BLACK HAT HACKER

The dark side of connectivity

DUST EXPLOSIONS

Avoiding combustible dust mistakes

SAFETY IN NUMBERS

Cross-jurisdictional data highlights underreporting

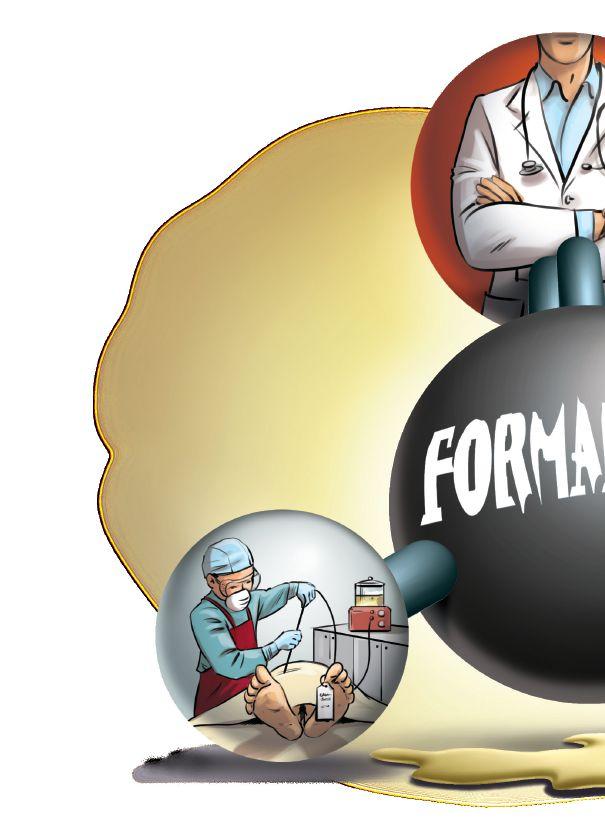

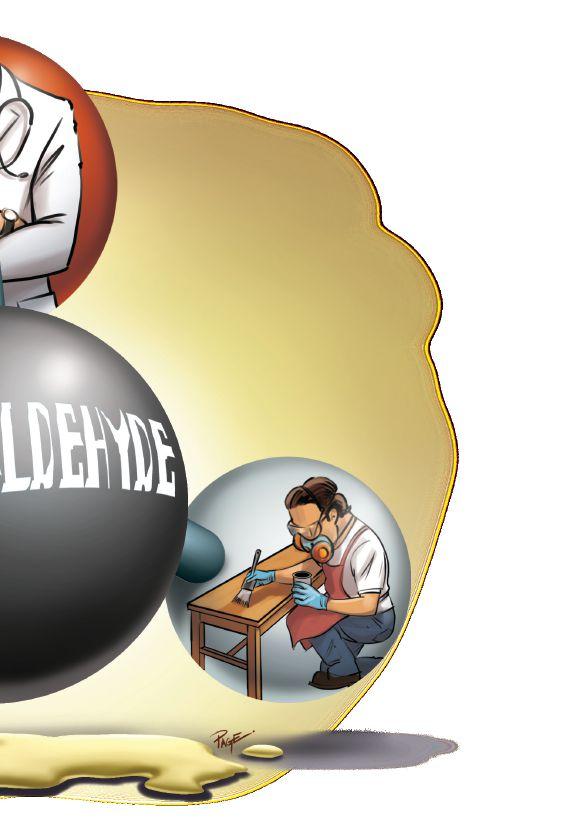

OCCUPATIONAL EXPOSURE

Working safely with formaldehyde IN THE EYE

Ready access to eye-rinsing facilities

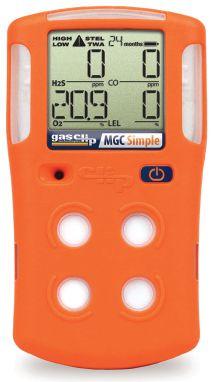

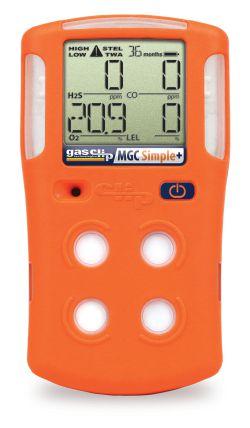

Detect combustible gases (LEL), hydrogen sulfide (H2S), carbon monoxide (CO) and oxygen (O2)

MGC Simple & MGC Simple Plus

uTwo or three year run time with no charging or calibration

uDetect in oxygen deficient or oxygen enriched environments

uLEL sensor is immune to sensor poisoning

uFails to safe

uSimple, one button operation

uLogs data at one second intervals whenever gas is detected

u100% Quality control tested

uFull two or three year warranty

Multi Gas Clip

The portable multi gas detector that can run continuously for two months on one charge due to advanced infrared sensor technology. Detects combustible gases (LEL), H2S, CO and O2.

Multi Gas Clip Pump

Compact, light-weight, handheld/wearable multi gas detector with internal pump draws from 75 ft. & runs for an average of 52 hours on a single charge. Detects combustible gases (LEL), H2S, CO and O2

Single Gas Clip

Eliminate downtime with our ultra-reliable portable gas detector. Detects H2S, CO or O2

Single Gas Clip Plus

Hibernate mode offers extended life option when detector is not in use. Detects H2S or CO.

Compatible Docking Stations

Portable, durable 4-bay dock stations

quickly bump test, calibrate & log data for up to four detectors at once with the push of a button.

Single Gas Clip Dock, Multi Gas Clip Dock, MGC Pump Clip Dock & MGC Simple Clip Dock

In the Internet of Things where everything is connected, technologies that were previously not vulnerable to hacking — like cranes — are now fair game. BY

ANDREW SNOOK

Avoiding Combustible-Dust Mistakes

Well-intentioned companies that try their best to manage explosive dusts often make mistakes that render their hazard-mitigation ineffective — even costly.

JEAN LIAN

Preventing Self Harm

managing occupational safety and mental health,

industries.

JEAN LIAN

The Next Lap

2019 marks my 12th year covering occupational health and safety news for OHS Canada. During the past decade or so, I have learned much not just about the art of writing and editing. I have also gained an understanding of the breadth and complexity of workplace-safety issues and how the human factor interacts with it.

One of the most rewarding aspects of my work as an oh&s journalist is to have people open up to me and share their personal experiences with work accidents.

There is no closure; only acceptance.

The severe physical injury or personal loss might have occurred many years ago, but the people who went through these experiences still recall vividly the events that led up to the incident. Time, it seems, has little effect on erasing the indelible mark that the trauma had imprinted on their minds and hearts. In other words, people move on, but they never forget.

I have also talked to fathers who lost their sons or daughters, widows whose soulmates were killed at work and employees who struggled with survivor guilt for living to tell the tale of a job-related accident while their colleagues did not.

One common thread that connects these people is that there is no closure; only acceptance — acceptance that they cannot turn back the clock and bring their loved one back, or replay the sequence of events so that things can be done right and prevent the mishap from occurring in the first place.

For some people, acceptance is not enough. They have transformed their pain into a calling by becoming safety advocates so that others would not have to go through what they did. Shining examples of people who have turned their grief into a driving force to bring about public good include the following: Rob Ellis, founder of MySafeWork, whose son was killed on his second day on the job; safety and motivational speaker Kina Repp who was maimed while taking on a summer job at an Alaskan fish cannery; and Janice Martell, founder of the McIntyre Powder Project. Martell, whose father was one of many miners who had inhaled finely ground aluminum dust known as McIntyre Powder that was administered to miners in northern Ontario between 1943 and 1979 to protect them against silicosis, created a registry for these exposed miners.

Oh&s reporting is a responsibility that I have always taken seriously. My job is not only to educate and inform; it is also to probe and ask questions. People who relive their pain by sharing their stories of personal loss with me seek answers that will hopefully help them make sense of what has happened. They want their stories to be told. For some, they want justice to be served.

Occupational safety is more than just compliance. Behind each statistic is a human face and numerous disrupted lives that will never be the same again. One quote that I will always remember came from a father who lost his son to a job accident. He described the loss as an open wound in his heart over which scar tissue forms through time. Every time he touches that wound, he knows his son is there.

As I move on to the next challenge in my career, I want to thank all my readers and people who have given me the honour of telling their stories, many of which have touched my heart.

Jean Lian

Vol. 35, No. 4

JULY/AUGUST 2019

EDITOR JEAN LIAN 416-510-5115 jlian@ohscanada.com

MEDIA DESIGNER MARK RYAN

ACCOUNT COORDINATOR CHERYL FISHER 416-510-5194 cfisher@annexbusinessmedia.com

CIRCULATION MANAGER JAY DOSHI 416-442-5600 EXT 5124 jdoshi@annexbusinessmedia.com

PUBLISHER PETER BOXER 416-510-5102 pboxer@ohscanada.com

GROUP PUBLISHER PAUL GROSSINGER pgrossinger@annexbusinessmedia.com

COO SCOTT JAMIESON sjamieson@annexbusinessmedia.com

EDITORIAL ADVISORY BOARD MEMBERS

DAVID IRETON, Safety Professional, Brampton, Ont.

AL JOHNSON, Vice President, Prevention Services WorkSafeBC, Richmond, B.C.

JANE LEMKE, Program Manager, OHN Certification Program, Mohawk College, Hamilton, Ont.

DON MITCHELL, Safety Consultant, Mississauga, Ont.

MICHELE PARENT, National Manager, Risk Management and Health and Wellness, Standard Life, Montreal, Que.

TERRY RYAN, Workers’ Compensation and Safety Consultant, TRC Group Inc., Mississauga, Ont.

DON SAYERS, Principal Consultant, Don Sayers & Associates, Hanwell, N.B.

DAVID SHANE, National Director, Health and Safety, Canada Post Corporation, Ottawa, Ont.

HENRY SKJERVEN, President, The Skjerven Cattle Company Ltd., Wynyard, Sask.

PETER STRAHLENDORF, Assistant Professor, School of Occupational and Public Health,Ryerson Polytechnic University, Toronto, Ont.

JONATHAN TYSON, Association of Canadian Ergonomists/Association canadienne d’ergonomie, North Bay, Ont.

Printed in Canada

ISSN 0827-4576 (Print)

ISSN 1923-4279 (Digital)

PUBLICATION MAIL AGREEMENT #40065710

CIRCULATION

asingh@annexbusinessmedia.com

Tel: 416-510-5189

Fax: 416-510-6875 or 416-442-2191

Mail: 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

SUBSCRIPTION RATES

Published six times per year – Jan/Feb, Mar/Apr, May/Jun, Jul/Aug, Sep/Oct, Nov/Dec

Canada $100/yr plus tax

USA $100/yr

Foreign $164.50

Occasionally, OHS Canada will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Office privacy@annexbusinessmedia.com

Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2019 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

$677,500

Fine issued to construction companies and supervisors on June 12 after a worker was fatally struck by ice while working in an excavation in Ottawa in 2016.

Source: Ontario Ministry of Labour

7,675

Number of orders issued in more than 2,300 field visits by Ontario inspectors in 2018.

Source: Ontario Ministry of Labour

92.6%

Percentage of school buses in Newfoundland and Labrador that passed mandatory annual inspections conducted by ServiceNL in spring.

Source: ServiceNL

56

The number of young people aged between 15 and 24 who died from a work-related injury in Ontario from 2009 to 2018.

Source: Workplace Safety and Insurance Board

1. Winners Unveiled: The Workers’ Safety and Compensation Commission (WSCC) announced winners of the 62nd Annual Mine Rescue Competition on June 1 in Yellowknife. Gahcho Kué Diamond Mine (De Beers Canada Inc.) won the Overall Surface trophy, and Diavik Diamond Mine (Rio Tinto Ltd.) clinched the Overall Underground trophy at the two-day competition, which saw six teams demonstrate mine surface and underground-response and rescue skills.

Source: WSCC

2. Farm-kids Safety: AgSafe, British Columbia’s agricultural workplace health and safety association, held a one-day Progressive Agriculture Safety Day (PASC) on June 14 for 140 grade four and five students at Sardis Elementary School in Chilliwack. PASC is an international program providing education, training and resources to make farm, ranch and rural life safer for children and their communities.

Source: AgSafe

3. Safe-Work Campaign: The Workplace Safety and Insurance Board (WSIB) in Toronto launched a new #PracticeSafeWork campaign aimed at young people starting summer jobs or entering the Ontario workforce for the first time. The campaign creates safety awareness among young workers and offers information on young-worker safety on its website, www.practicesafework.ca

Source: WSIB

4. To The Rescue: Nova Scotia’s wildfire fighters answered the call to help fight wildfires in Ontario by sending a 21-person crew of wildfire fighters, who left Halifax for Thunder Bay on July 5. The crew is expected to be on the fireline for several weeks.

Source: Nova Scotia Government

5. New Appointment: The Workers’ Compensation Board of Prince Edward Island (WCB PEI) welcomed its new chief executive officer on June 21. Following the retirement of Luanne Gallant in April 2019, Cheryl Paynter will take over as the WCB’s chief executive officer.

EXPLOSION LEVELS RESTAURANT

Source: WCB of Prince Edward Island

An explosion destroyed a KFC restaurant in Eden, North Carolina on July 11. There were no injuries as no one was in the restaurant when the explosion occurred at 1 a.m. The cause of the explosion, which caused the building to collapse and scattered debris on the road, is being investigated.

Source: Associated Press

360°

OH&S UPDATE

CAUSES FOR INCIDENT CITED

FEDERAL — Short staffing and deviation from standard procedures by air traffic controllers led to the loss of separation between an Air Transat Airbus A310 and a Cessna 421 light twin-engine aircraft near the Montreal/Pierre Elliott Trudeau International Airport last May. This is the conclusion made by the Transportation of Safety Board of Canada (TSB) report released on July 10.

On 16 May, 2018, both aircraft were inbound to land at Montreal-Pierre Elliott Trudeau International Airport. The Airbus was coming from the west and was to fly north of the airport and land on Runway 24R, while the Cessna was inbound from the northeast and scheduled to land on Runway 24L.

A loss of separation between the two aircraft occurred when both aircraft were about 18 nautical miles northeast of the airport. At the closest point, the two aircraft came within 152 metres vertically and 1.7 nautical miles laterally of each other. Normally, the

aircraft should be separated by at least 305 metres vertically or three nautical miles laterally.

Although seven controllers and a shift supervisor would have been scheduled to work that evening, absences and illness reduced that number to three controllers and a supervisor. As a result, six sectors of airspace normally divided among the controllers had to be combined and controlled by just three, which increased each area of responsibility, workload and complexity.

The TSB’s investigation also found that with the Cessna approaching from a sector to the northeast, control responsibility for it was not transferred to the next sector according to standard procedure. A controller-in-training responsible for the receiving sector was initially unaware of the presence or intentions of the Cessna until it entered his airspace. As a result, he did not have an opportunity to develop a plan to deal with the converging traffic.

As well, the instructor, who was both

CONSULTATION ON TRAINING UNDERWAY

VICTORIA — Consultations to help develop British Columbia’s mandatory entry-level training for Class 1 commercial driver’s licences will begin this summer, as the province beefs up training to bolster trucking safety.

“Safety on our highways is our top priority, and advancing the skill development of new commercial drivers would make roads even safer for everyone,” Claire Trevena, Minister of Transportation and Infrastructure in Victoria, says in a statement on July 4. “That is why we are exploring what a practical and consistent mandatory training program for new commercial truck drivers could look like in B.C.”

The province will gather input from the trucking and driver-training industries and other stakeholders to see how a Class 1 driver training program can be aligned with recently introduced entry-level Class 1 driver training standards in other Canadian jurisdictions.

Consultations will also look at how a provincial program could incorporate the entry-level training guidelines that is currently under development by the Canadian Council of Motor Transportation Administrators for inclusion in Canada’s National Safety Code standard.

“Everyone has a stake in ensuring that new commercial

the shift supervisor and responsible for the trainee, was distracted by other tasks and was unable to monitor the developing situation accurately. The controller-in-training later noticed the Cessna on the display, and the required separation was re-established. Both aircraft landed without incident.

X-RAY RISK RAISES CONCERNS

CHILLIWACK — An emerging health risk could impact the manufacturing industry as the growth of X-ray technologies continue without effective programs to control radiation risk.

This is the warning that the Manufacturing Safety Alliance of BC and Radiation Safety Institute of Canada (RSIC) jointly issued on July 9, following an exploratory review to understand the prevalence of X-ray radiation risk and control within the manufacturing sector.

“Education, proper risk-assessment tools and effective controls are neces-

drivers have a minimum body of skills and knowledge before they begin operating some of the largest and heaviest vehicles on B.C. roads,” says Mike Farnworth, Minister of Public Safety and Solicitor General in Victoria.

The Association has recommended that the province considers minimum standards for entry-level training for Class 1 drivers, and that this focused consultation is designed to help define and set effective standards, Farnworth notes.

“The BC Trucking Association welcomes today’s announcement by the provincial government to begin consultation on this critical issue,” says Dave Earle, president and chief executive of BC Trucking Association in Langley.

“Development of a commercial driver training standard has been a key priority for our industry for many years,” Earle says. “Our shared goal is to ensure that drivers entering the industry meet enhanced training standards, improving road safety outcomes for all road users.”

Consultations on Class 1 mandatory entry-level training will be led by the Ministry of Transportation and Infrastructure, with support from ICBC and the Ministry of Public Safety and Solicitor General.

sary to mitigate these risks,” says Steve Horvath, RSIC’s chief executive officer.

An online radiation awareness course and interactive survey were conducted to determine the level of understanding about risks associated with radiation. Completed surveys indicate that there are few well-developed radiation-safety programs in place.

Larry White, a training and resource development specialist who has been working on the project for the Alliance, says what surprised him most in the survey results was how few people know about the risks of radiation even when they are working with it almost every day, and that there is an overall lack of awareness around proper safety protocols. Radiation is often a part of weld inspections, internal inspections, fill inspections and non-destructive testing. “Exposure over time can really harm people” White cautions.

The RSIC and the Alliance signed a memorandum of understanding to work together to provide radiation education

and support to organizations with radiation risks.

X-ray and radiation sources are prevalent in manufacturing and other sectors such as farming, forestry, saw mills, pulp and paper, construction, pharmaceuticals and chemical processing.

Horvath says the collaboration between the two agencies has resulted in practical solutions for employers in the province to avoid potential health risks associated with new and developing Xray source technologies.

“The hope is that it will help fill a void, help to improve radiation safety in the workplace and reduce radiationrelated injuries,” White adds.

REPORTING SYSTEM IN FORCE

VANCOUVER — In the wake of the global measles outbreaks, reporting immunization status among school-age children will be mandatory in British Columbia starting in the new school year.

Looking for More Comfort & Fit DSI has it!

Very lightweight – less than 1 oz

9.5 base curve lens for better coverage

Exclusive anti-fog coating

Double injection temple arms and soft nose-piece to prevent slipping in hot and humid environments

Dyna Shield

Contemporary dual-lens design with half-frame

Available in Clear, Amber, Smoke and I/O Mirror lenses

Fits a wide variety of different faces

The Vaccination Status Reporting Regulation will require parents and guardians in British Columbia to provide public-health units with immunization records for students enrolled in the provincial school system, according to a provincial government statement.

“This mandatory reporting of the immunization status of students will ensure the public health system is prepared in the event of an outbreak,” Adrian Dix, Minister of Health said on July 5.

Parents or guardians of children with an incomplete or missing record will be contacted by public health to provide their child’s immunization information. With up-to-date records, public health can reach out to families with children who are behind on their immunizations and provide an opportunity to catch them up, or discuss any concerns with parents, the statement adds.

“Improving the rates of immunization of children and youth is critically important for student safety and healthy schools across B.C,” says Minister of

Dyna Shield

Education Rob Fleming.

For students from kindergarten to Grade 12 who are currently in the provincial immunization registry, public-health officials will review school-enrolment records in late August and into October to match them against immunization records. For the first year of reporting, the goal is to help parents get their children up to date on immunizations by the end of the school year.

Apart from presenting a public-health hazard, the measles outbreak is also an occupational risk to those who work in the transportation, education and health sectors. If a worker is at risk of being exposed to measles, the employer must develop and implement an exposure-control plan to identify at-risk workers, according to WorkSafeBC.

Preventive controls include providing measles vaccination to workers, enforce proper hand-hygiene practices, disinfecting work surfaces and using personal protective equipment.

FLOTATION DEVICE MADE MANDATORY

RICHMOND — Wearing a personal flotation device (PFD) or a lifejacket is now mandatory for all crew members who work on the deck of a commercial fishing vessel to improve worker safety.

This requirement was the result of amendments that WorkSafeBC made to Part 24 of the Occupational Health and Safety (OHS) Regulation, which regulates diving, fishing and other marine operations.

The amendments, which took effect on June 3, regulate specific conditions under which crew members are required to wear PFDs on commercial fishing vessels. Previously, crew members on a fishing vessel need to don a PFD only when working under conditions that involved a risk of drowning.

“Commercial fishing is one of the most dangerous occupations in British Columbia, and drowning is the leading cause of death among B.C. fishermen,” Patrick Olsen, manager of prevention field services for WorkSafeBC, said in a statement on June 19. “Wearing a PFD reduces the risk of drowning and has been proven to save lives.”

Between 2007 and 2018, there were 24 work-related deaths in the commercial fishing industry, 15 of which are related to drowning.

The amendments are consistent with recommendations made by the Transportation Safety Board after the fatal capsizing of the fishing vessel Caledonian near Tofino, British Columbia in September 2015. Three crew members were killed. The lone survivor was the only crew member wearing a PFD.

“No matter what your role is on the vessel, crew safety affects everyone,” Olsen says.

CONSULTATIONS ON AGRICULTURAL SAFETY BEGIN

EDMONTON — Consultations to repeal farm workplace legislation, or Bill 6, has begun as Alberta paves the way to introduce the Farm Freedom and Safety Act.

Devin Dreeshen, Minister of Agriculture and Forestry, will undertake a consultation tour to meet farmers, ranchers and organizations across the province over summer. According to the provincial government, the previous government’s Bill 6 was passed with limited public input and in the face of strong opposition from farmers.

“Alberta farmers need common-sense rules that promote farm safety — not process, not red tape,” Dreeshen said in a statement on July 12. “We are going to repeal Bill 6, and I plan to meet with farmers this summer to develop the legislation to replace it.”

The government will seek input on flexibility in meeting workplace standards, allowing a choice of workplace insurance in the market or the Workers’ Compensation Board if basic coverage standards are met, exempting small farms from employment standards legislation, promoting education and best practices to improve farm safety and minimizing red tape while ensuring basic safety standards.

The online survey will run until August 31.

DEADLINE EXTENDED FOR FARM, SCHOOL DRIVERS

EDMONTON — Alberta is extending the deadline for farmers and school bus drivers to meet training requirements as new commercial drivers under the Mandatory Entry-Level Training (MELT) requirements for drivers seeking Class 1 and Class 2 commercial licences, which the province introduced on March 1.

Farmers and farm workers can apply for an extension to meet the training and testing requirements for a Class 1 driver’s licence before March 1, 2021. New school bus drivers will have until July 31, 2020 to meet the requirements for a Class 2 driver’s licence.

The extension is in response to school bus drivers and farming industries, which have indicated that they needed more time to adjust to MELT requirements considering the highly flexible and seasonal industries in which they work, Ric McIver, Minister of Transportation says.

“Our government is committed to taking steps to work with farmers and school bus drivers to ensure we have a robust driver-training system in place that works for industry, without compromising safety. This extension ensures these key industries can continue their work without disruption, particularly during the busy back-to-school and harvest seasons,” he adds.

RISE IN VIOLENCE PREVENTABLE: PROVINCE

REGINA — Workplace injuries caused by violence rose 16 per cent in 2018 in Saskatchewan. Some of these injuries could have been prevented if employers and workers had paid attention to and acted on the warning signs of aggressive behavior, according to a WorkSafe Saskatchewan statement on June 25.

In order to spot the potential for violence at work, it is important to know that workplace violence encompasses any

situation in which an employee is abused, assaulted, threatened or harassed by a co-worker, supervisor, client, patient or a member of the general public. It includes physical attacks such as hitting, biting and pushing and verbal and psychological abuse like demeaning remarks and intimidation.

While it can be hard to predict when an individual may turn violent, signs of high stress levels can indicate if an individual many become aggressive. The Canadian Centre for Occupational Health and Safety (CCOHS) in Hamilton, Ontario says warning signs include crying, sulking or temper tantrums; excessive absenteeism or lack of punctuality, disrespect for authority, refusal to acknowledge job-performance problems, swearing or emotional language, blaming others for mistakes and complaints of unfair personal treatment.

Body language and non-verbal cues that could signal when a person may become violent include sweating, signs of extreme fatigue, pacing or repetitive movements, clenched jaws or fists and violation of personal space like getting too close, the CCOHS notes.

Knowing what violence is also necessitates an understanding of what it is not. The Saskatchewan government says workplace harassment should not be confused with ordinary work disagreements and does not include daily management or supervisory decisions over work assignments, job assessments and evaluations, workplace inspections, implementation of appropriate dress codes and disciplinary actions.

If someone at a workplace shows one or more warning sign for violence, share your concerns with your supervisor, human resources department or a counsellor with your employee assistance program, the statement advises. An employer’s written violence-prevention policy, if there is one, is a good place to find out how complaints are investigated and resolved.

FATALITY PROMPTS FINE

TOTTEHNHAM — A worker fatality led to a $160,000 fine issued on July 18 to a Japanese engineering firm.

The fatality occurred at a construction project located in a manufacturing facility in Tottenham, Ontario, according to a statement from the Ministry of Labour.

On August 30, 2017, two workers employed by Access Limited were installing a new metal stamping press and feeder. It was determined that it would be safer to do so overnight when the equipment was not being operated by technicians.

The power to the press machine was turned off, but a piece of equipment known as a destacker feeder remained powered. On that night, one of the workers briefly left the work area to observe the other worker performing diagnostic testing at the destacker feeder control panel.

Upon returning, the worker discovered the co-worker’s body in front of a part of the destacker feeder known as the DB bucket car — a small, mechanized cart that travels along rails. There is fencing surrounding the loading area for the bucket car, which has an opening to allow the car to

The working world has never experienced such dynamic change. As the world’s No. 1 trade show for the sector, A+A offers the best possible overview of developments in occupational health and safety. Around 1,900 exhibitors from more than 60 countries contribute their products, solutions and ideas to making work safer, healthier and more efficient. Because: PEOPLE MATTER

leave the loading area to the unloading area. The body was pinned between the edge of the bucket car and the frame of the fencing surrounding the bucket car opening. There were no witnesses to the incident.

A Ministry of Labour investigation determined that the likely cause of the fatality was that the bucket car had started and moved along the rail towards the opening of the fence while the worker, who was performing diagnostic tests on the stamping press and feeder, was within the fenced area. As a result, the worker was pinned within the equipment, causing fatal injuries. The investigation also found that safety interlock circuits installed around the bucket car had been overridden.

The company pleaded guilty to failing to take reasonable precautions to prevent the starting of the bucket car where a worker may be endangered by such movement.

INSPECTION BLITZ TARGETS YOUNG WORKERS

LONDON — The Ontario government has launched targeted inspections focusing on the safety of students who take up jobs in summer. The inspections follow months of outreach to businesses by the Ministry of Labour to educate and help them create safe workplaces.

“New workers are three times more likely to be injured during their first month on the job,” Minister of Labour Monte

McNaughton said in a statement issued on July 15. “That is why we are doing this. Families should expect that when their sons and daughters go to work each day, they will come home safely.”

Inspectors will focus on workplaces that are newly registered with the Workplace Safety and Insurance Board and have not had a proactive health and safety visit in the last five years. Retail, restaurant, food, beverage, hospitality and recreational services will be the focus of inspections.

The blitz will run until August 30.

FIRM PENALIZED OVER JOB-RELATED DEATH

TORONTO — A Toronto company that provides concrete for the construction industry was fined $130,000 on July 9 over a worker fatality.

On January 16, 2017, the worker was operating a concrete pump owned by Torrent Shotcrete Canada Ltd. at a residential building in Toronto that was under construction. At the end of a pumping period, the hopper had to be cleaned so that residual concrete would not harden.

The worker, who was cleaning out the hopper using a power chisel, fell into the hopper as the concrete auger was running. There was no eyewitness to the incident, and it was not known how the worker fell into the hopper.

According to Ontario’s Ministry of Labour, on the top of the hopper was a grate that prevented access to the auger. The hopper was equipped with a sensor to stop the movement of the auger upon the opening of the grate. The sensor would allow power to the auger as long as it was in contact with a metal piece that was attached to the grate.

A Ministry investigation found that the sensor on the hopper in question had been rendered inoperative by a metal washer that had been taped onto it, which would cause the sensor to allow power to the auger even when the grate was open. The wiring for the sensor had also been altered to falsely indicate that the safety grate was closed, allowing uninterrupted power to the auger when the grate was open, even though the sensor not been disabled by the taped washer.

The company pleaded guilty to failing to ensure a grate sensor on a concrete hopper was not rendered inoperative.

LAW AGAINST VIOLENCE NEEDED: UNION

TORONTO — Canada’s largest transit union is calling for federal legislation to protect transit operators in the wake of a brutal assault against a bus driver in Hamilton, Ontario.

“As he has done for the past 30 years, an ATU operator working for GO Transit pulled up to a bus stop, except this time a passenger unleashed a barrage of punches and kicks on him, resulting in hospitalization. Twenty-two other passengers had to witness this traumatic assault,” says ATU Canada President John Di Nino.

The operator sustained a head injury in the incident, which occurred in broad daylight on July 9 in a busy, urban centre

in Hamilton. The perpetrator, who was arrested, stayed at the scene and taunted the operator after the assault. A suspect was taken into custody.

Di Nino says concerted effort from all levels of the national government is needed to put violence-prevention measures in place. He also calls for a Canadian version of the Transit Worker and Pedestrian Safety Act — a bill in the United States that is making its way through the Congress with the help of the international union.

The bill calls for assault-mitigation infrastructure, de-escalation training, a national database to track assaults and modification to bus specifications to address blind spots and ergonomic issues.

Di Nino says a similar bill is needed in Canada to identify the risk of violence on transit systems and approve measures to mitigate this occupational hazard. He made references to violent incidents against transit operators in the last four years, including a fatal stabbing in Winnipeg and Edmonton, as well as more than 4,000 sexual assaults against passengers.

He also highlights the link between fare disputes and violence against operators. In many cases, arguments over fares escalate into violent altercations.

“It is a national crisis that Ottawa should be addressing through a national transit strategy with dedicated operational funding and a national database of operator and pedestrian assaults,” Di Nino says. “Politicians go to work and expect to leave their office alive at the end of the day; transit professionals do not have that luxury. Ottawa must take action now.”

CONSTRUCTION COMPANY FINED

OTTAWA — A construction firm in Ottawa was fined $60,000 on July 3 over a worker fatality at a townhouse site.

MC Oakvillage GP Inc. was the constructor of a project of about 200 townhouse units in Oakville, Ontario. On February 21, 2018, a worker was installing aluminum siding on the second-floor balcony on one of the units that was under construction.

There was a single, two-inch by four-inch piece of wood installed horizontally at the open edge of the balcony at a height of approximately 1.2 metres from the balcony floor.

The worker, who was descending the ladder, grabbed on to the wooden piece, which gave way. As a result, the worker lost balance and fell over the side of the balcony, sustaining a fatal injury.

An investigation by Ontario’s Ministry of Labour revealed that the wooden piece was not nailed or securely fastened in place. Guardrails on the balcony were installed with a “compression fit” approach using a 2x4 wedged between two brick posts to avoid damaging the brick columns.

There was no engineering for the design of the rails to assess what load they could support. Neither was there other guardrail in place to protect workers from falling.

The company pleaded guilty to failing to use a guardrail system to protect workers who are exposed to a fall of more than three metres.

FALLING CONCRETE CLAIMS ONE

TORONTO — A construction company was fined $200,000 on June 26 over an incident in which falling concrete claimed a worker’s life.

The incident took place on March 27, 2017. J.N.D. Erectors Limited, a subcontractor on the site, was tasked with erecting panels of preset concrete onto the exterior wall of the building. The panels were transported via a flat-bed truck, and a crane and hoist were used to lift the panels from the truck.

The panels were supported by two A-frames bolted to the truck, with transport chains securing two panels to each other. A worker unhooked the chains from one panel, and the first panel was hoisted away by crane. While the worker was preparing the second panel weighing 6,000 pounds, it shifted and toppled onto the worker, causing fatal injuries.

A structural engineer with Ontario’s Ministry of Labour stated in a report that the toppling could have been avoided if the panel had been secured at all times.

The company was found guilty of failing to ensure that material or equipment at a project shall be stored and moved in a manner that does not endanger a worker.

WARNING ISSUED ON MISLEADING CALLS

SAINT JOHN — WorkSafeNB is urging employers to exercise caution as some firms are making misleading and sometimes, aggressive sales calls to employers in the province.

These calls suggest that their employees must be trained immediately because of the new legislation on workplace violence and harassment, as well as on the Workplace Hazardous Materials Information System (WHMIS). The caller also stated that a business may be shut down if they do not incorporate this training.

“These organizations are not working on behalf of WorkSafeNB,” the government office clarified in a statement on July 8. “If you are contacted by an agency or person offering to provide training, you should know that you have options available, and you should explore those options to ensure that you find the best and most cost-effective training for your workplace,” the statement added.

An amendment to General Regulation 91-191 of the Occupational Health and Safety Act addressing workplace violence and harassment came into effect April 1. Changes to the WHMIS regulation have been in effect since June 2014.

WorkSafeNB reminds employers that WHMIS training, which can be provided by any qualified person or agency, must meet the regulation’s minimum requirements.

PROVINCE SUPPORTS HOME-CARE SAFETY

HALIFAX —Nova Scotia is investing $1.86 million to support the purchase of safety equipment and education opportunities

for home support workers, the provincial government announced on July 18.

Health and Wellness Minister Randy Delorey says these investments provide staff with the tools they need to do their jobs more safely.

An investment of $1.36 million will support education and training opportunities through groups like the Health Care Human Resource Sector Council and LearnSphere and non-violent crisis intervention training for nurses, while $500,000 dollars will be used to buy equipment, including slider sheets and transfer belts to help home-support workers move clients more safely to prevent job-related injuries.

“This is a welcome investment in the health system,” Jeff Densmore, regional executive director for the Victorian Order of Nurses (VON) in Nova Scotia, says in a statement. “Ensuring that VON nurses and Continuing Care Assistants are able to provide care without risking their own health is key to our ability to serve our clients well. We look forward to the improvements this will bring.”

Funding for the initiative came from Canada-Nova Scotia Home and Community Care and Mental Health and Addiction Services Funding Agreement.

HEAT-STRESS PREVENTION URGED

CHARLOTTETOWN — The Workers Compensation Board (WCB) of Prince Edward Island issued a heat stress reminder on July 5, urging employers to take precautions to protect workers.

“While there is no one-size-fits-all solution for all workers and workplaces, being aware of the risks of heat-related illness is an important first step,” Danny Miller, director of occupational health and safety in Charlottetown, said in a statement. “Employers need to recognize the risks and take reasonable steps to reduce them. Workers must be made aware of the risks and be encouraged to speak up when there is a heat or sunrelated concern.”

Heat stress refers to a variety of heatrelated disorders like heat exhaustion

What Company produces a Respirator with the Most Benefits

Straps welded on wings, no deformation of respirator when adjusted

Straps are sonically weld, no staples

and heat stroke, which can be fatal. Symptoms include weakness, muscle pain, light-headedness, nausea and high body temperatures. Environmental hazards like exposure to heat, high humidity and limited air flow can also cause heat stress. Contributing factors include the worker’s hydration level, clothing and physical exertion.

Preventive steps to avoid heat stress include drinking plenty of water and limiting sun exposure between 11 a.m. and 4 p.m. when ultraviolet rays are at its highest. Applying sunscreen, having adequate ventilation in the workplace, taking breaks in the shade or an air conditioned space, ensuring workers safety by providing adequate supervision and using a buddy system to watch for signs of heat stress among co-workers are also recommended.

“If you experience the initial signs of heat stress, remove yourself from the environment, drink water, monitor the symptoms and advise someone in case you need further assistance or medical treatment,” the statement adds.

?

Curved nose clip for a better comfort and fit Clear valve cover for easy inspection

Adjustable strap on all models

Available version for welders

Complete variety from N95 to P100

Call your nearest distributor for more information and a trial

Nose and face seal closed cell foam for more comfort and fit Watch the new Dyna-Pure Series Half Mask & Fullface Mask coming soon!

Adjustable strap made of elastic cloth material for more comfort

Drop down easy to perform Unique Butterfly valve, reduce resistance to exhalation

WCB EYES FISHING SAFETY

CHARLOTTETOWN — The Workers’ Compensation Board of Prince Edward Island (WCB PEI) launched an education and compliance initiative to boost fishing safety.

According to a statement on June 7, occupational health and safety officials will visit wharves to ensure that fishers are wearing their personal flotation devices (PFDs).

“The goal of the initiative is to protect fishers by ensuring their compliance with the OHS Act and Regulations and raising awareness of the importance of workplace safety,” Stuart Affleck, Chair of the WCB, said in a statement.

The Occupational Health and Safety Act considers a fishing vessel a workplace. Within the regulations under the Act, there are provisions set out to address worker and employer responsibilities where there is a risk of drowning.

“Because the results of not wearing a PFD can be devastating, it is important that we do all that we can to reduce the risk for those working on fishing vessels,” says Tory Kennedy, acting chief executive officer for the WCB. “We know that if there is a higher compliance with PEI’s safety legislation, the probability of workplace accidents is reduced.”

Fishing has the single highest fatality rate of any sector in the country. There have been a number of fatalities in the fishing industry on Prince Edward Island over the past few years, according to a 2017 study by the Globe and Mail.

PTSD PRESUMED WORK-RELATED

ST. JOHN’S — All workers in Newfoundland and Labrador who are covered by the workplace-injury system will be eligible for presumptive coverage for post-traumatic stress disorder (PTSD) occurring on or after July 1.

This change brings Newfoundland and Labrador in line with the movement taking place across the country to update workers’ compensation legislation that recognizes work-related mental health injuries.

“This progressive legislation will help

injured workers receive the assistance they need earlier, leading to better outcomes in improving the worker’s overall health and well-being,” Sherry GambinWalsh, Minister Responsible for WorkplaceNL said in a statement on June 25.

The legislation, which was proclaimed in December 2018, presumes workers to have developed their diagnosed PTSD as a result of a traumatic event or multiple events at work. The diagnosis must be made by a psychiatrist or registered psychologist using the most recent edition of the Diagnostic and Statistical Manual of Mental Disorders.

“There is widespread recognition that first responders are at risk of developing an operational stress injury, such as post-traumatic stress disorder, due to cumulative stress and/or single incident psychological trauma,” says Joseph A. Boland, Chief of Police, Royal Newfoundland Constabulary. “This new legislation will offer the assistance needed to help support the overall health and well-being of our employees.”

COMPANIES FACE CHARGES

ST. JOHN’S — A company in Newfoundland faces charges on June 18 over an incident that saw the partial amputation of a worker’s foot.

The charges stem from an investigation by the Occupational Health and Safety (OHS) Division of Service NL, following an incident in October 2017 at the wharf construction site at the harbour in St. John’s. RJG Construction Lim-

ited of St. John’s has been charged with nine safety violations.

The charges relate to the following alleged failures: provide and maintain a safe workplace; offer necessary information, instruction, training and supervision; ensure workers and particularly supervisors are made familiar with the hazards; make sure that safe work procedures are followed; ensure that work procedures promote the safe interaction of workers and their work environment; the use of a mobile crane met the requirements of CSA Z150; the oh&s program included written safe-work procedures appropriate to the hazards and work activity; implement its oh&s program; and ensure that material was placed in a secure manner that did not constitute a hazard to a worker.

In a separate incident, two companies and an individual have been charged over a fatal incident on June 19. Two employees sustained fatal injuries near Come by Chance when the transmission line that they were erecting between Bay d’Espoir and Western Avalon fell to the ground.

The employer, Forbes Bros. Ltd., has been charged with seven violations, while a supervisor was charged with one count over the alleged failure to ensure the health, safety and welfare of all workers under his supervision. The principal contractor, Newfoundland and Labrador Hydro, was charged with one count that alleges its failure to ensure that an employer and workers comply with oh&s regulations.

Follow us on Twitter @OHSCanada

So, what’s on your mind?

Ever wonder what other oh&s types are thinking about? Find out by making our website poll at www.ohscanada.com a regular stop.

Ridesharing causes spike in traffic deaths: study

By Jean Lian

Ride-hailing is associated with a three-per-cent increase in the number of motor-vehicle deaths and fatal accidents, according to the latest research from the University of Chicago Booth School of Business.

The rise in accidents appears to increase over time, and that rate has stayed steady through weekdays, weeknights, weekend days and weekend nights, according to a July 8 statement releasing the findings of the study, The Cost of Convenience: Ride-hailing and Traffic Fatalities.

The findings are based on staggered roll-out dates from Uber and Lyft. Researchers reviewed the eight quarters before and after ride-hailing was adopted in large cities in the United States from 2001 to 2016 by analyzing traffic volume, transportation choices and accidents rates.

While the number of roadway deaths in the United States stood at 32,885 in 2010 — the lowest level since 1949 — that number increased to more than 37,400 in 2016. The authors conclude that the introduction of ride-hailing services in 2011 accounts for roughly a three per cent hike in automobile deaths nationwide, which translates to 987 fatalities each year.

Reasons cited for ride-hailing’s contribution to the growth in traffic fatalities include more cars on the road, leading to more accidents, and injuries and deaths involving drivers, passengers, bikers and pedestrians. The most significant increase in accidents occurred in larger cities, which saw a rise in new-car registrations when ride-hailing was available. Bike and pedestrian fatalities from accidents involving cars also increased at a similar rate to all driving fatalities in cities that have introduced ride-hailing, the study notes.

Although ride-hailing offers benefits that include safe and affordable transportation options, more carpooling for riders and job opportunities, “the annual cost in human lives is non-trivial,” the study states.

Meanwhile in Canada, one province has made the first stride towards making ride-hailing a reality. Ride-hailing firms will be able to apply to operate in British Columbia as of September 3. “Our plan has made it possible for ridehailing companies to apply to enter the market this fall, with vehicles on the road later this year, while ensuring the safety

of passengers and promoting accessibility options in the industry,” Claire Trevena, Minister of Transportation and Infrastructure, said in a statement on July 8.

The Passenger Transportation Board (PTB) will start accepting applications in the fall to determine the supply, boundaries and fares charged to passengers. All regulations will be in force on September 16 to support full implementation of ride-hailing services after the board decides on the applications it receives.

Study links porn use and unethical behaviour

Viewing pornography can lead to unethical workplace behaviour like sexual harassment, suggests new research out of Brigham Young University in Provo, Utah.

The study’s findings attribute the link between pornography consumption and the rise in unethical behaviour to dehumanization, or a viewer’s propensity to objectify others or view them as less human.

“Pornography is often framed as an issue affecting only individuals and relationships outside of a business context,” study co-author Melissa Lewis-Western, the University’s professor of accountancy, said in a statement on June 25.

She argued that businesses function off the decisions people make. “If you have a societal phenomenon that a lot of people are participating in and it negatively impacts individuals’ decisions, that have the potential to impact organizational-level outcomes.”

The findings are based on data gathered from an experiment involving 200 participants and a nationally-representative survey of 1,000 other individuals. In the experiment, one group was tasked with recalling and recording their last experience viewing pornography. Meanwhile, members of the control group were asked to recall and record their most recent experience exercising. Both groups were then tasked to watch a boring, 10-minute video consisting of a blue background with a monotone voice speaking with subtitles.

Researchers found 21 per cent of those who had recalled their last experience viewing porn did not finish viewing the video but lied about it, compared to only eight per cent of those in the control group. This represented a statistically significant 163-per-cent increase in shirking work and lying for those who view pornography. Similar evidence was obtained from the survey, the statement notes.

As porn consumption gives rise to dehumanization, the incidence of sexual harassment or hostile work environments is likely to go up with increases in employee pornography consumption. “Organizations should be mindful of those risks,” says Nathan Mecham, study co-author and a

Ph.D. student at the University of Pittsburgh.

“If you have a larger portion of your employees that are consuming pornography at work, it is likely changing their behaviours, and those changes are likely negative,” LewisWestern cautions.

The study suggests that companies should take steps to reduce pornography consumption in the office. These measures include preventive controls, such as internet filters and blocking devices, and having policies and penalties to prohibit porn consumption at work.

“If your manager is regularly watching pornography at work, then our research suggests that the way you are treated is going to be different in negative ways,” Lewis-Western says.

Psychosocial factors shape mental health

Employees with higher levels of job control, social support and job security not only have a lower likelihood of mental illness, but also have a higher chance of having a flourishing mental health.

This is the findings of a study, Psychosocial Work Conditions and Mental Health: Examining Differences Across Mental Illness and Well-Being Outcomes published in June by Toronto’s Institute of Work and Health (IWH).

According to an IWH statement, previous studies have looked at the link between psychosocial work factors and poor mental health among workers, but little is known about work factors that support positive mental health.

The study, which examines the association between psychosocial work conditions and mental-health outcomes among a representative sample of Canadian workers, examined data from the 2012 Canadian Community Health Survey (CCHS) on mental health conducted by Statistics Canada of working-aged Canadians living in the ten provinces. The data comprises responses of more than 10,000 people aged 15 to 74 years who worked at least eight hours a week.

“A higher level of job control, social support and job security increased the odds of a worker being free of mental-health disorders by eight to 15 per cent,” the study concludes. “They also increased the odds of a worker reporting positive mental well-being by 10 to 14 per cent.”

Psychological work demands were not significantly linked to poor or positive mental health. These findings were similar for both men and women, once personal factors were taken into account. “Given that workplace interventions should aim to both prevent mental disorders and improve mental well-being, focusing on the psychosocial work environment may provide an opportunity to do both at the same time,” the researchers suggest.

Avoiding sting allergies when working outdoors

Summer is the busiest season for outdoor workers in construction, landscaping, logging and agriculture. But sharing outdoor spaces with nature and her critters also carries the risk of insect bites from an angry wasp.

Small, local reactions with a raised warm and red area that settles down over 24 hours are common, Morissa Ladinsky, associate professor at the University of Alabama‘s Birmingham’s Division of General Pediatrics and Adolescent Medicine, said in a statement on July 8. But more serious reactions like an increasingly large, warm and red welt progressing over one or two days or longer, accompanied by nausea or vomiting, could signify a mild, non-life-threatening allergy. “Wasp stings are infamous for this,” Ladinsky says. “Our bodies differ in the level of inflammatory mediators we release to get the tiny drop of toxin out of our system.”

For most cases, anti-inflammatory agents like topical calamine, Benadryl or hydrocortisone and oral ibuprofen should suffice. Homemade remedies, like applying a paste made of cornstarch and cold water, can also ease the pain.

Rare but serious life-threatening reactions include rapid swelling of the lips, eyes and ears, dizziness, presence of hives or welts on body areas far from the sting site, sensation of the throat closing in and difficulty breathing. Ladinsky says immediate medical attention is required for an individual experiencing these reactions.

An allergy visit along with EpiPen ownership will become necessary going forward, as an individual who is genetically predisposed to severe sting allergy requires one or more exposures to the venom before the body responds in a life-threatening way. As such, many people do not manifest anaphylaxis with a first or even second sting.

For those who work outdoors in summer, covering up by wearing light-coloured, loose clothing made of tightly woven materials like nylon or polyester, donning long-sleeved shirts tucked into long pants, wearing closed-toe shoes or boots and putting on a hat are good preventive measures. So is using an approved insect repellent, notes information from the Government of Canada’s website.

Jean Lian is editor of ohs canada

Follow us on Twitter @OHSCanada

THE WEAKEST LINK

BY ANDREW SNOOK

In the Internet of Things where everything is connected, compromised confidential data is not the only consequence of a breach in cybersecurity. Technologies that were previously not vulnerable to hacking — like cranes or industrial equipment — are now fair game.

Depending on who you ask, the hacking of technologies has taken place for more than a century. Some published articles date hacking all the way back to the days of manipulating switchboards for phone companies like Bell Telephone in the late 1800s, while others trace the origination of the term “hack” to the 1960s when members of the Massachusetts Institute of Technology’s Tech Model Railroad Club used to “hack” their train sets in an effort to modify them. No matter when you date it, the hacking of technologies has come a long way.

A case in point is an online video, posted earlier this year, of a tower crane’s radio frequency controller being hacked into and taken over in Italy by an ethical hacker to demonstrate cybersecurity weaknesses within the technology, with the permission of the company overseeing the jobsite.

As tower cranes typically work in high-density urban areas, hoisting tens of thousands of pounds of equipment up into the sky, the potential for physical and financial toll from hacking is high. But construction equipment is only one of many areas where cybersecurity breaches can create occupational health and safety risks.

“The minute you have networks, and the minute you are connected to the outside world through these networks, cybersecurity becomes an issue,” says Harry Sharma, director of innovation and technology with The Conference Board of Canada in Ottawa.

Thanks to the interconnectivity and digitization of the manufacturing and construction industries, hackers with malicious intent today have a wider pool of targets than ever before. “It can lead to a lot of physical damage as well

as potential financial damage, so the challenges are in both realms,” Sharma says.

For this reason, cybersecurity plays a more prominent role than before in workplace-safety planning. But what does cybersecurity mean in today’s ever-changing world?

Chris Dodunski, chief executive officer of CyberHunter Solutions in Toronto, defines cybersecurity as a blend of people, process and technology. “What you are doing is you are instructing people, or defining process, or configuring technology to protect the confidentiality, data integrity and digital availability of whatever it is you are protecting,” he explains. In short, cybersecurity is guarding confidentiality, integrity and availability, or what he calls the CIA Triangle.

Dodunski says every industry weighs its CIA Triangle differently, with varying focus on the each of the three as-

pects of this triangle. “If you are looking in the healthcare industry, obviously, confidentiality is very important. But so is the integrity of the information that you are looking at,” he says. In the case of the banking or commerce sectors, data availability would be of greater importance.

And how does this apply to workplace safety? Technologies that typically exist in industrial and manufacturing spaces are no exceptions since most things have gone digital these days.

“We are constantly modernizing and networking these environments in order to improve efficiency or to operationalize things from an automated workflow perspective,” Dodunski says. “We are connecting on these things that were previously never online and never part of the Internet, or never available to the Internet.”

That means technologies that were previously not vulnerable to hacking are now fair game. “If someone can get into your industrial control systems, then they can start tampering with safety controls — things like your monitoring systems or shutdown mechanisms, or whatever is happening inside that environment.”

It is the threat to workers’ physical safety that makes breaches at industrial plants and construction sites that much more dangerous and vulnerable. There are a variety of ways through which cybersecurity breaches can create risks for employees at these facilities. An example is environmental systems.

“People don’t realize a lot of what you see in terms of the thermostat, the lights, the communication system — it is all delivered through online technology. So while it creates incredible efficiency, it creates incredible risk,” suggests Katherine Thompson, chair of the Canadian Advanced Technology Alliance’s Cyber Council in Ottawa. The financial damage to a manufacturer and the risk to those who work in that environment is high if hackers manage to hack into the lighting system in a manufacturing plant that is very much climate controlled and take over that feature.

Or a hacker with a personal vendetta against mining companies who managed to shut off air-purification and ventilation systems in a mine, Dodunski illustrates.

WORLDS COLLIDING

The line between physical security and cybersecurity has been blurring as technologies continue to advance and break down barriers that once separated these two worlds.

“These have been independent silos,” Dodunski explains, citing the physical security guys who deal with cameras and door access, and cyber people who work with computers, networks and wireless access. “But companies are beginning to recognize the importance of merging these two worlds to improve the security of their organizations.”

These worlds are not the only ones that can no longer remain in silos. With so many systems now interconnected and digitized, the need for a company to merge workplace safety with cybersecurity planning is higher than ever before.

“Cybersecurity is the pivotal technology for both safety and security,” says cybersecurity expert Claudiu Popa, chief

executive officer of Datarisk Canada in Toronto. “Without cybersecurity, humans are at risk of data and privacy breaches, personal attacks and physical violence. Mechanical systems are electronically controlled and remotely inspected. There is no longer a line between the physical and the electronic when it comes to occupational health and safety risk management.”

Workplaces that have adopted remotely controllable technologies, video surveillance and the Internet of Things have effectively opened a ‘backdoor’ for malicious access and unauthorized activity, he adds.

THE HUMAN FACTOR

There are several theories out there in regards to best practices for cybersecurity hygiene, how often systems should be tested and the best answer to the risks presented by bring-your-owndevice (BYOD) practices in workplaces.

But one thing most experts agree on is that employees are still the most vulnerable point in most companies’ cybersecurity strategies. “The weakest link is people,” Thompson says. “Year after year after year, study after study shows us the biggest source of data breaches in an online incident is human error.”

“There is no longer a line between the physical and the electronic when it comes to oh&s risk management.”

Dodunski agrees, adding that his own company uses social engineering as one of the ways to test the level of cybersecurity in companies. The method involves leaving USB sticks with enticing tags like “Salary Increases” or “Honeymoon pics XXX’ around public areas on a campus like lobbies and bathrooms.

“Most people are curious enough to put a USB stick into their computer, their laptop, or whatever it is to see what’s on it. And in fact, the statistics are pretty high,” he reveals. And weaponized media is a big deal. “You plug in the wrong thing, and all of a sudden, you have got a compromise.”

In addition to weaponized media, email, weak passwords, improper configuration of your security stack and the web are still common ways for hackers to infiltrate companies’ networks. “The web is still a huge vector of attacks. So if you don’t have proper controls on how people use the web, just going to the wrong website can invite attackers into your organization,” Dodunski explains.

Although employees are often the targets of hackers looking for an easy way to access companies’ networks, corporate culture need to take on some of the blame when breaches occur. “Much has been said about cybersecurity hygiene, but without a corporate culture that enforces discipline and supports operational security, the best cybersecurity framework will have an effective lifespan numbered in weeks instead of years,” Popa says.

The challenge is often a lack understanding by employees of the roles they play in the cybersecurity of their company. “The problem is one of communication,” Popa says. “People have different expectations, and if you don’t communicate to them the degree to which they are accountable for what they do with their privileged access, they assume that it is somebody else’s job.”

Seemingly small actions can have a big impact on a company’s cybersecurity, says Brennen Schmidt, principal of ALEUS Technology Group in Regina, Saskatchewan. A Facebook quiz could mean an empty bank account. An employee who plugs into a router to work from home could be the very thing that a hacker uses to bring down the power grid of the company the employee works for.

“Putting up a fence at a job site won’t do much good if the threat is coming through online and out-of-sight channels. It is time to start putting the same level of effort on cybersecurity as companies do on their job sites,” Schmidt says.

Many companies invest in hardware like firewalls to protect a company’s computer network and security cards for staff to get in and out of a building, but overlook the importance of arming those people that use technologies with the understanding and knowledge of the role they play in terms of security and securing their environment.

“Cybersecurity is not just an IT issue,” Thompson says. “It involves the responsibility of operations or infrastructure; it is a full engagement.”

Computer practices that offer the most convenience also present the biggest risk. “Convenience, as I always say, is the opposite of security,” Popa says.

It is vital for companies to impress upon all their staff that security is everybody’s business. “If you are touching anything that is sensitive, that means you have privileged access to technology and resources,” Popa says. “You are a valued member of the company or the organization. As such, you are responsible for everything that you touch.”

MANAGING BYOD

The bring-your-own-device (BYOD) practice has always been a hot topic for debate. For Thompson, BYOD practices also create exponential risk to an organization.

“A lot of these devices coming in have downloaded various amounts of apps that are very easy for a hacker to exploit,” she explains. “If you look at the most secure environments in terms of national intelligence, national security, they do not allow any kind of BYOD device be within the walls of their organization.”

Just the camera feature on a phone can create incredible risk for an organization — taking pictures of surrounding infrastructure, the technology and confidential files. “There is a lot of power for good, and a lot of power for not so good, in a handheld device,” Thompson notes.

Dodunski says managing cyber risks is all about visibility. “You need to be watching how people interact with your data, how people interact with your digital resources, and you need to understand what’s normal and what’s abnormal. If you cannot see that a new device has been brought into the network and is starting to download every file off of your file share, then you are going to be in trouble,” he says. “But BYOD certainly makes it that much more difficult, because everything you are bringing in is potentially another threat actor.”

According to Popa, BYOD is typically an indicator of risk maturity in an organization. “An organization that has the right cybersecurity framework in place will be just as secure with or without BYOD,” he says. “An organization that does not have a proper framework in place will be very vulnerable by the adoption of bring-your-own-device practices, because if they don’t have controls to enforce proper practices, then every single device will be different, and every single device will be at a different threat factor.”

Popa stresses that the main safety check to address the risk of BYOD is to have a standardized framework of controls in place. Cyber-risk assessments need to be conducted as part of an effective cybersecurity program, but they should be broken up into phases to maximize their effectiveness.

“An organization-wide assessment is a lot to do at one time, and the value of a point-in-time assessment is limited, leaving large gaps for exposures to creep in during the year,” Popa explains. “Risk assessments should be performed monthly or quarterly and add up to a complete cycle of security, and privacy assessments completed every year.”

cilitate the process and take things from there,” he says. “It is no longer a confusing process, but a straightforward activity that should be adopted by all organizations.”

Schmidt stresses that communicating cybersecurity risks with the necessary team members is vital before a breach takes place. “It is best to get a crisis-response team in place ahead of a breach so everyone has an idea how they are to respond,” he suggests. “A failure to notify customers, regulators and other third parties could prove costly, especially if a breach involves information or activities which span multiple borders.”

Dodunski concurs that an incident response plan is necessary for every organization. “If you are taken down by ransomware, are you still going to be in business 30 days later? Are you prepared for that? Business-continuity planning, disaster response and incident-response planning is an essential piece to the overall cybersecurity program you have.”

Since November 1, 2018, most organizations are subject to The Personal Information Protection and Electronic Documents Act (PIPEDA), which requires organizations to report to the Privacy Commissioner of Canada any breaches of security safeguards involving personal information that pose a real risk of significant harm to individuals. They must also notify the affected individuals about those breaches and keep records of all breaches.

“Employees are still the weakest link in most companies’ cybersecurity strategies.”

Spreading cyber-risk assessments over the year also enables the respective processes of auditing policy enforcement and reviewing device configuration, security posture from an external perspective and detective controls to be rolled out month by month. “These are all distinct efforts that should not be carried out simultaneously, because it just ends up being a sweep of noise. And then suddenly, you are looking for the signal in that noise,” he says.

Popa advises companies to inform employees that cyberrisk assessments are being performed. “Don’t do it in a vacuum, and don’t do it independent of your workforce, because they are part of the organization.”

WHEN BREACHES OCCUR

In the event that a cybersecurity breach has occurred, Popa says all suspected incidents should be brought to the attention of an appointed risk manager within an organization.

“If it is identified as a data breach, the company’s cyberinsurance company will appoint a breach coach who will fa-

“It was a law that should have come 20 years before and, unfortunately, it came 10 years after it was enforced in the United States,” Popa says. “It is going to be very difficult to catch up.”

Canada has been seen as an oasis for hackers because of the ignorance and apathy, and the lack of capability around detecting breaches,” adds Popa, who attributes this primarily to a lack of incentives in detective controls. He cautions that Canadian companies that are not investing in security today will no longer be competitive tomorrow.

Educating employees on cyber risks and how their actions and online practices can make their company vulnerable to cyber attacks is an important element of a cybersecurity-awareness program. For such a program to be effective, “it needs to be applicable, interactive, accessible, enforced and maintained,” Popa says. “Its monitoring and enforcement must be distributed in nature so that everyone can participate in its health and effectiveness.”

He expects cybersecurity in Canada will eventually improve, but not without heading down the curve first, particularly over the next 18 months.

“I imagine some companies are just going to go out of business because they literally have not been planning for the kind of investment they need to make in cybersecurity,” Popa speculates. “But certainly, the next 18 months will present the inflection point in the risk maturity of Canadian businesses.”

Follow us on Twitter @OHSCanada

Andrew Snook is a writer in Toronto.

AVOIDING COMBUSTIBLE DUST MISTAKES

BY JEAN LIAN

Combustible dust, which is a mixture of fine solid particles that are liable to catch fire or explode upon ignition when dispersed in the air, is a hazard common to many industries. Woodworking facilities, chemical manufacturing, food production, grain elevators and any facility that manufactures or processes sugar, flour and metal are workplaces where combustible dusts are present.

While well-intentioned companies try their best to manage explosive dusts in their facilities, many make mistakes that render their hazard-mitigation ineffective — even costly.

In 2018, there were 194 dust fires and explosions resulting in one fatality and 39 injuries in North America, compared to 145 dust fires and explosions resulting in six fatalities and 52 injuries in the previous year, according to Jason Reason, director of combustible dust services with SEAM Group in Indianapolis.

While conducting a dust-hazard analysis (DHA), implementing controls and documenting the effectiveness of the preventive measures taken is a good process to follow, “there are a lot of mistakes that occur,” says Reason, who spoke at Safety 2019 in New Orleans on June 10. “Most of the time, it is possible to avoid these mistakes.”

Some common combustible-dust mistakes are as follows:

IGNORANCE ABOUT DUST HAZARDS

The most common mistake is not knowing the hazards of the dust present in a workplace. “Wood dust is not wood dust; corn is not corn,” says Reason, adding that there are differ-

ences that affect their explosive properties. He showed a video of sparks emitted each time rain hit iron dust on a filter. “Dust is so small that when water hits it, it actually sparks. And this is just plain iron dust coming out of a steel shop.”

Testing is necessary to know if combustible dust is present and what type of dust it is, so that appropriate safety measures can be taken. “This is why knowing your dust becomes invaluable,” Reason says. “Whatever test data you have is going to affect the next step.”

NOT UNDERSTANDING A DUST-HAZARD ANALYSIS

According to Reason, many people do not understand what a DHA is. So what exactly is a DHA? “Let me tell you what it is not,” he says. “It is not dust testing,” which indicates whether combustible dust is present in a workplace, but does not tell you whether or not you have a hazard. “The DHA is going to tell you if you have a hazard.”

A DHA is a systematic review to identify and evaluate the potential fire, flash fire and explosion hazards associated with the presence of one or more combustible particulate solids in a process or facility. Reason describes a DHA as a road map to hazard mitigation and shows a company what it needs to do to mitigate the risk. An effective DHA will gather and review information, conduct onsite visits to observe processes, evaluate risks and safeguards, issue a report with detailed recommendations and provide a finalized report based on feedback and comments.

Elements of an effective DHA include looking at the fol-

lowing: sources of ignition and industrial ventilation systems; dust testing and dust reactivity; environmental health and safety programs and policies; housekeeping and cleaning methods; fire-protection, explosion-protection and prevention systems; preventive maintenance programs; emergency egress; and personal protective equipment.

A DHA that is done right can yield five to 10 times return on investment in the form of savings from unnecessary controls and sometimes increasing productivity, he adds.

UNDER- OR OVERTESTING

The other common mistake is not doing enough testing or overtesting. Testing may not be required where reliable inhouse, commodity-specific testing data or published data of well-characterized samples are available. But the absence of previous combustible-dust incidents cannot be used as a basis for deeming a dust to be non-combustible.

As there are easily a dozen types of dust tests out there, Reason advises companies that may have combustible-dust hazards on their premises to conduct a DHA from scratch.

“What you are trying to do is to figure what is the minimum number of tests you need to do and the minimum number of samples you need to take to do whatever it is you are trying to do,” he says.

THE IMPORTANCE OF A QUALIFIED PERSON

if an individual is qualified to perform a DHA: the experience the individual has that qualifies him or her to perform a DHA; how many DHAs he or she has performed; has the person performed a DHA for similar processes; can the person provide references from previous companies they have conducted DHAs for and provide a sample DHA report; and who will be performing the DHA, or will it be outsourced to a third party.

Asking the individual to describe the DHA process is also a good indicator of their knowledge and experience in this area. “Unfortunately, there is not a prescriptive way to do it. There is a lot of wiggle room in this,” Reason says.

It is also important to read the report that follows a DHA and determine whether it will address existing problems and if the recommendations can practicably be acted upon.

TESTING RAW MATERIALS