JUNE 2021

Vol. 37, No. 3

Established 1985

www.mromagazine.com

Twitter: @mro_maintenance

Instagram: @mromagazine

Facebook: @MROMagazine linkedin.com/company/mro-magazine

Reader Service

Print and digital subscription inquiries or changes, please contact

Beata Olechnowicz, Audience Development Manager Tel: 416-510-5182 Fax: 416-510-6875

email: bolechnowicz@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400 Toronto, ON M2H 3R1

Mario Cywinski, Editor 226-931-4194 mcywinski@annexbusinessmedia.com

Paul Burton, Senior Publisher 416-510-6756 pburton@annexbusinessmedia.com

Maryam Farag, Associate Editor 437-788-8830 mfarag@annexbusinessmedia.com

Ilana Fawcett, National Account Manager 416-829-1221 ifawcett@annexbusinessmedia.com

Alison Keba, Media Designer Catherine Giles, Account Co-ordinator 416-510-5232 cgiles@annexbusinessmedia.com

Scott Jamieson, COO sjamieson@annexbusinessmedia.com

Machinery and Equipment MRO is published by Annex Business Media, 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1; Tel. 416-442-5600, Fax 416-510-5140. Toll-free: 1-800-268-7742 in Canada, 1-800-387-0273 in the USA.

Printed in Canada

ISSN 0831-8603 (print); ISSN 1923-3698 (digital)

PUBLICATION MAIL AGREEMENT #40065710

Subscription rates.

Canada: 1 year $65, 2 years $110. United States: 1 year $110. Elsewhere: 1 year $126. Single copies $10 (Canada), $16.50 (U.S.), $21.50 (other). Add applicable taxes to all rates.

On occasion, our subscription list is made available to organizations whose products or services may be of interest to our readers. If you would prefer not to receive such information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer

Privacy@annexbusinessmedia.com, 1-800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2021 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

Recently, Maintenance and Equipment MRO conducted a poll on our LinkedIn company page, asking: “What is the most important aspect of your maintenance program?”

Condition-based maintenance was seen as the most important at 37 per cent, with preventive maintenance next at 36 per cent, predictive maintenance at 25 per cent and other at one per cent. While the comments section of the poll pointed out other methods that are used, such as proactive, and corrective/reactive maintenance, as well as those who mentioned all are equally important.

With the poll being so close, and comments outlining other methods, what this illustrates is maintenance programs are an all-encompassing job, and neither one aspect overrides the need for the rest.

In order to minimize downtime as much as possible, maintenance departments need to be able to use a combination of the following:

•Condition-based maintenance;

•Preventive maintenance;

•Predictive maintenance;

•Proactive maintenance;

•Corrective/reactive maintenance;

•And other maintenance techniques.

Switching gears, recently MRO along with the rest of Annex Business Media’s Manufacturing Group teamed up to host a virtual summit called Women in Manufacturing, which was inspired by ongoing efforts to break the barriers that discourage women to enter the manufacturing industry.

An accompanying website was also launched, which is dedicated to highlight the impact women are making in the manufacturing sector (h p://www.womenincanadianmanufacturing.com/). On this web site, find conversations with industry leaders in forms of podcasts, videos, and feature articles.

Our cover story for this issue of MRO, Bev Goodman Becomes First Canadian Woman to Lead Ford of Canada (page 12), is just one example of the content available on the web site. Fun fact; Goodman is the second (of three) female presidents of Ford I have had the privilege of doing a question and answer with, as a few years ago I was able to interview Dianne Craig.

Additionally, MRO’s associate editor, Maryam Farag, conducted a great series of interviews with women in the maintenance, reliability and operations space.

They include:

•A podcast interview with Suzane Greeman from Greeman Asset Management Solutions.

(www.mromagazine.com/podcasts/podcast-suzane-greeman-greeman-asset-management-solutions)

•A video interview with Kim Nelson from Royal Containers. (www.mromagazine.com/features/video-interview-with-kim-nelson-from-royal-containers)

•And an interview with Andrea Descargar from Green City Plastics Inc. (www. mromagazine.com/features/interview-with-andrea-descargar-from-green-cityplastics-inc)

Be sure to check out the above content that features some inspiring women in the manufacturing and maintenance world. They are all great role models for young women who are thinking about a career in the manufacturing sphere.

Predicting rotating equipment issues is easy with SKF Pulse. This portable Bluetooth™ sensor and free mobile app allows you to quickly evaluate asset health on demand and prevent machine failure. Get expert advice without investing in complex technology.

• On-the-spot machine diagnostics with visual alarm indicators

• No need for training or diagnostic expertise

• Connect directly with SKF experts for analysis and diagnostic reports

• Pulse Check diagnostic reports include recommended corrective actions, if required

MRO spoke with Goodman about her career, taking on the roles of President and CEO, being a role model, and where the company is heading.

Did the ISO 55000 PC251 Miss a Word / 8

The team that developed the asset management - management systems standard 5500X may have missed the one word that is essential for achieving sustainable asset management.

MRO Quiz / 18

Troubleshooting power transmission coupling problems.

What’s Up Doug / 10 Bearings and value to production facilities.

Notebook / 3

Five Things You Need to Implement a Precision Maintenance Program / 14 Precision maintenance can be used as a process improvement strategy. A strategy that will pay dividends.

101 / 24 How to streamline world class maintenance and other equipment improvement activities.

Data

The Canadian Renewable Energy Association (CanREA) brought together 175 renewable-energy experts from across Canada for a twoday event focused on recharging Canada’s economy with renewables.

CanREA’s Spring Forward event explored how wind energy, solar energy and energy storage will play a key role in boosting economic growth and job creation post-pandemic, while supporting critical 2030 and 2050 climate targets.

“We called this event Spring Forward because that is exactly what Canada needs to do right now,” said Robert Hornung, President and CEO, CanREA. “Canada has only reduced its GHG emissions by 1.1 per cent in the last 14 years and our country just set a target to reduce emissions by a minimum of 40 per cent in the next nine years. We need to spring into action and accelerate the deployment of clean, renewable electricity if we are to succeed in beating the climate crisis.” MRO

The Building Opportunities in the Skilled Trades Act, a legislation designed to make the province’s skilled trades and apprenticeship system easier to navigate, was introduced by Monte McNaughton, Minister of Labour, Training and Skills Development.

Under the proposed legislation, Skilled Trades Ontario would become the province’s industry-informed training authority to lead the promotion, research and development of apprenticeship training and curriculum stan-

dards. It will also provide client-facing services, including apprentice registration, issuance of certificates and renewals, and conduct equivalency assessments offered digitally.

As recommended by the Skilled Trades Panel’s first report, Ontario will streamline the apprenticeship system by establishing a new crown agency. The ministry will provide system oversight and be responsible for regulatory decisions, financial supports and take on responsibility for compliance and enforcement of the skilled trades. MRO

PEMAC Asset Management Association of Canada announced the launch of the Maintenance Work Management Certificate.

The program is designed for maintenance practitioners such as planners, schedulers, supervisors, coordinators, and other operations personnel who work alongside maintenance.

According to PEMAC, the training ensures professionals have the skills to ensure the right maintenance work is done on the correct assets, at the right time, using the right resources.

Using Module 1 and Module 6 of the larger Maintenance Management Professional (MMP) program, this offering will provide an overview of the benefits of an integrated maintenance management strategy, and then focus on the fundamental principles of work management processes with emphasis on maintenance work planning, scheduling, and work coordination methods.

Participants who successfully complete Module 1 and Module 6 of the MMP program can apply for the certificate on the PEMAC website. MRO

Thordon Bearings Inc., a Thomson-Gordon Group company, has appointed Anna Galoni as CEO, taking over for Terry McGowan, who has retired a er 14 years in the role.

enchmark PDM has added Duane Dys to its team as a Technical Sales Representative for Alberta. Dys has many years of sales experience and will be the point of contact for the Western Canada. His focus will be on sales and services of alignment and measurement tools, vibration monitoring instruments and training. MRO

Galoni joined the Burlington, Ontario-headquartered company in 2007 a er graduating from Queens University with a Masters’ Degree in Epidemiology. She held a number of senior roles in several departments including human resources director, and new product development director and chair, Thordon Bearings.

As the company’s first female CEO, Galoni hopes the appointment will encourage more women to consider senior executive positions in the maritime and industrial manufacturing sectors. MRO

The PC251 team that developed the asset management - management systems standard 5500X may have missed the one word that is essential for achieving sustainable asset management.

BY CLIFF WILLIAMS

The PC251 team made some great steps in identifying that the long known, but not o en stated in a standard, fact that leadership and workplace culture are determinants of realization of value. They further explain in (ISO 55000 2.4.2 c).

This includes:

1) Clearly defined roles, responsibilities and authorities.

2) Ensuring that employees are aware, competent and empowered.

3) Consultation with employees and stakeholders regarding asset management.

This is first time that I know of where something as nebulous as leadership and workplace culture has been included in an ISO standard, but I am not sure it was given as much guidance as it should have. Then again, the topic could very likely require its own ISO standard and still would not be able to cover all of the variables that exist in both leadership and workplace culture

Still, they did provide guidelines, and I believe that if we follow these guidelines we will be well on our way to implementing an effective asset management system, or at least have the basic requirements and foundation to build on. But to complete the process, I think we need to add the mystery word that I think they missed.

Just to give this some context, I have been teaching the fundamentals of asset management for the last five years - for employees of numerous organizations from all types of environments - manufacturing, utilities, municipalities and engineering. During these sessions we discuss their current state and what are some of the obstacles to them improving their asset management performance.

Most of the participants want to believe they have a good basis for moving forward with asset management and often dismiss the idea that there are obstacles. They contend there are not really

any obstacles. But it’s just that they don’t necessarily fully understand the nuances of asset management. Once they grasp the nuances they will be able to move forward quickly. What we find as we progress through the training, is that they actually haven’t grasped the complexity and scope of asset management and as such, not been able to recognize these obstacles.

Many of the students feel that they have a good hold on point one where people understand their roles and their authorities, and have made progress on point two with people ge ing used to empowerment.

When I ask what is in the way of them progressing further and becoming more adept at asset management, a er some discussion around the topic, the majority seem to come to the same conclusion; they usually bring up one word: silos. Now, this is not the word that PC251 missed. This usually prompts more dis-

cussion around points one and two, and when we get a li le deeper we find that, yes, people understand their roles, some even understand how they impact others, yes, they have authority and yes, they are empowered - but no one is checking that they are using those attributes to be er asset management; no one is actually measuring their success. Having authority and being empowered are nothing new. We talked about them in leadership education for years, but we always accompany them with the mystery word: accountability.

None of this works if we do not hold people accountable for their actions; hold them accountable for advancing the asset management journey. When we allow people to remain in their silos and not hold them accountable, we are reinforcing that as long as we tick the boxes and proclaim that we are employing asset management, then we are doing fine. Listening to the students, as this

seems to be the current state of play for most of them. They are trying to move forward but constantly bump into silo walls, and when they look to leadership, they see that they have moved on. They have ticked the boxes of points one and two, and consider the job done.

This is where point three comes into play: Consultation with employees and stakeholders regarding asset management.

It should not only be about si ing down and discussing asset management in general, or what the organization hopes to gain from it. It needs to be where leadership create the culture for asset management; they need to show that they clearly understand the roles that people play in the process, provide expectations from people, set their goals and give them objectives so that everyone is clear as to what success looks like.

Too many times this does not happen and so people do not truly understand if they are winning or not. It is a bit like playing hockey but forge ing to put out the nets. Everyone is playing hard (at least for while) but they do not know whether they are winning or not. The side effect of this is that the ‘hard play’ and the bruising checks quickly stop and people stand on the blue line and dump the puck down the other end of the ice.

Maybe if the PC251 team had added the word “accountability” to point one so that it read: Clearly defined roles, responsibilities, authorities and accountabilities.

It may have at least raised the idea that leadership includes accountability and prompted leaders to view how well they hold their people accountable.

Now, accountability is not exclusive to asset management, and should form part of every leader and culture. But because for most organizations asset management is going to mean a change to the existing culture, it is essential to make it sustainable.

For most people the word

“accountability” brings in negative connotations that involves some form of discipline or chastisement. Sometimes this is true, but it really should be the last resort of holding someone accountable. Why not view them as learning opportunities where you can correct behaviour by increasing understanding, supporting efforts, changing approaches or removing roadblocks, etc. The goal as a leader should be to garner the best efforts of the people you are working with, and as a leader in the asset management environment, to derive the greatest val-

ue from those assets by holding them and yourself accountable. MRO

Cliff Williams is author of People – A Reliability Success Story. He is a maintenance and asset management educator, and a keynote speaker at conferences around the world, who believes success is achieved through people. Currently Cliff shares his knowledge and experience as an advisor on maintenance and reliability for people and processes, and asset management with TMS asset management and is a facilitator for PEMAC’s Asset Management Program.

Let’s use an example of a mining/cement operation to illustrate the value that bearings bring to production facilities.

BY DOUGLAS MARTIN

Although not all the assets discussed may be all in manufacturing facilities, the concepts can be extended to many other industrial applications and the critical pieces of machinery used.

At a mining and mineral processing conference on lifecycle management a couple years ago, a question was asked: which asset type gives the most problems? The survey indicated that 44 per cent of the respondents picked conveyors as their number one headache. Next in line was mobile equipment, scoring only 17 per cent.

Diving deeper, a review of an iron ore mine determined that the number one cause of conveyor pulley failure, causing

the conveyor to be shut down for repair, was bearing damage. So clearly, the performance of bearings can be the critical component of a critical asset.

If we think about repairing machinery and how it affects an industrial facility, the number one cause of accidents in which workers were injured is machinery repair, followed by handing of supplies and materials, then the use of non-powered hand tools. All things related to machinery repair.

To add another level, according to a survey by a mining authority, 43 per cent of injuries were caused while a worker was performing maintenance or checking a conveyor, and 24 per cent of fatal mining accidents involved conveyors.

A goal of a production facility should be to extend the mean time between fail-

ures (MTBF) of rotating machinery to reduce these risks.

A mining pulley on a large overland conveyor costs about a million dollars to change. The pulley itself costs about $400,000 to repair. The typical repair cycle of a pulley at an oilsands operations is two years to replace the lagging (pulley cover). This is a normally accepted “wear life”. If the bearings last only 18 months, (¾ of the expected life), then there is a loss of $100,000 in the potential value of the pulley rebuild (hoping that the bearing loss did not cause secondary damage that required additional repairs).

If this expected life continues at this reduced rate for eight years, then the additional cost to the mine site will be $1.4 million. Sometimes, when the bearings are put out to bid, the best price wins, as o en bearings are assumed to be a commodity and they are all the same in terms of performance. Note my article from the November 2020 issue of <i>MRO<i> how bearings do differ in levels of quality (and therefore performance) despite all meeting ISO standards.

Say the bearing replacement cost was $50,000 from a premium bearing company and the “standard” bearing company offered the bearing for $10,000 less. A er the eight years of premature failures, the purchasing group would have saved $40,000, but cost the mine site $1.4 million in additional maintenance.

To look at this in another way, the investment in the best quality bearing available provides a return on investment (ROI) of 3,500 per cent. One could replace “best quality bearing” with an overall upgraded solution that could include a sealed bearing or premium grease or some other improvement with the intent to extend life.

In the example above, I did not include the loss of production for downtime. If this is factored into the equation, then we could see even more savings. The table below shows how quickly a premium product can justify its cost just by extending the operating time (extending mean time between failures). The time to pay off investment is simply looking at how much the extension of MTBF is recouped by the value of production. In other words, if the replacement bearing runs longer than it has added value by the hourly value of production.

There was a cement batch plant that I worked on a problem with. As it turned out, the blending device had some standard bearings and housings that were between the blending tank and the drive gearbox. These bearings failed unexpectedly and the bearings needed to be changed. As a result, the plant was down for 1.5 days. Had this facility invested in a split bearing (a premium product), the repair could have been done in four hours, as the gearboxes and couplings would not have needed to be removed. What did the day out of service cost?

A typical batch plant loads 200 to 500 trucks per day. Cost per cubic metre of concrete is $150 and a truck carries 10 cubic metres of concrete or about $1,500 per truck. Therefore, the lost day of production cost this plant in revenue somewhere between $300,000 to $750,000. The bearing assembly that was on the shelf was worth about $1,500 and the premium assembly that they could have avoided the lost day of revenue was $7,800. Had this bearing assembly been on the shelf, the ROI would have

been at least 3,846 per cent. Even the cost of inventory at 10 per cent per year ($780 per year) is still a bargain given the lost revenue.

In these cases, we have explored how investing in the best bearing solution for your production equipment can provide a significant ROI. In some cases, you gain by investing in greater mean time between failures, MTBF, (running longer between bearing changes) in other cases it can be by investing in a premium product (or tools for example) that can reduce the MTTR, ge ing the machine

running again sooner.

Certainly, these numbers will vary from industry to industry and maybe there are some different levels of criticality of the machines, but no ma er how you slice it, the longer and more reliability a machine runs, the lower the total cost of ownership is. MRO

Douglas Martin is a heavy-duty machinery engineer based in Vancouver. He specializes in the design of rotating equipment, failure analysis, and lubrication. Reach him by email at mro.whats.up.doug@gmail.com. 21_0970_MRO_JUN_CN Mod: April 27, 2021 9:51 AM Print: 05/12/21 11:43:04 AM page 1 v7

Earlier this year, Ford Motor Company of Canada, Limited named Bev Goodman as its new President and CEO. She became the third woman to hold the roles, and the first since Dianne Craig, who was President and CEO from 2011 until 2017. The first woman to ever lead the Canadian operations was Bobbie Gaunt, who was in charge from 1997, until her retirement in 2000. Goodman; however, is the first Canadian woman to lead the company.

BY MARIO CYWINSKI

MRO had the opportunity to speak with Bev Goodman recently to ask her about her career, taking on the roles of President and CEO of Ford of Canada, being a role model, and where the company is heading.

Goodman who took over for Dean Stoneley, who moved on to another role within Ford Motor Company, has been with Ford of Canada for 25 years, and began her career as an intern on the finance team, since then she has worked in parts and service, sales and marketing, finance, and most recently as the director of marketing communications.

She now leads Ford of Canada’s operations, including its national headquarters, regional offices, vehicle assembly and engine manufacturing plants, parts distribution centres, research and development sites, and connectivity and innovation centres.

MRO: You have been with Ford for 25 years; can you discuss your career at the company? How has it prepared you for the role of President and CEO of the Canadian operations?

Bev Goodman: I began my career at Ford of Canada in 1996 as an intern on the finance team and I’ve had the opportunity to build experience in many

other areas of the company in the last 25 years. A er leaving the finance team, I worked in parts and service, sales, and marketing. I was also the general manager for our eastern market area, which is Ford’s largest sales region in Canada. Ford of Canada is a multi-faceted, fastpaced organization and each of my previous positions taught me something new about the company and the people who make it successful. All of these lessons are now helping me serve as CEO.

MRO: Do you see yourself as a role model for young females who want to be leaders at a global company?

BG: I would be happy to think that any young person could be inspired by my story and use that motivation to confidently pursue their own career aspirations. My success was born from hard work, a laser focus on what I wanted to accomplish as an individual while learning from all the smart, strategic people around me and, finally, from a strong commitment to an organization that I care deeply about. I am grateful to have had a career filled with new opportunities and a supportive network of colleagues who inspired me to think big. I hope others can find the same level of inspiration in their professional journeys.

MRO: What advice would you give them if they wanted to get into manufacturing?

BG: The best advice – regardless of the industry that you’re looking to break into – is to stay open, curious, and commi ed to learning. Talk to people within the industry, and outside of it; make connections and build your own network. Always be on the lookout for the trends that are driving progress and change. And finally, surround yourself with a diverse group of people that will push you, help you to grow, and ultimately to expand your personal perspectives.

The disruption in our industry has led to some exciting new growth opportunities. Today’s automotive sector requires forward thinking, a broad cross-section of people and skills, and diversity of thought. Our future success will be focused on consumer experiences enabled by technology. I see a future for our industry that includes significant opportunities for those organizations and individuals who challenge the standard ways of doing things.

MRO: How did you get into working for an automotive manufacturer?

BG: For my start in the industry, I was lucky enough to get an internship at Ford of Canada while I was working on my MBA at McMaster University. For the next 25 years, I was offered a wide range of opportunities in so many different areas of the company, and now, have the privilege of serving as the CEO.

MRO: Ford announced the retooling of its Oakville Assembly Complex to become a ba ery-electric vehicle manufacturing facility starting in 2024. Can you discuss how this affects Ford’s Canadian operations? Will the plant have any unique aspects versus a regular internal combustion engine vehicle plant? How integral will the plant be in Ford’s global operations?

BG: At Ford, we’re commi ed to fighting climate change globally and we’re all-in on EVs. This includes a US$22 billion global investment in electrification and EVs through 2025, and a commitment to becoming carbon neutral by 2050.

As a part of this global investment, in Canada we announced a planned $1.8 billion transformation of our Oakville Assembly Complex from an ICE site to also become a BEV manufacturing

“For my start in the industry, I was lucky enough to get an internship at Ford of Canada while I was working on my MBA at McMaster University. For the next 25 years, I was offered a wide range of opportunities in so many different areas of the company, and now, have the privilege of serving as the CEO.”

-Goodman

facility. With this investment, a family of ba ery-electric SUVs will be built at OAC marking the first time ever that a full-line automaker has produced full BEVs in Canada for the North American market. Our investment will also bring the opportunity for ba ery pack assembly to OAC – another first for Canada and Ontario.

This investment is great news for Oakville, for Ontario and for the Canadian automotive industry. On a macro-level, an auto assembly plant is incredibly important to the broader manufacturing ecosystem as it anchors the supply chain and manufacturing base around it. The economic impact is tremendous, as each auto job has the potential to create up to seven additional spin-off jobs.

MRO: Ford’s F-150 has been the best-selling vehicle in Canada for a number of years, can you see a day when an electric version of the vehicle is the model of choice for buyers?

BG: I am proud to say that Canadians have made Ford the top-selling brand in Canada for twelve consecutive years and Ford F-Series Canada’s best-selling pickups for 55 years in a row.

At Ford, our plan is to electrify our most iconic nameplates – from the Mustang Mach-E, to F-150, and beyond. Looking ahead to 2022, an all-new, all-electric Ford F-150 is coming and will be Built Ford Tough.

Our customers, from across our lineup, have told us exactly what they would need from an electrified vehicle – and we’ve listened. Each of Ford’s electrified vehicles will amplify the best a ributes that our customers love, such as performance, capability, and convenience – with no compromise.

Ford is not new to electrification. From hybrids to plug-ins, and full battery electric vehicles, globally we’ve put more than 800,000 electrified vehicles on the road in recent years. MRO

Mario Cywinski is the Editor of Machinery and Equipment MRO magazine, Plant magazine, and Food and Beverage magazine, is a member of the Automobile Journalists Association of Canada, and a judge for Canadian Truck King Challenge. He has over 12 years of editorial experience; over two years of maintenance, reliability, and operations experience; over 16 years of automobile industry experience, as well as small business industry experience.

Precision maintenance can be used as a process improvement strategy. A strategy that will pay dividends.

BY JOHN LAMBERT

This process is easy to implement. In fact, you do most of the work already. The beauty of it all is that there is not a lot of cost involved and if you’re smart, you can implement the process on one machine at a time.

In simplistic terms, precision maintenance means working to a recognized standard tolerance or specification. Just doing that will improve your work processes, and the payoff is a much improved and reliable machine (asset). It is important to note that “recognized” means that the standard is approved by an organization such as the Canadian Standards Association (CSA), the International Standards Association (ISO) or the American National Standards Institute (ANSI). There are many used in the industry, a common one is the ISO 10816 vibration standard tolerance chart.

Are there exceptions to using a recognized standard? Absolutely. There is the American Petroleum Institute API686, and while only a guideline and not a standard, this document was the go-to bible for anyone doing pump installations and still is.

When implementing precision maintenance, there are five things that you should already have or need to have to be successful.

Work procedures are wri en documents that follow the work process. You have them as part of your preventive maintenance program. But do you have them for a pump overhaul? The procedure should include the standard tolerances and specifications you would need doing the work. What this would

give you is consistency. If you do not have wri en procedures or old outdated ones, the best people to write them are the tradesmen, as they know the work process the best. Be er still, do it as a team building exercise as it creates buy-in. However, they must be clear, no ambiguity, all must understand and be on the same page.

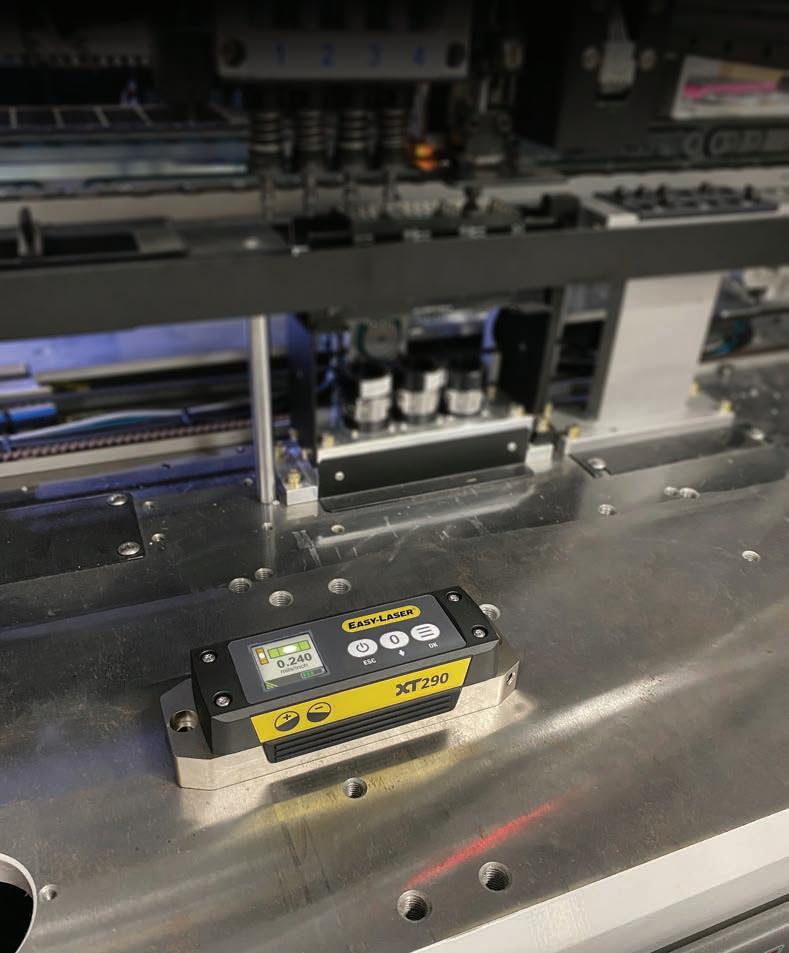

Precision maintenance requires exact measurement. Obviously, you need in-

struments that can achieve this. The actual recommendation is to use instruments that can measure under the tolerance you require. The tighter the tolerance, the be er the result, but you cannot have a tolerance that you cannot measure. This means you need the right tools for the job. Always try to use digital so that the measured value or result is saved electronically. It is a known fact that when using instruments such as theodolites, dial gauges or levels for example, the greatest error occurs during the trans-

fer of the seen value. One piece of advice is: do not buy junk. You need something that the team will use. Get them involved in choosing the tools required.

3. Data processing system

This is so important because it gives you an organized structure. You probably have a PM program, which of course is a must, that is controlled by a CMMS/ EAM system. In it you will have planned work orders, back log orders, PM schedules, CBM tasks, etc.

Depending on the capabilities of your CMMS/EAM, you should have an individual file for all the plants assets. In each one, there should be a benchmark record of the machines normal operating condition. For example, the normal operation temperature and where you would take those measurements should be known to verify this. Simple enough to do, but so helpful for the PM tech. There should also be an asset history file.

And this is where we o en see the breakdown in the system. There may be a file, but what is missing from many is the asset/machines installation report or a coming into service report. This is the information that controls the reliability of this machine. Imagine if you had to do a breakdown analysis a er a failure and did not have this information? You would be relying on guess work or maybe wrong information.

A precision maintenance program guarantees that you have this file because a precision machine installation has mechanical measured items such as these below.

1. Base flatness and level

2. Sha runout

3. Coupling runout

4. Pipe and conduit strain

5. So foot

6. Offline to running (OLTR) machinery movement

7. Sha centerline to sha centerline (alignment)

All of these items and the recognized standard tolerances/specs can be found in ANSI/ASA S2.75-2017/Part 1. With an installation report and a commissioning report, it guarantees the machine has a good starting point when starting service. And throughout its life, there will be added work to this report such as an “as found” and an “as le ” alignments, or a base flatness change as things do move over time.

A maintenance shop foreman once sug-

In today’s world of COVID, we use scientific knowledge to help us make choices about our health. That is not unlike what you do with your condition-based maintenance program.

gested that not everyone in the shop had the same sized toolbox and that he would pick and choose who to put on what job. What he meant was that not everyone has the same skill sets. For example, a company once bought an expensive and not so user-friendly laser alignment system. The problem is that not all the shop guys can use it. It may be taken to the job site, but unfortunately not used correctly or not used at all. This is one of the reasons we are developing training videos to help support some tradesmen who struggle with new technology. They can take their time and review it as o en as they like, especially before going out to do an alignment job. With precision maintenance, all should be proficient in taking and recording measurements. So, you may want to invest in training.

The right team culture

I first heard the term precision maintenance from Ralph Buscarello of Update international, who taught me sha alignment using dial indicators almost 40 years ago. Others were promoting this as the next big thing, but the reality is that it has been with us for a long time. Some companies, not a lot, do it, others do it but not as successfully.

If you are in maintenance, whether in management or skilled trades, embarking on such a program as this is challenging. It is a very worthwhile program, but it is a big commitment to do it and stay with it. The overall benefits are large in the form of machine/asset reli-

ability. A side benefit is that you have to do this together as a group, dare to even say team, which does put some people off. However, there are different cultures that produce different teams. You may want to hug every morning before starting work but others will not. In today’s industrial environment, it should be evident to all that we have to work together in order to compete. So, the advice is that you sit down collectively and ask some tough questions, such as: can we do this and what do we need?

In today’s world of COVID, we use scientific knowledge to help us make choices or decisions about our health. That is not unlike what you do with your condition-based maintenance program, where decisions are based on the measurement/data that is taken. It is the same with this program. It is data driven. Quantifiable, reproducible measurements are taken, analyzed and compared to a standard. Decisions and/ or actions are taken and the whole process is documented.

For well over 10 years, our training has been called MAAD, which is an acronym for measure, analyse, act and document. The suggestion would be that you do something along the same lines as this if you want to improve your maintenance process. And quite simply, do the job right, as you are doing the work already. MRO

John Lambert is the President of BENCHMARK PDM. He can be reached at john@ benchmarkpdm.com.

ManufacturingJobsite.ca is Canada’s premier online job portal for the growing manufacturing sector. A laser focus on the right people across the country’s largest manufacturing media audience means you get the right applicants the first time. No more massive piles of unqualified applicants, just professional employers reaching qualified professionals.

Powered by the top manufacturing media brands in Canada, the reach to over 500,000 industry professionals on ManufacturingJobsite.ca is amplified by:

Website advertising to 185,000 qualified monthly site visitors

A comprehensive and magnifying reach across multiple associated job boards

Email promotion and job alerts to 131,000 industry emails using Canada’s largest CASL-compliant direct access to manufacturing professionals

Social media promotion to all brand networks on Facebook, Instagram, Twitter and LinkedIn

Power transmission couplings connect two shafts that turn in the same direction on one centerline. Three principle types exist; rigid, flexible and special purpose.

BY L. (TEX) LEUGNER

Rigid couplings are used in applications where misalignment is not a factor, flexibility is not required, and where the coupling is not required to absorb load shocks or torque changes. Rigid couplings connect sha s using bolted flanges, keyed sleeves or ribbed clamps bolted together over the sha ends with keyways. They are used primarily for vertical drive systems. Lubrication is not required, but larger couplings, or those running at high speeds, may require balancing to reduce vibration.

Flexible couplings also connect two rotating sha s, but are designed to dampen vibration, absorb some shock loading, and provide some axial movement or end float of the sha s, as well as compensate for minor misalignment. The three categories of flexible couplings include: mechanically flexible, material flexible and metallic grid couplings, that provide a combination of mechanical and material flexibility.

Special purpose couplings include mechanically flexible U-joints, constant velocity joints, magnetic couplings, eddy current, fluid couplings and the Schmidt or offset coupling designed to handle large parallel sha offsets of up to 18 inches and 1,000,000 in-lbs of torque.

Does the maintenance group recognize where mechanically flexible couplings should be applied?

Logic: Gear and chain couplings provide a flexible connection by permi ing coupling components to move or slide over each other. Some minor misalignment is provided by the clearances between gear teeth and chain, and sprocket teeth respectively, however, sha s should be aligned to less than 0.002 inches to ensure long coupling life. Approximately 75 per cent of gear and chain coupling failures are caused by misalignment or improper or insufficient lubrication. Some newer types of gear and chain couplings contain nylon gear sleeves or nylon chains and these types do not require lubrication.

Are the applications of the material flexible coupling types recognized?

Logic: These couplings incorporate elements that accommodate a certain amount of bending or flexing. The flexing materials that provide the connection between the coupling drive and driven components include laminated discs, bellows, diaphragms or elastomeric materials that may include rubber or plastics, such as neoprene and urethane. Generally speaking, these coupling types require li le maintenance other than alignment, and their service life is limited by the fatigue limit of the flexing material itself.

Are the applications of combination mechanical/material flexible couplings recognized?

Logic: These include the popular grid coupling; a compact unit capable of transmi ing high torque at speeds up to 6,000 rpm. The construction of the coupling consists of two flanged hubs, each with grooved slots cut axially on the outer edges of flanges that are connected by using a serpentine spring grid that contacts the grooved slots. The flexibility of this grid provides torsional resilience that offers some misalignment and end float, dampens vibration, and may reduce peak or shock loads by up to 25 per cent. Grid type couplings require lubrication using good quality coupling grease in the areas of the grooved slots and serpentine spring.

Does the maintenance group understand why couplings fail?

Logic: Couplings fail for several reasons, but the primary causes are improper selection for the particular application, excessive misalignment, improper, inadequate, or insufficient lubrication, harsh environmental or operating conditions, and excessive speeds or loads. A common application is variable high torque machine trains operating at moderate speeds that require a serpentine spring and grid coupling. Vertical pump sha s would use flanged or split rigid couplings, while transmission of high torque at all speeds would require a chain or gear coupling.

Does the maintenance group understand the coupling alignment factor?

Logic: There is a perception that flexible couplings can accommodate a great deal of parallel offset and/or angular sha mis-

alignment. This is untrue. Depending upon the coupling type, flexible couplings can only accommodate from ¼ to about 2 ½ degrees of misalignment and high speed, high load drive applications must be aligned to close tolerances. Symptoms of misalignment include, but are not limited to, coupling noise, powdered rubber particles, or leaking lubricant directly below the coupling (depending on coupling type), premature or frequent bearing or seal failure at one or both machines, “so foot” condition at foot bolts, shimmering of oil on base plates or near the foot bolts, high operating temperatures and/or vibration at or near the coupling.

Allowable misalignment tolerances based on machine speed

Does the maintenance group understand coupling lubrication application?

Logic: The coupling types that require lubrication are gear, chain, combination mechanical, and material flexible grid couplings. Lubricants used for gear and grid couplings include ISO 460 compounded oils for low speeds and centrifugal G forces up to 8000 applications, ISO 100 rust and oxidation inhibited anti-wear oils for high speeds with centrifugal G forces of over 8,000, and low temperatures of -20°C (-4°F) applications. NLGI Grades 1 and 2 coupling greases may be used for gear, chain and grid type couplings.

Centrifugal Force “G” may be calculated from the equation: G = 14.2 X 10 – 6 DN2 Where d = pitch diameter of the coupling in inches And N = revolutions per minute.

Oil or grease can be used at coupling speeds of 3600 to 6000 rpm. Where coupling speeds that exceed 6000 rpm, oil is recommended. These units contain access plugs for re-lubrication that must be properly torqued a er re-lubrication to ensure safety. Re-lubrication and inspection intervals should be carried out at least annually or more frequently for high temperature applications. The amount of lubricant is important. Gear couplings may lock up and lose flexibility if they are overfilled. (Any increase in vibration of the coupling a er re-lubrication suggests overfilling).

If a coupling requires disassembly for re-lubrication, ensure that the two flange halves are marked for correct reassembly use specified coupling flange bolts properly torqued, and install new seals or gaskets if the old seals and gaskets have any damage. Before reassembly of grid type couplings, inspect the serpentine spring for damage, wear or fatigue cracks, and inspect the grid grooves for excessive wear or evidence of fatigue. On chain and gear type couplings, inspect the chain, sprocket and gear teeth for looseness wear and evidence of fatigue.

Does the maintenance group understand the operational factors?

Logic: Operating conditions play a large role in the long life and reliability of flexible couplings. Operating temperatures will affect not only the lubricant, but can seriously shorten the life of the materials used in elastomeric couplings. Generally, seals and coupling components cannot withstand temperatures much above 104°C (220°F) and group I mineral base oil begins to oxidize at 71°C (160°F). These guidelines should be understood and applied by machinery operators, and as a result, when high operating temperatures and/or where zero “backlash” is required, flexible disc couplings are recommended over elastomeric types.

In addition, solvents, caustic process fluids and water washing practices may be harmful to some elastomeric couplings and disc, grid or gear couplings may be required. Wherever high loads and speeds are required, disc and gear couplings may be the best choice. Finally, if high temperatures are being experienced, remember that an angular misalignment of as little as 0.001 inches can increase adjacent bearing temperatures by as much as 18°C (65°F). Coupling operating conditions and environment, lubrication and alignment are all related. MRO

L. (Tex) Leugner, the author of Practical Handbook of Machinery Lubrication, is a 15-year veteran of the Royal Canadian Electrical Mechanical Engineers, where he served as a technical specialist. He was the founder and operations manager of Maintenance Technology International Inc. for 30 years. Tex holds an STLE lubricant specialist certification and is a millwright and heavy-duty mechanic. He can be reached at texleug@shaw.ca.

The subject of data quality is not a particularly exciting one, and this is likely why it is often overlooked or just pushed off to the side

BY TIM WHITE

Its importance is not always understood, and poor data quality is commonly the root cause of why many new system implementations are perceived by end users as unsuccessful. Though, data quality has become more important than ever, as companies embark on the journey of using OT and IIoT data to monitor their systems and assets. Having implemented systems such as this, I can assure you that if you do not think you have data quality issues, just wait.

Data quality is deemed to be high if it correctly represents the “real world” construct

to which it refers. Characteristics of high-quality OT data are complete, standards-based, consistent, accurate, and timely. An organization must be able to trust its data and be able to extract useful information from it easily. ISO 8000 breaks data quality down into three distinct areas: syntactic, semantic, and pragmatic.

Syntactic data quality: Syntactic quality is the degree to which data conforms to its specified syntax. Syntax refers to rules on the arrangement of words. In the OT data arena, this can apply to not only how data are described, but also the correct spelling of words. In a nutshell, what is being referred to here is consistency.

Semantic data quality: Semantic quality is the degree to which the data corresponds to what it represents. Simply put, the data must be meaningful to the user and represent the “real world”. For example, a temperature reading from a control system would have no meaning unless we know what it is measuring. Is it the ambient temperature or of a running machine?

Pragmatic data quality: Pragmatic quality is the relevancy of the data being collected. It must be timely and useful to the end user. A measure of this may be somewhat subjective because different individuals may have different requirements. For example, a data scientist may need data collected at a 1Hz (once per second) rate for analysis but a five-second rate may be acceptable for a technician’s monitoring consoles.

Raw data from process control systems is normally not useful without processing before analysis. Data tags must be mapped to the asset they are relevant to, defined as to what they are measuring, and many times even need units of measure assigned.

As a first step in your OT journey, an organization should develop and document a standard of how this will be completed and then managed going forward.

Start with the syntactic quality first. Remember that the goal here is consistency. Areas that should be addressed include:

• Data tag descriptions – Tag descriptions should have a consistent syntax. Have a strategy session to define your approach. Many times, so ware is built with limitations on character counts, so be sure that this is considered.

• Abbreviations – Nothing can be more frustrating than to have different abbreviations within a data set. For example, will it be Celsius or C, Motor or MTR.

• Acronyms – Determine which words and phrases will be wri en out and which will use regularly accepted acronyms. This could apply to site names, units, manufacturing lines, etc. For example, is it Pipestills 4 or PS4.

• Hierarchy – OT data historians normally require data tags to be mapped to the related assets they are monitoring. This usually requires a hierarchy to be built for the information. As a best practice, this should be a carbon copy of the hierarchy within the EAM system.

• Units of Measure (UOM) – It is not uncommon for OT systems data to not have units of measure associated with them. To make ma ers worse, units of measure can be different based on the location of the plant. With global companies, this can be sometimes confusing and can affect data models and their outputs. A great example is temperature. Is it providing a reading in Fahrenheit or Celsius? Which UOM will you standardize on or will you calculate the missing measurement

and provide both?

• Labels and Identifiers – Most OT data historians also provide the ability to use monitoring screens to display the information being collected. Take this opportunity to define how screens and the content they display will be labeled. While this will not affect the use of the data, it will provide for a professional and standardized look for the overall system.

This brings us next to semantic data quality. It is imperative that you understand what the data is referencing and that the data being recorded is accurate. This can be a very time-consuming initiative, but the data for the new systems used by analysts and data scientists must be meaningful and represent the real world.

Most of us are dealing with dated plants and control systems. Many times, these systems do not have the reference information needed to understand what the data is representing. The tag identifier in the control system will help determine what the reading is referencing, but may

Semantic data quality will require the most effort to resolve. As issues are discovered and addressed, be sure to document them as part of the standards. Successful use of the data and turning it into meaningful information will rely on this work. Finally, we will discuss pragmatic data quality. Is the data complete and timely? When using OT data to perform further analysis, this can arguably be the most important criteria. One must ensure that all the expected data tags are being collected and that all of the data is arriving with no unintentional gaps between readings. Failures with pragmatic data quality can o en be hidden and will reveal themselves right at the time one is trying to perform a manual analysis or applying even simple data calculations or models. Defined standards and monitoring will help inform administrators of potential problems.

Data collection standards - The OT data from industrial control systems can have many parameters set for how it is collected, but the wrong decisions will affect its usefulness. This is why standards should

“I can assure you that if you don’t think you have data quality issues, just wait.”

not have the unit of measure. This will all need to be researched and the additional information created within your historian as new control system data is added.

Sensors can also send incorrect data, which in turn will cause calculations and models to return inaccurate results; commonly referred to as false positives. There are a couple of different scenarios in which this happens.

Data spikes – Sensors occasionally will send an incorrect reading that would be physically impossible to have occurred. As an example, a temperature that has been steady at 100 degrees suddenly spikes to 500 degrees and returns to 100 in a ma er of seconds. Consider building persistence gates into the models so that these readings are ignored. If spikes become more frequent, then that is an indicator that the sensor may be going bad and should be replaced.

Sensor dri – Over time, sensor readings may start to dri , thereby giving an incorrect reading. This may point to a need for calibration. This can be included as part of the data model and alerts can be established to automatically indicate the need for maintenance to be performed.

be developed for data collection, which must be carefully designed in light of how the data will be used. Below are some settings to consider.

Rate of collection – Data communication rates within industrial control systems are described in Hertz (Hz) or cycles per second. Modern systems designed to capture OT data will have se ings to adjust this rate. The typical rate of collection is 1Hz however there are instances where the desired rate may be higher or lower.

Exceptions – Exceptions can be set in systems that define when data will record (be saved). In the case of analog data tags, values are many times carried out to as much as four decimal places. This level of granularity may not be useful, so it is common to have exceptions set to the rate of collection. For example, pressures could be set to only record when there is a change that meets a certain threshold, such as two psi or two bar. Additionally, a switch that is normally in the off position would not need to record a value of “0” every second. This data tag could be set to only record on a change of value, so when the switch is moved to the “on” position it would record a “1” and then record a “0” when it is switched back off.

Minimum rate of collection – As discussed earlier, pragmatic data quality failures can many times be hidden. When the data tag collection rate is set to only record on a change of value (as previously described), the failure to collect data may not always be obvious. Because of this, it is useful to set minimum rates of collection to ensure that a data tag is still active. Consider se ing these tags with a minimum rate of four hours. This will instruct the system to record the value whether it has changed or not as long as the tag is still active.

Monitoring – Another way of ensuring pragmatic data quality is through monitoring of the systems responsible for collecting the data. There will be multiple components involved, such as interfaces, tunnellers, and gateways, along with processing and storage. Sometimes, due to interface limitations, multiple instances of the interface have to be set up in order to collect all of the desired tags. Any one of these components can fail, o en without any indication. A good practice is to add dashboards to your system that monitor the status of each of these tools.

Taking the time to define standards of data collection will pay huge dividends long-term. These standards, along with system monitoring, will help to ensure that your pragmatic data quality is acceptable.

Data quality is rarely addressed at the beginning of a digital transformation. The focus is always on “ge ing the models built” and showing an ROI quickly. This becomes a double-edged sword, because when poor quality data begins to affect the success of the initiative, it causes rework in order to fix the problem. Take the time up front to address the issues discussed here. If that is done, the rest of the implementation will move smoothly, scalability will increase, and that ROI will become a reality. MRO

References

1. 2015 ed. ISO 8000-8: Data Quality - Part 8: Information and data quality: Concepts and measuring, ISO

2. Oliver Adam Mølskov Bech, 16 November 2018, Data Quality Management, DTU, 13 April 2021, h p://apppm.man.dtu.dk/index.php/Data_Quality_Management

Tim White is a Senior Manager at T. A. Cook, providing services related to digital asset performance management. Previously he worked in the industry as a global director for asset management, responsible for 83 sites across the globe.

The podcast features conversations with industry experts about maintenance, reliability, and operations. Topics that are of utmost importance to MRO readers.

Previous guests and topics have included:

• Sco MacKenzie – Maintenance at TMMC Plants with a Focus on the Environment

• Martha Myers – Importance of Networking and Education in Maintenance

• Doc Palmer – Focus on Scheduling and Planning of Maintenance

• James Reyes-Picknell – Managing Maintenance and Reliability

• Shawn Casemore – Engaging Your Employees in a Safety Culture

For sponsorship opportunities, contact Paul Burton, Senior Publisher, pburton@annexbusinessmedia.com

For guest/topic suggestions, contact Mario Cywinski, Editor, mcywinski@annexbusinessmedia.com A Podcast brought to you by

mromagazine.com/podcasts/

There are many equipment improvement programs available for maintenance departments with the purpose of improving equipment reliability. Many of these programs fail to produce the improvements they promise for a number of reasons.

BY PETER PHILLIPS

Looking at why this happens and what can be done to harness the power these programs, let’s identify some challenges that are faced with these programs and how simplifying the World Class Maintenance (WCM) process elements can speed up the implementation.

In 2011, I wrote a MRO article identifying the steps of how to implement WCM world-class maintenance program. It has been 10 years, and since then, I have been involved in many WCM projects. Recently, in a conversation with several plant reliability managers, we realized the WCM

program has not really progressed as far as we would have liked it to. So, we decided it was time to review all the elements of a WCM project.

First of all, let’s have a quick review and look at what WCM means. There is no one definition of WCM, achieving worldclass maintenance is about the creation of a cohesive partnership between equipment operators, maintenance technicians and engineers, as well as anyone that has a stake in the ownership of equipment reliability. Improving maintenance effectiveness and efficiency is critical to the overall success of any manufacturer, and

commitment from both operations and maintenance is paramount. Think of it as a parental relationship where production and maintenance are the parents of equipment and between them, they make the right decisions for the equipment’s operational health and well-being.

WCM is a proven continuous improvement methodology that helps prioritize resources to a ack problems and losses with the aim to achieve a safe, sustainable manufacturing process with zero loss and zero defects.

However, there are bumps in the road along the way that prevent maintenance departments from achieving their WCM goals.

Looking at some of the challenges that facilities face when implementing and improvement program, the following are the top four issues that companies need to acknowledge and address to successfully implement world-class maintenance for the longterm.

1.

Systems like WCM require many resources to implement and can be very labour-intensive, especially in the beginning phases. Additional work effort and continuous input from maintenance and production employees is needed to keep the project moving ahead. We need other people and resources for WCM training to provide guidance and support to maintain the sustainability of the improvement process. Over a period of time, as they get better at executing the WCM process, companies start to realize the benefits of the system and the resources required, however, it is still a big challenge to support the system long-term. There is sometimes a lack of commitment and it becomes difficult to sustain the implementation.

2. Lack of understanding

WCM, like any other new system, requires people who will be the experts in the implementation and its processes. They need to know WCM in-

timately and how to facilitate the implementation and provide the right guidance and knowledge in easy-to-execute steps that every person will understand. The lack of understanding of WCM and system knowledge can lead to complications through the implementation stages.

Maintenance and production employees will be new to WCM projects, and at first glance it looks like a lot of extra work to them. It is important to convey to the team that the implementation of WCM

will not affect them in a negative manner. Although WCM requires a lot of commitment, the long-term benefits will allow them to carry out their work responsibilities with less interruptions to equipment issues and breakdown. It is important the WCM leadership have a positive outlook and create excitement and motivation for the team to work together. This takes the right type of person to lead this enthusiasm, so choose leaders wisely.

4. Cultural shift

While WCM projects are being imple-

mented, the plant may still be in the firefighting phase. Past maintenance practices will still be in play as technicians and operators continue to fix equipment when they fail. It is important to foster a cultural shi and mindset of the people who operate and maintain equipment. They need to be taught to think about and address the root causes of the failures rather than acting upon equipment problem symptoms. Many times, companies will enforce new strategies, like the WCM, without having a game plan to get out of the old paradigm. People need to be shown the way and need to under-

with equipment information, preventive maintenance activities, equipment drawings and spare parts information. Then the documents are maintained in large binders that need to be updated during the complete lifecycle of the machine.

The solution: although machine information still needs to be gathered, we developed data gathering forms in a digital format that can be easily uploaded, accessed and maintained in the CMMS. This has saved many hours, and, in some cases, days of not having to create manual equipment documents and binders.

WCM is a proven continuous improvement methodology that helps prioritize resources to attack problems and losses with the aim to achieve a safe, sustainable manufacturing process with zero loss and zero defects.

stand the process. Ultimately, in order to get buy-in from the people involved in the project, they will want to know how it will improve their job.

In the past month, being involved with a WCM project team, we have been reviewing our progress with WCM projects that focus on a single piece of equipment or process. These projects identify the elements needed to properly maintain and sustain the equipment over a long period of time; basically over the complete lifecycle of that machine or process. These projects are generally carried out on critical equipment and processes or on equipment that have poor reliability. Critical equipment makes up approximately 5 per cent of the total number of equipment assets. These projects can be very labour-intensive and even complicated to follow, and therefore can take several months to complete.

Our project team has been reviewing the complete WCM process in order to make it simpler and faster to complete without affecting the integrity of the WCM system. We have reviewed every element in every step of the process and have simplified or eliminated non-value-added activities.

Here are four actions we have taken to streamline the process:

Projects can be very paper-based and require many manual forms to be filled out

AM (autonomous / operator maintenance) duty sheets are the periodic inspections and checks that an operator needs to perform on their equipment. In WCM, these paper-based duty sheets and PMs (technician preventive maintenance) are normally tracked using AM and PM calendars. The calendars are posted on a display board near the equipment or process. We found these manually updated calendars rarely used due to their complexity and time required to keep them updated.

The solution: once again we turned to the CMMS. In practice, all equipment maintenance should be recorded in the CMMS, which provides work history and tracking. Consequently, the need for manual calendars used to track equipment maintenance has been eliminated.

During the implementation of a WCM project, it is common practice to document the complete project journey. A before and a er picture, graphs and documents as well as milestones and improvements details are displayed on project boards. The idea is to display the elements of the project in a visual format so people can see the project progress. The boards are also a significant part of a WCM audit.

Though, these details storyboards are essential in early WCM projects, as they support the project process. However, as the team becomes more experienced per-

forming WCM projects, the question is whether we need all this detail. Updating the many display boards requires a lot of time and may not be value-added.

The solution: simplify and reduce the number of display boards to only display specific meaningful information. This saves hours of updating the many documents and charts that are normally displayed. Our team found that it is possible to reduce the number of project boards to less than half.

Contaminants generally come from the manufacturing process or the surrounding environment. WCM requires a team to solve equipment contamination issues. This element of a WCM project is one of the most time-consuming activities.

The solution: the team identified two distinct categories; equipment contamination and component contamination. Dividing contamination into the two categories allowed us to focus on the question, does all contamination affect equipment reliability? It was found that some equipment and area contamination would not cause adverse effects to the equipment wear components, and, therefore, were added to housekeeping duties. Contamination that would affect the lifecycle of the wear components were identified as high-priority items and need to be solved. Having identified these two categories and separating them has significantly reduced the time it takes to complete this element of the project.

In conclusion, regardless of what equipment improvement program you use, take a step back and evaluate the process. Can non-value-added activities be modified or completely removed from the improvement project? Can the process be made simpler and easier to use and maintain? Can information be integrated with some technology or so ware you already have, like the CMMS?

Everyone is busy in a manufacturing environment. Reducing the time it takes to complete the steps in a WCM project will save many labour hours and allow your facility to complete more WCM projects in a given time period. MRO

Peter Phillips is the owner of Trailwalk Holdings Ltd., a Nova Scotia-based maintenance consulting and training company. Peter has over 40 years of industrial maintenance experience. He travels throughout North America working with maintenance departments and speaking at conferences. Reach him at 902798-3601 or peter@trailwalk.ca.

DEMO DAYS is a new manufacturers video portal which will help you learn about new products and services from Canada’s leading manufacturers.

DEMO DAYS features dozens of video demonstrations in a variety of categories: Additive Manufacturing, Automation, Cleantech, Cyber Security, Electronics and Electrical, Maintenance, Manufacturing/Production, Material Handling, Packaging and Software.

Visit DEMO DAYS and connect with suppliers today.

SKF has extended its explorer range with a four-row cylindrical roller bearing 4rCRB, aimed at demanding applications in long product rolling mills.

It offers up to 50 per cent longer service life than the previous generation 4rCRB, and it helps overcome challenges caused by contamination, high loads, varying speeds and reversing torques.

Explorer bearings feature reduced friction, increased hardness and improved steel quality that gives them the ability to withstand heavier radial, and axial loads and allows them to run longer than standard bearings. www.skf.com

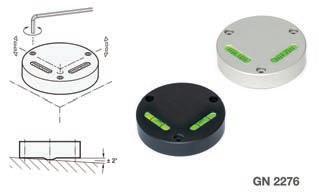

bull’s eye and screw-on spirit

Winco expanded its existing selection of bull’s eye and screw-on spirit levels with two new models: cross spirit levels GN 2276 and screw-on spirit levels GN 2283.

The cross spirit levels GN 2276 combine two perpendicular linear levels within a single, round aluminum housing. There is one version with a flat underside for direct installation and a second version with an alignment ball on the bo om side for adjustment. The second type, designated JV, allows the

Continental launched a collaboration, sensIC project, with partners from industry and R&D. Continental is driving the project forward with its integrated sensor technology based on printed electronics for hoses and lines installed in electric vehicles (EVs).

The project involves installing hoses for thermal management in EVs with integrated temperature sensors. The electronics are designed so as to rule out manipulation during production, at subsequent stages of the supply chain or during actual use.

As an electronic, non-clonable identifier, a differential PUF circuit based on printed transistors and silicon-based read-in and read-out electronics is integrated with a sensor circuit. The sensor circuit contains a silicon IC that communicates with the hybrid PUF via a corresponding interface made possible by a specially engineered, packaging technology, thus forming a “secure” overall system. www.continental.com

Harting’s solution with har-modular has flexibility on PCBs. As a modular principle, in terms of size and architecture, har-modular is based on the DIN 41612 ledges used for decades. Har-modular provides a modular system of different modules for the transmission of all vital lifelines by way of a online configurator. Developers can combine and order individual modules for power, signals and data that are customized and fine-tuned to their applications. Various modules enable many possible combinations, and can be ordered as from batch size one. Meaning prototypes can be fi ed quickly, flexibly and cost efficiently, while series production can also be launched. www.harting.com

spirit level to be adjusted using the three installation screws to set a zero-point adapted to the specific situation with a variance of +/two degrees.

Screw-on spirit levels GN 2282 is available as a directly mountable, flat version AV and as an adjustable version JV with an alignment cam on the bo om.

Both are available in two sensitivity ratings: two millimetres of bubble movement correspond to either six or 50 minutes of arc. www.jwwinco.com

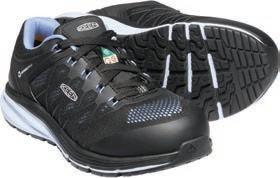

Keen Utility’s CSA Vista Energy series features KEEN. ReGEN, a lightweight performance cushioning midsole.

The work sneaker features asymmetrical carbon-fibre toes that are 15 per cent lighter than steel. Its custom carbon-fibre safety toes offer an unobtrusive fit. The sneaker incorporates non-metallic puncture resistant midsole plate for workers who require entrance through metal detectors on the job or are looking for lighter weight protection.

The CSA Vista Energy series is constructed with a non-marring, two-layer mesh upper to increase breathability and air flow within the shoe.

The CSA Vista Energy series is available in both men’s and women’s silhoue es. It will be available in a breathable mesh low version and another low height option, Vista Energy XT, with a synthetic upper offering abrasion-resistance for both men and women. www.keenfootwear.com

On May 13th, Annex Business Media’s Manufacturing Group teamed up to host Women in Manufacturing, a one-day virtual summit that brought together industry experts and thought leaders to promote gender equity, diversity and inclusion in Canadian manufacturing. Visit womenincanadianmanufacturing.com to view on-demand content.

THANK YOU TO OUR SPONSORS

PLATINUM SPONSOR

Is your reliability program up to the coming challenges? I don’t mean solving problems that have already happened with root cause methods. That’s too late. And it won’t make sure you achieve operational excellence as we emerge from the pandemic.

COVID-19’s uncertainty led to belt-tightening measures. Capital replacements were deferred. Contractors were dismissed and their work either deferred, stopped indefinitely or brought in-house. A lot of PM work got deferred. Shift arrangements were shuffled to allow for distancing and minimize contacts. Training stopped. For more than a year now, it’s as if everything went on hold for many of us. Quietly, we’ve lost some experience too, as many of those last few baby-boomers hit retirement age.

Supply chains were strained and deliveries slowed. Where plant production levels dropped, the stresses on your machinery, equipment and systems were also reduced. You might have noticed that things ran well compared with the hectic pace you had before COVID hit. Did you ever think that maybe you had been doing too much of the wrong maintenance before COVID? If things are running better despite the deferred maintenance and capital replacements, then maybe so. Or maybe not.

What will happen as you ramp back up? If you had reliability problems before COVID and you haven’t changed your reliability program (maintenance), then why wouldn’t those problems return?

The podcast features conversations with industry experts about maintenance, reliability, and operations. Topics that are of utmost importance to MRO readers. Previous guests and topics have included:

• Sco MacKenzie – Maintenance at TMMC Plants with a Focus on the Environment;

• Martha Myers – Importance of Networking and Education in Maintenance;

• Doc Palmer – Focus on Scheduling and Planning of Maintenance;

• James Reyes-Picknell – Managing Maintenance and Reliability; and Shawn Casemore – Engaging Your Employees in a Safety Culture. MRO

We’ve all heard forecasts – we are heading into another “roaring ‘20s”. Demand for products is going to soar. Production will need to ramp up quickly to meet demand, and your plant will need to stay reliable. There’s money to be made – if your plant can sustain production at high levels.

Belt-tightening got you through COVID-19, but it won’t help with the recovery. While it was relatively quiet, did you do anything to ensure that production can ramp up to normal, or higher, levels? If not, then you might be in for a rough time in the “new normal”.

Operational excellence was cited as a top priority by CEOs in the very recent PwC Survey of CEOs. They know it will be needed to survive the recovery. If that’s your boss’ priority, then what are you doing to make sure you achieve it?

You know that you cannot achieve operational excellence if your plant is breaking down frequently. It’s time to re-engineer your maintenance programs for higher performance. That old maintenance program that didn’t work so well before needs to become a reliability program.

It’s not too late to learn about reliability, understand how and why things fail and what you can do about them. Reliability centered maintenance (RCM) is excellent for that. Even if you can’t pull together teams and do full RCM analyses, you can apply what you learn in the training. Don’t wait much longer or you might be setting yourself up to fail as the global economy recovers. MRO

Roger Thostenson Lubriplate District Manager OK, AR, Northern TX & MS

Lubriplate has been helping industry meet its lubrication needs for more than 150 years. In that time, we have learned what works and what doesn’t. Put our experience and knowledge to work for you.

Lubriplate offers a full range of ultra high-performance synthetic and petroleumbased lubricants that have been engineered from the ground up to provide a number of cost saving benefits including; extended lubrication intervals, reduced friction, multiple application capability and lubricant inventory consolidation.

Lubriplate offers its Complimentary ESP Extra Services Package to all of its customers at no additional charge. Services include; Complete Plant Surveys to help determine your exact lubrication needs, Color Coded Lube Charts and Machinery Tags which simplify maintenance procedures, Lubrication Training Programs and Follow-Up Oil Analysis.