ALL ABOUT CMMS

MACHINERY AND EQUIPMENT

FEBRUARY 2021

Vol. 37, No. 1

Established 1985 www.mromagazine.com

@mro_maintenance

Instagram: @mromagazine

Facebook: @MROMagazine .com/company/mro-magazine

Print and digital subscription inquiries or changes,

Beata Olechnowicz, Audience Development Manager Tel: 416-510-5182 Fax: 416-510-6875

email: bolechnowicz@annexbusinessmedia.com don Baker Rd., Suite 400 Toronto, ON M2H 3R1

Mario Cywinski, Editor 226-931-4194 mcywinski@annexbusinessmedia.com

Contributors

Rehana Begg, Bryan Christiansen, John Lambert, L. Tex Leugner, Douglas Martin, Martha Myers, Doc Palmer, Peter Phillips

Paul Burton, Senior Publisher 416-510-6756 pburton@annexbusinessmedia.com

Jason Bauer, Media Sales Manager 416-510-6797 jbauer@annexbusinessmedia.com

Ilana Fawcett, National Account Manager 416-829-1221 ifawcett@annexbusinessmedia.com

Andrea M. Smith, Media Designer

Catherine Giles, Account Co-ordinator 416-510-5232 cgiles@annexbusinessmedia.com

Scott Jamieson, COO sjamieson@annexbusinessmedia.com

Machinery and Equipment

MRO is published by Annex Business Media, 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1; Tel. 416-442-5600, Fax 416-510-5140. Toll-free: 1-800-268-7742 in Canada, 1-800-387-0273 in the USA.

ISSN 0831-8603 (print); ISSN 1923-3698 (digital) TION MAIL AGREEMENT #40065710

Canada: 1 year $65, 2 years $110. United States: 1 year $110. e: 1 year $126. Single copies $10 (Canada), $16.50 (U.S.), $21.50 (other). Add applicable taxes to all rates.

On occasion, our subscription list is made available to organizations whose products or services may be of interest to our readers. ould prefer not to receive such information, please contact our circulation department in any of the four ways listed above.

Privacy@annexbusinessmedia.com, 1-800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2021 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

Investing in Ontario

While 2020 may have been a year many of us want to forget, with the COVID-19 pandemic wreaking havoc across many industries in Canada, bright spots did emerge. Major manufacturers have started to invest heavily in Ontario, after years of pulling production out of Canada to other international destinations.

In November 2020, General Motors Canada announced that they will bring truck production back to the Oshawa Assembly Plant in January 2022, as well as investing in its St Catharines Propulsion Plant, and Woodstock Parts Distribution Centre. The investments totaled over $1 billion CDN. This was followed by news in January that GM is going invest another $1 billion CDN to convert its CAMI manufacturing plant in Ingersoll, Ont., to produce its new electric light commercial vehicle, BrightDrop EV600, to be ready for delivery in late 2021.

Not to be outdone, Ford Motor Company of Canada announced in October 2020 that it (along with provincial and federal governments) are investing a total of nearly $2 billion CDN in Ford’s Oakville Assembly Complex. The investment will see the complex retooled to become a battery electric vehicle manufacturing facility beginning in 2024. Ford will also introduce a new engine program at its plant in Windsor, Ont.

Also in October 2020, Stellantis Canada (formerly FCA Canada), announced it will invest over $1.5 billion CDN at its plants in Ontario. With the majority going to its Windsor Assembly Plant, to install a multi-energy vehicle architecture (which include PHEV and BEV vehicles). It will also invest in its Brampton Assembly Plant, and Etobicoke Casting Plant.

Combining this with earlier investments from Toyota Motor Manufacturing Canada (in 2019) for its Woodstock and Cambridge plants, and there is no doubt that automotive production in Ontario is alive and well.

Switching gears, this issue or MRO magazine, focuses on computerized maintenance management systems (CMMS). We have a great cross-section of viewpoint from our expert writers on the many aspects of CMMS. Rehana Begg looks at “how a CMMS/EAM system keeps maintenance facilities on track,” in her article Go Live or Go Home. Peter Phillips describes how in 2021, “many maintenance departments will either be implementing their first maintenance software or upgrading to one of the hundreds of new CMMS systems on the market,” in his article Successful CMMS Implementations. Next, Bryan Christiansen explains How to Use A CMMS to Increase Work Accountability in the Maintenance Department. Finally, Doc Palmer looks at CMMS: the Good, the Bad, and the Ugly

And now for some MRO self-promotion, be sure to listen to our In Conversation with Mr. O podcast, we have had some great guests on the show in 2020, and our first guest for 2021 is Martha Myers, who discusses the importance of networking and education in the maintenance world. Have a look at our Mr. O page for more about this episode.

Mario Cywinski Editor

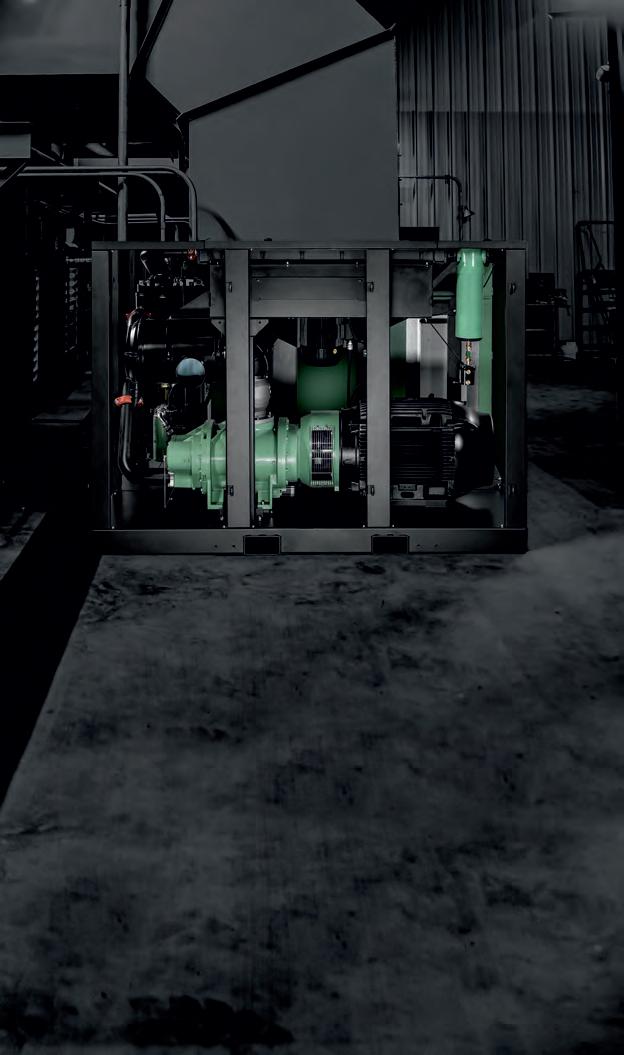

Photo credit.

of Canada

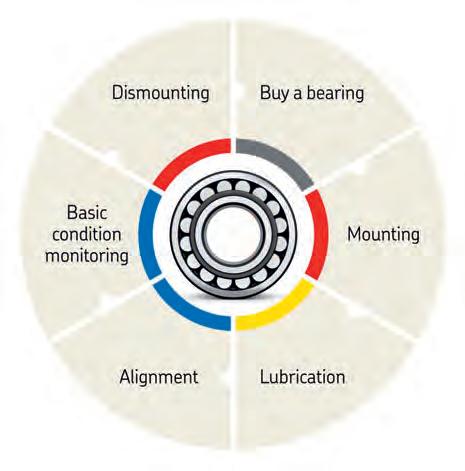

SKF TOOLS HELP KEEP YOUR MACHINES RUNNING

Improve your efficiency with solutions from SKF

» Bearing fitting kits TMFT Series

Poor fitting, usually using brute force, accounts for 16% of premature bearing failures. SKF’s TMFT Bearing Fitting Tool Kits are designed for quick and precise mounting of bearings, while minimising the risk of bearing damage.

https://bit.ly/3lFCzuy

» Shaft Alignment Tool TKSA Series

» SKF EasyPull mechanical puller TMMA series

The patented SKF EasyPull is one of the most user-friendly and safe tools on the market. The series is equipped with spring-operated arms and a solid design.

Avoid damaging the shaft with improper removal techniques, the TMMA series will assist you in the secure way to remove your bearings.

https://bit.ly/3kDQTCx

The TKSA Series are easy to use laser alignment solutions for achieving accurate shaft alignments. With two wireless measurement units, large sized detectors and powerful lasers, the instrument performs in even the most challenging conditions.

https://bit.ly/2IIwIGc

By applying the right maintenance practices and using the correct tools in all stages of the bearing life cycle, you can considerably extend your bearing’s service life and thereby increase plant productivity and efficiency

More at: https://bit.ly/2KduY8B

» SKF Portable Induction Heater TWIM series

The TWIM 15 features glass-fiber, high-temperatureresistant plastic construction that allows a low temperature difference between the inner and outer rings of the bearing. It is compact, lightweight, contains automatic temperature monitoring, and detects bearing size to heat appropriately for easy use.

https://bit.ly/36GMcmx

» SKF SYSTEM 24 Single Point Automatic Lubrication

Continuously delivers precisely measured amounts of lubricant to desired points via a gasdriven pump. It is ideal for lubrication points difficult or unsafe to reach manually, or where there are a large number of lubrication points where manual greasing would be less effective.

https://bit.ly/36Cl6N6

Go Live or Go Home / 10

Maintenance 101 / 14

In 2021, many maintenance departments will either be implementing their first maintenance software or upgrading to a new CMMS systems on the market.

/

Social Media

As the world becomes more digital and connected, it is more important than ever that organizations are properly collecting and utilizing their data.

NTN Makes Appointments

NTN has made new appointments to its Canadian operations.

Sean Barron has been named to the position of Quebec Sales Manager at NTN. He has over 26 years of bearing industry experience, including starting with NSK in 1994, and joining NTN in 2015. He served as territory manager for the last five years, where he expanded NTN’s presence in the Quebec marketplace.

Rittal Systems Ltd Canada Names New President

Rittal Systems Ltd., Canada has named Andre Bousette as its new President, taking over for Tim Rourke, who has resigned.

Barron will be responsible for developing sales programs and operations for the Quebec market and managing key account channels. He will also be in charge of implementing and managing virtual sales activities, identifying new market opportunities and more Giovanna Sacco has been named as Territory Project Manager. Sacco will report to Sean Barron, and will be responsible for creating, implementing and virtually managing each sales project plan to support the distribution network and end user customer base. She will play a lead role in monitoring the entire project scope and success of each customer project, including virtual call cycles and sales strategies.

Sacco brings over 17 years of sales experience, managing all aspects of industrial distribution having worked for BDI, Cascades, Acier Rive-Nord and Acier Vaudreuil Steel. She has overlooked operations from technical sales support to customer service and project management. MRO

Motion Industries Rebrands

MBousette has been with Rittal for 25 years, in 1990 he began as an outside sales representative in Montreal and surrounding area. In 1997, he became regional sales manager for Quebec. He was national sales manager from 2004 to 2008. Most recently, he was regional sales director for eastern Canada. Bousette has over 30 years’ of experience in the manufacturing and automation fields. He holds a Bachelor of Commerce Degree from Concordia University and post-grad qualifications from McGill University. Rourke completed 25 years of ser-

vice to Rittal in 2020. In 1995, he joined Rittal as an outside sales representative in eastern and northern Ontario. In 1997, he became regional sales manager for Ontario. He then moved on to regional sales manager for western Canada.

In 2002, Tim moved into a business development role, helping Rittal grow through a targeted approach to markets and industries. In 2010, he became the business operation manager. In 2015, Rourke took over as president of Rittal. In recent years, Rourke has been a founding member of the German Technology Day events and has initiated the ‘Women in Tech’ EFC scholarship. Under his leadership, Rittal has given back to the community through social committee initiatives. MRO

SKF Names New President and CEO

Rickard Gustafson has been appointed as President and CEO by the board of AB SKF, taking over for Alrik Danielson. He will be joining SKF in the first half of 2021.

Gustafson is currently the President and CEO of the SAS Group, which he joined 10 years ago. Before that he was CEO of Codan/Trygg Hansa, he has also held several positions within General Electric.

otion Industries, Inc., announced it will re-brand to “Motion,” in time for its 75th anniversary. The re-brand is intended to solidify the company’s structure and help advance its position in the marketplace.

“The goal of this change is twofold: 1) to have the name ‘Motion’ as well as the ‘Mi’ logo synonymous with and increasingly recognized as the premier industrial solutions company that we strive to be every day

“I’m excited and grateful for the opportunity to join SKF, a highly respected company within its industry,” said Gustafsib. “SKF has a clearly defined strategic direction, and I look forward to engaging with the organization and further accelerate the ongoing transformation into an even more customer focused, innovative, efficient and sustainable business.” MRO

for our customers, and 2) to promote and reflect that the Motion structure and strategy is cohesive, allowing a deeper focus on sales, expertise, and customer service that make us different and valued,” said Randy Breaux, President, Motion. The basis of the word “Motion” in the name stems from the company’s role in keeping industry’s operations and machinery running – in motion. MRO

GM Bringing Commercial EV Manufacturing to Ontario

General Motors is bringing production of its BrightDrop EV600, an electric light commercial vehicle, to the CAMI manufacturing plant in Ingersoll, Ontario. GM will be investing approximately C$1 billion to have the EV600 ready for delivery in late 2021.

With the investment, CAMI becomes Canada’s first large-scale auto plant converted to produce electric delivery vehicles in Canada. Work to convert CAMI will begin right away.

BrightDrop is a new GM business that offers an ecosystem of connected and electrified products and services designed to help with delivery of goods and services from the first to last mile. Initial products are an EP1 electric e-pallet, a software platform for fleet and asset management, and EV600.

“BrightDrop offers a smarter way to deliver goods and services,” said Mary Barra, Chairman and CEO, GM. “We are building on our significant expertise in electrification, mobility applications, telematics and fleet management, with a new onestop-shop solution for commercial cus-

tomers to move goods in a better, more sustainable way.” MRO

CanREA Hosts Operations Summit

Over 250 industry professionals attended The Canadian Renewable Energy Association (CanREA) inaugural two day Operations Summit, virtually.

“Operations professionals are the people who project developers come to when they want to know if a dream concept is both possible and practical,” said Phil McKay, Senior Director, Operations, CanREA. “This is the conference that answers the question: what is possible? And not just right now, but five to ten years from now: what is coming down the pipeline for the engineering marvel that is our industry?”

Speakers looked at 2020 and focused on the path ahead, by sharing how they navigated this year. They also spoke about signifi-

cant operations and maintenance trends developing in Canada.

“Over the next five years, we will see massive innovation in the O&M space in Canada. It will be unlike anything we’ve seen before,” said Robert Hornung, President and CEO, CanREA. “Our members are already pushing the boundaries of what technology can do, but as wind, solar and storage come together to accelerate a de-carbonized grid, we will seize the opportunity to bring it to the next level.”

A session on “Critical Infrastructure Protection,” by Mollie Johnson, Deputy Minister for the Low Carbon Energy Sector, Natural Resources Canada’s Assistant, discussed threats and opportunities affecting the security of Canada’s electricity-system infrastructure, and Canada’s response. Also, Tyler Hamilton, MaRS Discovery District) and Tom Rand, ArcTern Ventures presented “A Conversation About Emerging Clean Tech Innovation,”

“Continuous improvement in the operations and maintenance of renewable energy assets is vital to the long-term success of this industry,” said Paul van der Weg, Managing Director, Canada, Siemens Gamesa Renewable Energy. “As a proud supporter of the CanREA Operations Summit, we appreciate the opportunity to showcase our commitment to driving innovation with solutions that extend the lifetime of our customers’ renewable-energy projects. The Summit is a great way to engage with industry partners and share best practices to the benefit of all Canadians.”

MRO

Tora Inc Joins Thorold Multimodal Hub

St. Catharines-based Tora Inc. will now occupy 60,000 square/feet of warehouse space within the recently-opened Thorold Multimodal Hub.

“This expansion is an important next step in our business growth,” said Scott DeMont, GM and Partner, Tora Inc. “From this new facility we are better able to provide our growing customer base with a wider range of services.”

The 200-acre multi-modal industrial complex in Thorold, Ontario, managed by HOPA Ports, is adjacent to the Welland Canal. It features marine, rail and highway access, and indoor warehouse and outdoor storage space. Benefits of the complex are proximity to U.S. border, availability of marine and rail, and strategic location in the Niagara-Hamilton-Toronto trade corridor.

“We’re pleased to welcome Tora to the HOPA Ports network,” said Jeremy Dunn, Commercial Vice President with HOPA Ports. “Tora’s business is a growing success story in Niagara, and we are delighted to be able to offer the facilities and transportation connections to help the company thrive.”

MRO

ATS CEO Receives Award

Advanced Technology Services, Inc. (ATS) announce its CEO, Jeff Owens, was named to the 2021 list of “CEOs Who ‘Get It’” by the National Safety Council.

“One thing I can promise is that ATS’s commitment to a strong safety culture and our employees’ well-being will never waver, and our journey for continuous improvement will never end,” said Owens.

Owens has committed himself to embedding safety in the company’s overall philosophy and core values by implementing a Live Safety/Beyond Zero culture, safety dashboard, and programs such as the President’s Award for Safety Excellence.

In 2020 – ATS went 89 days (greater than one million hours) without a recordable incident and 144 days (greater than two million hours) without a lost time incident.

The annual award recognizes executive leaders who go above and beyond to protect employees both on and off the job through: risk reduction, performance measurement, safety management solutions, and leadership and employee engagement. MRO

Cummins Makes Executive Changes

Cummins Inc. Engine segment have made executive changes. Amy Boerger has been named as Vice-President and General Manager, North America in charge of the North America region for On-Highway. José Samperio take over for Boerger as Executive Director, Sales for U.S./Canada in the field sales and support organization. Lyndon Jones, has been named General Manager of Leasing for North America, replacing John Malina.

“As the world’s largest independent engine manufacturer, we continue to strive to be the power of choice for all global commercial vehicle OEM’s and end-users alike. Cummins lives our brand promise of innovation and dependability in everything we do. In order to ensure we hit our goals in North America, we have made some executive changes as the core of Cummins’ strength is our great regional leaders across the globe,” said Brett Merritt, Vice President, On-Highway Engine Segment, Cummins Inc. Boerger will now lead a single organization for North America, with dealer, fleet and OEM teams. She has been with Cummins for 37 years in a variety of roles and organizations in sales and service, OEM and general management roles.

“Amy is clearly recognized as the industry expert for Cummins, has long-standing relationships across all parts of the truck and bus businesses, and serves in a variety of leadership roles in the American Trucking Industry. Amy has long led the Sales and Support organization, helping grow our leading market share in North America. She will now expand this responsibility to lead the entire North American business, setting it up for long-term success,” said Merritt. José Samperio will report to Boerger and lead the end-user sales and support team for national accounts. Samperio has 20 years of experience, mostly with Cummins, taking on roles of increasing levels of responsibility; most recently serving as the strategy leader for the engine segment.

Lyndon Jones will also report to Boerger. Jones will be responsible for the execution of the strategy of the leasing business over the company’s enterprise. He has been with Cummins since 2005, in leadership positions within the engine and distribution segments. MRO

Ford of Canada Names New President and CEO

Ford Motor Company of Canada, Limited, has named Bev Goodman as its new President and CEO, taking over for Dean Stoneley, who will take on a newly created position of General Manager, North America truck, Ford Motor Company.

“During a year of extraordinary challenges, Dean led the Ford of Canada team to its twelfth consecutive year of sales leadership and now brings his agile leadership approach and strong customer focus to the critical role of maintaining Ford’s dominance in the North American truck market,” said Kumar Galhotra, president, Americas and International Markets Group, Ford.

“At this time of rapid change in the auto industry, Bev demonstrates a deep understanding of what matters most to our customers now, and in the future. She also has a proven track record of working collaboratively with our dealer partners and a commitment to innovation as Ford accelerates its efforts to deliver high-quality, high-value vehicles and services.”

Goodman will lead Ford of Canada’s operations, including its national headquarters, regional offices, vehicle assembly and engine manufacturing plants, parts distribution centres, research and development sites, and connectivity and innovation centres.

“I look forward to embracing new ways to serve our customers across the country as we introduce iconic vehicles such as the Mustang Mach-E, Bronco and F-150 hybrid,” said Goodman. “We’ll focus on delivering the benefits of electrification and connectivity to consumers, including plans for the C$1.8-billion transformation of our Oakville Assembly Complex to a battery electric vehicle manufacturing facility and continuing to grow our advanced connectivity and innovation centres,” Goodman said.

Goodman has been with Ford of Canada for 25 years, and began as an intern on the finance team, she has worked in a variety of functions including finance, parts and service, sales and marketing, and most recently as director of marketing communications. MRO

GO LIVE OR GO HOME

How a CMMS/EAM system keeps maintenance facilities on track.

BY REHANA BEGG

When the World Health Organization declared COVID-19 as a pandemic in March 2020, the impact would challenge emergency preparedness, and test resilience across industrial, commercial and institutional sectors.

At the time, Metrolinx, the Province of Ontario’s largest transport services agency, was in the throes of an enterprise-wide computer systems upgrade. The onslaught of the pandemic threw a spanner in the works for a go-live date of August 2020.

“The term ‘pivot’ is a bit of a cliché, but you really have to be ready to take anything that comes your way,” said Rajes

Perumal, a supervisor in the plant maintenance group at Metrolinx who was moved into a planning role to help with the implementation. “Whether it’s training for an asset management system or deciding on what has caused a major power failure at a site, you brainstorm very quickly and get the ideas out on the table and adjust. That’s not an easy task, but it is a doable task.”

The vision for replacing a 19-year-old CMMS (computerized maintenance management system) at Metrolinx, said Perumal, was to bring everything under a single platform – an enterprise asset management (EAM) system –which would not only facilitate future

lifecycle analysis on of physical assets, but also develop an enterprise-wide asset hierarchy designed to connect all business units, from maintenance at one end, to procurement, human capital management systems and financial on the back end.

Touchpoints and training protocols

Perumal recalls two main events stemming from the pandemic that notably affected the course of the implementation at the Willowbrook Rail Maintenance Facility (one of two maintenance facilities servicing the Metrolinx fleet).

The first was the requirement to sanitize touch points. Even before the coronavirus outbreak, Metrolinx had been working with a consulting firm to assess its facilities and make recommendations on best practices. Due in February 2020, the timing of the assessment aligned with public health directives to prevent the spread of COVID-19. For instance, the assessment included guidelines and recommendations for custodial staff on proper cleaning techniques and its documentation.

“With greater transmission risks we

needed to reconfigure and recalibrate the number of times we would sanitize touch points throughout the day,” said Perumal. “The CMMS helped in coordinating and implementing a regimented cleaning schedule.”

The second event was the system’s training roll out. When physical distancing measures were enforced, the implementation at the maintenance facility had already advanced to the training phase. Since there was no telling how long the pandemic might last, the training team decided it would be prudent to forge ahead with training administrators, super users and power users on the software. Initial plans to host fullday classroom sessions with groups of 12 people were whittled down to virtual sessions of three or four.

“A system is only as good as the operators using it,” said Perumal. “Without an adequate amount of training, users cannot feed the needed information into the system, which doesn’t do us any good, or causes confusion.”

After using the system for six months, Perumal’s team is starting to see maintenance patterns emerge. Their data

capture capability has been crucial for operating efficiently, he says, and the team is able to look at processes from a lean perspective.

Start tracking

The global lesson learned from the pandemic, is that logistics and supply lines are vulnerable in crisis environments, points out Leon Wasser, President of

Wasser Resources in Toronto. This reality has made it critical to forecast all of the needs of the manufacturing process, “because the supply chain can’t be interrupted,” said Wasser.

For proof, said Wasser, look to the auto parts manufacturers that had to retool and manufacture ventilators instead of car parts on an emergency basis. “It illustrates why being able to forecast all

CHROME

Increasingly, enterprises rely on remote monitoring operations, fault detection and course correction. Asset management systems give plants the ability to re-design complex processes and increases opportunities for remote operations and optimize productivity.

–Wasser

“We’ve learned the hard way that we have to increase our management of processes,” said Wasser. He also advises that a CMMS can be used to remotely manage and schedule critical processes, such as disinfecting components, while effective scheduling and social distancing protocols can provide a safe operating environment.

Manufacturing process

of the components, including expertise, is of critical importance,” he said.

A CMMS, regardless of the industry, is above all else a forecasting and management system – a veritable “crystal ball,” said Wasser, whose is also an authorized agent for Eagle Technology CMMS and EAM software.

“If plants need components, expertise and logistics going forward, they will not only need to know what a normal process requires, but also what alternate supply routes might be available. The CMMS gives plants the tools to be able to look into the future, map out all of the inputs and outputs – including engineering, components, regulatory approvals – that you need to complete your manufacturing process,” said Wasser.

He has consulted on multiple installations and training, including with CSA Group (formerly the Canadian Standards Association), regards a CMMS as a necessary risk management tool. De-risking the manufacturing process

is especially critical in a crisis environment, he said, and a CMMS can help identify those risks and engineer ways to mitigate those risks.

According to Wasser, there are three elements of the overall manufacturing process where CMMS technology can help de-risk plants during a crisis situation: hygiene (basic maintenance), manufacturing processes, and inventory management.

Basic maintenance/ hygience

“COVID-19 is unique due to its infectious nature, but in food packaging plants, where disinfection goes hand-in-hand with safety, de-risking through clean hygiene practices is especially important,” said Wasser, referencing as a cautionary tale how Cargill Canada’s meat processing plants were temporarily shuttered due to significant COVID-19 outbreaks, and how the company came under scrutiny for failing in its safety protocols to protect essential workers.

In times of crises, manufacturing processes may need to be re-engineered, said Wasser. “In normal situations, if you have a CNC issue or another sensitive tooling process issue, you might call a service person to reprogram it or change components,” he said. “But in a crisis situation, the maintenance technician might not be available.”

Increasingly, enterprises rely on remote monitoring operations, fault detection and course correction. Asset management systems give plants the ability to re-design complex processes and increases opportunities for remote operations and optimize productivity, according to Wasser.

Inventory management

It rarely makes sense to have too many spare parts on hand, said Wasser. (“Spare parts and components cost money.”) At the same time, he said, no plant can afford to be short of a critical component at a key juncture, and it is why managing that supply is crucial. Going forward, plant managers will need to know what’s required in their normal manufacturing processes, but will also need to know what their alternate supply routes might be.

Manage risk

A key metric for maintenance is “near-zero unplanned downtime for critical assets, which includes those used to produce revenue,” said Ralph Rio, Vice-President, Enterprise Software, with ARC Advisory Group. He argues in a white paper that without maintenance, or when it functions below capacity, downtime “increases chaos among employees,” meaning it undercuts productivity, and stokes missed shipments, loss of revenue and shareholder value. Rio’s perspective rings true when applied to the Cargill meat-packaging dilemma – and might even be characterized as prescient. Wasser points out that even skilled risk managers would not have been able to figure out what might go wrong in a pandemic. “After March 11,

many things went wrong,” he said. Still, unplanned events can interfere with the manufacturing process at any time, and risk managers will need to work hand-in-hand with plant managers to figure out what could go wrong, said Wasser.

“You’re not going to buy a spare injection molding machine, but you could identify components that are vulnerable and can wear down,” he said. “You might also want to keep an inventory of small components, and you might want to keep a secondary or even tertiary sup-

plier in your file for moments when your primary supplier is not able to operate.”

Game changer

A year ago, neither Wasser nor Metrolinx’s Perumal could have predicted that car manufacturers would have to get into the medical ventilator business. “That was inconceivable, and yet it happened,” said Wasser. “Thanks to platforms like Zoom and Microsoft Teams, geography has disappeared as a factor in business.”

In terms of maintenance, the need for accountability systems has forever been elevated.

“The pandemic has taught us that business as usual was rote,” said Wasser. “That’s no longer adequate. It has to be dynamic because things are changing day by day – technology changes, the inputs change, the outputs change, and what clients expect has changed.” MRO

Rehana Begg is a Toronto-based freelance editor. She has spent the past decade in the trenches of industrial manufacturing, focusing on engineering, operations, asset performance and management. Reach her at rehanabegg@ rogers.com.

Des-Case Connected Breathers with IsoLogic® Sensor Technology

• Monitor critical assets 24/7

• Extend breather life by up to 20%

• Monitor difficult to reach locations

• Proactive diagnostic tool

• Access data anywhere in real time

• Shorten lube routes

SUCCESSFUL CMMS IMPLEMENTATIONS

In 2021, many maintenance departments will either be implementing their first maintenance software or upgrading to one of the hundreds of new CMMS systems on the market.

BY PETER PHILLIPS

Both new installs and upgrades take considerable number of hours and extra resources to implement a long-term successful CMMS solution.

Recently, I participated in a maintenance system conversion and want to share the experience, to help prepare companies for the work necessary to implement maintenance software.

Just over a year ago, French construction producer Saint-Gobain purchased US-based Continental Building Products (CBP), and added the three plants to their CertainTeed Gypsum Division (CTG). My role with CTG is to support their maintenance systems, and therefore was asked to participate on a team to convert the three plants to the Saint-Gobain ERP system. Helping lead the plants to convert their previous maintenance system to SAP Plant Maintenance, which is used by all CertainTeed divisions.

In March 2020, the maintenance conversion team was formed, and team members were introduced to the implementation steps, and timeline that would be followed for the conversion. Beginning with the mountains of equipment, preventive maintenance, and spare parts records, work started on gathering and refining the data that would eventually be uploaded into the SAP database.

Luckily, the majority of the CTG implementation team had worked together on four other CMMS conversions, and had a detailed project plan to use from the previous transitions to SAP. The new CBP team members were introduced to master data nomenclatures and templates, which would need to be populated for uploading into SAP.

Before any template could be populated, equipment lists, preventive maintenance plans, and spare parts in the storeroom, would need to be reviewed,

purged and cleansed. Depending on the number of records and standards used in the old software, this exercise would take two to three months. Updating data to the standard CMMS nomenclatures is a time-consuming step in the conversion process, and is often a hard concept to understand. The usual question is, what difference does it make how a piece of master data is named?

In the example, it’s easy to see how standard naming convention provides an organized structure for the equipment records. First, a good nomenclature looks very clean. Second, it is very easy to read, and to find a specific piece of equipment or other master data record. Search functions within the software become extremely useful when tradespeople are looking for a specific piece of equipment or spare part, when standard nomenclatures are used. In fact, every piece of master data is developed with the end user in mind.

A poorly constructed CMMS system is difficult to navigate, and to perform simple work order processes, as a result of

The success of this implementation lies with the teams, the standard processes and procedures that were used during the eight months of preparations, and the dedication from personnel at the three CBP plants.

this CMMS often fail. Following CMMS fundamentals and standards are critical parts of successful implementations.

Once the master data had been prepared for upload into the new system, attention moved to the workflows, to be followed by the end users. In order to have an effective CMMS system, every person must carry out specific duties in the work order flow process. Every position will have its own set of responsibilities, starting from the maintenance manager to the planner, supervisor, storekeeper and tradespeople. Every person has the responsibility to move

the work order to the next step until it’s final completion. Properly executed and completed work orders provide accurate historical data from cost analysis to equipment records, that can be used to improvement reliability, and for troubleshooting equipment problems.

In this implementation the team went through three mock data conversions, which were uploaded into a test SAP database. On each load, the data was reviewed, corrected, and reloaded into new templates, and made ready for the next mock load.

Training is a key part of every new

software implementation, and during the testing multiple training sessions were delivered to train every maintenance person.

We allowed one month between each test and after the third mock load we did a test run. This simulation occurred in November 2020 for a three-week period. During this time, the data and processes inside the SAP test environment were extensively tested. The plants used the software as though it was live data, a dress rehearsal before going live.

After the simulation, and until the end of December, we asked the plants to continue to use the SAP test environment to further familiarize themselves with the software. Final data changes were also made during this time and everything was loaded into the live SAP database ready to be launched.

In January, we went live with the SAP Plant Maintenance module, and other SAP modules production, finance, and warehousing; where each module had their own team. The go-live support lasted three weeks, with dedicated people at each plant and other support people behind the scenes.

Meetings were held several times a day to report any problems, and issues were solved quickly. Overall, the launch was successful with no showstoppers. The three new plants will continue to have support over the coming months, and participate in bi-weekly meetings to keep them up to date on SAP changes and enhancements.

The success of this implementation lies with the teams, the standard processes and procedures that were used during the eight months of preparations, and the dedication from personnel at the three CBP plants.

This year many companies will embark on this journey. This one took nearly one year for three plants from start to finish, and the support will continue for several months. CMMS systems are a crucial tool to maintain equipment and to help improve reliability. My advice is not to underestimate how long it will take and the resources that will be needed to transition to a new software. MRO

Peter Phillips is the owner of Trailwalk Holdings Ltd., a Nova Scotia-based maintenance consulting and training company. Peter has over 40 years of industrial maintenance experience. He travels throughout North America working with maintenance departments and speaking at conferences. Reach him at 902798-3601 or peter@trailwalk.ca.

WHAT CONDITIONS REQUIRE TIMELY OIL DRAINS AND SERVICE

Oils do not wear out. Meaning, the base oil does not generally deteriorate; however, oil gradually loses its ability to carry out its functions of lubricating, reducing friction, and heat dissipation.

BY L. (TEX) LEUGNER

The gradual loss of lubrication quality is caused by self-generated oxidation due to overheating, viscosity changes caused by fuel dilution, or the shearing of viscosity improvers, water entry into the system, directly or through condensation and the gradual depletion of the additives as they counteract acids, disperse and suspend foreign materials.

There are other conditions that contribute to oil degradation to a lesser degree, among them poor quality fuel, equipment operation in over-cooled conditions, lean air/fuel ratios, and emission control systems that are malfunctioning, or have been removed or disconnected. Conditions that contribute to oil degradation and necessitate regular oil drains are described below.

Does your staff understand that oil degradation is self-generated?

Logic: every engine, hydraulic system, gear drive, gas turbine or other machine slowly wears as it operates. Tiny, sub-micronic particles, of such elements as iron and copper, become catalysts that slowly attack the oil. These tiny metallic contaminants, (that are the result of wear not the cause of it), combine with carbon soot and varnish particles resulting from normal lubrication processes circulate in the system and through chemical action, create more wear. These solid particles act as a fine grinding compound and will slowly scratch and score roller and journal bearing surfaces, crankshaft journals, cylinder liners, gear sets and hydraulic components.

Normal full-flow filters are rated at about 10 micrometers in turbine and hydraulic systems, and 40 micrometres in engines, and will not remove these sub-micronic particles. Furthermore, if these filters become plugged, or if the by-pass valves within them remain open for long periods of time, such as at cold start up, contaminated oil will be pumped throughout the system. It is

important to remember that if the levels of self-generated contamination are allowed to increase until some damage by abrasion is caused, it will be too late to prevent more ongoing damage, even if the dirty oil is drained.

Can your maintenance group recognize the symptoms of oil oxidation?

Logic: oxidation is defined as a chemical deterioration of oil caused by continued contact with oxygen and catalysts such as copper. Oxidation causes the oil to thicken or increase in viscosity and darken in colour, sometimes dramatically, causing acids to form. This results in reduced oil flow and reduced heat dissipation that in turn accelerates the oxidation process.

Any practice that increases the operating temperatures of critical plant machinery must be avoided. Oil sump temperatures in diesel engines operating at high speed, and under heavy loads, can reach or exceed 150oC (302oF) with piston ring temperatures exceeding 310oC (590oF). Turbochargers may operate at up to 100,000 RPM with oil temperatures exceeding 315oC (600oF). If turbocharged engines are shut down immediately after operating at these temperatures, oxidation degradation of the oil can take place very quickly resulting in varnish formation.

Inoperative emission controls, thermostats with too high opening temperatures, etc, will increase the thermal load on gasoline engines, in turn increasing the rate of oxidation. Improperly adjusted air/fuel ratios contribute to oxidative oil thickening, because blow-by gases are produced containing high concentrations of nitrogen dioxide compounds that rapidly promote oil thickening.

Hydraulic systems operate best when the bulk oil in the reservoir does not exceed 60oC (140°F). Oxidation rates within hydraulic and turbine oils will approximately double for every 10oC (18°F) increase in temperature, causing sludge and varnish deposits and acid build-up causing corrosion. Oil temperatures in enclosed gear drives provide best service between 55 – 65 degrees C. Turbine bearing pad temperatures should not exceed 108°C.

Does the maintenance group understand the problems caused by water contamination?

Logic: any water entry into hydraulic or turbine systems can cause severe damage, particularly in systems with

very close tolerances such as hydrostatic piston pump systems. Water contamination caused by condensation is a common problem in North American climates due to dramatic changes in temperatures. Hydraulic or turbine oil with a “milky” appearance is an indication of water in excess of 2,000 parts per million (PPM), and action must be taken to replace the oil or remove the water through special filtration systems available for this purpose.

In gasoline engines, the combustion of one gallon of gasoline produces about one gallon of water, and any moisture entering the crankcase through “blowby” can cause rusting, corrosion, sludge deposits, and separation of additives from the base oil. Water entering the oil in a diesel engine can be extremely

Any water entry into hydraulic or turbine systems can cause severe damage, particularly in systems with very close tolerances such as hydrostatic piston pump systems.

harmful, particularly if poor quality fuel is used. Poor quality fuel is generally high in sulphur content, and when water combines with sulphur dioxide, acids are formed that will immediately attack bearing surfaces. Water content in gear drives in excess of 400 – 500 ppm can reduce rolling element bearing fatigue life by up to 50 per cent.

Can the maintenance group recognize symptoms of poor fuel use?

Logic: the use of poor quality diesel fuel can cause severe corrosion problems, due to the formation of acids resulting from high sulphur content. If, however, it is necessary to use fuels with more than 15 ppm (0.0015 per cent) sulphur content, lubricating oil with a minimum API service rating of FA- 4 should be used. These oils are better able to counteract acids than oils of lesser quality.

Today, a more serious problem is premature wear of fuel system components due to the poor lubricity of diesel fuel, as a result of the removal of sulphur, which is a natural lubricant. Proper engine maintenance, such as correct and timely servicing of diesel particulate filters (DPFs) is critical. Ensure that water jacket temperatures are maintained above 79.5oC (175oF). Never operate an engine with the wrong thermostat, and excessive idling of diesel engines must be avoided. Unleaded gasoline is recommended for all gasoline engines, not only to reduce emissions, but to reduce the formation of lead compounds that form deposits, and contribute to self- generating contaminant wear within the engine.

Does the maintenance group recognize the indications of additive depletion in oil?

Logic: when base oils are formulated and blended with additives, these chemical elements are slowly “used up” in performing their functions. Anti-wear and extreme pressure agents are depleted as they are deposited on metal surfaces. Detergents and dispersant are used up as they continue to counteract and suspend contaminant particles in the oil.

Additives that protect against acid attacks are depleted as they counteract acid formations within the oil. The additive package will eventually become depleted or ineffective, if the oil is allowed to remain in service for extended periods. It is important to know that spectrometric oil analysis will continue to record additive chemicals on oil analysis reports even if these additives are no longer effective.

The only sure method of monitoring additive depletion is to establish a regularly, scheduled oil analysis program that not only monitors the rates of component wear, but also monitors total base or total acid number as applicable to diesel engine oil and industrial lubricants respectively, to determine a cost-effective oil drain and service schedule. MRO

L. (Tex) Leugner, the author of Practical Handbook of Machinery Lubrication, is a 15year veteran of the Royal Canadian Electrical Mechanical Engineers, where he served as a technical specialist. He was the founder and operations manager of Maintenance Technology International Inc. for 30 years. Tex holds an STLE lubricant specialist certification and is a millwright and heavy-duty mechanic. He can be reached at texleug@shaw.ca.

BY BRYAN CHRISTIANSEN

Sound data management is critical in several areas. For most billing and supply chain information, production data, quality data, and machine data come to mind first. Among these areas, however, maintenance data should not be forgotten.

Companies are doing their best to adapt to new maintenance technology. As part of this, organizations should be considering data management strategies for their maintenance data. The term “data management” means several things:

• Collection of the right amount of meaningful data - directly from the source (i.e. not entered manually);

• Storing the data in a manner that is organized and intuitive; and,

• Enabling easy access to the data to those who need it.

Why is it important to have good, accurate data readily available for analysis? Beyond simple understanding of the operation, a good data strategy allows for many advanced opportunities.

For example, it’s necessary for accurate failure analysis. When a failure occurs, it is prudent to understand what happened, so that the operation can avoid it happening again. As Tex Leugner writes in the MRO Quiz article Data Collection Necessary for Effective Failure Analysis, “it is highly recommended that a section of the work order be devoted to the collection of failure information.” After collection, the data can be stored and accessed for future maintenance work on the asset. Beyond failure analysis, this sort of data strategy is also needed for a more comprehensive understanding of the maintenance performance. Tracking work performance and

efficiency is nearly impossible without a good amount of clean data.

Maintenance work accountability and CMMS

Looking at work accountability, first, remember the goal of accountability is not to assign blame. The reason to increase accountability is to improve the overall maintenance program. If improvement is the aim, then a determination of baseline data is needed.

To get a good understanding of maintenance accountability, you need to get an effective measure of maintenance performance. After all, how can you stress accountability without having data to support your arguments?

A CMMS allows for this measurement as it can capture all sorts of relevant maintenance information.

When properly used, a CMMS can provide the platform to fulfill a maintenance data strategy. The CMMS schedules maintenance tasks automatically, allows maintenance techs to input their work output and notes, and stores the maintenance data so it can be retrieved later. A CMMS also allows for running of reports in real-time that can provide meaningful actions. In short, it drastically lowers the amount of administrative effort associated with running a maintenance department.

Maintenance cost is not enough

Traditional methods of measuring maintenance performance have been limited to tracking maintenance spend, and perhaps overtime hours. This is a simplistic and flawed way to

Looking at work accountability, first, remember the goal of accountability is not to assign blame. The reason to increase accountability is to improve the overall maintenance program.

measure the maintenance performance.

Tracking performance solely by maintenance cost can reduce your response actions. The only way to react to a rising cost is to lower it, and this is not always the most effective way to improve your maintenance department.

Maintenance cost is definitely an indicator to track, but it should not be the sole measure of maintenance effectiveness. With a CMMS tracking proper information, more is possible, which allows you to get to more meaningful indicators of maintenance performance.

General performance indicators

With a CMMS in place, more accurate measures of maintenance performance can be determined. This leads to greater understanding of how well the maintenance team is doing. With better data, the team can be held more accountable. In other words, you’ll be able to correlate maintenance actions with maintenance metrics.

Possible indicators include:

Maintenance work efficiency – assuming you have an idea of how long a task should take, you can see if your technicians are spending the appropriate amount of time on work. This can lead to theoretical workloads, overtime plans, and other metrics.

Maintenance backlog – the backlog in work orders or labour time. The backlog should not be growing over time, so this KPI could indicate a further issue.

Maintenance schedule compliance – a measure of how much

the schedule was followed, and a potential indicator of how well the preventive maintenance program is working.

Mean time to repair (MTTR) – is calculated by dividing the downtime length by the total number of downtime events. This indicator could show whether maintenance efficiency is increasing or decreasing.

Mean time between failure (MTBF) – is the average time between failures on an asset. This is an important indicator to determine preventive maintenance priorities.

Maintenance cost as a percentage of replacement asset value – world class operations have this percentage less than two per cent.

Maintenance cost per production unit – with the caveat about maintenance spend tracking, this is perhaps a better measure of maintenance efficiency.

These types of indicators are more meaningful than a basic indicator like cost. With better indicators in place, you can direct maintenance more precisely on how to improve. For example, you can tell your maintenance staff something like “maintenance schedule compliance needs to increase from 75 to 90 per cent,” or “on pumps one to five, MTBF needs to increase from 500 hours to 2,000 hours.” This type of goal is much more understandable than “decrease maintenance spend this quarter.”

Further accountability with CMMS data

A CMMS lets maintenance managers gather details for further accountability amongst their staff. The CMMS can store work instructions for a routine task, or common troubleshooting direction. The technicians can store their work in digital logs, so that they can be audited later. These logs or notes can be used as references for future work on the asset.

The CMMS data also can be used to break down work metrics in other ways. For example, individual performance can be found quickly and used for comparisons. This information can be valuable in finding best practices, then sharing across the department.

Holding your maintenance staff accountable can be a tricky ordeal if you don’t have the proper system in place. A CMMS allows you to generate, store, and access maintenance data efficiently. When you have a good data strategy in place, you can use hard data to hold your maintenance team accountable. The CMMS data can help you develop smart, defined goals that are measurable. With a CMMS and good data strategy, improvement in maintenance becomes clear and actionable. MRO

Bryan Christiansen is the Founder and CEO at Limble CMMS (a mobile CMMS software). He can be reached at bryan@limblecmms.com.

TOOLS OF THE TRADE

Using the right condition monitoring tools doesn’t have to be hard.

BY JOHN LAMBERT

Many years ago, I worked as a shift mechanic in a large manufacturing plant. One of my duties was to conduct the shift walk around. This entailed going to each section of the plant and examining equipment to see that it was in a safe working condition. This meant that if I went into the tank farm where we had a lot of chemical pumps, I would make sure that there were no leaks, no puddles on the floor, and no strange noises. Another area of the plant was called the fan room, and in it were four high speed fans, the largest being five foot in diameter. They were an overhung fan design assembly, and the shaft was supported by two large

pillow block bearings. The shaft would have been at least six inches in diameter. As a result of a serious breakdown in the past, we checked these fans by putting our hands on the bearings cover to see if it was running hot or not.

This was a very primitive way of checking, but it was many years ago, and not many plants had any measurement equipment, especially for temperature. Later, upon becoming a foreman in the same plant, I bought a temperature gun, so we could take a quantifiable measurement. This changed the shift walk around. Now I could see a temperature range that the bearing would be in. We also used it for many more applications.

If you think about checked it with our hands, it was a little crazy, as one of these bearings exploded during an earlier breakdown. If you have ever seen a large high-speed fan wreck itself in a small, confined space, it is not pretty.

Buying a simple temperature gun now is a no brainer. The fact that it will give you a quantifiable measurement is invaluable. Why? Because to control a process you have to measure it. In maintenance, we have been proving that to be true. A simple temperature gun should be in every toolbox in the shop.

Still keeping it simple, Figure 1 is an Infrared image of a motor that is online (in operation). The image was taken by a display unit that is part of a laser shaft alignment system. It is a tool that tradespeople can use to take a simple temperature reading, but also can determine if thermal growth must be compensated for. They can use it as a before and after measurement that can be added to the report and history file. Yes, temperature measurements and how they are taken has changed a lot.

If I ask the question “When a tradesperson installs a pump and motor machine unit, how do they know if the work has been done correctly”? The common answer is that the alignment results from the laser shaft alignment system will indicate that the shafts are aligned (collinear). However, that’s only the shaft alignment portion of the installation.

You would also expect a detailed report on what was measured. Below is a list of what you should expect to be mea-

Figure 1

Figure 2

Photos: EasyLaser

sured from the “AMERICAN NATIONAL STANDARD Shaft Alignment Methodology, Part 1: General Principles, Methods, Practices, and Tolerances,” and it states:

The final shaft orientations shall be documented as a permanent record. The documentation shall be in the report form and include recommendations as listed below. As alignment work may be conducted for new installation, as part of repair work, or during preventative maintenance work, not all, of these items are always applicable. All items that are measured shall be reported in addition to any items observed that may affect the machine operability or reliability.

1. A description of the machine and its location.

2. Date.

3. Instruments and methods used for measurement.

4. Person completing the task.

5. Tolerance requirements.

6. Offline to Running (OLTR) movement data.

7. Base condition flatness and level

8. Shaft and/or hub run outs.

9. Machine, pipe, or conduit strain.

10. Soft foot.

11. The as-found shaft orientations.

12. The as-left shaft orientations.

13. The as-left axial spacing.

14. Visual inspection (e.g., foundation and external connection items pipes, ducts, conduits, machine condition).

15. A statement regarding compliance to this standard.

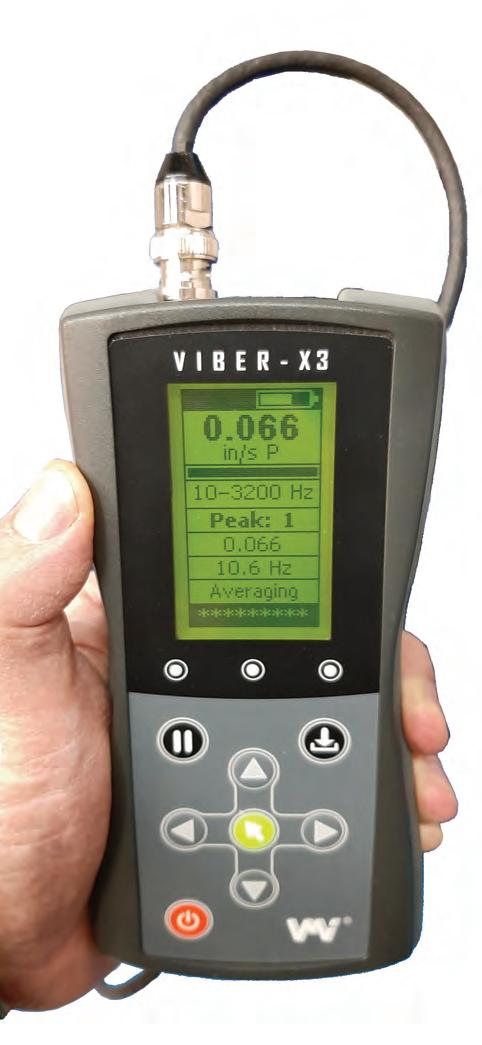

Whilst these are all important items as to what was measured, they do not give an assessment of the condition of the machine. For example, you can have a run out condition but still align the shaft. It is the same for pipe and casing stress, or a thermal growth condition. What these items or a combination of them will do is vibrate when the unit is operating. To assess that, you need another measurement device, and it can be a simple vibration meter.

Vibration gives you the most information on a pump and motor unit. Many people back away from these meters because they do not understand the value, the result it shows. The most common unit of value in North America is a velocity reading measured as inches per second. You can look at it as the distance the amount the machine is moving over the time period of one second.

Simple measuring and monitoring of vibration can give your tradesperson a tool, so they know if the installation/alignment they just did is acceptable or not. This is a very powerful tool because it gets us on the path to why. Why is this machine vibrating more than its twin?

What he or she is measuring is a combination of items such as unbalance, misalignment, looseness, machinery structural strain, frame and foundations strain, and resonance. Most of these meters also give a bearing condition value and he/she can take readings in the axial, vertical, and horizontal planes, and compare these measurements to a known standard.

You can compare to the equipment manufacturer’s specification, the history record of the piece of equipment itself, or from another similar machine. These comparisons will give a good indication of the condition of the machine that you want to monitor. Then you can decide if any action must be taken. When tradespeople have access to simple condition moni-

toring tools, they will find other uses for it. One of our customers uses their vibration meter to measure piping. If a pipe is not correctly supported, it can vibrate and effect the pump. A sort of “tail wagging the dog” scenario.

An often overlooked issue is thermal growth. The reason for this is it is not easy to measure without the correct equipment. When you measure thermal growth, it is the machine’s casing you need to measure. In figure 2, you can see two laser detectors on brackets that are mounted on the machines casing. They can be bolted or epoxied in place. It is best to have them close to the shafts centre line as you can because what you are looking for is machine casing movement that affects the position of the shafts.

With an alignment tool, there is a live trend program that will show the growth/movement when the machine reaches full operational temperature. The values you see are what you use as targets. These targets are input into the alignment program before you take the measurements to compensate for the machine movement. It is movement because yes, most machine will grow upward, but machines can move left to right and down. For example, the inlet of a large blower can shrink down.

When you give the right tools to tradespeople it does not take them long to find other uses for them. Many are using the live trend program to measure the movement of the shafts as they bolt up the piping on a pump. They add this to the alignment report, which gets added to the machine’s history.

They do this because the new ANSI standard for shaft alignment states,

External forces from piping strain, flange strain, conduit strain, attached ductwork, etc., applied to machine cases subject to shaft alignment tolerances, shall not be sufficient to cause changes in the shaft alignment of magnitude greater than 50 micrometers (2 mils) vertical or horizontal measured at the coupling.

Is this something you measure?

The moral of the story is having the right tools is important. Knowing what to measure and the correct tolerance is crucial. That is why we call it precision maintenance. MRO

John Lambert is the President of BENCHMARK PDM. He can be reached at john@benchmarkpdm.com.

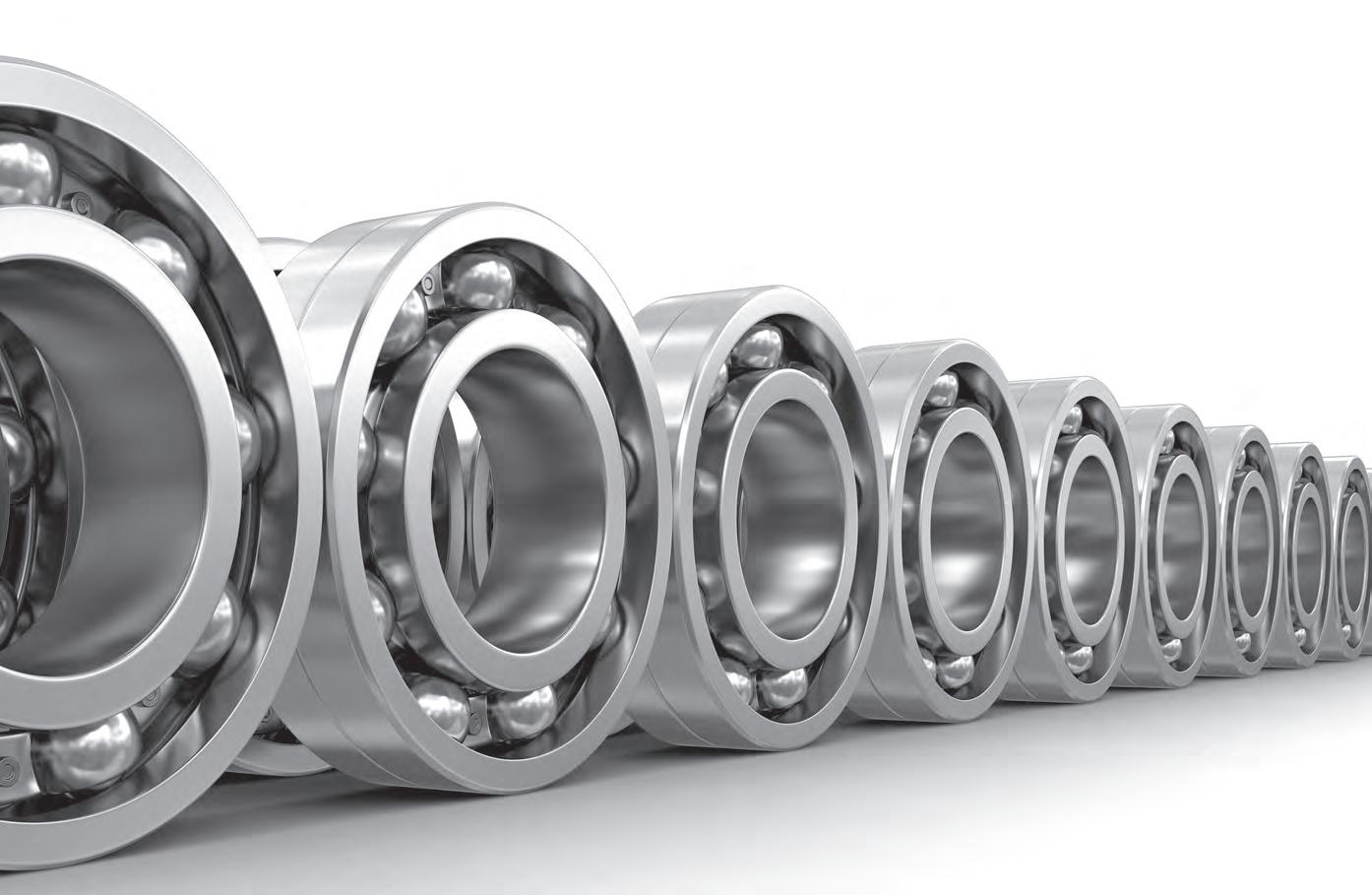

WATER AND BEARINGS

The most effective way of preventing damage by water, is preventing water from getting into the bearing.

BY DOUGLAS MARTIN

Water affects bearings in two ways. First, by corroding the contact surfaces, which can lead to: surface damage that will create initiation points for fatigue (spalling); surface damage that can create initiation points for ring or roller fracture; and, creation of iron oxide particles that will act as an abrasive medium when rolled over. It should be noted that corrosion generally occurs at standstill when the bearing is not rotating.

Second by lubricant interruption. When water comes between the roller and race surface, it is squeezed out of this interface. Compare this to the behavior of oil. Oil, under pressure, increases in viscosity until it is like a layer of silver (metal between the roller and race preventing contact). Since water cannot support the load applied between the roller and race interface in this manner, it allows metal-to-metal contact leading to abrasive wear and surface-initiated fatigue. This damage occurs when the bearing is rotating.

Therefore, water poses a threat to the bearing both while operating and while stationary.

In turn, what are the solutions?

Sealing and grease

The most effective way of preventing damage by water, is preventing water from getting into the bearing. The least costly of the solutions, is often already at hand, but poor practices don’t protect the bearing as it should be protected.

To accomplish protection from water, one needs effective sealing and greasing. Note the term greasing is used, as opposed to lubrication. Since grease serves

two purposes (lubrication and sealing), in a wet environment, sealing is the more important role that grease plays.

An effective seal is one designed for the application. It should prevent both the ingress of water and allow drainage of water from the seal, should any be able to penetrate the barrier. Some sealing solutions are designed thinking only of preventing water ingress without the allowance from draining or purging with grease.

Stainless Steel

“Common bearing” stainless steel is a compromise in two ways, first, it is a poor bearing material, and second, it is truly stain “less”, so it still will corrode but less than standard bearing steel. Although a few different grades are used for industrial applications, none are a good bearing materials or fully corrosion resistant.

For a stainless steel, as hardness increases, corrosion resistance decreases, therefore, there must be a compromise between a material that resists corrosion, and a material that can carry a load.

The downside to “industrial grade” stainless steel is the loss of bearing capacity. In the book, STLE Life Factors for Rolling Bearings, Erwin Zaretsky, tabulates the “life factor” for bearings of standard bearing steel (52100) as three

and the “life factor” for stainless steel used for bearings (440C) as 0.6, suggesting that the predicted life of stainless steel is five times lower than standard bearing steel.

It is true that several “premium” grades of stainless steel exist, and are used in aerospace and racing applications. However, they do not appear in general industrial applications, typically because the cost to produce the material makes the cost of the bearing too expensive for the benefits. In fact, some of this stainless steel will outperform regu-

The most effective way of preventing damage by water, is preventing water from getting into the bearing.

lar bearing steel, but it is at a price that can only be afforded by aerospace and Formula 1 race cars.

Also, stainless steel only combats corrosion, it does not combat poor lubrication conditions. Therefore, you may make a bearing corrosion resistant, but you still have not addressed the lubrication issues.

Coatings

The generally accepted coatings used for industrial bearings rolling surfaces are zinc alloy coatings. The benefit of such coatings is they are applied to standard bearing steel, so there is not a loss in bearing capacity. As well, zinc surface coatings are a “tribological thin coating,” which means it improves the performance under poor lubricating conditions. As such, coatings can address both the corrosion issue and the lubricant interruption issue.

Availability

The availability of a corrosion resistant product in the industrial market is a function of the overall use in industry. Meaning, that bearing companies do not make all their bearings in the choice of regular steel, stainless steel or coated steel. Rather, the sizes are limited, for instance, if you wanted a stainless-steel deep groove ball bearing, the maximum size would be for a 50 millimetre shaft. In terms of unit block ball bearings, the shaft size goes up to about one and 15/16”.

There are specific bearing sizes related to an application that are produced regularly. For instance, in the oil and gas industry in Western Canada, some compressors use bearings with high nitrogen stainless steel, with success. These bearings, both angular contact ball bearing and cylindrical roller bear-

ings are made in the specific common sizes used in a handful of compressors. The cost of a bearing set is about 10x the cost of a bearing using standard materials. However, in the application, they pay for themselves with the elimination of production losses, as a result of bearing failures from the corrosive environment of sour gas.

This comes back to the point about the best way to address a water issue. Prevent it from getting into the bearing in the first place, and it will save money in terms of poor machine performance, or the expense of a bearing that can tolerate the conditions. MRO

Douglas Martin is a heavy-duty machinery engineer based in Vancouver. He specializes in the design of rotating equipment, failure analysis, and lubrication. Reach him by email at mro.whats.up.doug@gmail.com.

CMMS: THE GOOD, THE BAD, AND THE UGLY

CMMS is a great tool for maintenance including planning and scheduling, but be careful and don’t abuse it. There is good and bad we need to recognize in using CMMS functionality over a paper system. Get the good, avoid the bad, and be better at maintenance.

BY DOC PALMER

Almost above all, CMMS allows us to make living job plans that can be updated over time. Gone are the days of researching old work orders to come up with a job plan for this time. Beyond the great benefit of the living job

plan, the good from CMMS for maintenance includes standardizing work processes, inventory control, information galore, finding work orders, schedule manipulation, PM generation, and problem diagnosis.

With computers we get better ad-

herence to standard information and processes. We can make fields required, and users have to fill them. For example, they have to pick a priority; which can’t be left blank. They have to pick an asset. They have to pick a work type. Nonetheless, they might pick an inappropriate priority, the wrong asset, or the wrong work type. However, at least they have to think about it. Consider having an “unsure” or “not applicable” choice for some required fields.

Better inventory control is a great return on investment. Automatic reorder points, links of spare parts to assets,

usage records, current stock levels, and other features are better online. How many stock items have levels below the reorder point, but no purchase order for replenishment? That is great information that we might not be reordering as we should. Many CMMSs have a feature that can automatically build bills of material (BOM) for assets whenever parts are used on a work order.

Information in general is better with a CMMS, especially for metrics and reports. Are we doing more PM each year or less? What is our most troublesome asset, work wise and cost wise? Would

we know as well without a CMMS?

The linking of information to assets in a common database is an especially helpful aspect of a CMMS. We can avoid different groups having different databases for nameplate information, motor frame size, and equipment history.

The computer offers great potential for scheduling. I’d like for the CMMS to help us pick work to schedule, but unfortunately many CMMS believe we already know what work to schedule. They guide in assigning known work a week in advance to individuals on specific days. It would be better if the system said, “for the labour capacity next week, how does this batch of work look?”

PM generation is wonderful in all CMMS. We don’t have to remember to recreate the monthly work order and get it to the right crew. Perhaps one of the best features is problem diagnosis. The computer can help us find if we’ve had this problem before and where? How widespread is the problem?

the job actually took. We don’t want to have perfect matching of estimates versus actuals. Don’t encourage people to input bad information in the CMMS for fear of looking bad. Use supervisors in the field to see how employees are doing. Also, be careful not to abandon thinking to the CMMS. “Why did the plant burn down? The CMMS forgot to tell us to work on the fire sprinkler system.” No, we forgot to put that work into the CMMS.

User friendliness is a concern. We could all retrieve an old work order out of a paper file. But the CMMS requires logging in and knowing how to do things online. Some systems are more “user friendly” than others, but don’t skimp on training as you implement a new CMMS, or bring new people on board.

Finally, one of the problems with the CMMS is measuring everything, just because we can. I’ve seen plants utilize the planner to gather CMMS data to compile metrics that manage -

Gaining great benefit from a CMMS is more complicated than simply implementing it. Management is buying a great sports car, but we need to know how to drive it.

Among the bad and ugly are issues with processes, costing, employee evaluations, abandoning thinking for ourselves, user friendliness, and metrics.

We must realize that if we don’t know what maintenance is, a CMMS won’t help us at all. No one has any business with a hand held calculator if they do not first know how to add, multiply, subtract, and divide. A CMMS will only speed up a faulty maintenance process.

Maintenance is keeping things from breaking, not simply fixing them as soon as they break. Does the CMMS help you realize that? Of course not. The CMMS helps you track work of whatever type you think you should do. We must avoid the thinking that “As soon as the CMMS is fully implemented, everything will be fine.”

Another issue is that people sometimes charge work or parts to the wrong work order number. Be careful analyzing the cost of past work.

Do not use the CMMS for employee evaluations. We want to know how long

ment never uses. It takes time to assemble information and I’d rather the planner not spend an entire day each week doing that. Planners should be planning. IT people can automate the metrics.

Gaining great benefit from a CMMS is more complicated than simply implementing it. Management is buying a great sports car, but we need to know how to drive it. Also, we need to know where we are going. Therefore, why did we buy the car? Why to improve plant reliability, of course. MRO

Doc Palmer, PE, MBA, CMRP is the author of McGraw-Hill’s Maintenance Planning and Scheduling Handbook and as managing partner of Richard Palmer and Associates helps companies worldwide with planning and scheduling success. For more information including online help and currently scheduled public workshops, visit www.palmerplanning. com or email Doc at docpalmer@palmer planning.com

WHAT’S NEW IN PRODUCTS

Brooks Instrument Glass Tube

Variable Area Flow Meters

Brooks Instrument adds GT1600 Series glass tube variable area flow meters to its family of variable area flow meter products. The flow meter features 316 stainless steel construction and a polycarbonate shield. The adjustable, transparent scale allows for offset correction to compensate for process variation. The process connection can be rotated 360 degrees. An alarm option is available for automatic monitoring of critical flow conditions. GT1600 is used for low- and high-flow gas and liquid applications.

GT1600 is available with a variety of connections to fit existing piping arrangements or mount to a panel or wall. It can also work as a drop-in retrofit for the Brooks Instrument GT1000, GT1300 and Full-View 1100 Series of flow meters. The glass tube and float can be replaced without removing the flow meter from the piping. experience.brooksinstrument.com/gt1600

Endress+Hauser ProLine T-mass

Endress+Hauser new generation Proline t-mass F/I 300/500 –offer bidrectional measurement and reverse flow detection.

Proline t-mass 300/500 measuring system comes with a gas engine as standard offering 22 gases to choose from and corresponding gas mixtures with up to eight components. Proline 300/500 units comprise an in-line version for pipes DN 15 to 100 and an insertion version for pipes and ducts DN 80 to 1500. Both provide dynamic correction for changes in pressure, temperature and gas composition.

The flow meters offer measuring accuracy (1.0 per cent), repeatability (and turn down (up to 1000:1), and temperature measurement up to 180°C, and pressures up to 40 bar. It offers SIL compliance and high operational safety, with heartbeat technology for diagnostics, monitoring and device verification.

Various transmitters are available: Proline 300 (compact) or Proline 500 (remote) series, with up to four inputs and outputs. www.ca.endress.com

Winco Specialty Hinges

Hinge GN 237.3, compact, heavy duty stainless steel hinge have a 180° range of motion, and shim washers. Depending on type, hinge bands have centring extensions. Hinge pin is secured against loss by a recess and supplied with lifetime lubrication. Asymmetrical band arrangement and associated possibility of a third fastening hole, can be mounted in areas with thinner material cross-sections.

GN 235, can be mounted with socket head cap screws and swivels by 180° without collision. It has horizontal and vertical slots and the hole pattern corresponds to existing hole arrangements. Also, the hinges have variable friction, and an integrated spring. It also includes integrated damping, indexing and locking functions.

Also available, a multiple-joint hinge with a 4x, 7x or 10x joint mechanism, which opens flaps and shifts their position at the same time; 180° is also standard, and internal installation makes use of slots.

GN 7237 stainless steel multiple-joint hinges are installed on the inside of flaps, hatches and doors. The hinges have a maximum opening angle of 180°. www.jwwinco.com

WAGO Modules for Harsh Environments

WAGO Ethernet-based PLC controller and I/O couplers for use in extreme environments, part of the 750 XTR series, have two switched Ethernet ports for feed through cabling and support XTR digital, analog, and specialty I/O modules.

PLC controller (750-890/040-000) has the ability to be programmed with WAGO-I/O-PRO based Codesys v.2 software and supports MODBUS TCP/UDP fieldbus communications

I/O couplers (750-362/040-000 and 750-363/040000) offer dedicated fieldbus ports with fast bootup times. The 750-362/040-000 supports MODBUS TCP/UDP, and 750-363/040-000 supports EtherNet/IP communications. www.wago.us

Creform Cart

Creform Corporation angled shelf cart has a 42” W x 26” D footprint and is rated for up to 600 lb. load capacity. It uses marine blue 28 millimetre plastic coated steel pipe and black metal joints. It features eight levels, each level having a slide pipe (with coated with low friction HDPE plastic) with a side guide.

Cart has a 15° angle of the flow lanes, and the levels can be repositioned or reconfigured with simple tools. It has four (four inch diameter) swivel casters with urethane wheels. The casters feature brakes that can be engaged. Push/pull handles are on both ends. Options: feet instead of wheels, solid surface shelves and gravi ty conveyors in place of the slide pipe.

Rechner Capacitive Sensor