heart&Stroke” and “Life. We don’t want you to miss it” are trademarks of the Heart and Stroke

Life’s best moments aren’t the big ones. They’re the billions of little ones. The simple ones we miss the most after they’re taken from us. And then it’s too late. That’s why we love life. And that’s why we’re doing everything possible to make sure you don’t miss it.

See how at heartandstroke.ca

who was observed in an area of the roof during a break, fell through the skylight. The worker was taken to hospital and pronounced dead, the Ontario Ministry of Labour reports.

Although the skylights had all of their covers on them, there were no guardrails, protective coverings or other means of fall protection to protect workers from falling through the skylights on the roof of the project.

AVERAGE TIME LOSS RISES

HALIFAX — Fewer injuries are happening but when they do, it is taking longer for workers to return to work. This is the findings of WCB Nova Scotia’s Report to the Community for the second quarter of 2018 released on November 9.

The length of an average claim and the number of days lost to workplace injury are both increasing. The index used to measure average claim duration increased to 121 days, up from 117 days at the end of 2017. “Too much time is being lost to injury in our province, and it is holding us back,” says Stuart MacLean, chief executive officer of WCB Nova Scotia. ““We all have a role to play in ensuring injured workers are supported as they recover and make safe and timely returns to work. The longer an injured worker stays off the job, the more complex the situation becomes.”

There were 1,343 time-loss injuries

from April to June, down slightly from the same period in 2017 when there were 1,351. Time-loss injury rate dropped to 1.73 time-loss injuries per 100 WCBcovered workers in the middle of this year, down from 1.76 at the end of 2017. But acute fatalities over the first two quarters increased over last year with nine fatalities. This year also marks a tragic year in fishing and construction.

“No one should die as a result of their work,” MacLean says. “The increase in 2018 speaks to the need for continued work by all of us to keep Nova Scotians safe on the job.”

IMPROVED ACCESS TO BENEFITS

HALIFAX — Frontline and emergencyresponse workers with post-traumatic stress disorder (PTSD) will have easier access to workers’ compensation benefits starting from October 26, as changes to the Workers’ Compensation Act introduced last year no longer requires these workers to prove that their PTSD diagnosis is work-related.

The Workers’ Compensation Board (WCB) of Nova Scotia has streamlined access to mental-health related benefits and established a dedicated team of case workers to better meet the needs of those with psychological workplace injuries, including PTSD. Over the next year, WCB will also develop an evidence-based PTSD prevention program in collaboration with first responders.

APPRENTICESHIP SYSTEM ENHANCED

HALIFAX — The Nova Scotia Apprenticeship Agency has additional tools and authority to enforce certification requirements in the compulsory certified trades after amendments to the Apprenticeship and Trades Qualification Act have been proclaimed on October 18.

The amendments, based on input from industry stakeholders, were passed by the House of Assembly in March. “It is important to ensure industry has access to the skills it needs to contribute to a vibrant economy,” Labour and Advanced Education Minister Labi Kousoulis says. “These changes will better protect the skills and safety of those who work in the skilled trades.”

“By the very nature of their jobs, some workers are exposed to traumatic and violent events, which can have a lasting impact on both their physical and mental health,” says Stuart MacLean, chief executive officer of WCB Nova Scotia. “These changes will help frontline and emergency response workers get the care and support they need quicker and more easily.”

Eligible workers include police, paid and volunteer firefighters, paramedics, nurses, correctional officers (including youth workers in a correctional facility), continuing care assistants, emergencyresponse dispatchers and sheriffs covered by the board. PTSD must be diagnosed by a psychiatrist or registered psychologist, and eligible workers who received a PTSD diagnosis on or after October 26, 2013 can refile a claim if they were denied benefits in the past.

SAFETY EDUCATION PROMOTED

FREDERICTON — WorkSafeNB has signed memorandums of understanding (MOUs) with community colleges in the province to enhance health and safety education for the future workforce.

New Brunswick Community College (NBCC) and Collège communautaire du Nouveau-Brunswick (CCNB) have resource personnel dedicated to health and safety education at their combined 11 campuses. These representatives collaborate with WorkSafeNB staff and

In addition to clarifying the Nova Scotia Apprenticeship Agency’s authority in issuing compliance or stop-work orders, the amendments also made it an offence to breach an order issued by an enforcement officer. Employers are required to assist enforcement officers in carrying out their duties, and the maximum penalties for the first and second offence have been raised from $5,000 to $10,000 and from $10,000 to $50,000 respectively.

“Strong enforcement levels the playing field for those companies who comply with the law and will ensure a safer work environment for all apprentices,” says Duncan Williams, president of Construction Association of Nova Scotia in Dartmouth.

With the changes, enforcement officers can inspect employers any time work is being performed. Recognized associations that register apprentices on behalf of employers and dispatch workers to job sites will be subject to enforcement provisions.

college instructors to help ensure that the health and safety curriculum adheres to the country’s best practices and provincial legislation.

“This collaboration will ensure quality safety curriculum and help instill a sound workplace health and safety culture in students — our future workers,” Douglas Jones, WorkSafeNB’s president and chief executive officer, says in a statement on October 4.

WorkSafeNB has longstanding relationships with CCNB and NBCC through consultation and its Back in Form program, which supports nursing students. CCNB president and chief executive officer M. Liane Roy says the partnership is critical for students entering New Brunswick’s workforce.

“Health and safety legislation continually changes with society and industry needs. Our students have to be equipped with the highest level of health and safety knowledge and understanding for their sector,” she says.

OPIOID GUIDELINES TIGHTENED

SAINT JOHN — WorkSafeNB has tightened guidelines for prescription opioids used by claimants who are recovering from occupational injuries.

According to a WorkSafeNB statement issued on November 1, highlights in the updated policy that took effect on September 29 include stricter monitoring, reducing the initial authorization period for opioid prescriptions from six weeks to two weeks and limiting opioid dosages to 50 mg morphine equivalent per day.

Dr. Paul Atkinson, WorkSafeNB’s chief medical officer, says the changes came after extensive consultation with the province’s medical community and the general public. “The new policy aligns with feedback received and with provincial and national guidelines. We will be asking physicians to follow up with their patients after their two-week opioid prescription to authorize an extension when warranted.”

Opioids are usually a short-term measure to treat pain associated with injury, disease or surgery. While opioids have therapeutic purposes, there

are risks associated with their use, such as addiction, overdose and death. “The research is clear that opioids are ineffective for chronic aches and pains and as such, should only be used when absolutely necessary,” Atkinson says.

NEW CAMPAIGN AIRED

ST. JOHN’S — A new safety campaign is being aired across media channels in Atlantic Canada to heighten awareness about the impact of workplace injury and the importance of prevention.

According to an October 9 statement from WorkplaceNL, the awareness campaign featuring advertisements on television, radio, print and social media is developed by workers’ compensation organizations in four Atlantic provinces and the Nova Scotia Department of Labour and Advanced Education.

Some 15,000 Atlantic Canadians suffer work-related, time-loss injuries every year that affect the economy, communities and their families. “This powerful campaign shows the impact that workplace injuries have on workers and families throughout our province and how quickly their lives can change,” says Honourable Sherry GambinWalsh, Minister Responsible for WorkplaceNL. “It is important that safety remains uppermost on our minds.”

Occupational injuries and time loss affect the region’s economic progress. “While we have seen significant progress over the last decade, we know that, on average, 13 workers in our province

are injured or fall ill due to their work each day,” says WorkplaceNL chief executive officer Dennis Hogan.

Threads of Life, Canada’s national organization for workplace family tragedy support, is also a partner in the campaign. “We were grateful and appreciative to have been part of the development of these ads,” says Shirley Hickman, executive director with Threads of Life.

FIRM, SUPERVISOR CHARGED

ST. JOHN’s — A construction company based in Sudbury, Ontario and a supervisor face charges over a January 2017 fatality at a Maritime Transmission Link worksite near Stephenville Crossing in Newfoundland and Labrador.

According to a statement from Service NL dated October 3, PowerTel Utilities Contractors Limited has been charged for five violations relating to the following alleged failures: provide and maintain a safe workplace; give the necessary information, instruction, supervision and facilities to ensure worker safety; ensure that workers and especially supervisors, are made aware of the hazards; safe-work procedures are followed; and work procedures promote the safe interaction of employees and their work environment.

The supervisor faces charges for failing to ensure the health and safety of workers under his supervision and to advise them of job hazards.

Follow us on Twitter @OHSCanada

So, what’s on your mind?

Ever wonder what other oh&s types are thinking about? Find out by making our website poll at www.ohscanada.com a regular stop.

Season change prompts shift to winter-driving mode

By Jean Lian

As the mercury dips and daylight gets shorter, British Columbia’s Winter Driving Safety Alliance is urging employers and workers who operate fleet or personal vehicles to prepare for winter driving since new rules requiring winter tires or chains on designated routes in the province took effect on October 1.

The province has made winter tires mandatory for passenger vehicles travelling on most highways in British Columbia. Commercial vehicles are required to carry chains, and drivers must equip their vehicles with winter tires if they plan to travel on highways in the North, the Interior, Vancouver Island and on the South Coast such as the Sea to Sky Highway. Driving without proper winter tires in good condition on designated highways can prompt a fine of $109.

sessing and addressing risks and ensuring that workers and contractors are instructed on safe driving procedures,” McCaskill advises.

Jean Lian is editor of ohs canada

Injuries drive costs in roadbuilding sector

By Andrew Snook

Managing workplace injuries was the top of the agenda at B.C. Road Builders & Heavy Construction Association’s 2018 Fall Conference, which took place from September 16 to 18 at the Grand Okanagan Resort & Conference Centre in Kelowna, British Columbia.

“Safety on the job must always be the top priority for employers and workers alike, and it can be particularly difficult when the workplace is mobile,” says Minister of Labour Harry Bains. “Be alert, be cautious and let’s all get home safely at the end of each shift,” he adds.

According to provincial regulations, an appropriate winter tire is defined as one with a mountain/snowflake symbol or M+S (mud and snow), in good condition and has a minimum tread depth of 3.5 millimetres. Drivers are encouraged to choose tires based on the region and conditions in which they drive. Tires marked with a mountain/snowflake symbol offer the best traction on snow and ice, while those marked with M+S offer better traction than summer tires, but are less effective than mountain/snowflake tires in severe winter conditions.

Each year in British Columbia, the number of casualty crashes caused by driving too fast for prevailing road conditions doubles in December, compared to October. The winter months from November to January are a particularly dangerous time for people who drive for work. Nearly 28 per cent of all work-related crashes resulting in injury and time-loss claims occur during those months, according to WorkSafeBC data from 2013 to 2017.

Darrin McCaskill, director of programs, projects and initiatives with WorkSafeBC, says hundreds of British Columbians drive tow trucks, taxis, delivery vans and buses every day. “Organizations need to prepare now before weather conditions deteriorate by winterizing their safety plans, as-

The managing workplace injuries workshop entitled, The Good, the Bad and the Ugly of Managing Workplace Injuries was presented by employer consultant and former long-time WorkSafeBC employee Cheryl Nomura who has more than 32 years of health and safety experience at WorkSafeBC. Nomura now works with employers and organizations to improve their financial health by reducing WorkSafeBC premiums through improving injury rates and claims duration.

According to Nomura who discussed the driving costs in the province’s road-building sector last year, road construction experienced the largest number of days lost due to injury with 4,501 days lost in 2017 and 129 claims filed. This is followed by highway maintenance with 4,192 days lost and 383 claims filed, and paving with 3,354 days lost and 151 claims filed.

The injury rate in highway maintenance, which is two times higher than the province’s average injury rate and continues to rise, was highlighted as a concern in the presentation. More than 50 per cent of the injuries are sprain and strain injuries, Nomura added.

She also covered the cost drivers for WorkSafeBC premiums, which is a combination of the number of claims filed, the claims costs paid by WorkSafeBC on each claim, the size of the company and its safety record as compared to other employers in the same rate group.

Injury prevention is key, but when accidents occur, both the employer and injured worker suffer losses. According to Nomura, two proven ways to help mitigate those losses are implementing sound injury-management processes and programs and proactive claims management.

The key principles of injury management include senior leadership commitment and support, clearly defined steps for dealing with workplace injuries, supportive workplace policies and climate and joint labour-management cooperation, she added.

Andrew Snook is editor of rock to road.

Safety expenditures shape oh&s outcome: study

By Jean Lian

How much an employer spends on health and safety is a prominent factor in reducing work injuries and illnesses, suggests a new study published in September by Toronto’s Institute of Work and Health (IWH) .

According to the study that surveyed 370 Ontario organizations comprising employers with 20 or more employees from 17 economic sectors, employer expenditures on protecting worker health and safety are substantial in many sectors. In 2017, the average estimated oh&s expenditure per worker each year among 334 Ontario employers was $1,303.

Among the 17 sectors, mining tops the list with an estimated annual safety expenditure per worker of $4,433, which is eight times higher than the average expenditure in the arts, entertainment and recreation sector. Expenditures in the goods-producing sectors involving hazardous work were three times higher at $2,417, compared to the service sectors at $847.

The proportion of estimated expenditure allocated to each of the five workplace-safety dimensions was generally consistent across sectors: 58 per cent to organizational management and supervision ($765 per worker per year); 22 per cent to staff training in health and safety ($297 per worker per year); 14 per cent to personal protective equipment ($184 per worker per year); two per cent to professional services ($25 per worker per); and four per cent ($52 per worker per year ) to new capital investment.

The findings of the IWH study are broadly similar to estimates provided by a recent study by the International Social Security Association headquartered in Geneva, Switzerland, which estimated an annual expenditure per employee per year of more than CAD$1,800 among a sample of predominantly European employers.

In Ontario, the incidence of work-related injury and illness over the past two decades has declined substantially. According to a 2015 paper, Divergent Trends in Work-Related and Non-Work-Related Injury in Ontario, the incidence of treatment for occupational injury at emergency departments declined by more than 30 per cent during an eight-year period from 2004 to 2011. The percentage of all injuries attributed to work exposures among working-age adults has decreased from 20 per cent in 2004 to 15.2 per cent in 2011.

Contributing factors to this significant reduction in

injury and illness due to occupational exposures include growth in service-sector employment relative to employment in the goods-producing sectors, the substitution of technology for human labour and strengthened regulatory standards pertaining to worker-health protection.

“Accurate information on employer expenditures and investments in oh&s can help stakeholders understand the progress made over recent decades in the protection of worker health. It can also provide sector benchmarks for employers and inform public policy aimed at influencing employer investments in oh&s,” the IWH study concludes.

Child fatality in factory prompts penalty

By Jean Lian

An Ontario company was fined $150,000 on November 13 in connection with an incident involving the death of a child in a factory last year.

The incident took place in Linwood, Ontario on July 6, 2017 when a supervisor employed by J.M. Lahman Manufacturing Inc. was at the facility, accompanied by two children. One of the children was roaming through the aisles of the facility unaccompanied. The supervisor used a crane to place three bundles of steel tubing, which had been left over from the day’s work, on top of a stack of similar bundles. Each bundle of tubing weighed approximately 2,140 pounds, and the total weight of the stack was estimated to be 15 tons.

In the process of moving the bundles of steel tubing, the stack of bundles dropped onto the child who had been moving about, killing the kid killed instantly. The other child, who was far enough away, was unscathed.

A Ministry of Labour engineer determined that the use of softwood spacers between the bundles and the use of insufficient numbers of bands to hold the tubes together contributed to the collapse. The investigation noted that other factors might also have contributed to the incident.

In a court in Kitchener, Ontario, Justice of the Peace Michael A. Cuthbertson meted out a $100,000 fine to the company for permitting a person under the age of 15 to be in a factory. The Occupational Health and Safety Act defines the factory as a workplace, while section 4(1)(b) of the Industrial Establishments Regulation (Regulation 851) prohibits the presence of persons under the age of 15 in a factory unless accompanied by an adult.

The company also received an additional $50,000 for failing to ensure that bundles of steel tubing were placed or stored in a manner such that they could not tip, collapse or fall as required under section 45(b) of the regulation, and a 25-per-cent victim fine surcharge.

Follow us on Twitter @OHSCanada

THE SEARCH FOR ANSWERS

Ten years after boilermaker David Fifi was determined to have died of natural causes, the Workers’ Compensation Board (WCB) of Manitoba is reviewing the case following the emergence of new medical evidence indicating that his sudden demise was caused by exposure to toxic gases.

By Jean Lian

For Lila Fifi, the review of her late husband’s case was a glimmer of light at the end of a tunnel. David Fifi was working on the electrostatic precipitator (ESP) project at Vale Inco mine in Thompson, Manitoba when he died of heart attack on November 6, 2008. On that day, Fifi had called his wife Lila, who was living in Winnipeg, complaining about difficulty breathing. “He was sick all night, he could hardly talk. He was gasping for air,” Lila recalled.

Fifi, who was in respiratory distress, called for an ambulance and was sent to Thompson General Hospital where he passed away. An autopsy report by the Office of the Chief Medical Examiner attributed Fifi’s death to natural causes by myocardial infarction due to coronary artery thrombosis. As a result of this determination, WCB Manitoba turned down Lila’s compensation claim on behalf of her deceased husband in April 2010. Manitoba Labour and Immigration’s Workplace Safety and Health (WSH) also ceased its investigation, according to a letter by Manitoba Family Services and Labour dated January 30, 2013.

Lila did not believe that her husband, who did not have a history of heart difficulties and was in good health prior to his passing, had died of natural causes. Her belief was partly guided by the fact that 49-year-old Brian Dupas, Fifi’s coworker at the same smelter, also died of a heart attack about two months earlier on September 15, 2008.

An email dated December 1, 2008 from the director of the Office of the Chief Medical Examiner in Winnipeg indicated that Dupas died of myocardial infarction. No toxicology was done as there was nothing to suggest that his death was a direct result of workplace exposure. “This unfortunately looks like two coincidental deaths due to heart disease,” the email noted.

There were also frequent gas-out incidents at the smelter where Fifi worked. According to the minutes of a meeting held on the day Fifi died, there were two gassing incidents on the previous day and that approximately half of the employees had reported feeling unwell. Since February 2008, there had been 40 major and approximately 100 minor gasout incidents. “The protocol is to leave the area when their monitors alarm” go off, the minutes of meeting stated.

“Alarms were going off all day,” Lila said, describing how the workers would run to seek shelter from gases in safe rooms when the alarms were activated. “Sometimes, there were not enough room in the safe rooms; sometimes the safe rooms were not sealed properly. You wait, and then you go back to work. Some workers could not get away, and the plumes of gas would overcome them.”

Another red flag that her husband could have been exposed to toxic substances at work were the daily conversations she and her daughter had with Fifi, who would ask his daughter to look up on the Internet about what happens when Teflon is burned. According to Lila, Fifi had mentioned in those phone conversations that Teflon rods, chairs and garbage were dumped in the furnace daily.

“Everyone is getting sick,” Lila said. “Men were vomiting in their masks when plumes of gas overcame them. The stacks were to be extended and not done, so they [gases] were getting down, drafting from them.”

RICK’S STORY

Rick Ranson started work as a welder and boilermaker at the open pit mine in Thompson on March 1, 2008, sorting and welding steel plates. According to Ranson’s timeline of his tenure at the mine that he furnished on November 26, 2008, many gas-out incidents occurred throughout the months, including one that occurred on May 16, 2008 when the sulphur dioxide (SO2) monitor registered 20 parts per million (ppm).

Standards from the American Conference of Governmental Industrial Hygienists set a threshold limit value of 2 ppm over an eight-hour period and 5 ppm for a 15-minute short-term exposure limit. Sulfur dioxide is a highly toxic, colourless, non-flammable gas or liquid with a suffocating

odour. At high concentrations, SO2 can cause pulmonary edema or lifethreatening accumulation of fluid in the lungs. Symptoms include coughing, difficult breathing and tightness in the chest, according to information from the Canadian Centre for Occupational Health and Safety in Hamilton, Ontario.

On November 20, 2008, Ranson received a note from his doctor indicating his blood pressure was in the stratosphere and that he was not fit to return to work. “I got sick,” Ranson said. He believed that one or a combination of gases caused his blood pressure to spike, “but because of the number of heavy metals given off by the smelter, finding the gas causing it is a lottery at best.” The next morning, Ranson tendered his resignation.

UNANSWERED QUESTIONS

Lila’s search for answers has proven to be a decade-long journey — and counting. The turning point came when Dr. Peter Markesteyn, forensic pathologist and former chief medical examiner for the University of Manitoba, penned a letter to Jon Gerrard, MLA for River Heights, Manitoba on July 20, 2018, stating that Fifi died as a result of pulmonary edema due to exposure to toxic gases and that while myocardial infarction was a significant factor, it was not causally related to his death. “In other words, Mr. David Fifi died with myocardial infarction, not because of it,” and his manner of death was “accidental.”

Dr. Markesteyn added that the original autopsy’s conclusion was made “without the pathologist being aware at the time of the autopsy of the distinct possibility, if not probability, that exposure to toxic gases had occurred.” As the pathologist’s opinion that Fifi had died of natural causes was reached without the benefits of any clinical history and toxicology, “the officers of WPSH [Workplace Safety and Health of Manitoba] relied on that information and concluded that, as it was a ‘natural death’, no further action (on their part) was required.”

trocardiography done on the day of Fifi’s death showed an acute ST-elevation inferior wall myocardial infarction, or heart attack. “In light of the information documented above, the forensic pathologist advised that he would not have concluded that the primary cause of death was pulmonary edema due to exposure to toxic gases,” the memo stated.

According to a Government of Manitoba spokesperson, WSH was notified that Fifi, a welder employed by Comstock Ltd., sustained a medical emergency in his home and died at Thompson General Hospital. On the same day, WSH also received a tip that workers on the smelter’s roof were feeling ill and that work had stopped.

“As part of this tip, WSH was made aware of the death of another ironworker approximately two months prior,” the spokesperson said in reference to Dupas. “Although the ironworker had worked at the smelter, the death did not occur at the workplace; therefore, [it] was not required to be reported to WSH.”

After receiving the above information, WSH initiated an inspection and preliminary investigation immediately, focusing on work conditions and occupational exposures in areas at the smelter where workers who reported feeling ill were working. As well, WSH collected information on the hazards and substances that workers may be exposed to, including the control measures in place to address the hazards.

“He was sick all night, he could hardly talk. He was gasping for air.”

A memo dated August 17, 2018 by Dr. Teresa Pun, internal medicine consultant with Manitoba WCB, seems to confirm Dr. Markesteyn’s observation. Dr. Pun spoke with the forensic pathologist who conducted Fifi’s autopsy after WCB Manitoba received Dr. Markesteyn’s letter in July. According to the memo, the forensic pathologist advised that he was unaware of Fifi’s probable exposure to toxic gases and that he had been documented to have had clear lung sounds bilaterally, which “is not concordant with a diagnosis of pulmonary edema as a presenting symptom.”

As well, the pathologist said he did not know that an elec-

“It was determined that Mr. Fifi had not been working in an area with a potential for high exposures on the day of his death, nor on the day preceding his death,” the provincial spokesperson reported. The Chief Medical Examiner’s determination that Fifi died from natural causes was communicated to WSH’s then Chief Occupational Medical Officer, who concurred with the decision. As a result of the attending officer’s preliminary findings, consultation with the then Director of Occupational Hygiene and the medical determination, WSH found no evidence that occupational exposures were a causal factor in Fifi’s death and discontinued its investigation.

The spokesperson added that since 2008, three Chief Occupational Medical Officers have reviewed the information that WSH has on file with respect to this incident, and all concurred with the Chief Medical Examiner’s initial determination that Fifi died of natural causes. “The Statute of Limitations under the Manitoba Workplace Safety and Health Act is two years; therefore, WSH would not re-open the investigation,” the spokesperson said.

WORRYING SIGNS

It has been a decade since Fifi passed, but the statements from his co-workers painted a vivid picture of work conditions then. Manitoba’s WSH division interviewed Fifi’s coworkers on the day after he died, and their statements confirmed that gas-out incidents were common occurrences.

Boilermaker foreman Sean McElmoyle, who died in July 2013, said Fifi was on his crew the week prior to his death. “We got high gas at least three times a day for at least six days. All members of the crew, including myself, are ill right now.”

Boilermaker James Keck who had worked with Fifi on November 5, 2008, noticed black smoke on the roof. A few days later, Keck was admitted to Thompson General Hospital. “I was vomiting after work, I had a problem standing up, felt hot and a tingling in my hands,” Keck said.

Boilermaker Doug Bell, who was working in the 204 duct line with Fifi, reported that they were constantly gassed from at least four different stacks, but he could not confirm if there were high readings of gas on the roof.

“We don’t always have gas monitors. There must have been because you could taste it and smell it through the respirator, and it was making my eyes water,” Bell said in the statement, adding that the casing of the flue line had rotted and gases were leaking out from the holes.

That was also the week that Fifi, along with Bell and several co-workers, started feeling sick. “We have been trying to tell these guys this since we started here that something needs to be done about the gas and dust from the stacks and flue line. It’s pretty sad that someone had to die before they will look at the problem,” Bell added.

sub-contracting arrangement involving multi-parties like Worley Parsons and Comstock contributed to diluting accountability for workplace safety that eventually led to David’s death,” Krudzo said.

In an email sent on May 22, 2009 to Mines Safety Branch of Manitoba Labour and Immigration regarding Lila’s FIPPA request that Vale Inco release certain documentation, a representative from Vale Inco Limited’s Manitoba operations explained this subcontracting structure: Vale Inco hired a third party, Worley Parsons, to manage the engineering, procurement and construction of the ESP project, and the construction company that executes most of the project’s construction work is Comstock. Fifi was a direct employee of Comstock, which was managed by Worley Parsons.

“We informed the service providers of the gases typical of a smelting operation. Procedures and practices were developed to protect the work crews. Each work crew was assigned a gas monitor, which was managed by Comstock,” the Vale representative stated in the email.

Lila’s search for answer has proven to be a decade-long journey.

Workplace conditions in the Thompson refinery just months before Fifi’s death also raised questions about the smelter’s safety record. According to a WSH report obtained through the Freedom of Information and Protection of Privacy Act (FIPPA), former mines inspector Dennis Fontaine emailed the refinery to relate his concerns regarding two incidents involving sulphuric-acid spills on August 18 and 21, 2006.

“We consider any sulphuric acid spills as very serious,” Fontaine wrote in the email. “We are also concerned with the number of overall injuries in the refinery. For 2006, there have been 193 injuries, 88 medicals and eight disabling. What does the refinery plan to do to reduce injuries?”

Fontaine’s incident investigation report into Fifi’s death also noted that employees working on the ESP project expressed numerous concerns, including what gases were coming out of the ventilators, could these gases trigger a heart attack, why workers were not given a lung functional test prior to starting work and the lack of plant maintenance relating to leaking gases and hot dust.

The lack of repairs and deficiencies in the design and structure of the operations built by Worley Parsons was also cited by Darlene Krudzo, an Ontario-based independent investigative consultant on occupational injuries. Krudzo has been working on Fifi’s case since 2011. “I do believe that the

Aside from the EPS project’s complex hierarchy of subcontracting arrangements, concerns over a conflict of interest with Worley Parson’s superintendent acting as safety personnel was also voiced by workers in Fontaine’s investigation report. “Worley Parsons, who designed the facility at Vale Inco and hired the subcontractors, were in charge of health and safety,” Krudzo said. “Comstock, for example, would be reluctant to blow the whistle on Worley Parsons, because Comstock is receiving contracts from Worley Parsons and Vale Inco.” Months before Fifi’s death, Vale Inco commissioned Pinchin Environmental Ltd. to conduct an industrial-hygiene testing within the smelter near roaster #2, in response to concerns raised by Comstock and Worley Parsons after one of the workers reported high levels of carbon monoxide (CO) at 400 ppm and SO2 at below 200 ppm from a four-gas monitor. From May 30 to June 8, 2008, monitors were set up in five locations at the smelter to collect measurements of SO2, CO, oxygen and the aggregate Lower Explosive Limit, or the lowest concentration of a gas or vapour capable of producing a flash of fire in the presence of an ignition source. Measurements were collected every 60 seconds over approximately 24 hours.

Results revealed that SO2 levels exceeding 100 ppm — considered immediately dangerous to life and health — were measured in three locations on several occasions. Elevated concentrations of SO2 measured over the sampling period appeared to be consistent with the use of roaster #2: levels were high for the first few days when the roaster was in use, remained low when the roaster was not in operation and increased when the roaster had been repaired on June 6, 2008.

“The risk of encountering concentrations in excess of 20 ppm appears to be high in all locations near any of the roasters,” the Pinchin report concluded. It recommended the use of full-face air-purifying respirators equipped with appropriate gas or vapour cartridges as the “minimum requirement” for all workers.

THE TURNING POINT

The second opinion by Dr. Markesteyn that Fifi’s death was accidental and caused by exposure to toxic gases prompted MLA Jon Gerrard’s letter to Manitoba’s WCB on July 23, requesting the board to “review the compensation claim made by Lila with respect to David Fifi, taking into account this new information.”

Dougald Lamont, MLA for St. Boniface also wrote to Cliff Cullen, Manitoba’s Minister of Justice and Attorney General, calling for a public inquiry into Fifi’s death to answer questions that include why Fifi’s death was classified as “natural” despite evidence to the contrary, how he and other employees were exposed to such unsafe working conditions, what processes broke down that resulted in information being withheld for eight years and who knew about the situation and dangerous conditions and failed to act.

“For many years, Mr. Fifi’s family and friends have been trying to get answers about why his death was classified as being from natural causes when there was no question that he and others were exposed to toxic gases in his workplace,” Lamont wrote.

Citing statistics that show Manitoba has one of the highest rates of time-loss injuries among all provinces in the last two decades, Lamont argued that a public inquiry would provide insight into conditions in the mine where Fifi had worked and “understand why, even with substantive rules

and regulations in place, there has been a failure to adequately achieve the goals we seek in terms of safer workplaces in Manitoba.”

According to a WCB Manitoba memo dated August 10, the board has received Dr. Markesteyn’s pathology report and has submitted Fifi’s claim to a WCB medical advisor for review. Darlene Muise, manager of communications with Manitoba WCB and SAFE Work Manitoba, said the WCB could not comment further on claim matters due to privacy reasons. Vale Inco did not respond to request for comment.

“Mrs. Fifi will continue to push for a public inquiry into her husband’s death and for others,” Krudzo said. “Recommendations would have to be handed down to change this system of connections and relationships which do not promote and secure the rights of workers.”

For Lila, Dr. Markesteyn’s report could well mark the beginning of the second phase of her quest for answers. “The biggest thing that is very disturbing is that these poisonings took place affected many workers who were working to provide for their families. It would be grossly criminal to allow such horrific experience of exposures and injuries without having parties held accountable,” Lila said. “I am determined to make sure this comes to light. My worker never returned home safely.” Follow us on Twitter @OHSCanada

Jean Lian is editor of ohs canada

THE NEW ORDER

By Kelly Putter

Flexible work is transforming the way Canadians work. From working from home and staggered hours to conducting meetings through teleconferences, employees today are in a better position to juggle work demands and personal commitments than their office-bound, nine-to-five counterparts three decades ago.

According to a 2018 survey by the Conference Board of Canada, more than 85 per cent of Canadian organizations offer flexible working options. The most common form of flexible work involves working for a stipulated number of hours that do not fall between 9 a.m. and 5 p.m. A whopping 93 per cent of the organizations that offer flexible work arrangements come under this category.

The second most common option is part-time remote work in which an employee works from home on certain days of a week or as needed. This is offered by 55 per cent of the organizations with flexible work arrangements. Other less popular options include job sharing, compressed work weeks and phased-in retirement.

“Employees value flexibility when it comes to when and where they work for a variety of reasons, and the demand for flexible work arrangements is likely to increase as the Canadian population ages,” says Allison Cowan, director of total rewards, human resources and labour relations research with the Conference Board of Canada. “Employers have an opportunity to support their employees in balancing their work and family responsibilities. Flexible work arrangements are a creative way to do this, and they may find their employees to be thankful, engaged and more productive as a result.”

But this flexibility can also give rise to health and safety issues, Cowan cautions. While the Conference Board survey did not specifically address oh&s issues in flex-work settings, it did point to a considerable lack of training for both employers and employees in this aspect: results show that 86 per cent of employees and 74 per cent of managers received

no formal training on flexible work arrangements.

“Employers need to make sure the right supports are in place for their employees and communicate effectively about expectations and the importance of working in a safe and healthy work environment,” Cowan stresses, citing the importance of a well-defined, flexible-work policy.

THE CHANGING FACE OF WORKPLACES

Flexible work arrangements are clearly changing the face of workplaces in Canada. It is also influencing who employers hire and how they gauge workplace efficiencies, according to Meredith Thatcher, a workplace consultant based in Ottawa. Hiring workers who are homebound due to a disability or life circumstance is a positive development as it widens the talent pool for employers, Thatcher suggests.

An ingrained conventional philosophy that optics, or an employee’s physical presence in the office is a measure of productivity, has been turned on its head owing in part to flex–work options. “It forces organizations to reconsider: do we manage by presence or do we manage by outcome?” Thatcher questions. Managing a workforce by outcomes means that managers need to plan concrete work initiatives to measure performance.

“We are at a tipping point with remote work in this country,” Thatcher says. “In 2016, the federal government did consultations on flexible work, and they themselves are already implementing a flexible work environment. We can expect to see legislation on it in the near future. Offering flexible work options is all about winning the talent war.”

The Occupational Health and Safety Act of Ontario defines a workplace as any “land, premises, location or thing at, upon, in or near which a worker works.” A flexible work arrangement falls under this definition, says Sault Ste. Marie, Ontario-based Shannan Boston, a health and safety consultant for Workplace Safety and Prevention Services (WSPS).

Since control over oh&s is reduced significantly when an employee does not work in an employer-operated site, the employer needs to shift its focus to that of prevention by

considering the following: the set up of an ergonomically friendly workstation; the availability and suitability of equipment for the job; physical conditions that include lighting, walkways and points of access and egress; and emergencyresponse measures such as a fire-safety plan and equipment.

Setting an example of managing workplace safety in flexible work arrangements is the WSPS, one of four health and safety associations in Ontario with about 250 employees, half of which work from home-based offices. The organization ensures due diligence through a home office set-up program in which office furniture and chairs are delivered to the homes of workers, followed by inspections to ensure that the furnishings are set up correctly and ergonomically, explains Kristina Dragun, a health, safety and wellness program lead with WSPS in Mississauga, Ontario.

The organization inspects employees’ home offices or remote work sites annually — only with their permission due to privacy issues — through virtual video calls like Google, Hangouts or Skype. Factors that an inspection looks at include whether the home office complies with the Fire Code, the presence of functioning smoke detectors and a safe means of egress in the event of an emergency, she adds.

PROVING CAUSALITY

One of the biggest challenges around workers’ compensation claims filed by remote workers is proving that the complaint is work related. Dragun cites claims with opposing outcomes to demonstrate how seemingly similar claims can have divergent results. One case relates to a WSPS worker who cut his hand on broken glass while fetching a glass of water in his kitchen. His claim was denied, because the worker was in the kitchen and not in his office at the time of the mishap. Another worker was preparing for a work-related trip and had to make her way into a crawl space in order to retrieve her luggage, hitting her head as a result. Her claim was approved as her preparation for a work trip was deemed work-related.

ing steps: assess the scene for safety; provide care for the injured; manage the scene; notify key players like the employer and family members; investigate to reveal all immediate and root causes; recommend changes to controls; report findings and action plan to all concerned parties; implement an action plan; and evaluate the effectiveness of change.

THE SOCIAL DIMENSION

Injuries may be top of mind when assessing claims, but psychological threats and violence risks are becoming increasingly common. For remote workers, loneliness and the lack of human connection can also take a mental toll.

Boston works in a WSPS office in Sault Ste. Marie where she is three-and-a-half hours away from her nearest colleague. Boston and her northern colleagues Skype regularly and perform weekly or bi-weekly check-ins. The team and its manager engage in teleconferencing, and when they do meet in person, business is always followed by a social event. The WSPS also offers a two-day, mental-health first-aid program to help workers recognize the signs of anxiety, depression or post-traumatic stress disorder. “People think it must be nice to work from home,” Boston says. “It is very lonely. When employers are considering flex-work arrangements, they need to take into account the mental-health aspect.”

“Offering flexible work options is all about winning the talent war.”

Working in isolation also presents a challenge when it comes to injury and illness, says Keith Fiering, a health and safety coordinator for CUPE Local 79 with the City of Toronto. An employee could suffer a seizure or heart attack while on the job. Workplace violence is another risk. “In the end, the need to be satisfied would be the ability to summon assistance. The same holds true for violence,” Fiering adds.

Filing a work-related claim in an employer-operated workplace is quite different from doing so while working remotely, suggests Wes Mazur of Grand River Occupational Health and Safety Inc., a consulting firm in Cambridge, Ontario. For a start, the odds of having a witness to substantiate a claim that arose when an employee was working at home is greatly reduced, as there is a good chance that the employee was alone at the time of the incident. Employers typically do not have access to an employee’s home to substantiate or dispute the claim, which complicates the process of conducting a meaningful investigation. “Due diligence is really hard to prove any time,” Mazur says. Doing so in a home office exacerbates the challenge, he adds.

Another issue centres on return to work and accommodation. “As an employer, how can I possibly make accommodation or make modified work arrangements if I don’t know if they have stairs or no stairs?” Mazur questions.

That said, there are proper ways to address an injury at a remote workplace, says Boston who outlines the follow-

Another vulnerability associated with flexible work arrangements is a cyber attack. Home-based Wi-Fi networks may not be secure, and not all employers provide encrypted computers or laptops. “You could be working on a computer that is not locked down at all,” Mazur warns. “Even with strong company policies, remote workers tend to save their work to their desktop rather than on the company’s secure network, which leaves files at risk of theft, fire, viruses and possibly, even hacking.”

Ways to mitigate this risk include connecting remote workers’ computers to a virtual private network server. This will give an employee’s computer at an off-site location the same level of security as that in an onsite workplace. Adequate anti-virus and other software to protect against cyber risk should also be installed. Administrative controls like developing information-technology policies, establishing a means to report an issue immediately and reviewing these procedures with staff are also key. “Employers should set clear policies and procedures to specifically address what responsibilities workers have for ensuring their home or remote workplace is safe,” Mazur says.

Follow us on Twitter @OHSCanada

Kelly Putter is a writer in Beamsville, Ontario.

The Silent Killer

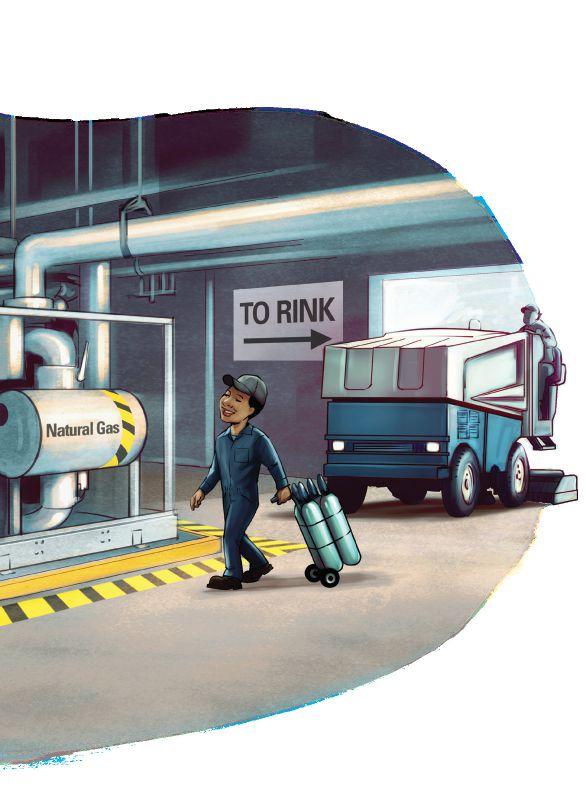

THREE TOO MANY: An investigation report that WorkSafeBC released on August 29 identified the causes behind the catastrophic release of ammonia at Fernie Memorial Arena in British Columbia on October 17, 2017, which killed three workers. The report found that a pinhole in the refrigeration-system component had compromised the refrigeration equipment, allowing the intermixing of brine and ammonia. When the compromised refrigeration equipment was put into service, it failed and exposed the workers who were performing maintenance on ice-making equipment to a lethal concentration of ammonia.

Other contributing factors include a lack of incident-response measures and the failure of oh&s systems to mitigate risks. The report also noted that the curling-rink chiller was past its life expectancy, having been in operation for about 30 years, while the industry norm for this design of chiller ranges from 20 to 25 years.

“A” FOR AMMONIA: Exposure to ammonia gas is a real occupational hazard that cuts across industries. According to WorkSafeBC, ammonia gas is most commonly found in farms (from compost piles, manure pits and any indoor or confined spaces where farm animals are kept), refrigeration systems (such as ice rinks and ice-manufacturing plants that use liquid ammonia) and fertilizers and cleaners (where liquid ammonia is diluted and combined with other chemicals).

The level of danger depends on the concentration of the gas inhaled and the duration of exposure. In low concentration, exposure symptoms include irritation to the eyes, nose and respiratory system and chemical and freezing burns on the skin. In high concentrations, just a few mere breaths can prove fatal. Ammonia’s distinct and pungent smell makes it easy to detect, although repeated exposure reduces one’s ability to smell the gas.

SAFE, NOT SORRY: Liquid ammonia is commonly used in mechanical refrigeration systems. Proper maintenance to prevent leaks or failures in these systems is critical, since liquid ammonia turns into a gas when released into the ambient air. In view of ammonia’s potentially deadly effects, ServiceNL in Newfoundland and Labrador developed a safety bulletin outlining the following preventive measures that owners and operators of indoor skating rinks can take:

• Conduct regular maintenance:

All facilities should have a preventive maintenance program in place that is based on the manufacturers’ recommendations for all refrigeration equipment in use. This

program will ensure the proper documentation of regular system maintenance, which should include compressors, pumps, evaporators, condensers, control valves, electrical equipment, ammonia-detection systems and emergencyresponse equipment.

• Install a ventilation and detection system:

All facilities utilizing an ammonia refrigeration system should have an ammonia-detection system installed in the engine room to detect an ammonia leak and trigger an independent ventilation system and alarm.

• Establish an emergency-response plan:

All facilities that use an ammonia refrigeration system should establish an emergency-response plan that include the provision for emergency repairs, evacuation procedures, location of safety showers and eyewash stations, phone numbers for the local fire department and hospital and any other pertinent information that may be required in the event of an ammonia leak.

STORAGE AND HANDLING: Adhere to proper handling and storage practices when working with ammonia and as far as possible, avoid working alone with ammonia. Do not

use ammonia near welding operations or other high energy sources. Use a suitable hand truck to move cylinders without dragging, rolling, sliding or dropping, and keep containers tightly closed when not in use or empty. Ammonia should be stored in a cool, dry area and out of direct sunlight. Keep ammonia cylinders separate from incompatible materials and always secure cylinders in an upright position to a wall, rack or other solid structure.

WHAT IF: Prevention is key, but if exposure to ammonia has already occurred, knowing how to respond in a prompt and informed manner can make a difference. In the event of an accidental release of ammonia gas, evacuate the area immediately, advises the Canadian Centre for Occupational Health and Safety (CCOHS) in Hamilton, Ontario. Isolate the site of exposure, use personal protective equipment as required, eliminate ignition sources and increase ventilation to the area, or move the leaking container to a well-ventilated secured area.

To contain and clean up an ammonia leak, knock down the gas with fog or fine water spray, but do not direct water at the source of the release. If possible, turn the leaking

container so that ammonia gas escapes rather than liquefied gas. Dike the spilled product to prevent runoff. The CCOHS also recommends the following first-aid measures, depending on the type of exposure: