After burning its last piece of coal, OPG Atikokan begins the transition to pellet power.

B.C.’s Pacific Carbon Trust is leading the development of the bio-coal industry.

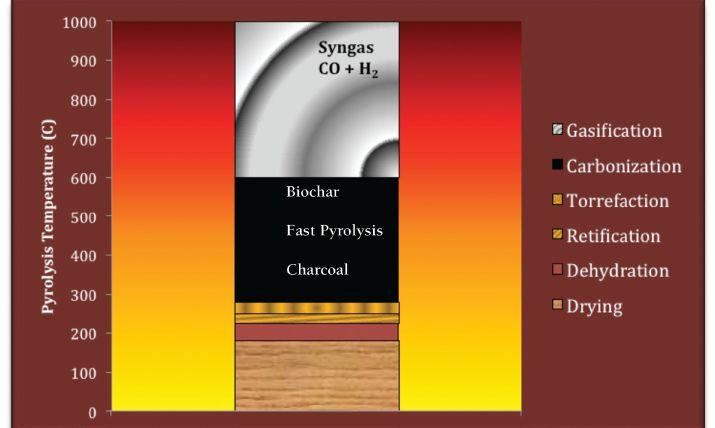

Temperature determines the state-of-matter yielded by pyrolysis: torrefied biomass, bio-oil, biocarbon or gas products.

From lignin to biofuels, CRIBE has accomplished much in four years.

Recent criticism of the biomass industry doesn’t add up once you look at the facts.

wo steps forward, one step back. As the biomass sector continues to move forward as an important tool in the fight against climate change, there have been recent attacks that biomass is “dirtier than coal,” an argument most thought behind us.

Recently in the U.K., government plans to subsidize wood-fired power stations have drawn the ire of environmental groups such as Greenpeace that say power stations that burn trees can be more damaging to the environment than coalfired generating plants and lead to carbon debt.

Response from the industry has been swift and emphatic. With input from the Wood Pellet Association of Canada and the BC Bioenergy Network, the European Biomass Association (AEBIOM) issued a statement regarding the sustainability and carbon neutrality of biomass.

He also argued that it’s wrong to claim that biomass leads to “carbon debt.”

“With sustainable forestry and the use of a mixture of biomass sources, carbon debt can be avoided altogether. Many forests around the world are actually in carbon credit as a result of better management linked to biomass energy use.”

Greenhouse gas emissions regulations are also playing a role at home in providing Canadian pellet producers an opportunity to grow the domestic market by supplying coal power plants, which have to meet new emissions regulations, starting in 2015.

According to Dr. Chuck Ray, an associate professor of wood operations at Penn State University, the rhetoric the biomass industry is hearing from NGOs might sound familiar.

“Choosing fossil fuels over biomass does irreversible damage to our climate and limits society’s opportunities to switch to renewable energy. Leaving unmanaged forests, however, is a poor option as it would deepen the carbon debt created by prolonged burning of fossil fuels.”

Paul Thompson, head of policy at the Renewable Energy Association (REA) in the U.K., which is part of the “Back Biomass” campaign, told the media that even when the biomass supply chain is factored in, its carbon footprint is dwarfed by that of coal, something the government is well aware of. That is why as part of its 2011 Renewables Obligation Banding Review, Britain’s government suggested biomass energy could contribute up to 21% of its renewable energy goals by 2020.

In this issue’s Final Thoughts column (page 30), Ray argues that misleading information about sustainable forestry, bioenergy and how the carbon cycle works is, unfortunately, all too prevalent.

“In fact, the use of misleading “carbon deficit” accounting seems to be just the latest angle at stopping forest harvesting, period. Just like “clearcutting” in the 1980s and “endangered species” in the ’90s, “carbon deficits” is the cause célèbre for those who would like to see a day when no forest tree is ever cut down. But this too will pass, and in the end, we’ll benefit from the knowledge gained by further, more balanced research into the workings of forest ecosystems and the carbon cycle.” • John Tenpenny, Editor jtenpenny@annexweb.com

Volume 5 No. 6

Editor - John Tenpenny (905) 713-4351 jtenpenny@annexweb.com

Associate Editor - Andrew Macklin (519) 429-5181 amacklin@annexweb.com

Editorial Director/Group Publisher - Scott Jamieson (519) 429-3966 ext 244 sjamieson@annexweb.com

Contributors - Monica Bailey, Robin Brunet, Gerald Kutney, Gordon Murray, Dr. Chuck Ray

Market Production Manager

Josée Crevier Ph: (514) 425-0025 Fax: (514) 425-0068 jcrevier@annexweb.com

National Sales Manager

Ross Anderson Ph: (519) 429-5188 Fax: (519) 429-3094 randerson@annexweb.com

Quebec Sales

Josée Crevier Ph: (514) 425-0025 Fax: (514) 425-0068 jcrevier@annexweb.com

Western Sales Manager

Tim Shaddick - tootall1@shaw.ca Ph: (604) 264-1158 Fax: (604) 264-1367

Media Designer - Emily Sun

Canadian Biomass is published six times a year: February, April, June, August, October, and December.

Published and printed by Annex Publishing & Printing Inc.

Printed in Canada ISSN 2290-3097

Circulation

Carol Nixon

e-mail: cnixon@annexweb.com P.O. Box 51058 Pincourt, QC J7V 9T3

Subscription Rates: Canada - 1 Yr $49.50; 2 Yr $87.50; 3 Yr $118.50

Occasionally, Canadian Biomass magazine will mail information on behalf of industryrelated groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above..

No part of the editorial content of this publication may be reprinted without the publisher’s written permission ©2012 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

www.canadianbiomassmagazine.ca

The National Research Council of Canada (NRC) achieved a major milestone for the aviation industry Oct. 31 as it flew the first civil jet powered by 100% unblended biofuel.

This historic flight symbolizes a significant step not only for the aerospace industry, but also towards advancing sustainable sources of renewable energy, said the NRC.

“Today, I flew the world’s first 100% biofuel flight,” said Tim Leslie, one of NRC’s pilots. “We have been working hard with our partners for many months, and it is most rewarding to see it all come to-

gether. It is truly inspiring to take this step towards an eco-friendly future.”

The biofuel flowed into the engine of the Falcon 20 – one of NRC’s specifically equipped and best-suited jet for this challenge – as it flew over the sky of Canada’s capital. A second aircraft, the T-33, tailed the Falcon in flight and collected valuable information on the emissions generated by the biofuel. Research experts at the National Research Council will analyze this information to better understand the environmental impact of biofuel. Preliminary results are expected to be released in the following weeks.

The U.S. surpassed Canada as the largest wood pellet exporter in the world in the first half of 2012.

According to the North American Wood Fiber Review (NAWFR), the expansion of wood pellet capacity in the U.S. South over the past few years has enabled it to export more pellets than Canada, making the U.S. the largest exporter in the world.

With continued investments throughout the southern U.S., export volumes are forecast to increase from an estimated 1.5 million tonnes in 2012 to 5.7 million tonnes in 2015.

The report said pellet exports from the two primary pellet-producing regions on the North American continent, the U.S. South and British Columbia, have continued to grow, reaching a new record high of 760,000 tonnes in the second quarter of 2012, according to data from the pellet industry and customs statistics compiled by (NAWFR).

Total Canadian exports to Europe in the second quarter rose 14% from the first quarter, with reports of B.C. pellet plants running at full capacity thanks to European demand. Pellet plants in Eastern Canada also continued small but frequent shipments over the Atlantic.

Three companies announced plans for constructing pellet plants in the state of Georgia in the third quarter of 2012. With six other pellet export plants already under construction and scheduled to begin operating in regions as widespread as Virginia to Texas, it is possible an additional 4.2 million tonnes of wood pellets will be crossing to Europe in 2015. This can be compared to an estimated 1.5 million tonnes likely to be exported from this region in 2012 as reported by NAWFR.

Exports from both Eastern and Western Canada are also on schedule to grow, though not at the explosive rate being witnessed in the U.S. South. Several new Canadian pellet facilities, such as Holbrook Forest Products in Roddickton, Newfoundland, have expressed their intentions to export pellets, but have yet to do so for various reasons, including inadequate export dock facilities.

n SARNIA, ON

Woodland Biofuels’ $12-million demo plant could be producing ethanol from wood waste by the end of the year, says president Greg Nuttall. The facility is located at the Western University Research Park’s Bioindustrial Innovation Centre in Sarnia. The demonstration plant will knit together what the company says is a series of proven technologies to make fuel ethanol from wood waste. “We will show, we think, a projected commercial cost of production that is significantly less than what it currently costs oil companies to produce a gallon of gasoline,” Nuttall said.

n MONTREAL, QC

Tembec officially launched a new steam turbine, driven by a biomass boiler, at its Tartas mill in France. According to Tembec, the new turbine, driven by a biomass boiler, will increase the Tartas mill’s production of green electricity and improve its energy self-sufficiency, while surplus green electricity will be sold to the EDF utility. All this will reduce costs for the Tartas mill, improving Tembec’s competitive position in the highgrowth specialty cellulose industry.

n HAMILTON, ON

Biox Corporation announced it has temporarily suspended production of biodiesel at its Hamilton facility based on the existing conditions within the U.S. biodiesel market. The company will monitor biodiesel market conditions, including biodiesel production volumes as well as trading liquidity and pricing, to determine the appropriate time to resume production. During the temporary suspension of biodiesel production, Biox will continue to operate the recently commissioned stand-alone glycerin refinement system to upgrade crude glycerin in inventory to technical grade glycerin.

Summit speakers debate the likelihood of large-scale biofuel production.

By Robin Brunet

Willwe ever achieve largescale biofuel production? That was the question that kept resurfacing amongst the 100-plus speakers during the five plenary sessions and four breakout tracks that made up the seventh annual 2012 Pacific Rim Summit on Industrial Biotechnology and Bioenergy, held in Vancouver between Oct. 9 and 12.

Prior to the summit, Biotechnology Industry Organization’s Industrial & Environmental Section executive vice-president Brent Erickson set the tone for the proceedings by telling the press, “The con-

tinued progress in industrial biotechnology toward commercial applications is a vital step in building a growing bio-based economy that can strengthen economic security and enhance energy security.”

That indeed became a main point of discussion during two key plenaries: “Flying Green: Why Airlines See a Bright Future in Biofuels,” and “Overcoming Regional Biomass Feedstock Supply Challenges with Public Policy and Science.”

In the former plenary, Warren Lampitt, general manager of technical programs for Air Canada, described the critical importance of drop-in fuels to his industry and

noted that “we need a feedstock chain that assures economically sustainable yields –because we can’t afford to pay premiums for biofuel, not if we are to fly in meaningful volumes.”

Steve Fabijanski, chief executive officer of Agrisoma, told speakers (including Sean Newsum, project manager for Boeing Commercial Airlines) that his company may have a solution. Agrisoma’s Resonance biofuel, a derivative of the brassica carinata oil seed, grows in harsh conditions; it’s currently being harvested on 6,700 acres in 27 North American locations and out-yields all other alternatives. “With Resonance, Canada’s

A worldwide leader in size reduction technology, Vecoplan works with individual customers to design, engineer, manufacture and implement technologically advanced, material specific, and application specific shredding, ferrous and nonferrous removal, size and density separation, screening and classification technologies and extremely efficient conveyor and bulk material handling, metering, storage and unloading technologies.

Contact Vecoplan today to learn more about our existing systems or to arrange a visit to one, or several, of our installations.

great rail system and processing and storage facilities, this country can be a leader in making biofuel viable on a commercial scale,” he said.

Lampitt, with reference to Air Canada’s goal of carbon-neutral growth from 2020 onward, remarked, “If you grow it, we will fly it.”

Newsum outlined Boeing’s two-pronged approach to reducing carbon emissions, which consists of building more efficient airplanes and increasing operational efficiency. But he stressed that sustainable and affordable biofuel is a key factor that will enable his industry to continue growing.

Moderator Ross MacFarlane, senior advisor of business partnerships for Climate Solutions, was even more outspoken. He cited cost, conflict and climate as the three main drivers for aviation biofuels and stated that the political and economic instability of fossil fuels has rendered vulnerable “the profitability and even the survivability” of airline companies.

He went on to note that although great strides have been made in biofuel test usage, some airline companies have transitioned to early commercial flights: “We now need to set up a feedstock chain from end to end

. . . we want to have 1,500 flights a day powered by biofuels, not 1,500 a year.” The speakers were united in the conviction that government can create policies to ensure that aviation fuels are not at a disadvantage, as well as maintain a stable policy environment to give investors confidence in continuing to pursue advanced biofuel development.

At the “Overcoming Regional Biomass Feedstock Supply” plenary, discussion focused on the fact that while the timber supply in North America has increased by over 60% in the past 60 years and therefore biomass supplies are abundant, it remains a low-value, high-cost market.

Anna Rath, president and CEO of biomass crop producer Nexsteppe, suggested that while the volumes of biomass necessary for commercialization may exist on home turf, the ability to process huge volumes is problematic. “Many companies are locating in Brazil due to that country’s facilities and experience,” she said. However, she predicted the same wherewithal will develop in North America “in the long run.”

The Canadian government’s potential to assist in the commercialization of bio-

mass production was debated. “The marketplace must be allowed to work,” said Linda Beltz, director, technology partnerships, for Weyerhaueser, adding that since global energy demand will increase by 50% by 2035, “all types of biomass have to be made available and useful.”

Michael Rushton, chief operating officer for Lignol Innovations, said that without government assistance “we wouldn’t be as far along as we are now.” However, “incentives provided by government have been inconsistently applied and influenced by interest groups.” Potential biomass players, he concluded, “are staying away until that landscape has settled.”

For his part, Rushton reminded audiences of a familiar impediment to widescale biomass production. “A lot of folk simply don’t believe that forests are sustainable,” he explained. “Peoples’ backs get up when they hear that new parts of a forest are opened up for logging.”

Erickson views the Vancouver event, which attracted over 300 attendees, as an unqualified success. Next year’s Pacific Rim Summit will be held in November in San Diego. •

By Gordon Murray

he mood in Europe was positive in October as I joined over 300 attendees at the 12th Pellets Industry Forum. This annual event – formerly held in Stuttgart – made its debut this year in Berlin. The industrial pellet market for large scale installations and power stations is primarily where the industry is experiencing growth in Europe, although some also point to an upward trend in the private heating market. Participants included power utilities, trading companies, pellet producers, equipment suppliers, engineering consultants, universities/technical institutes, and government representatives.

Some of the main themes of the event included developments in the industrial and heat markets; developments in boiler and stove markets; evolving sustainability requirements in the European Union; and logistics and technology. I gave a presentation in which I discussed logistics challenges for Eastern Canadian pellet producers shipping to Europe and described opportunities for pellet buyers to take advantage of surplus pellet supply in Eastern Canada. Interested readers can find this presentation at www.pellet.org/publications.

Ekman Group is the marketing agent for Vyborgskaya Cellulose, the 900,000-tonnes-per-year pellet plant near St. Petersburg, Russia. Ekman vice-president Arnold Dale gave an update on developments in the international pellet market, noting, “Many people believe that industrial pellets are of inferior quality to domestic markets. This is simply not true.”

He went on to say, “Politically driven rapid growth is creating uncertainty. However, I expect that the global market will reach 80 million tonnes by 2020, with the U.K. alone accounting for 25-30 million tonnes.”

Dr. Martin Junginger, a professor at the University of Utrecht in the Netherlands, reviewed his recent study on the carbon

payback from wood pellets sourced in the Southeast U.S. He told the audience, “The fact that bioenergy is ultimately renewable is not debated, but the time until repayment of any carbon debt is under debate.”

Junginger discussed his modelling of the life cycle of pellets made from lowgrade logs from Georgia pine plantations. He accounted for harvesting, transportation, pelletizing, ocean shipping, combustion at the power plant, and subsequent forest regrowth at both the stand-level and the landscape-level. He concluded, “Stand level analysis shows a modest carbon repayment time of between five and 11 years depending on site productivity, while analysis at the landscape level shows practically no carbon repayment time at all.”

Peter-Paul Shouwenberg of RWE Essent gave a presentation on developments in sustainability certification for industrial pellets. He noted, “Sustainability is a prerequisite for the further growth of biomass use for energy. We have already been confronted with various issues such as the high price of biomass and its complex technology. However, problems around sustainability of biomass have had enormous impact, negatively influencing the bio-based reputation.”

Shouwenberg reviewed recent efforts by power utilities to demonstrate sustainability and concluded by saying, “Utilities, pellet associations, and inspection companies will be working together to develop and implement an industry-wide sustainability scheme by September 2013 to replace existing company-specific schemes.”

Harold Arnold of U.S.-based Fram Renewable Fuels was not convinced of the need for certification: “I acknowledge the good intention of sustainability certification, but believe that it could result in reduced trade and would not necessarily accomplish what was intended. In the U.S. we have many small land owners – 55,000

in the southern U.S. alone – so forest certification is not practical. The U.S. already has strong sustainability laws and many regulatory authorities enforcing these laws and there are criminal charges for noncompliance.”

Arnold explained that unintended consequences of sustainability certification could be “…more corporate owned plantations; exclusion of residuals as feedstock; and jeopardized economic sustainability –all leading to weakened industry growth.”

Hugo Du Mez outlined the Port of Rotterdam’s ambition to become the major biomass transportation hub for Europe: “The Port of Rotterdam is the number 5 port globally and number 1 in Europe. Our port handled 435 million tonnes of cargo in 2011. We have been very successful in becoming a transportation hub for the thermal coal market and would like to do the same for biomass. Rotterdam is ideally situated to serve power plants in the Netherlands, the U.K., Belgium and Denmark, and heat markets in Germany.”

Martin Bentele of the German Wood Fuel and Pellet Association described the German market: “The German forest area is 11 million hectares. Sawmills produce 10 million tonnes of sawdust and wood chips. Sixty pellet plants will produce two million tonnes of pellets in 2012.”

He went on to say, “Germany is almost 100% a heat market. Our advantage is that pellets cost 40% less than heating oil. We are happy serving the heat market and we are completely opposed to wood pellet cofiring in power utilities.” •

Gordon Murray is executive director of the Wood Pellet Association of Canada. He encourages all those who want to support and benefit from the growth of the Canadian wood pellet industry to join. Gordon welcomes all comments and can be contacted by telephone at 250-8378821 or by e-mail at gord@pellet.org.

By Monica Bailey, Director, FPAC

he forest products industry is hiring. That may surprise many people who have associated the sector with cutbacks and mill closures. However, after some difficult years, the industry has turned the corner and is once again offering solid careers.

The forest products sector now has a green and growing future. As we have previously mentioned in these pages, the Forest Products Association of Canada (FPAC) has unveiled Vision2020, an ambitious plan to propel the industry forward by improving its environmental performance by 35%, by generating an additional $20 billion in economic activity from new products and markets, and by renewing its workforce with 60,000 recruits including women, indigenous peoples and new Canadians.

The 21st-century forest products industry requires techno-savvy, innovative trailblazers who care about their future, the

environment and quality of life. There is no better example than FPAC’s first recipient of the Skills Award for Indigenous Youth, Baillie Redfern. Baillie is a young Metis and graduate researcher at the University of British Columbia in the field of medicinal plant genomics. Her work focuses on the development of new bioproducts from balsam fir, including pharmaceuticals and cosmetics.

Creating smart, green, everyday consumer products from wood fibre is just one of many career avenues available in the forest products industry. In fact, no matter where in the business you work – on the mill floor as a mechanical engineer, or in the forest as a forestry technician – the jobs are part of the greenest industry in Canada.

That’s because unlike minerals and oil, forests are renewable – we are part of nature’s cycle and regenerate whatever is harvested. The forest industry has worldclass environmental credentials, including

the most certified forests in the world, a decrease of more than 70% in greenhouse gas emissions since 1990 and a partnership with environmental groups under the Canadian Boreal Forest Agreement. The sector is producing more and more bioenergy at mill sites and selling excess electricity to the grid. And the list goes on.

There is also a long list of jobs to be filled – millwrights, electricians, international sales staff, truck drivers, foresters, chemists, engineers and more. A major challenge remains the need to compete with other sectors, especially the oil patch for skilled labour. To attract workers, the sector intends to highlight its impressive track record for accommodating work-life balance, which includes flexible work hours, skills and training development, career growth, community life, and the ability to have dinner at home should you want to without the burden of flying off to work camps.

Still, we recognize the need for additional strategies to reach out to women, aboriginals and new Canadians. Look for a new initiative to be announced early next year, expected in February at the Paper Week job fair in Montreal. Let there be no doubt – Canada’s forest products industry is on the move and eager to welcome new employees to be part of Canada’s greenest workforce.•

Monica Bailey is director, communications and member relations, for FPAC. She is responsible for the strategic development and implementation of FPAC’s communications, new media, marketing and promotions activities.

FEATURES OF BEAST® RECYCLERS: PATENTED CUTTERMILL SYSTEM AVAILABLE AS TRACK OR TOWABLE UNIT KNIFE SET-UP FOR CHIP PRODUCTION ALSO AVAILABLE WITH ELECTRIC MOTOR THROWER ATTACHMENT FOR END-LOADING

Experience for yourself the economic benefits that the Beast® can bring. No other grinder offers the versatility and range of end products like the Beast! The uniformity of the product is a result of the Beast’s unique patented cuttermill system, which allows you to cut, split, grind or chip material in a single pass. A more uniform product means lower fuel production costs! Drive one of our track Beasts to the material, and drive down your biomass fuel costs. With four models to choose from and engine options up to 1,200-horsepower, you can’t go wrong.

When it comes to the grind, don’t get left behind. Find out why Bandit horizontal grinders outperform the competition everytime.

By John Tenpenny

developing a next-generation clean tech system requires just the right combination of circumstances, and proving that the technology works is just the first step.

The tougher challenge is commercialization and that means finding partners willing to risk significant amounts of capital and convincing them of the benefits of the project.

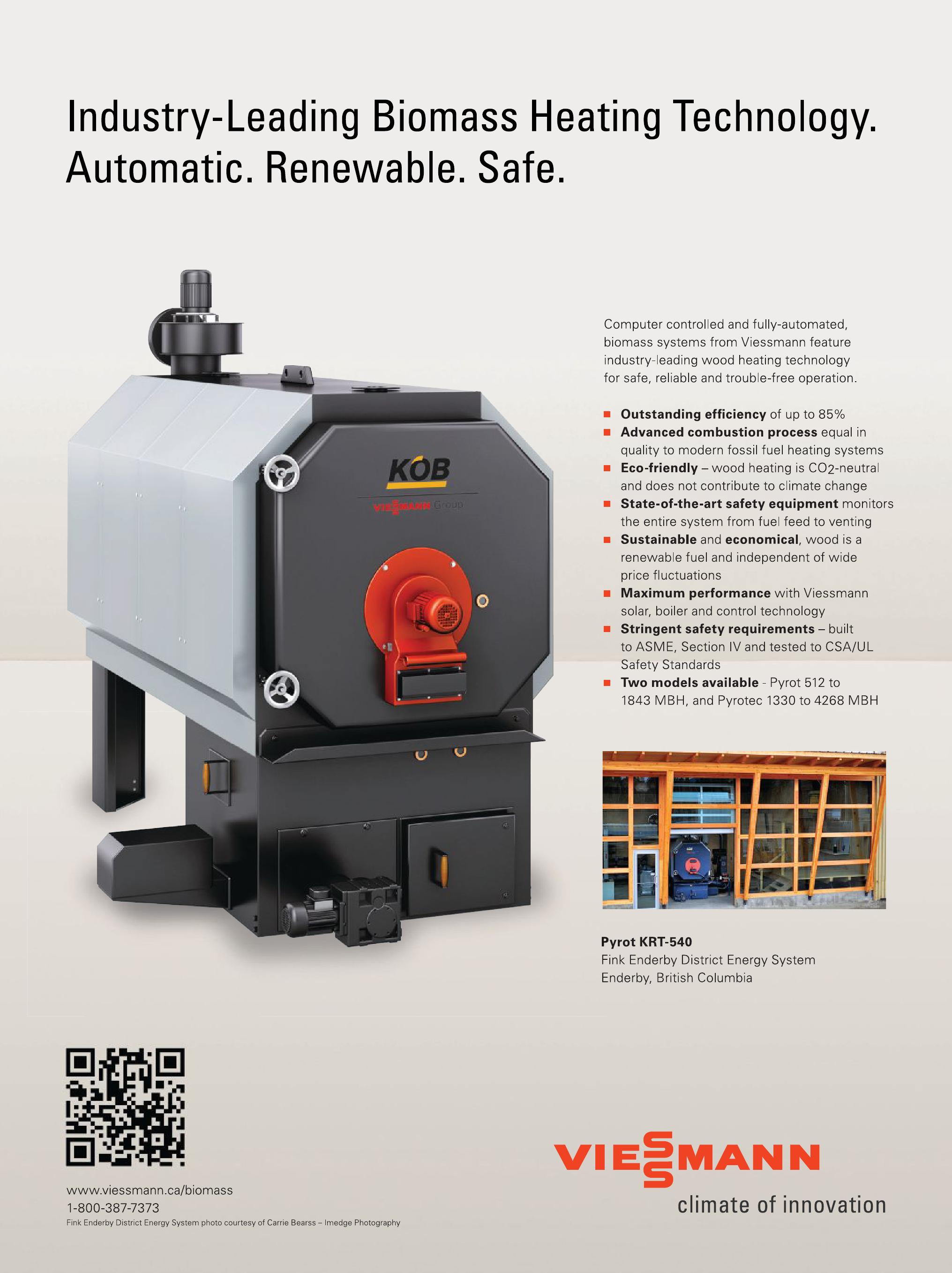

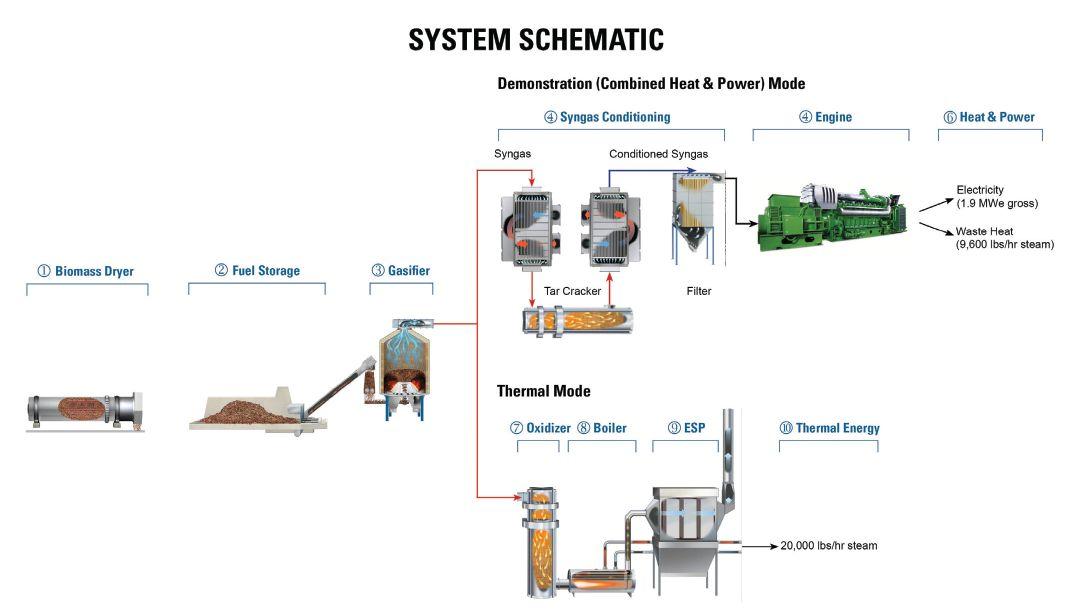

The perfect storm seems to have gathered on the UBC campus in Vancouver, where the university has partnered with Nexterra Systems, GE and others to launch an energy-from-renewable-waste combined heat and power (CHP) system. The project combines Nexterra’s first commercial demonstration of gasification and syngas conditioning technology with GE’s high-efficient Jenbacher internal combustion engine (IC) to generate electricity.

Officially named the Bioenergy Research and Demonstration Facility (BRDF), the $34-million project is the first development to produce economic, community-scale heat and power using an IC engine fuelled by biomass. Langley-based Cloverdale Fuels delivers two to three truckloads daily of locally sourced biomass, consisting of tree trimmings and wood chips diverted from local landfills.

The CHP system has two main operating modes. The first, “thermal-only mode,” uses commercially proven gasification technology developed by Nexterra to turn biomass into a clean synthesis gas, or “syngas.” The syngas replaces natural gas used to produce steam and hot water to meet campus heating needs.

In the second, “demonstration mode,” the syngas is conditioned to remove impurities such as tar that would normally “foul” the internal combustion engine, then cooled, filtered and injected into the GE Jenbacher gas engine that drives the generator to produce electricity. Additionally, heat from the engine is recovered and directed to the district heating system. The system will deliver global electrical efficiencies that are 25% higher than traditional methods of producing biomass-based electricity at this scale.

The thermal system can handle biomass moisture content above 50%, whereas the demonstration system requires the biomass to be dried until the moisture content reaches 25% or less. It takes a particle of feedstock approximately an hour to transit the system.

The electricity produced will feed into UBC’s power grid, which will result in revenue to UBC through a “displaced load agreement” with BC Hydro. UBC is BC Hydro’s second largest customer.

GE’s Jenbacher gas engine will produce 2 MW (megawatts) of

LEFT MAIN: Nexterra’s gasification system converts wood residue into syngas.

FROM LEFT TO RIGHT: Nexterra’s syngas thermal cracking/conditioning system feeds the GE internal combustion (IC) engine; Cloverdale Fuels of Langley drops off two or three truckloads of waste wood each day at UBC’s Bioenergy Research and Demonstration Facility (BRDF); the fourstorey BRDF building was constructed using cross-laminated timber (CLT).

DEMONSTRATION (CHP) MODE

1. Biomass Dryer – dries “wet” (e.g. up to 55% moisture content) biomass to 20% moisture content.

2. Fuel Storage – wood residue delivered to storage facility and conveyed to gasifier.

3. Gasification Technology – gasification process converts wood residue into clean, renewable synthetic gas or “syngas.”

4. Syngas Conditioning Technology – syngas is conditioned and upgraded to meet fuel specification for engine.

5. Engine – high-efficiency internal combustion engine operates on syngas instead of natural gas to generate electricity and heat.

clean, renewable electricity that will offset UBC’s existing power consumption, enough to power approximately 1,500 homes. The engine system will also generate 3 MW of thermal energy, enough steam to displace up to 12% of UBC’s natural gas consumption. In thermal mode, the system can produe 7 MW of heat. This will reduce UBC’s greenhouse gas emissions by up to 5,000 tonnes per year, which is the equivalent of taking more than 1,000 cars off the road.

“This exciting facility targets a major challenge facing society – the need for new, clean energy solutions that work at a community scale,” said UBC president Stephen Toope. “This is a flagship exam-

6. Heat and Power – system will produce 2 MWe power (4% of current peak use) and 9,600 lb./hr steam, or 12% of what is needed for current campus use.

7. Oxidizer – the syngas is conveyed into an oxidizer where it is combusted, with the resulting flue gas directed through a boiler.

8. Boiler – hot flue gas enters the boiler to produce steam for campus heat distribution.

9. Electrostatic Precipitator (ESP) – the flue gas is cleaned in an ESP that filters out virtually all particulate matter.

10. Thermal Energy – system will produce 20,000 lb./hr steam, or 25% of what is needed for current campus use.

ple of UBC as a living laboratory, where researchers, staff, students and partners collaborate on innovations targeting the pressing challenges of our day.”

The startup of the system represents the culmination of more than four years of product development work and collaboration with GE’s Gas Engines business. Prior to installing the gas engine at UBC, Nexterra successfully completed more than 5,000 hours of trials at its Product Development Center in Kamloops.

The project is also noteworthy for its use of wood. The four-storey, 1,900-square-metre facility, conceived by FPInnovations as a pilot demonstration project, is also the first North American commercial application of

cross-laminated timber (CLT), a new solid wood building material that can be used as a low-carbon, renewable alternative to steel frame construction. Designed by McFarland Marceau Architects, 410 cubic metres of CLT panels were used for all load bearing walls and most non-load bearing partitions, suspended floor and roof decks.

Since its founding in 2003, Nexterra’s focus had been perfecting a core gasification technology that would take waste feedstocks and reliably convert them into syngas, says president and CEO Mike Scott. “The idea was to compete against conventional biomass waste combustion systems

and be cleaner and more efficient, with lower operating costs,” he says.

Its first commercial plant was commissioned in May of 2006 at a Tolko plywood mill near Kamloops that produces 38 million BTUs per hour. Since then, Nexterra has delivered six commercial plants in North America.

Shortly after, GE Jenbacher approached Nexterra after looking for a biomass gasification system to feed its engines, and not having much success.

“That’s when we started looking into a gas clean-up technology,” says Scott. “We had to find a way to get the tar out of the gas in a cost-effective and reliable way, and since we couldn’t find a system that worked, we thought we’d be better off developing our own proprietary system.”

After beginning testing, the company signed an MOU (memorandum of understanding) with UBC in 2009. Then the real work began.

UBC wanted to be an early adopter as well as support global companies in the power generation business, and according to Brent Sauder of UBC’s Sustainability Ini-

tiative, partners had to be found in order to get the rest of the project off the ground.

“UBC has its investment based on the performance of the thermal system,” he says. “We then de-risked the rest of the project by getting really good support from the various levels of government.”

Supporting the BRDF at the federal level were Natural Resources Canada and Western Economic Diversification Canada, while at the provincial level, the BC Innovative Clean Energy Fund and the Ministry of Forests, Mines and Lands got involved. Sustainable Development Technologies Canada, the BC Bioenergy Network, the Canadian Wood Council and FP Innovations were also enlisted.

“Something like this does not happen by one company going it alone,” says Scott. “It really does take a village.”

The village included the university community, not just students and faculty, but residents who live in the area.

“Building bridges with the community allowed us to raise their comfort level,” says Sauder. “And knowing Nexterra had a track record on emissions gave us the

confidence that we were going to meet or exceed the city’s air shed requirements.”

A 24-hour air monitoring station on the site backs up his claim. “There’s no way you can tell if the plant is running or not by looking at the data.”

Scott says the company is excited about taking its gas cleanup and thermal cracking technology global and sees potential in international markets where power prices are relatively high, where there are renewable energy incentives and where there is built-in preference for distributed energy.

“We’re seeing interest in the U.K., Korea and Japan,” he explains. “Places that are ‘energy-stranded’ and have to import liquid natural gas.”

Although low natural gas prices in North America have had a chilling effect on renewable energy, Scott believes Nexterra may yet get an opportunity to replicate the system closer to home.

“There is a reasonable chance that over the next three to five years, a lot of natural gas in North America is going to be shipped offshore and we may see prices

After burning its last piece of coal, OPG Atikokan begins the transition to pellet power.

By Andrew Macklin

Whenthe Ontario government introduced the Green Energy Act in 2009, it sought to create a greener economy. The elimination of coal-fired energy generation, targeted for the end of 2014, meant that there would be a need for an increased amount of renewable energy solutions for Ontario’s energy supply mix. But it also meant that it was up to Ontario Power Generation to find new solutions for generating electricity at several key power stations across the province.

“OPG is committed to making sure that all coal-fired plants in Ontario are converted on schedule, by the end of 2014,” said

Chris Fralick, plant manager, northwest thermal for OPG.

One of the four coal-fired generating stations affected by the Green Energy Act and operated by OPG, is located on the outskirts of Atikokan, Ont, a community of close to 3,000 located 200 kilometres west of Thunder Bay. The facility opened in 1985 using coal-fired power generation. At its peak, the generating unit can produce up to 211 megawatts of power. Annually, the plant produces as much as 1 billion kilowatt-hours of electricity, or enough to supply approximately 83,000 homes and businesses for one year. The power supply is primarily used to provide power dur-

ing peak demand times, as well as to back up electricity generation. To generate that much power, the Atikokan facility burns 90,000 tonnes of coal annually.

The coal being used to power OPG’s Atikokan was low sulphur lignite coal, which was being transported by train from Western Canada. The coal was burned in a lignite-fired boiler, which uses recirculated flue gas from the top of the boiler to heat and remove moisture from the coal. Once the lignite is dried, it has the tendency to ignite spontaneously. However, the use of flue gas as the drying method does help to prevent that. Lignite-fired boilers also include the use of special pulverizers that grind the

OPG announced the supplier contract agreements for providing the 90,000 tonnes of pellets per year required for the Atikokan facility.

Atikokan Renewable Fuels, owned by Ed Fukishima, was granted 50% (45,000 tonnes) of the supplier contract. Fukishima will be producing the pellets at the former FibraTech property in Atikokan, which he purchased in 2009 for the purpose of constructing a pellet-production facility with a 140,000 tonnes/year capacity.

Resolute Forest Products will provide the remaining 50% of the supply of the annual pellet supply for OPG Atikokan through its Thunder Bay facility. Within 24 hours of the announcement of the supply contract, RFP announced that it would be constructing a pellet production facility on the site of its Thunder Bay operation.

Both facilities are expected to be delivering pellets to OPG Atikokan before the facility comes online in early 2014.

coal and recirculate the flue gas; these fall into the category of hammermills for grinding soft coal. While the resulting emissions are lower than those of some other types of coal burned for power generation in other parts of the country, the emissions are still greater than what the province was willing to accept under the standards provided in the Green Energy Act.

In August 2010, Ontario’s energy minister directed the Ontario Power Authority to begin discussions with OPG on a power purchase agreement for biomass-produced electricity from OPG Atikokan. After nearly a year of negotiations, on July 19 of this year, it was announced that the power purchase agreement had been reached, and that a conversion project would take place that would see the Atikokan facility make the change from burning coal to burning wood pellets to produce energy for the electricity grid in northern Ontario.

The conversion project is the first of its kind in Ontario, creating the largest capacity 100% biomass fuelled power plant in North America. The total cost of the conversion was announced as a $170-million investment that is expected to create up to 200 construction jobs over the course of the 18-month project timeline.

The total scope of the construction phase involves two major projects: retrofitting the current equipment to convert from burning coal to burning biomass, and building new storage and handling facilities specifically for wood pellets.

“Construction of the new storage and handling facilities will take place on the west side of the plant,” said Al Arnott, director of Atikokan biomass conversion –hydro thermal. “The two new silos being built will have a capacity of 5,000 tonnes each, and that construction will also involve a transfer building, unloading facility and conveyors for moving the biomass to the boiler house.”

OPG recognized several primary benefits for moving forward with the decision to convert the current Atikokan facility from coal to biomass, rather than explore alternative fuel and location options.

One of the most positive results of the decision to convert from coal to biomass is the fact that the employee base for both

operations stays the same.

“The conversion project will mean that jobs are not lost at our Atikokan facility,” said Brent Boyko, manager of the Atikokan Generating Station. “We currently employ approximately 90 people here, and those jobs will be retained as a result of the conversion.”

Second, the conversion project protects the investment already made at the current facility. To date, $700 million has already been invested in the OPG Atikokan generating plant. The current facility already offers enough land for the entire scope of the conversion projects, is completely plugged into the electricity grid and has the primary infrastructure needed for power generation. Those investments are protected by the conversion of the existing site. Construction of an alternative site would have meant losing a large number of those original investments, as well as providing cost increases for the development of a new site.

There is also a strong recognition of the environmental implications of shifting to biomass. OPG understands the reduction of greenhouse gases generated using biomass versus coal. Oxides of sulphur will also be eliminated as a result of no longer using coal, and it is estimated that nitrous oxide emissions will be reduced by close to 60%. Also, OPG hired the Pembina Institute, a Canadian non-profit think-tank that helps to provide sustainable energy solutions, to conduct an analysis of the processing and harvesting of two million oven-dried tonnes of forest-based bio-

mass in Ontario at four OPG coal plants. The study found that production of that volume was sustainable in Ontario and would significantly reduce greenhouse gas emissions at OPG’s coal-fired powergeneration facilities.

In August, the first contractor was announced for the project. Aecon Group Inc. signed a contract with OPG that would give Aecon’s Industrial division control of the design and construction work for the storage and handling facilities. The contract, valued at approximately $85 million, has involved the use of companies familiar with the area, including Taranis Contracting Group of Thunder Bay.

“We are very pleased to be part of this project,” said Ryan Jones, president of Taranis. “We are happy to work with Aecon on the construction of such a significant project for the future of energy generation in northern Ontario.”

In October, the second component of the conversion project was awarded to U.K-based Doosan Power Systems. The full EngineeringProcurement-Construction (EPC) company

was given the contract to implement the electrical, mechanical and instrumentation services for the retrofit of the coal-fired machinery for use in biomass combustion.

One of the primary components of the conversion project is the local sourcing of the biomass that will be provided to OPG Atikokan each year.

“Part of our agreement with the provincial government is that all of the biomass must be locally sourced,” said Fralick. “All of the pellets provided to OPG Atikokan will come from supply agreements with producers in Ontario.”

Previously, the 90,000 tonnes of coal used at the power-generation facility was imported from Western Canada. With this new agreement in place, the money spent purchasing the estimated 90,000 tonnes of wood pellets will stay in Ontario. With current cost-pertonne for pellets sitting at around 130 euros, or $165 Cdn., that equates to $14.85 million in new revenues for the forestry industry in northern Ontario. That’s a strong new revenue source for one of Canada’s most depressed wood products markets.

On Sept. 11, OPG Atikokan burned its last piece of coal. The plant is now shut down while work begins on the conversion of the coal-fired equipment to biomass. However, current electricity demands in the region should allow OPG to meet both residential and commercial power needs with the Atikokan facility shut down.

“The short term demand outlook for power is relatively soft, not near the peaks of the early-to-mid 2000s,” said Fralick. “As a result, OPG Thunder Bay should be able to meet any supply shortfall caused by the temporary shutdown of OPG Atikokan that can’t be met by hydroelectric generation in the region. However, importing power from neighbouring jurisdictions is also an option.”

Work has begun on the construction of the new storage and handling facilities on the west side of the plant as well as on the conversion inside the plant. OPG currently expects that it could be ready to begin accepting biomass by the end of 2013 or, at worst, the first quarter of 2014. •

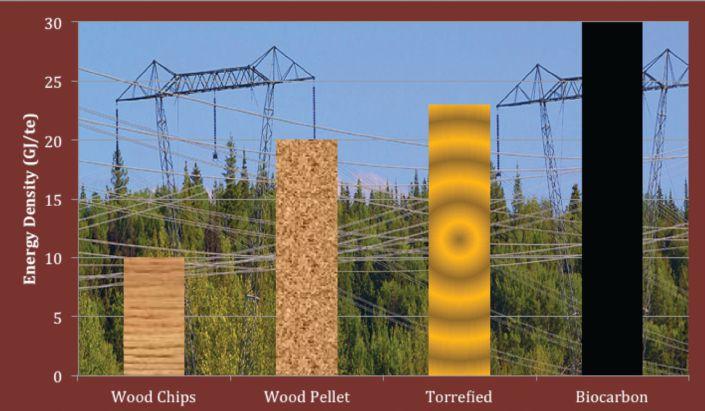

Bio-coal, made from roasted biomass, has comparable energy density to coal but with a significantly smaller carbon footprint.

B.C.’s Pacific Carbon Trust is leading the development of the bio-coal industry.

By John Tenpenny

Sinceits inception four years ago with a mandate to drive the growth of B.C.’s low-carbon economy, Pacific Carbon Trust has retired 1.5 million tonnes of carbon offsets. Now it is expanding its mandate and beginning to stimulate new activities, including the production of bio-coal.

The provincial Crown corporation recently launched a request for proposals specifically to purchase carbon offsets resulting from switching from fossil-fuel coal to renewable bio-coal. It says both bio-coal producers and coal users point to a difficult gap in the pricing between coal and bio-coal, which is why Pacific Carbon Trust is responding to the emerging biocoal industry’s needs by reserving a portion of its offset portfolio for greenhouse gas emissions realized by switching from coal to B.C. bio-coal.

“We are offering to purchase greenhouse gas emissions reductions from fuelswitching projects in B.C. where coal

and other greenhouse gas intensive fuels are replaced by B.C. bio-coal,” says Scott MacDonald, CEO of Pacific Carbon Trust.

“The revenue stream realized by the sale of emissions reductions can support B.C. bio-coal producers in transitioning to full commercial operations.”

By switching from coal – an emissionsintense, non-renewable energy source – to sustainable bio-coal, coal users can reduce the greenhouse gas emissions at their facilities, thereby creating the opportunity to realize offsets for the tonnage of emissions avoided.

According to MacDonald, this allows traditional coal users to both save on the carbon tax applied to coal and generate revenue from offsets through fuel-switching, making the price of bio-coal per tonne on par with that of coal.

“The bio-coal industry, which is the next generation “wood pellet” industry, holds significant export potential and improved competitiveness for B.C.’s existing and growing export biomass industry,”

says Michael Wheedon, executive director of the BC Bioenergy Network.

Bio-coal suppliers are getting financing and lining up supply, but what’s missing, says MacDonald, is a firm price that makes the venture economically viable and Pacific Carbon Trust is trying to fill that gap.

Having a carbon tax is the first step in changing those fundamental economics, he says.

“If you’re burning coal in B.C., you’re paying a carbon tax. If you switch to biocoal you no longer pay the carbon tax and in essence there is a $30/tonne emissions savings. We can compound that by buying offsets. The combination of the two are often enough to kick the economics over the threshold.”

Through its commitment to buy a certain volume of offsets per year, MacDonald says, those burning coal now have the price certainty needed to make the switch to bio-coal. It would also give the suppliers the certainty to open up the supply chain and begin building a supply.

“British Columbia has tremendous potential to become a global leader in bioenergy by supporting the growth of the bio-coal industry,” says Jerry Ericsson, president of Diacarbon Energy Inc., a Burnaby-based producer of renewable fuels. “This RFP sends an important signal to investors that there will be a reliable market for bio-coal, which helps companies like Diacarbon move forward towards commercialization.”

Traditional coal is used extensively in industry in B.C., particularly by cement manufacturers, such as Lafarge, which has previously sold offsets to Pacific Carbon Trust for a fuel-switching project at its Richmond cement plant.

That project saw Lafarge reduce the amount of coal burned by replacing a portion of this coal with biomass and other materials from construction waste, which otherwise would have gone to a landfill.

The company says it is always looking for other ways to reduce emissions.

“Lafarge has many varied sustainability initiatives worldwide geared to reducing our environmental footprint,” says Randy

Gue, director of resource recovery and business development at Systech Development, a division of Lafarge. “We view bio-coal as another potential opportunity to further reduce this footprint by increasing the renewable energy component of our fuel requirements. We look forward to seeing this industry develop into a viable and robust business.”

Bio-coal is created through the torrefaction

•

(French for “roasting”) of biomass that results in a dry, enhanced product with an energy density on par with the energy density of coal. It is a high-grade solid fuel suitable for multi-purpose commercial and industrial use that is easy to transport and store. It has similar characteristics to ordinary coal with the vital difference that it is a clean, renewable resource.

During torrefaction of biomass, the biomass typically loses 20% of its mass but only 10% of its energy content. After being torrefied, biomass can be densified – typically into pellets or briquettes – to further improve its energy properties.

MacDonald says the abundance of biomass available in B.C. in the form of slash piles, mountain pine beetle kill wood and other byproducts of the pulp and paper industry, is one reason B.C.’s emerging bio-coal industry has tremendous potential to meet local demand and become a major international supplier. He cited a report conducted earlier this year by Bloomberg New Energy Finance estimated that there is a need for 700 bio-coal plants worldwide, each with an annual output of 100,000 tonnes over the next 10 years. The report noted Canada is well positioned as a potential supplier.

Pacific Carbon Trust has invested in many greenhouse gas projects as part of its aggressive plan to address climate change, with bio-coal being the just the latest.

“As a supporter of the province’s cleantech sector through innovative emissions reductions projects and technologies, Pacific Carbon Trust has a role to play in the growth of this nascent industry,” adds MacDonald. “Just as we have supported low carbon practices in other B.C. sectors, Pacific Carbon Trust is supporting the creation of a marketplace for this alternative fuel.”

Temperature determines the state-of-matter yielded by pyrolysis: torrefied biomass, bio-oil, biocarbon or gas products.

By Gerald Kutney

Weuse the pyrolysis of biomass every day without realizing it. The roasting and baking of foods are such processes. Common pyrolysis reactors include toasters and barbecue grills. Caramel is produced by the pyrolysis of sugar, and another popular product is roasted coffee.

Pyrolysis is the thermal decomposition of biomass occurring in the absence of oxygen. The products of biomass pyrolysis (Figure 1 on page 22) include torrefied biomass, biocarbon, bio-oil and producer gas (methane, hydrogen, carbon monoxide and carbon dioxide).Depending on the thermal environment and the final temperature, pyrolysis will yield mainly biocarbon at low temperatures, less than

450˚C, when the heating rate is relatively slow, and mainly gases at high temperatures, greater than 600˚C, with rapid heating rates. At an intermediate temperature, but at higher heating rates, the main product is bio-oil.

The choice of one technology over another is often determined by the state-ofmatter of the biofuel that is desired.

The mildest pyrolysis process is torrefaction. During this reaction oxygen-rich compounds are volatilized from the biomass, including non-condensables such as carbon dioxide (80%) and carbon monoxide, and condensables such as water (60%), acetic acid (25%), methanol,

T he Por t of B el ledu ne is your trans PO RT ati on sol uti on to the world !

formic acid and furaldehyde. These products mainly originate from hemicellulose, which is decomposed in the process. Torrefied wood is thus mainly composed of cellulose and lignin. Torrefaction reaction rates are highest in straw, followed by hardwoods and softwoods, but the final properties are similar. The various reaction rates are attributed to the differing hemicellulose structures found in the different types of biomass.

The torrefaction reaction begins at 200˚C, but the practical range is 250˚C to 280˚C. In the torrefaction process, temperature is a more important factor than reaction time, which is typically 30 minutes or less. Care must be taken not to go much higher in temperature as car-

Wood pellets, wood chips, and all forms of wood products are handled at the Port of Belledune; not only does the port connect to strategic shipping routes, it is also an intermodal gateway with a rail spur and direct congestion-free access to a highway system spanning North America. www.po

bonization begins in the range of 280˚C to 300˚C. The temperature is generally the major operational control parameter to determine the properties of the torrefied wood. Higher temperatures generally lead to higher energy densities, but yields decline. An optimum control point is autothermal operations where the energy of

the volatiles is enough to supply the energy of the process.

When first invented, torrefied wood was often called “red charcoal” (charbon roux or Rothkohl) or “brown charcoal.” The word torrefaction, itself, is derived from the French word “torrefier,” which means “to roast.” Research on torrefaction began

in France during the 1830s, and the selfbinding property of torrefied wood was known by the turn of the 20th century; for example a U.S. patent was issued in 1901 to Joshua Gardner on the formation of briquettes of “partially-carbonized” sawdust. Another early American report of torrefaction was by Cleburne Basore in his Fuel Briquettes from Southern Pine Sawdust in 1929.

Today, interest has switched from briquettes to pellets, through development by firms such as ECN and Topell building the first torrefied wood pellet facility in Europe. Overall, when torrefied wood is pelletized, the physical properties are improved:

• The product is water-resistant: can be stored outdoors on a coal pile, and generally does not reabsorb moisture after drying.

• The fibrous nature is reduced and the grindability has been improved.

• Energy density is higher than that of a wood pellet.

• Bulk density is higher than that of a wood pellet, reducing transportation

costs on an energy basis.

• No binder is necessary to form the pellet.

• Biological degradation is greatly reduced.

• Various biomass feedstock can be utilized.

• Uniform quality improves combustibility.

The targeted market for torrefied biomass is the coal-fired power sector. Torrefied wood is being used in Europe, and in North America, where trials have recently been carried out at the GWF Power Systems’ Pittsburg, Calif., petcoke power plant and at the James River power station in Springfield, Mo.

As one goes from a wood chip to a wood pellet to a torrefied pellet to a biocarbon briquette, the general chemical and physical properties of the biomass are transformed more and more into a coallike product. A generic technique to illustrate the chemical properties of various fuels compared to coal is to plot the hydrogen-to-carbon ratio versus the oxygento-carbon ratio of the fuel, which plot is called a Van Krevelen Diagram. The most obvious property is the rise in higher-energy density (Figure 2 on page 24).

Above 300˚C, carbonization of biomass commences and the thermochemical reactions become exothermic (i.e., heat-generating), which drives the higher-temperature pyrolysis with no (or little) external energy being applied. Biomass undergoes major chemical modifications at these higher temperatures.

Carbonization mimics coalification whereby nature converts plant matter into coal. Whereas coalification takes 300 million years, carbonization converts plant matter into charcoal, which has an energy density similar to bituminous coal, in 300 minutes (or less).

As the temperature of pyrolysis increases, mass is lost as oxygen-rich volatiles and the energy density of the remaining solid matter rises. Chemically, the percentage of carbon rises as the oxygen declines. The more carbon (and hydrogen) and the less oxygen that a material contains, the greater its energy density.

The higher energy density of charcoal compared to wood was one reason for its use in early industrial applications, such

as blacksmithing, glassmaking and the iron industry. Currently, global production of charcoal is nearly 50 million tonnes.

A new market for charcoal is emerging as a renewable coal replacement for electricity generation. For industrial markets, the product is called biocarbon instead of charcoal; the latter term is reserved for recreational use. Biocarbon has another role to play in the fight against climate change as it can be used to sequester carbon in the soil. Biochar is the agricultural appli-

cation of biocarbon. When applied to soil, biochar acts as an agricultural catalyst by promoting plant growth, but is not consumed. Since it is a catalyst, its benefits continue for generations to come without further addition. The biochar holds nutrients and fertilizers longer in the soil and provides other benefits encouraging plant growth. At the same time, the carbon has been sequestered or the carbon of the original biomass has been fixed and will not naturally return its carbon into the

Maximum production. Low operating cost. The Bühler RWPR-900 is the ideal pellet mill for your biomass applications. The RWPR was designed with massive roll bearings to withstand the extreme pressures of biomass pelleting. To ensure ease of operation the pellet mill is equipped with a simple V-belt drive system with minimal moving parts. This top of the line pellet mill provides an effective and effi cient pelleting solution. For more information please visit www.buhlergroup.com.

Bühler Inc., PO Box 9497, Minneapolis, MN 55440, 763-847-9900, buhler.minneapolis@buhlergroup.com, www.buhlergroup.com

Heavy Duty Pellet Mill

Maximum Production. Flexible controls optimize process

Low operating costs. Rollers, dies and other wear parts are designed for maximum performance and longevity to increase uptime and profi tability.

Safe operation. A combined overload shear pin and belt slip monitor protect the pellet mill from overloads or foreign material entering the die.

atmosphere. Biochar is one of the most promising agricultural breakthroughs since the discovery of fertilizers.

Producing biocarbon is achieved through the process known as slow py rolysis. Heating the material very quickly, or fast pyrolysis, produces bio-oil, with biocarbon as a byproduct.

Gasification is a pyrolysis process that creates producer gas, a low-energy gas containing mainly carbon monoxide and hydrogen (methane may also be present, especially at lower gasification temperatures). A pioneer in biomass gasification was Philippe Lebon (or Le Bon)

D’Humbersin (1767-1804). In 1801, he put on a light demonstration in Paris that was fuelled by the gasification of wood. Unfortunately, the young entrepreneur was murdered three years later, before he could develop the technology further.

Biomass gasification technologies can be divided into three categories: fixedbed, fluidized-bed and entrained-flow.

Fixed-bed gasifiers use a simple grate system whereby the process begins with a combustion zone that produces carbon dioxide and water; these products are then passed through a reducing zone to produce carbon monoxide and hydrogen. Fixed-bed reactors are usually utilized in systems of less than 5 MW. There are two types of fixed-bed gasifiers – updraft and downdraft – each of which has its advantages. Updraft gasifiers are a simple design but are prone to higher release of tars and other impurities. Downdraft gasifiers, while reducing the tar content, require a drier biomass feed and lose some of the biocarbon with the ash.

Fluidized-bed gasifiers are structurally more complex than fixed-bed, but generally

produce a cleaner and more uniform producer gas. These facilities are usually in the range of five to 100 MW. Most larger-scale biomass gasification facilities have utilized fluidized-bed reactors, especially bubbling, which uses an inert heat-transfer medium such as sand.

Entrained-flow gasifiers are generally for larger units in the range of 50 to 500 MW and are the most efficient of the three technologies.

These processes can utilize two types of reactants, either air or steam.

Gasification has advantages over direct combustion or incineration of biomass, the most important of which is that the emissions are generally an order of magnitude lower than the emissions from an incinerator. As well, a more consistent fuel is sent to the boiler and ash is not carried directly into the boiler.

An important route to synthetic liquid fuels is related to the gasification process. The products of gasification, carbon monoxide and hydrogen, are called syngas when not contaminated by tars. Syngas can be converted into a variety of liquid fuels by the platform technology known as Fischer-Tropsch or FT technology. In 1925, Franz Fischer and Hans Tropsch discovered that syngas could be catalytically combined to form hydrocarbons (i.e., oil). Similar catalytic reactions can convert syngas into methanol or ethanol.

Although the products of the pyrolysis technologies vary greatly, they are all founded on a similar basic technology, the heating of biomass in a low-oxygen atmosphere. The separation between them depends on the temperature of the reaction. While the basic technologies have been known for over a century, only a few biomass-based facilities have been constructed, as the economics of these processes often cannot compete against those of fossil fuels. The result is that few plants have been constructed and fewer still have been a commercial success. •

Gerald Kutney is managing director of Sixth Element Sustainable Management, an Ottawa-based consulting firm that provides executive services for investors and project developers in the area of bioenergy, biorefining, bioproducts and related biomass–based technologies.

Stay up-to-date on new projects, start-ups, government programs, fibre supply and more with Canadian Biomass’ weekly e-news.

SIGN UP AT www.canadianbiomassmagazine.com

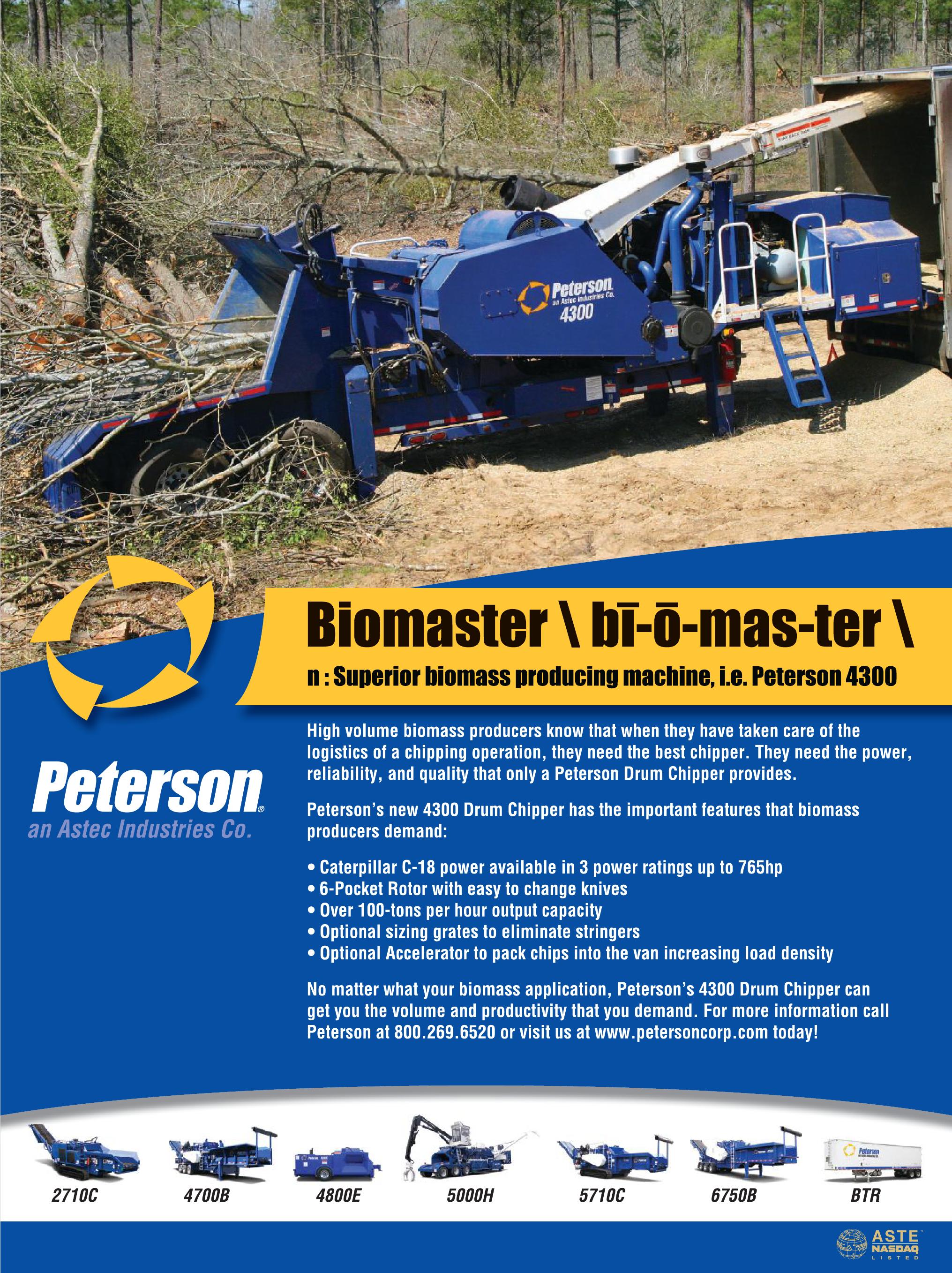

The new Morbark ® Advantage 3™ high-performance chipper drum gives you improved biomass fuel chip quality, reduces your costs, and is backed by a limited three-year warranty. It comes standard on most new Morbark drum chippers and can be retrofitted to most Morbark units without modification. Either way, you get three significant advantages:

• Higher-Quality Chips – The Advantage 3 is wider, has higher inertia, and incorporates Babbitt-style counter-knives, so it produces better, more consistent chips.

• Dramatically Lower Costs – The drum’s AR 400 heat-treated steel skin, enhanced knife design, and recessed pockets provide wear-part and maintenance cost savings of more than 70%.

• World-Class Warranty – The Advantage 3 comes with a limited three-year warranty, and is supported by Morbark’s extensive dealer network for unsurpassed peace of mind.

The exceptional Morbark Advantage 3 chipper drum comes standard with most units in our full line of heavy-duty industrial drum chippers. Learn more at www.morbark.com or call 1-800-831-0042.

From lignin to biofuels, CRIBE has accomplished much in four years.

By Andrew Macklin

Afterfour years of providing funding to help grow the bioeconomy in Canada, the Centre for Research and Innovation in the Bio-economy is nearing the end of its current mandate. Established during the province’s 2008 budget under the Ministry of Research and Innovation, the centre’s $25-million grant was given to help support projects in the province that helped establish a strong bioeconomy.

“We are very pleased with what we have accomplished since the beginning of our mandate in 2009,” said Lorne Morrow, chief executive officer for CRIBE. “Northwestern Ontario is becoming a national centre for driving the bioeconomy forward.”

Based at Confederation College in Thunder Bay, CRIBE has been a driving force for a large number of bioeconomy projects in Ontario. Offering up to 50% of the project cost for viable project submissions, CRIBE has provided endless opportunities for the development of value-added wood products.

The Domtar/Battelle project is the largest venture supported by funding from CRIBE. Up to $6 million has been provided to assist in the project, which looks to convert waste wood into fuel. For Battelle, the world’s largest nonprofit research and development

organization, this is its first collaboration with a Canadian bioenergy company.

“Having Battelle involved in this project was a major factor for providing the investment in this project,” said Morrow. “Battelle is an international leader in applied science and they provide a great amount of expertise that is invaluable to the project.”

The Domtar/Battelle project will use fast pyrolysis to produce biogas and biooil from waste wood. Fast pyrolysis is the rapid thermal decomposition of organic compounds in the absence of oxygen, which can then produce compounds that can be used for biogas and bio-oil. The grant from CRIBE is helping to start the production, optimize the process and refine the material in order to create a high-quality end product. The pilot plant, which is being built at Domtar’s Dryden, Ont., facility, is expected to carry a capacity of 100 tonnes/day.

At Resolute Forest Products in Thunder Bay, the development of a world-class lignin lab and demonstration plant has been created in a partnership with CRIBE, RFP, FPInnovations and Natural Resources Canada. The funding for the project includes an $850,000 grant from CRIBE, $500,000 from NRCan and facilities provided by RFP.

FPInnovations staff are involved in the operation of the laboratory facilities, and provided the scientific testing of the materials.

The FPInnovations Lignin Pilot Plant is the only facility of its kind in North America. Companies from around the world have the ability to have lignin, extracted from black liquor, tested, characterized and evaluated. In tandem with the lignin pilot plant, which will produce 100 kilograms per day of lignin from black liquor, researchers will be able to determine the qualities of lignin resulting from different wood species. That information will help FPInnovations create an understanding of the best use for lignin from an individual wood product. That understanding could prove to be invaluable in the future development of the value-added wood product industry in Canada. Both the lab and pilot plant are currently operational, and RFP is in the process of seeking buyers for the lignin being produced.

In Cambridge, Ont., an investment of $180,380 by CRIBE is helping Thesis Chemicals find ways to use lignin in the development of pharmaceutical and agricultural products. With approximately 95% of today’s chemicals being developed from petroleum, there is an inherent value in

finding renewable sources for creating medicines and medical treatment applications.

“Thesis is a leader in the development of green technologies for chemical manufacturing that are from sustainable resources,” said Morrow. “This grant will further expand our understanding of what lignin can provide in the creation of green technology.”

Southern Ontario is also home to one of CRIBE’s most significant investments, $3 million in funding to a partnership involving Lakehead University’s Biorefining Research Initiative and G2 Biochem in Chatham. The original grant was given for G2 Biochem, a collaborative partnership that included international partners Novozymes and Andritz, for support in the development and design of biorefining processes. By using poplar, G2 Biochem’s plan is to develop a system for the recovery of lignin, hemicellulose, and bark extracts. That project has since been adapted, and G2 Biochem is now developing a pretreatment stage for the front end of its existing pilot plant.

“The scope change had little effect on the CRIBE project since most of our studies were being done on the existing pilot

plant,” said Morrow.

As for Lakehead University, its involvement will be to use its lab facilities to develop value-added wood products from the extracted elements. That is expected to include bioproducts such as biochemicals, adhesives and biopharmaceuticals. As well, the partnership will give Lakehead students access to G2 Biochem’s facilities, as results from the joint studies will be used by CRIBE for further value-added wood products business promotion throughout northern Ontario.

The legacy of CRIBE’s presence at Confederation College has been cemented with the creation of a biomass testing facility being constructed at the campus. The BioEnergy Learning and Research Centre will include a demonstration space, a fuel testing lab, and a 150-kilowatt boiler for the study and research of associated emissions monitoring equipment. The new centre will provide a training ground for students looking to get involved in northern Ontario’s emerging bio-economy. The centre will also provide biomass and biofuel producers in the Thunder Bay region with a testing

facility for chemical compounds and pellet production. That includes people like Ed Fukishima of Atikokan Renewable Fuels, who received a grant of $70, 839 for the testing and production of natural additives for making better wood pellets. While that project is currently being done in concert with Lakehead University, the Atikokan project will be able to benefit from the facility at Confederation.

“Companies like Atikokan Renewable Fuels will strongly benefit from the facilities at Confederation College,” said Morrow. “It will allow people like Ed (Fukishima) to test their pellet formulas in a boiler facility, have the pellet analyzed and retrieve data that can help to improve his production.”

With several of CRIBE’s investments just starting to provide positive results for the growing bioeconomy in northern Ontario, it remains to be seen if the Ontario government will provide another investment in the organization to continue to move initiatives forward. Unofficially, CRIBE’s mandate has been extended to March 31, 2015, but additional funding for the program has yet to be announced. •

Vermeer has announced the completion of its family of mini skid steers with the addition of the S450TX. A 226.8-kilogram SAE-rated operating capacity with a 648.6-kilogram tipping capacity gives the S450TX a lot of muscle for its size. Vermeer has incorporated a four-pump hydraulic system, which provides performance and efficiency when powering attachments. A single pilot-operated joystick is now integrated into the S450TX platform, which makes the machine easy to manoeuvre and operate in comparison to manual control systems. The operator can also experience a smooth range of operation without having to balance the engagement of two separate controls. The S450TX offers the customer the ability to customize the machine with the choice of engine and track options. The Kubota 24.8-horsepower diesel engine and Kohler EFI 27-horsepower gas engine both provide excellent torque performance and are designed for those who use attachments requiring greater engine torque. The narrow seven-inch track provides a smaller machine footprint for tight work areas, while the standard nine-inch track offers reduced ground pressure for increased flotation and stability.

Timber Products Inspection (TP) has entered into agreements with three pellet fuel manufacturers to begin implementation of the PFI/ALSC Pellet Fuel Standards Program. TP will provide third party testing and inspection services in accordance with the Pellet Fuels Institute (PFI)/American Lumber Standard Committee (ALSC) Pellet Fuel Standards program to American Wood Fibers (Marion, Virginia and Circleville, Ohio), Curran Renewable Energy (Massena, New York) and Marth Wood Shavings & Supply (Marathon and Peshtigo, Wisconsin). Each of these manufacturers is currently working on setting up their internal quality management programs with the intent of complying with the PFI/ALSC Pellet Fuel Standards Program. Once each facility is ready, TP will conduct an initial inspection to verify compliance, followed by on going auditing and testing to assure continued compliance. By achieving compliance with the PFI/ALSC Pellet Fuel Standards Program, each of these manufacturers will be able to display a Quality Mark on their bags indicating that they are producing pellets that are compliant with the fuel grade listed on their bag. TP, accredited by ALSC as an auditing agency and as a testing laboratory for the PFI/ALSC Pellet Fuel Standards Program, will play a key role in ensuring the pellets produced are consistent in quality. Through regular testing and plant audits, TP will help oversee the quality process, and provide necessary guidance to ensure consistent quality.

M-E-C Company, a worldwide supplier of industrial dryer systems, recently announced that Stephen D. Rice has joined the company as vicepresident of sales. Rice has spent the last 30 years of his career in various senior management positions, including an extensive background in the wood products industry. Rice’s most recent experience in the forest products industry was with Kilntek, Inc., where he served as president of the company. Rice was responsible for establishing a business for manufacturing and installation of equipment for drying lumber and various combustion systems. Prior to that, Rice served as managing director of four engineering divisions throughout the U.S. and Canada for Moore International with complete responsibility for the product lines of lumber dry kilns, wood-fired combustion systems, veneer, and gypsum board dryers.

The Model 200UC Utility Chipper brings low cost with reliable performance and production to the popular 12-inch capacity disc chipper segment. It’s similar to Bandit’s popular Model 200XP, but features a lightened frame and chipping disc along with a plastic fuel tank. These changes allow the Model 200UC to ride comfortably on a smaller 6000-pound axle with 15-inch wheels, making this machine easier to tow and manoeuvre. It shares the same 14 x 17-inch chipper throat opening and feed system with the Model 200XP, and it can be equipped with engines from 48 to 97 horsepower. The end result is a manoeuvrable chipper that delivers the production and capability of a 12-inch machine, but with a lighter weight and a lower price point compared to many other machines in this segment. This is an ideal fleet chipper, and the Model 200UC is especially well suited for utility clearing thanks to its combination of weight, size and large throat opening. It’s an inexpensive, no-nonsense 12-inch disc chipper with the ability to compress and chip large, limby branches without sacrificing manoeuvrablity.

FEBRUARY 13-15, 2013 • Montreal Wood Convention Montreal, Quebec www.montrealwoodconvention.com

MARCH 19-20, 2013 • International VDI Conference –Biomethane Frankfurt, Germany www.vdi-wissensforum.de/en

APRIL 3-5, 2013 • Northeast Biomass Heating Expo Saratoga Springs, New York www.nebiomass.com

APRIL 8-10, 2013 • International Biomass Conference and Expo Minneapolis, Minnesota www.biomassconference.com

APRIL 10-12 • Biomass Serbia 2013 Novi Sad, Serbia www.icm.si

OCTOBER 3-5, 2013 • All-Energy Canada Toronto,

www.all-energy.com/canada.htm

• 560 TV Lines

• 2.9, 4.3, 6, 8, 12, 16 mm lenses

• All Weather, Extreme Environment

• Heavy Gauge Di-Cast Metal Alloy & Titanium Components

• Tri-Axial Mounting System

• –60°C to +60°C

• –76°F to +140°F

• Waterproof, IP68 Rating

• Vibration Resistant

By Dr. Chuck Ray

isleading information about sustainable forestry, bioenergy and how the carbon cycle works is prevalent in society.

Information posted earlier this year on the website of the Natural Resources Defense Council (NRDC) is an example of just such misleading information and illustrates clearly the lack of understanding of forest ecosystems and the carbon cycle in general.

A video and its accompanying text on the website decry the use of forest harvesting for biomass energy. However, the organization admits, “Biomass can be harvested and utilized in ways that reduce pollution

time periods. Rather than comparing one forest harvested immediately and one left for 50 years, consider the forest as one made up of 50 different forest stands harvested at a rate of one per year, and growing at a rate of 2% each year. This is closer to reality and yields a cumulative impact of a sustainable harvest in perpetuity, with no real starting or ending point to the carbon cycle.

practice that many in the industry believe is a suboptimal use of the forest resource compared to right-sized biomass harvesting that can improve the overall ecosystem quality of the forest.

The use of misleading carbon deficit accounting seems to be the latest angle at stopping forest harvesting.

Also consider that each of these stands was collecting carbon from the atmosphere before it ever reached harvesting age. In the example, the stand harvested in Year One had been growing for at least 50 years on the harvest date. It will be ready to be harvested again at the end of another 50-year cycle. Thus, the “carbon deficit” is only real if you ignore the fact that the trees gobbled up carbon before they were harvested.

By following sustainable harvest guidelines, society will benefit from the capture of woody conversion of carbon stock to energy in our homes and businesses. Ultimately, if we don’t, the carbon is returned back to the atmosphere anyway, one way or another.