MAINTENANCE IN THE FUTURE

DECEMBER 2021

Vol. 37, No. 6

Established 1985

www.mromagazine.com

Twitter: @mro_maintenance

Instagram: @mromagazine

Facebook: @MROMagazine linkedin.com/company/mro-magazine

Reader Service

Print and digital subscription inquiries or changes, please contact

Beata Olechnowicz, Audience Development Manager

Tel: 416-510-5182 Fax: 416-510-6875

email: bolechnowicz@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400 Toronto, ON M2H 3R1

Mario Cywinski, Editor 226-931-4194 mcywinski@annexbusinessmedia.com

Paul Burton, Senior Publisher 416-510-6756 pburton@annexbusinessmedia.com

Maryam Farag, Associate Editor 437-788-8830 mfarag@annexbusinessmedia.com

Ilana Fawcett, National Account Manager 416-829-1221 ifawcett@annexbusinessmedia.com

Melanie Morgan, Brand Sales Manager 437-218-0941 mmorgan@annexbusinesmedia.com

Graham Jeffrey, Media Designer

Catherine Giles, Account Co-ordinator 416-510-5232 cgiles@annexbusinessmedia.com

Scott Jamieson, COO sjamieson@annexbusinessmedia.com

Machinery and Equipment

MRO is published by Annex Business Media, 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1; Tel. 416-442-5600, Fax 416-510-5140. Toll-free: 1-800-268-7742 in Canada, 1-800-387-0273 in the USA.

Printed in Canada

ISSN 0831-8603 (print); ISSN 1923-3698 (digital) PUBLICATION MAIL AGREEMENT #40065710

Subscription rates.

Canada: 1 year $65, 2 years $110. United States: 1 year $110. Elsewhere: 1 year $126. Single copies $10 (Canada), $16.50 (U.S.), $21.50 (other). Add applicable taxes to all rates.

On occasion, our subscription list is made available to organizations whose products or services may be of interest to our readers. If you would prefer not to receive such information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer

Privacy@annexbusinessmedia.com, 1-800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2021 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

Maintenance: the past, the present, and the future

Like many things, maintenance management has its origins in the manufacturing industry. Back in the day, factories handled their machines in a simple manner; use it until it breaks, and only repair it when it can no longer work.

There seemed to be no planned maintenance, as the main focus was on corrective maintenance. Likewise, it seemed like downtime was not as critical as it is today; therefore, running assets on breakdown maintenance was not seen as a huge issue.

However, the Second Industrial Revolution (mid-to-late 19th century) brought electricity-driven machines, creating a need for more sophisticated maintenance. Plant engineers gradually became more proactive in maintaining them, and established a pattern of frequency-based maintenance.

Looking at this through a modern lens, it seems wasteful and inefficient, as they would typically change the parts following a strict schedule, whether that was needed or not.

By the 1950s, the manufacturing space became increasingly competitive, and there was no tolerance for downtime in the industry. This was a result of the industry undergoing rapid reconstruction to recover from the after-effects of the Second World War.

Japanese engineers started a new trend that involved following the manufacturer’s instructions about the care of each machine during operation. That trend gave birth to what we know now as “preventive maintenance.” Gradually, they encouraged technicians and other specialists in charge of machinery to develop schedules for lubricating the equipment, then noting and reporting any observations to help prevent damage from happening to the machines.

From that time to now, more proactive elements have been adopted in maintenance strategies, resulting in development of the popular strategies used today, such as “predictive maintenance”, “condition-based maintenance” and “reactive maintenance.”

Fast forward to today, the most suitable type of industrial maintenance is predictive maintenance. Thanks to technology, data regarding the state of your machinery is available at all times, and a computer system can predict issues and decide when it is the ideal time to make a repair or a replacement before a breakdown occurs.

The last 50 years (especially from 2000 to now), innovations in technology in every area of our lives have drastically increased, and of course, maintenance management is not left out, which brings us to Maintenance 4.0.

Maintenance 4.0 includes ways to analyze and recommend actions to take in order to ensure reliability and asset management are digitally assisted.

The impact of Maintenance 4.0 and new technologies affected many aspects of maintenance management. In this issue of MRO, we look at the future of maintenance. You will come across several industry experts explaining the changes that took place recently during the global pandemic, and the predictions for the future of the maintenance world in every corner of the industry.

Also, make sure to check out Peter Philips’ article, where he discusses How Industry 4.0 Holds the Future of Maintenance. In addition, Bryan Christiansen speaks about Technology and Modern Maintenance, and Cliff Williams looks at Asset Management in the Public and Private Sectors – is There a Difference?

SKF Pulse™

Combining the SKF QuickCollect portable sensor and the SKF Pulse app allows you to quickly evaluate asset health on demand and prevent machine failure. Get expert advice without investing in complex technology.

Rely on SKF

• On-the-spot machine diagnostics with visual alarm indicators

• No need for training or diagnostic expertise

• Connect directly with SKF experts for analysis and diagnostic reports

• Pulse Check diagnostic reports, available via the app, include recommended corrective actions

Future of Maintenance / 8

Now is a good time to look at how maintenance has evolved and where it’s heading.

Technology and Modern Maintenance / 16

Modern maintenance tools and technologies that will make life easier for maintenance professionals.

How Alignment and Condition

Monitoring Extend Motor Life / 22

Learn why you should pair alignment with a condition monitoring program.

Planning Reactive Work / 12

We’ve always been told that we cannot plan reactive work.

MRO Quiz / 18

The establishment of an effective failure analysis program.

Asset Management / 24

In the public and private sectors – is there a difference?

What’s Up Doug / 14

The evolution of facilities maintenance.

Maintenance Operations / 20

The smart move to more efficient and safer maintenance operations.

Maintenance 101 / 26

Industry 4.0 and the future of maintenance.

Editor’s Notebook / 3

Industry Newswatch / 6 What’s New in Products / 29 In Conversation with Mr. O / 30

Siemens launches Manage MyMachines MindApp

Siemens launched Manage MyMachines; a MindApp within the emerging Mindsphere concept. This cloud-based “platform as a service” enables the full data-tracking of machine kinematics and production data.

For the builder, this development translates into an ability to monitor the global install base. Shops and production departments, in tandem with their system integrators and other business partners, will benefit from display of all CNC equipment on the floor, regardless of location, brand, function or usage.

As a MindApp within the Mindsphere portfolio, Manage MyMachines is integrated in the cloud-based, open IoT operating system, as it allows access to all critical machine tool information, from bearing temperature to production by shift or job, all in a selectable priority scale, based upon user needs. Unexpected line downtimes and off-normal machine kinematic conditions can be identified and rectified.

Predictive maintenance can be programmed, so an upcoming failure can be anticipated, with alerts sent to a local distributor, for example, to deliver the needed components.

Complete asset management is further possible via Manage MyMachines, as resource consumption and energy usage are trackable, all in the cloud and accessible through the app in real-time. MRO

GreenPower Motor Company announces agreement with Perrone Robotics

GreenPower Motor Company Inc. and Perrone Robotics announced their OEM agreement, where the two companies will deliver the next generation of the AV Star, which was developed for the Jacksonville Transportation Authority in 2019. Through this OEM agreement, GreenPower’s EV Star, a multi-purpose, zero-emission, min-E Bus will be up-fitted with Perrone’s TONY (To Navigate You) autonomous vehicle retrofit kit, which will transform the EV Star to the AV Star. The AV Star aims to be a mobility and transportation choice for cities, municipalities, public and private campuses. The vehicle is capable of carrying up to 16 passengers, is ADA compliant, FMVSS compliant, and can travel at highway speeds. MRO

Festo appoints Director of Sales for Canada

Festo announced the promotion of Jean-Francois Paquette to Canada Sales Director, North American Sales.

In his new position, Montreal-based Paquette will focus on leading the sales objectives and planning strategy for the Canadian sales organization, setting and meeting revenue and profitability targets for Canada as part of the North American region goals.

Paquette has been the District Sales Manager for Festo’s Eastern Canada district the past four years, and will continue to fulfill those duties along with his new responsibilities until a successor for his old role is appointed.

Paquette will report directly to Holmes as well as locally to Roy Pietila, CFO for Canada. MRO

Skills Ontario celebrates National Skilled Trade and Technology Week

The National Skilled Trade & Technology Week (NSTTW)is a week-long event to promote and host awareness-raising events around many career opportunities in the skilled trades and technologies in Canada.

This annual celebration was created by Skills/Compétences Canada (SCC) and is celebrated by SCC, and member organizations like Skills Ontario among others.

Over the week, Skills Ontario hosted social media celebration, recognizing the five sectors of the skilled trades and technologies: construction, industrial, motive power, service, and technology, along with launching new career profile videos of skilled professionals discussing their career paths and their advice to Ontario youth.

“We’re thrilled to be celebrating National Skilled Trade and Technology Week,” said Ian Howcroft, CEO, Skills Ontario. “We welcome young people to explore and discover all their potential pathways – there are amazing opportunities in the skilled trades and technologies!”

SCC hosted “A Virtual Career Exploration” event for NSTTW, where attendees learned about careers in the skilled trades and technologies, interacted with over 30 industry and education partners, answered trivia questions, and learned about the 9 Skills for Success. MRO

ABB Canada recognized as one of Canada’s Top 100

Employers by Mediacorp

ABB Canada has been ranked among Canada’s Top 100 Employers by Mediacorp for “facilitating ongoing employee communications and providing a healthy and safe work environment.”

Mediacorp‘s Canada’s Top 100 Employers competition “recognizes employers with exceptional human resources programs and forward-thinking workplace policies.”

Winners are selected based on performance and offerings in eight key areas, including: physical workplace, work atmosphere and social; health, financial and family benefits; vacation and time off, employee communications, performance management, training and skills development; and community involvement.

Emerson marks 75 years in precision cleaning and welding technologies

Emerson celebrates the 75th anniversary of its Branson brand, which specializes in ultrasonic technologies for plastics and metal welding, and precision cleaning.

The Branson portfolio includes offerings beyond ultrasonics; developing nine other materials joining technologies including laser, vibration and infrared welding. Emerson marked the anniversary at its new $49 million global headquarters for welding and precision cleaning technologies that opened in January.

“We are extremely proud of our history and how we revolutionized the use of ultrasonics in so many remarkable ways,” said Vernon Murray, President, Emerson.

mCloud Technologies Corp. announced it has equipped two initial locations in Saudi Arabia with mCloud’s AssetCare solution for HVAC and indoor air quality.

Facilitated through its partnership with URBSOFT, a provider of urban technologies and services supporting the Saudi Vision 2030 initiative in the Kingdom of Saudi Arabia, mCloud will optimize the indoor air quality and energy efficiency in the restaurant Casa Pasta in Khobar City and CHICK “N” DIP in the Dhahran Mall in Dhahran City, owned by Althawaqh Food Company (AFCO) Restaurant Group.

21_2316_MRO_DEC_CN Mod: October 18, 2021 5:04 PM Print: 10/28/21 page 1 v2.5

THE FUTURE OF MAINTENANCE

It’s been a year where various regulations and restrictions are in place since a global pandemic took hold in early 2020. Many processes around the world have changed to adapt, including maintenance practices. In turn, now is a good time to look at how maintenance has evolved and where it’s heading.

BY MARYAM FARAG

There is no doubt that the future of maintenance will include digitization and automation.

The expanded deployment of digital technologies across manufacturing plants, facilities, utilities, and other organizations is set to reduce labourious

tasks, optimize maintenance schedules, increase preparedness and productivity, create safer environments for workers and improve the bottom lines of industrial organizations.

MRO enlisted a select group of maintenance experts – whose expertise in-

cludes asset management, maintenance consulting and training, supply chain management, and CMMS software – to help us build a snapshot of the future of the maintenance industry.

Asset Management

First, we spoke to Leonard G Middleton, Consultant at Asset Management Solutions, who believe that the one consistency we can expect is change.

“The rate of change will continue to accelerate, and organizations will need to be resilient, agile, and learning continuously, if they are to successfully ride the wave of these changes.

“With the increased automation and digitization, our capability to measure assets, processes and even people performing tasks continues to accelerate. However, our ability to assimilate this tsunami of data remains limited. Improved tools will be required to convert this often-incoherent stream of data

into intelligent relevant information to make timely and informed actionable decisions.

“Recent circumstances, such as the global pandemic and global warming, demonstrated linkages (global supply chain disruptions, severe weather events) that many may not have realized existed, and now need to address those opportunities and constraints provided by the new normal, and be flexible and resilient for future disruptions.

“There remains a key source of competitive advantage for organizations: people. Capable motivated people that are flexible, embrace change and the learning that goes with it, will enable intelligent leadership to have the performance of their organization to exceed that of comparable competitors.”

Also speaking about asset management was Suzane Greeman, Principal Asset Management Advisor at Greeman Asset Management Solutions Inc.

“Asset dependent firms are beginning to embrace the growing complexity and uncertainty in their operating contexts. As the operating contexts continue to shape the role of the organization’s asset management system, it is clear that it is a fundamental element of the business model of asset dependent firms.

“A key role of the asset management system is to create trade-offs among the various capitals that the firm owns, and among its combination of assets, strategic direction of the business model, risks and opportunities in the external environment, and stakeholder value.

“Some external drivers that can be anticipated as the external context triggering changes in asset management systems include increased: external stakeholder activism driving, oversight from external agencies and executives,

requirements to implement strategic asset management plans (SAMPs) and execute against the plans, use of asset management strategies and SAMPs to demonstrate long term risk assurance by external partners. As well as the use of SAMPs to demonstrate the organization has the capability to perform appropriate trade-offs and allocate funding by external financial partners including financial institutions and investors.

“Asset-intensive companies have been doing some form of asset management for a long time. However, the need to create formal asset management systems to lend structure and to assure stakeholders that risks are being managed, is not going away, and is simply taking its place as a permanent fixture in the operating context.

“While asset owning companies do not always overtly include their asset management systems as part of their business models currently, responding to changing operating context will require a tight partnership between the two. A partnership that will position asset management systems as key business systems.”

Sustainability

Next, we spoke with Mariete F Pacheco, Managing Director at FRW Services Inc., who sees a continuation of sustainability within MRO, that has evolved a great deal over the years.

“Initially the strategy was implemented to win government contracts and tenders or as a method to save money.

“Acceptance of more sustainable products and practices has accelerated due to the greater emphasis on environmental and climate change concerns. The call for sustainability has gone beyond government requirements and has be -

come a greater demand from consumers looking for corporate responsibility, and from business customers who are creating a sustainable supply chain across their supplier base.

“Sustainability is becoming more than a competitive advantage for organizations looking to differentiate themselves in the marketplace, it will soon be the norm and table stakes in some industries as governments roll out climate change mandates, looking to create circular economies.

“Sustainability also dovetails in the recent resurgence in re-shoring of manufacturing and buy local messages some communities are encouraging. There are limited regulations generally outside of North America that certify or warrant products as sustainable or better for the environment. Combine this with the ongoing uncertainty of the global supply chain, organizations are sourcing these sustainable products and many operationally critical products domestically to mitigate risks associated with raw material shortages, shipment delays or sky-rocking price increases.

“For some organizations, the sustainable products were used merely as a stopgap alternative during the recent supply chain challenges, but as short-term challenges extended into longer-term issues, organizations have come to embrace these alternatives as commonplace due to their stability in availability and consistent performance.”

Maintenance Management

MRO also spoke to James Reyes-Picknell, Principal Consultant at Conscious Asset, who mentions that the management of maintenance is becoming far more challenging and no longer a role that can be fulfilled by competent technicians.

“Maintenance and its management have been headed south for a while. Short-sighted management decisions have long been setting the stage for more asset unreliability. Then came a pandemic that exacerbated some problems while hiding others.

“People skills, combined with the ability to think and then act strategically are becoming far more critical. Complexity is growing in parallel with our loss of ability to deal with it easily.

“COVID-19 changed how people work, especially where work is done on computers or in offices. However, maintenance isn’t an office job. Machines continued to operate and break, and maintenance never stopped. For technicians in the field, there were changes to shift and teaming arrangements, elimination of shift overlaps, reduction in contractor use, elimination of training, and outside consulting services and in some cases, a sustained increase in overtime.

“Implementation or upgrading of CMMS continues. Digitization initiatives continued to progress with growing interest in AI, machine learning and leveraging “big data.” Systems are becoming more feature rich, more integrated, and more complex. Most users of these systems still don’t measure their own results – an indication that the very systems intended to help in measuring, are missing the mark.

“What’s occurring in the workforce is a shift from dependency on others, to

greater dependence on our own workforces, but with less training and minimal preparation. Some changes worked well (reduced contracting to supplement labour shortages), but others have not (reduced contracting when specialized services were needed).

“Training was reduced and even shut down in many companies. The need for outside help and consultants is likely to jump as companies realize they can’t keep up as post-COVID-19 demand surges.

“We are also nearing the end of the baby boomer retirements. A lot were retiring, and a lot of experience was being lost before the pandemic, and now COVID-19 has accelerated that trend. The window of opportunity to transfer knowledge to the less experienced workers is shrinking.

“The reduced demand for products lowered production pressures. Plants ran at lower outputs, lower stress levels, ran equipment with lighter loads, and suffered fewer failures. They seemed to run more reliably. Repairs are waiting longer and taking longer because of continuing supply chain problems.

“The move to digitization won’t correct all problems, at least not quickly enough. Machine learning and AI have their limitations. They are still not mature technologies. Expectations of technology still exceed capabilities. Corporate unwillingness to share data also leads to slower development of AI. Plenty is being learned as the early adopters make their attempts. Many of those first efforts at digitization are fail-

“The rate of change will continue to accelerate, and organizations will need to be resilient, agile, and learning continuously, if they are to successfully ride the wave of these changes.”

-Leonard G Middleton

ing to achieve desired results, not total failures, but are largely disappointing.

“Newer and younger tech savvy managers expect that technology can “save the day,” but are being disappointed regularly. Realizing that they must learn people skills and develop a greater understanding of processes to achieve their companies’ goals.

“Today, and for the next few years, we see management going through a modern-day era of enlightenment. Technology development will continue, and capabilities will improve, but not fast enough. Managers can’t depend on technology as much as they would like. Many of the lessons learned from past mistakes are lost already, or in danger of being lost for want of methods and the corporate willingness to capture it. Smart people will learn quickly, but not until the mistakes are repeated.

“We see short term pain, gradual enlightenment in parallel with some good technology development, informed by those who understand the processes. That combination can truly help solve problems. Emphasis will shift from technology and back to people and processes as this awakening occurs. Gradually, perhaps within a generation, we’ll all move from a maturity level described as “learning” into varying levels of “competence.” MRO

Maryam Farag is the Associate Editor of Machinery and Equipment MRO magazine, Food and Beverage magazine, and Plant Magazine, Annex Business Media. Reach her at mfarag@ annexbusinessmedia.com

HOW BOWMAN INTERNATIONAL

INNOVATED

A WORLD-FIRST SPLIT ROLLER BEARING FOR HIGH-LOAD APPLICATIONS

For the first time in split roller bearing history, there is a bearing specifically designed to accommodate high axial load as well as increased radial load applications across a range of heavy-side sectors.

Harnessing the unique component production capabilities of additive manufacturing, the new Bowman Advanced Split Roller Bearing delivers up to 75% higher radial load capacity and up to a 1000% increase in axial load capacity in both directions.

Here, Chris Ager, Business Unit Manager for Bowman International’s Split Bearing Division, explains the thought process behind the design and the significance of innovating products for specific applications:

Q: Describe how you went about innovating a ‘world-first’ bearing. When innovating a new bearing, we prefer to use a ‘blank page’ design philosophy, rather than simply trying to evolve or change an existing product. This enables us to scrutinise each sub-component, and understand it’s strengths and weaknesses, before working out how to improve in accordance to the specific application we are designing for.

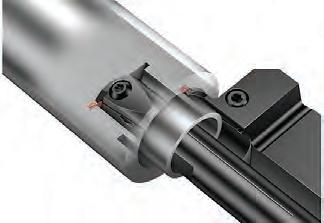

For example, a traditional split roller bearing accommodates axial load as a secondary consideration, relying on sliding contact from race lips alone. We knew that in order to innovate a bearing that would optimise performance and reduce failure in high-load applications, the axial force would need its own integrated axial rolling element - something that has long been impossible to achieve with traditional component manufacturing techniques. Harnessing new technologies such as additive manufacturing, we were able to overcome this barrier and succeed in making a bearing that accommodates much higher radial and axial forces with great success. When innovating a product for a specific environment it’s important to design for both the primary issue (in this case high-load capacities), but also any secondary issues too. When studying high load applications, we identified two additional issues – the lack of available space around the system which made replacement and maintenance difficult, and the importance of maintaining uptime in busy and time-critical environments.

To meet these secondary needs, we knew that our new roller bearing needed to be split to the shaft. This would enable engineers to assemble it radially around the shaft, eliminating the need to disconnect the coupling and move other equipment such as motors, gearboxes or pumps in order to complete any maintenance. The radial assembly of our new bearing delivers up to ten times quicker installation times compared to equivalent solid bearings, saving time and money on planned and reactive maintenance.

Q: Explain why additive manufacturing was the right method for creating the new Bowman Advanced Split Roller Bearing.

Bearing components, by their very nature, tend to be round objects manufactured from rings or rods and the most complex component is usually the bearing cage. We knew that as soon as there was an emerging technology that could create complex forms in resilient

materials, this would likely be the answer to creating a bearing cage with enhanced performance capabilities.

Additive manufacturing allowed us to create strong durable cages with highly complex geometries that could not be manufactured in any other way - the resulting cages create bearings with superior performance to other manufacturing methods, all at a reasonable price point and no tooling required.

For more information on Bowman’s new Advanced Split Roller Bearing, search ‘Bowman Split Bearings’ online.

YOU CAN PLAN SOME REACTIVE WORK

We’ve always been told that we cannot plan reactive work.

BY DOC PALMER

“The horse is already out of the barn and we just need to get the horse back in the barn.”

“We should spend our time planning the proactive work to get the barn into better shape so horse don’t get out in the first place.”

“We also don’t want to slow down swift supervisor response to the reactive work.”

However, we can plan some of the reactive work to improve our maintenance results. We can run the Deming Cycle to improve the quality of some of the reactive work, and we can schedule some of the reactive work to improve our productivity. We can accomplish both of these objectives without slowing down supervisors.

First, consider the practice of planning. The best planning practice is using

planners as craft historians that give head starts to jobs and save useful information for everyone. This craft historian strategy implements the Deming Cycle to make better plans over time, and does not presume plans are somehow perfect.

Indeed, we are not trying to replace the skill, experience, and wisdom of trained craftspersons with perfect job plans. Job plans should aim to eventually be great guides for new persons, and handy references for senior persons, but plans are always living works-in-progress.

Combine this strategy with the knowledge that not all reactive work will start today. Many times, reactive work is not an emergency that must start today. Consequently, a planner needs only to check with the crew supervisor anytime a new reactive job pops up and ask if the super-

visor thinks the job will start today. If the job will probably start today, then don’t bother to plan the job at all!

But if the job will not start today, the planner can knock out a quick job plan. If there is no existing plan, the planner might simply do a quick field check, make a quick judgment of what is needed, and call it a day.

What kind of plan is that? It can be a great job plan. The planner has added craft and time requirements to allow better assignments. The planner has clarified the scope to at least get the execution going in the right direction. After the execution, as always, the planner looks for feedback (longer ladder, additional gaskets, different bolts, etc.) to improve the plan.

So, in the future, even for a reactive planning effort, there might already be a living plan from the past! Why

wouldn’t we want the planner to attach the better job plan; the better head start? Why doom a craftsperson to reinvent the wheel and not receive the better head start if the planner had time to attach it? The key to the whole notion of planning some of the reactive work is to check with the crew supervisor first. Never, ever, suggest that the supervisor should wait on planning. But if the job won’t start today, knock out a quick job plan and run the Deming Cycle of continuous improvement to promote better and better maintenance work over the years.

Second, consider the practice of scheduling. The best scheduling practice for maintenance productivity is starting crews with weekly, fully loaded schedules to defeat Parkinson’s Law.

Parkinson’s Law states that, “The amount of work

Photo: SpicyTruffel / Adobe Stock

assigned expands to fill the amount of time available.”

We must start crews off with fully loaded schedules each week. But because real life does have a lot of reactive maintenance, it must be allowable to break the schedule.

Starting crews off with 100 per cent loaded schedules, and achieving 40 to 90 per cent schedule compliance, yields more work completed than 70 per cent loaded schedules and 90 to 100 per cent schedule compliance. And more work completed than normal means the completion of more proactive work. But what about all the new reactive work that will happen next week? We expect reactive work by allowing to break the schedule.

We can also make more credible weekly schedules by first planning some of the reactive work. Some of the reactive work where we knocked out a quick job plan actually ends up waiting in the backlog at the end of the week. It turned out not quite reactive as we thought. And rather than fuss at operators to avoid the urgent priority selection, it turned out to be a good idea that we had checked with the supervisor and had knocked out a quick job plan.

That planned reactive work can be put in the weekly schedule for the next week. Don’t break the weekly schedule next week for work you know about this week! You can put it in the schedule because the quick plans provide craft and time estimates. It gets better. We can now bundle lesser priority work with the more reactive work in the next week’s schedule.

“If we are going to LOTO that system next week, we might as well go ahead and do these other two jobs that have been lingering in the backlog.”

And lower priority work

lingering in the backlog is normally proactive work that otherwise is hard to work into the reactive churn of real-life maintenance.

Be better than most plants that simply let all the reactive work bypass planning and scheduling. Check with the supervisors and then plan the new reactive work that won’t start today. Run

the Deming Cycle to make as many plans and jobs better over the years.

Additionally, put any of that planned work into the next week’s schedule if it is still in the backlog at scheduling time. Make fully loaded schedules as credible as possible to have superior productivity and complete extra proactive work. Don’t be a

normal good plant. Be a superior great plant! MRO

Doc Palmer, PE, MBA, CMRP is the author of McGraw-Hill’s Maintenance Planning and Scheduling Handbook, and Managing Partner of Richard Palmer and Associates, which helps companies worldwide with planning and scheduling success. E-mail Doc at docpalmer@palmerplanning.com.

THE EVOLUTION OF FACILITIES MAINTENANCE

The future might be hard to predict, but having witnessed how things have changed over the years, it can help in establishing future predictions for the maintenance world.

BY DOUGLAS MARTIN

There are many traditional industries that are generally declining; they are more in survival mode as opposed to growth mode. There are also industries that are cyclic, based on commodity prices.

Many of these facilities had engineering groups as well as maintenance and condition monitoring departments that were well staffed. As time has passed, first, the engineering groups were reduced, then the maintenance groups were reduced. There were efforts made to create reliability groups, but often these were the maintenance groups re-named as reliability groups, but functionally, they were still called upon to do maintenance, which drew them away from their task of reliability.

Even with technicians who perform the vibration tasks, when the time comes to do system maintenance on a down day (i.e. to re-install sensors and cables if needed), they are drawn away to do mechanical repairs, which are deemed more critical than the system maintenance.

There are newer facilities in different countries around the world that have become the leaders in the industries that were once strong locally. Certainly, they have the benefit of new equipment with significantly greater capacity. However, they would also be burdened with the repayment of the capital cost of the facility. One of the main advantages is the structure of the company, where the facility is a “production” company whose only responsibility is to produce. The responsibility for the maintenance and reliability of the operation is contracted out to specialists who are experts in their services and their product. The problem that has been faced by local companies is that this model does not fit well with the existing structure/culture of labour and employment practices. However, over time, it is evolving.

Examples of such evolution is the use of haul trucks in mines. The model has changed from a mine site owning the truck to the mine site paying the truck owner (OEM or OEM representative) for operating time, and the truck owner takes responsibility for the maintenance and reliability of the vehicle. In other words, the mine site only pays for the operating hours of the haul truck as opposed to the capital cost and maintenance.

Another example is the packing of systems instead of in-

dividual components. For example, some large facilities that once had in-house motor rewind departments, shifted the motor repair to local motor shops. Another example is that mine sites replace complete pulleys instead of simply changing the single bearing.

OEMs are getting involved in the life cycle of their machines. Recall a number of years ago, a large paper machine manufacturer discussed that since papers machines were not being built, their survival depended on spare parts sales. Today, machinery OEMs are moving into a roll of taking responsibility for the life cycle of the machine that could include remote monitoring of the machine.

Another issue that has arisen from the recent cycles of commodity pricing (and especially oil pricing) is the push and pull of personnel between the industries with high commodity prices and those with low commodity prices. An example was the drain of talent from the pulp and paper industry into the oil and gas industry, then with the contraction of oil and gas, the

reverse migration of talent.

Current Internet technology is facilitating this transition. With cloud data technology, data can be readily accessed from around the world at any time. Process and operational data can be transmitted around the world as live data, so instead of needed experts in house to understand the data, operating companies can have centres of excellence within the organization to provide expertise to the facilities within the organization. Instead of “in company” expertise, smaller organizations can take advantage of supplier COEs (centres of excellences) for advice. With the advent of wireless sensor devices, machine monitoring has become that much easier. Previously, a sensor would have to be wired to a router, then the router to be connected to the facilities’ LAN. With this structure, there was level of labour intensity to first wire the sensors then to wire the LAN. Although some degree of wireless-ness was achieved by using internal WiFi networks, these often have weaknesses in both speed and security.

It appears that machine monitoring has taken a giant step forward in reduction in overall cost and ease of installation. Machines will be monitored on systems that are not necessarily housed locally and monitored by a greater level of expertise (and with the assistance of artificial intelligence).

Today, with the advent of widespread and strong cellular networks, there is no longer a need for a LAN, and a machinery surveillance network is easily set up without the need for wiring. To this point, sensors can be simply attached to a machine point without the need for cabling (power and signal). In other words, to physically install a sensor, all that is needed is to install that sensor, either in a pre-drilled hole, onto a button glued to the position, or even using a magnetic anchor. The cabling of sensors to a switch box or a router is no longer needed. This often was the most time and labour consuming task when setting up a monitoring system.

The wireless sensors then communicate with their router and that router communicates its data to the cloud. The data can then be accessed anywhere in the world using a standard Internet browser connection. Of importance, by connecting through the Internet, the local facility does not need to have the complex software loaded locally. This also means that the local IT department does not need to maintain the expert software on the local machines as well as ensuring the local machines are maintained to run the expert software.

In terms of data security, a wireless sensor array as described is not a security threat in terms of exposing the user to cyberattacks. In other words, since the data is sent directly from the router to the cloud, outside of the facility’s LAN, there is no data channel to the facility’s network.

So, what is the future of maintenance?

It appears that machine monitoring has taken a giant step forward in reduction in overall cost and ease of installation. Machines will be monitored on systems that are not necessarily housed locally and monitored by a greater level of expertise (and with the assistance of artificial intelligence). Although emergency repair work will likely be done by a team of local first responders, proactive repair work will be done by experts in the machinery that is being repaired that are hired in a planned fashion.

Machinery maintenance and reliability may be done by the OEM or the OEM’s local dealer, and the user will pay for the operational availability of the machinery, opposed to the capital expense and subsequent upkeep. MRO

Douglas Martin is a heavy-duty machinery engineer based in Vancouver. He specializes in the design of rotating equipment, failure analysis, and lubrication. Reach him at mro.whats.up.doug@gmail.com.

TECHNOLOGY AND MODERN MAINTENANCE

Modern maintenance tools and technologies that will make life easier for maintenance professionals.

BY BRYAN CHRISTIANSEN

Modern production facilities incorporate several technologies to improve the autonomy and efficiency of processes. These advancements continue revolutionizing maintenance strategies, with companies aiming to eliminate downtime and streamline workflows. A modern maintenance professional requires technical knowledge on a variety of equipment and sufficient digital knowledge to facilitate proactive detection, diagnosis, and correction of equipment errors before they result in costly breakdowns.

With the advent of technology, maintenance ceases to be the responsibility of technicians alone. Proper maintenance is vital for improving the reliability and availability of production assets. It has significant impacts on the bottom line of a company. Modern maintenance technologies and tools transform the operations of organizations by:

• Improving communications at all levels

• Enhancing the transparency of routine operations

• Streamlining (lessening) maintenance workloads

• Enhancing compliance

• Controlling maintenance budgets

• Standardizing maintenance operations.

Emerging technology trends are continually revolutionizing maintenance management. Let’s review predominant technologies, their relevance in maintenance operations and their effects on maintenance professionals.

IoT, cloud technology and condition monitoring

Stiff competition dictates that companies should keep operations running. To avert breakdowns, companies are implementing condition monitoring technologies, which consist of sensors and communication networks. Sensors continuously monitor the health and the working conditions of equipment. They collect vast amounts of

data and transmit them to internal or cloud-based servers.

The industrial internet of things (IIoT) allows maintenance professionals to collect and analyse data in real-time. It enables them to proactively identify underlying problems and resolve them before they cripple processes. Professionals leverage periodic equipment operating data to develop predictive algorithms and models for evaluating the reliability of different facilities.

Traditionally, to perform failure mode, cause, and effect analysis, it was necessary to sift through physical maintenance records. It was a time-consuming and error-prone process. However, as cloud technology advances, maintenance professionals can remotely access, summarize and visualize thousands of maintenance records in a matter of seconds. That way, professionals spend less time evaluating and troubleshooting equipment defects.

IoT and cloud technology will continue to support a shift from reactive maintenance to data-driven predictive

maintenance (PdM). Unlike reactive maintenance, PdM allows maintenance professionals to develop effective maintenance schedules. Aside from reducing the overall maintenance cost, PdM ensures an even distribution of maintenance workloads.

Remote inspection

Inspections form a part of preventive maintenance interventions across industries. Even so, some components of equipment or facilities are difficult to access. Visual inspections allow maintenance professionals to identify signs of wear that may escalate to failures. Inspecting some sections of facilities like chemical processing plants exposes maintenance professionals to health risks. Remote inspection allows companies to monitor the structural integrity of components without disassembling equipment or risking the lives of professionals.

Companies conduct remote inspections using videoscopes, borescopes or fiberscopes. They rely on high-definition

Photo: Michael Traitov / Adobe Stock

IoT and cloud technology will continue to support a shift from reactive maintenance to data-driven predictive maintenance (PdM).

Unlike reactive maintenance, PdM allows maintenance professionals to develop effective maintenance schedules.

cameras to capture and transmit images and videos. Maintenance technicians view these images on portable screens, smart goggles, or eyepieces. For remote inspection of larger spaces, maintenance professionals utilize CCTV cameras or drones, which capture and relay videos in real-time. Drones and CCTV cameras reduce the total inspection time owing to their wide coverage angles. Breakthroughs in robotics and artificial intelligence have given birth to small climbers, crawling, and flying robots. These devices can navigate some hard-to-reach or hazardous areas.

Remote inspection allows maintenance professionals to monitor rotary equipment, pressure vessels, pipes, power plants and chemical facilities. The devices maintain digital inspection records, which improve the quality and accuracy of inspections. They minimize inspection time and guarantee the safety of maintenance personnel.

CMMS technology

Computerized maintenance management systems (CMMS) continue to evolve with transformations in technology. The data storage, processing and storage capabilities of computing devices and CMMS platforms allow maintenance professionals to centralize staff, tools, and spare management. These programs have evolved from simple platforms for storing maintenance records to sophisticated programs compatible with cloud technologies and mobile devices.

The benefits of CMMS programs to maintenance workflows are immeasurable. They store detailed information on every piece of equipment owned by a company, manufacturer manuals, spare part information, standard maintenance checklists, troubleshooting information and maintenance schedules. Supervisors utilize these platforms to approve work requests and assign work orders to technicians. The versatility of these programs means that authorized professionals can remotely access and update crucial maintenance information, monitor the progress of maintenance work and analyse the efficiency of mainte -

nance strategies.

By centralizing data management on CMMS platforms, companies standardize maintenance operations, leaving no room for errors when performing corrective or preventive maintenance, thus enhancing the safety of processes and technicians. More companies are adopting flexible work arrangements. They need to monitor the productivity and training needs of dispersed teams. CMMS platforms facilitate the documentation of maintenance tasks and guarantee the availability of maintenance and training information whenever required. CMMS programs simplify collaboration among maintenance teams.

Augmented reality and virtual reality

Maintenance professionals require periodic training to sharpen their technical abilities and acquaint them with emerging digital tools. Companies have been relying on printed manuals, graphs, and physical models to conduct training of maintenance professionals. As technology advanced, companies shifted to video conferencing, presentations, and digital manuals. Training maintenance professionals through these methods demand the physical presence of participants.

Augmented reality (AR) and virtual reality (VR) technologies are quickly gaining pace and promise to revolutionize training for maintenance professionals. With COVID-19 striking the globe, there was a need to limit physical interactions. Vendors and manufacturers utilize AR to create cyber representations of complex systems to demonstrate the interdependence of parts and processes. Maintenance professionals receive a walk-through of the entire facility. Virtual reality utilizes pre-recorded maintenance sessions to outline troubleshooting procedures or information.

These technologies improve the training of new staff as they can easily visualize how experts perform maintenance tasks at hand. AR technologies evaluate maintenance records to identify skill gaps and customize training programs to enhance the quality of maintenance work across the board. Manufacturers include recommended procedures in

AR and VR platforms. It assists maintenance professionals in conducting timely and accurate troubleshooting. AR and VR solutions serve as a perfect reference point when maintenance professionals encounter new equipment or complex systems.

Leak detection tools

Industrial systems contain a blend of equipment and technologies that convey or utilize the three states of matter. The leakage of liquids and gases indicates underlying failures and poses safety risks to operators and occupants of a facility. Leak detection is a preventive maintenance strategy that utilizes several digital tools and technologies to pinpoint the source of liquid or gas leakage.

Ultrasonic leak detectors enable maintenance professionals to locate leaks in pressurized systems, capture, convey and store digital records of facility leakages. Air and gas leak detectors are vital for identifying the emission of combustible gases. Minute traces of combustible gases may result in fire accidents.

Leak detectors are vital for promptly identifying the source of gas or liquid leak and enables maintenance professionals to implement corrective measures within the shortest time. By correcting defects at an early stage, technicians can control maintenance workloads and enhance their safety.

Technology presents several opportunities for maintenance professionals. Digital tools and platforms help maintenance personnel to reduce workloads and enhance the quality of maintenance work. They facilitate remote monitoring and maintenance, significantly boosting the safety and compliance standards of companies. Investing in digital skills is becoming inevitable for modern maintenance professionals. Companies need to keep abreast with emerging technology trends and find innovative ways to incorporate new tools and technologies into their maintenance workflows. MRO

Bryan Christiansen is the Founder and CEO at Limble CMMS (a mobile CMMS software company, https://limblecmms.com). He can be reached at bryan@limblecmms.com.

THE ESTABLISHMENT OF AN EFFECTIVE FAILURE ANALYSIS PROGRAM

Failure analysis programs are in place at production and manufacturing plants in many industries, but they tend to stop at a certain stage.

BY L. (TEX) LEUGNER

These programs are in place to determine and understand the root causes of component and machine failure, avoid recurrence, reduce costs, and improve equipment reliability. Unfortunately, and frequently, the root cause failure analysis process stops at the identification of the physical causes of a component or machine failure.

Root causes can be categorized into physical, human, and latent (organizational and managerial) causes. When the failure analysis team stops at uncovering the physical causes, a complete picture of why the failure occurred in the first place has not been fully investigated and determined. Delving into greater depths to identify human or latent causes of failure allows one to recognize incorrect or inadequate human actions, or inappropriate corporate policies that unknowingly or unintentionally permit the wrong or inappropriate human actions to occur.

A common example of human causes is lack of training in many maintenance or operational functions. A latent and very common cause of failure is a philosophy among some plant executives and managers that maintenance is a cost rather than an investment, which creates mistakes because the deference of scheduled PM tasks, in favour of production results in unexpected stoppages or failure.

What are the most common types of failures in your particular facility?

LOGIC: There are several very common types of failures, they include overload or over-speed (a common result of a latent cause); fatigue, of bearings for example, which can be considered normal if the bearing has reached the end of its life cycle; corrosion, causing material loss in a component; elevated temperatures, resulting in lubrication failure or changes in the metallurgical condition of the component.

What methodology of failure analysis is used in your facility?

LOGIC: There are six typical steps recommended in the failure analysis process. First is “diagnosis”: inspect the component carefully, using high magnification photos to determine if the failure is one of those frequently occurring, such as corrosion, temperature, lubrication related or fatigue.

Next, “collect background data”: frequently failures are a direct result of an inadequate repair just completed and review the machines complete maintenance history in detail.

Then “inspect the component (or pieces of it)” with a good quality microscope, develop a logic tree and list every symptom of the failure. Now “complete a detailed chemical, scanning electron microscopy or metallurgical analysis” to determine the related condition of the component or its pieces. Then “determine

the physical failure mechanisms and arrive at a conclusion”. Finally, “determine human and latent root causes” that may have contributed to the failure.

Does your organization fully understand that failures can occur throughout a machine’s life cycle?

LOGIC: Without exception, failures belong to one or more of these seven causes: faulty design, material defect, manufacturing or processing deficiencies, assembly or installation defects, unintended service applications, maintenance neglect or procedural deficiencies, and improper operation.

How does your organization prepare and complete improvement projects?

LOGIC: ypical projects include changes to machinery to increase production. If a project does not consider proper material selection, accurate dimensioning and any operating condition that changes the operational result, failures will occur. One such recent production increase project was that of a conveyor system in a crushing plant. In order to supply more material to satisfy a newly acquired crusher, the conveyor system was expanded to increase the supply of material. Wider, stronger belts were installed, along with an improved support roller and bearing system. The gear drive mechanism which operated the conveyor failed catastrophically six weeks later. No thought had been given to whether the drive system could support the increased capacity.

How does the organization manage and facilitate increased customer demand?

LOGIC: Often customer demand necessitates increased production that may call for modifications to machinery. If the organization doesn’t give serious thought to how and why modifications are managed, failures will occur.

Plant management simply ordered increased speed of production machinery. Within three weeks, bearing failures began to occur. If a typical bearing load is doubled, the life cycle of the bearing may be reduced by as much as 90 per cent. Doubling the rated speed of a bearing can also reduce its life by as much as 50 per cent.

of many equipment reliability specialists, contributes directly to a two-to-five per cent reduction in plant productivity in North America. Poor operating practices are the direct result of two conditions prevalent in our present society; an uncaring attitude by workers, and an absence of appropriate training (in fact, the absence of adequate training may be directly related to worker attitudes).

Regardless of whether it’s physical, human, or latent causation, root cause failure analysis should be carried out after every incident or failure, no matter how insignificant or unimportant it may appear at the time. This is the only way an organization has any chance to effectively eliminate recurrences entirely while continually improving its operational and human resources.

To remain competitive, the goals of industrial plant facilities must include high levels of machine reliability, to reduce downtime, extend equipment life, reduce repair costs, improve equipment efficiency, reduce capital costs, increase productivity, and maintain employee morale and satisfaction. Maximum equipment and process reliability cannot be achieved or maintained if the plant is continually subjected to breakdowns, inadequate or incorrect repair procedures or recurring failures. MRO

L. (Tex) Leugner, the author of Practical Handbook of Machinery Lubrication, is a 15-year veteran of the Royal Canadian Electrical Mechanical Engineers, where he served as a technical specialist. He was the founder and operations manager of Maintenance Technology International Inc. for 30 years. Tex holds an STLE lubricant specialist certification and is a millwright and heavy-duty mechanic. He can be reached at texleug@shaw.ca.

These engineering guidelines must be kept in mind whenever production increases are demanded by an unknowing management, or if machine modifications are considered. The obvious lesson is that every machine or mechanical drive system is only as strong as its weakest component. It is important to remember that about 80 per cent of bearing failures are usually a symptom of a much larger problem, such as excessive loads or speeds, extreme vibration conditions, poor lubrication practices, extreme temperatures, improper replacement bearing selection and/or poor installation.

After a failure has occurred, does your organization review its operational procedures and practices to address human root causes?

LOGIC: As discussed above, failures are often related to human and latent causes. A typical example is related to poor operating and maintenance practices. These may be one of the most common causes of machine failure, and in the opinion

THE SMART MOVE TO MORE EFFICIENT AND SAFER MAINTENANCE OPERATIONS

Regardless of their size or the industry segment in which they operate, manufacturing companies are constantly striving to increase efficiencies within the various processes they employ.

BY JONATHAN BEAUMEL

Arguably, maintenance is one of the primary areas in which companies are continually seeking ways to lower costs and cut the time taken to perform essential tasks. With many maintenance operations still planned and performed manually, often by experienced operators performing sometimes basic yet time-consuming tasks, it is easy to see how manufacturers are sometimes swimming against the tide when it comes to achieving efficiency goals.

In an effort to improve in this area, more and more companies are turning to innovative and disruptive technologies to streamline processes and reduce the time and costs involved within their maintenance operations.

One laborious yet highly important task is the need for maintenance engineers to manually check the torque level of every single bolt that might be in place within a particular piece of machinery, engine, or countless other structures or vehicles.

This has led to the emergence of certain solutions that are designed to eradicate the high level of time demanded in such instances. Examples of such solutions include those that use ultra-sonic waves to perform inspections. However, despite enabling accurate measurements, this method has plenty of critics, who point out certain fundamental limitations. Most notably, such devices require having physical access to the bolt, as the device needs to be plugged in on top of it. Ultra-sonic solutions also require information such as the length of the bolt, which might not be known or readily to hand.

A smarter approach to maintenance operations

Aerospace is one of the foremost vertical sectors in which maintenance, repair and operations (MRO) processes require efficient, as well as standardized, safe practices and solutions providers have been looking at ways to address this fundamental issue for years. It has al-

ways been apparent that maintenance engineers needed something that would meet head-on the fundamental challenges within processes themselves, while also overcoming the shortcomings of existing solutions.

This has seen companies in the industry develop new technologies that enables touchless and wireless measurement of bolt axial load. Importantly, this means that instead of having to manually verify the torque level of every single traditional bolt, maintenance engineers are notified about those specific fasteners that are either too tight or too loose so they can attend to them accordingly in just a few seconds. This offers an added immediate benefit from a safety aspect as the device can reduce the eventuality of breakages in bolts caused by repeated over tightening during manual checks.

Designed to improve efficiencies within MRO, these technologies perform the fundamental role of a standard washer but uses intelligent connectivity to provide maintenance and service engineers with a clear picture of axial loads. This has been demonstrated by incorporating a strain gauge and a transmission system, which via an appropriate reading device, relays the information to maintenance engineers.

Photos: JPB Système

Quantifiable efficiency gains

Airbus Helicopters is one use-case in the industry which has noticed quantifiable efficiency gains across helicopter engine maintenance by using industry 4.0 practices. Usually, a helicopter can require a periodic check that necessitates removal of its engines and interior trim even before maintenance engineers can gain access and check the bolts. Once checked, the engine needs to then be re-installed and a ground-run undertaken to ensure correct installation of the engines. This is a very labour-intensive process heavy maintenance operation that would typically take around two days and require two engineers to check about 12 bolts.

Lifting off in other industries

Beyond aerospace and aeronautic industries, new technology in the industry can also potentially address several other sectors that demand extremely high safety standards and efficient maintenance processes.

For example, opportunities exist in the energy and renewable resources markets.

MKETHE SWITCH

One such application scenario is with nuclear power, where nuclear energy companies could easily perform essential checks on radioactive waste tanks by using a drone from a safe distance. Similarly, manufacturers of wind engine turbines for power generation could leverage the benefits of new technology in conjunction with a drone, saving time (and ultimately costs), as well as overcoming safety issues inherent with hard-to-access wind turbine blades. There are many other examples in which these fundamental issues can be addressed and overcome with such solutions – including chair lifts and cable cars at ski resorts, or high-level rides at amusement parks.

Crunching data for predictive maintenance

When using smart technology, there is a more far-reaching potential that has become evident. The amount and level of data provided by new devices that can be accessed, analyzed, and processed, could in due course enable accurate live monitoring and offer the opportunity to

enjoy predictive maintenance. Parameters that could be registered and leveraged include tension, date, location, temperature, to name a few.

This means that whether it’s an engine for an aircraft manufacturer, wind turbine, or amusement park ride, those companies could be alerted if there is a requirement to perform maintenance –be it for a sudden and immediate issue or just according to schedule.

Ultimately, most manufacturers or companies that are required to perform maintenance checks on machinery or other infrastructures set themselves clear goals when it comes to reducing time and cost across such processes. Thanks to innovative providers that commit to addressing and solving these fundamental challenges with smart technology solutions, manufacturers will be well equipped in their constant quest to continually improve efficiencies. MRO

Jonathan Beaumel is a Design Engineer at JPB Système.

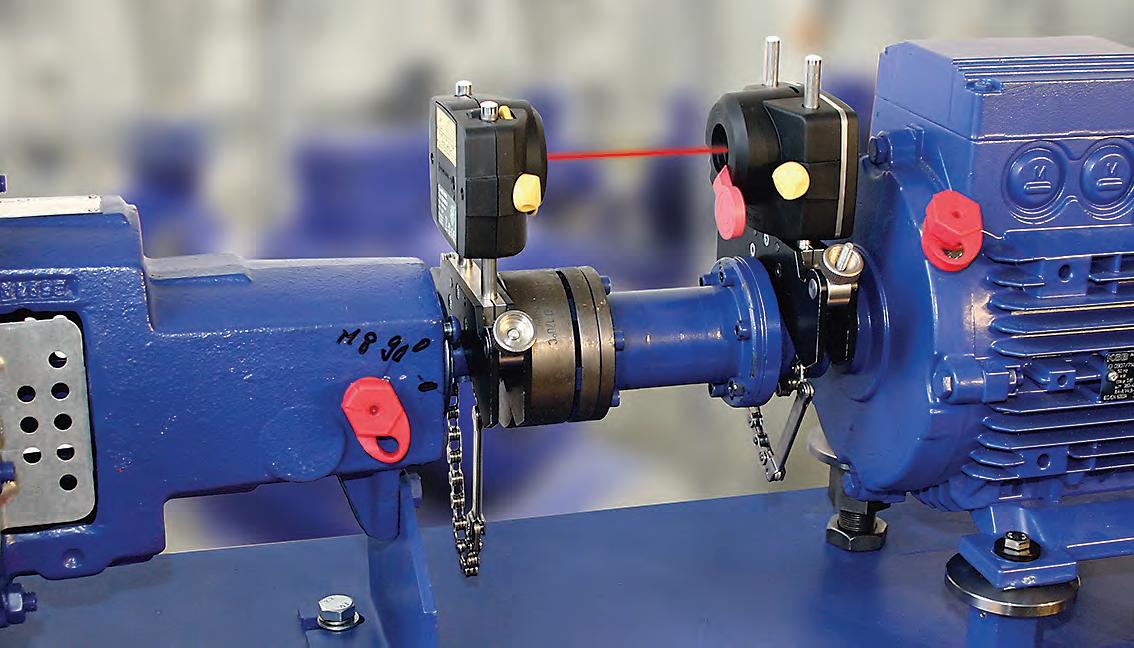

HOW ALIGNMENT AND CONDITION MONITORING EXTEND MOTOR LIFE

Alignment is a critical component of extending motor life. Learn why you should pair alignment with a condition monitoring program.

BY ERIC ELDER

When machinery is misaligned, it can cause downtime, slow down production, increase energy costs, and damage machinery. Misaligned machines can also run hot as a result of consuming excess energy. This means not only higher energy bills, but also potential lubrication breakdown and safety concerns. Proper shaft alignment is especially important for rotating equipment operated at high speeds.

Misalignment happens when the centerlines of the driver and the driven equipment shafts are not colinear, or in

a straight line with one another. Correct shaft alignment increases the operating lifespan of machinery. A properly aligned shaft provides the most efficient power transmission from a motor to the driven equipment.

By shifting alignment from being an afterthought to a regular occurrence, you not only extend motor life — you free up your maintenance team to focus their time on true priorities. When equipment is properly aligned, there’s less need for repairs and replacements, because components last longer. But alignment isn’t a one-time thing. To understand how alignment changes over time, you need to collect and analyze condition monitoring data using handheld tools and sensors.

Consequences of misalignment

Poorly aligned machinery requires more replacement parts than properly aligned

machinery, so it’s more expensive and time-consuming to maintain — and diverts parts and labour from other needs. For example, misalignment can cause seals to fail. And when a seal fails, it can cause fluid leaks and harm other machine components. Seals themselves can also be expensive to replace.

Misalignment is also a leading cause of excessive vibration. It can also cause premature failures in bearings, couplings, or shafts. These failures can also go on to damage other components or lead to downtime.

Flexible couplings can tolerate more misalignment than rigid couplings, but they still have certain requirements and tolerance limits. Using flexible couplings is not a substitute for proper alignment, and improper coupling choices can cause failures. A coupling that is too tolerant of misalignment for the application, for example, can cause increased vibration

Photo: Fluke

or unbalanced rotation.

Motors face three main types of misalignment: angular misalignment, offset/parallel misalignment, and combination misalignment (which is when a motor shaft experiences both angular and parallel misalignment at the same time).

Achieving and maintaining precision alignment

Attention to a machine’s alignment should not end with installation. New equipment should be checked for changes in alignment after several months in case of settling, and the most production-critical equipment should be checked on a regular cadence. Alignment data can also be captured whenever equipment is down for maintenance. Over time, this data can provide insights about ways that alignment can be improved.

For example, it’s crucial to know the correct operating temperatures of a machine’s components and record them during normal operation. Heat can cause materials to expand and change a machine’s alignment. Different materials expand at different rates, as well as at different thresholds. Also, keep in mind that OEM data can sometimes differ from real-world operating conditions. Once you have an established baseline of temperatures, any deviations will stand out.

Alignment is not a fixed, static state, and misalignment can be caused by many different factors or conditions. A machine’s alignment can change when the machine experiences changes in temperature, pressure, load, or vibration.

Condition monitoring can detect misalignment problems before they lead to failures and downtime, with vibration monitoring being especially effective. A thermal imager can spot a coupling that is too hot, but that won’t reveal the cause. Vibration data offers a fuller picture of asset health, with certain types and locations of vibration indicating alignment issues.

There are vibration monitoring tools available for a wide range of budgets and applications, whether you want a handheld tool for collecting basic data during route-based maintenance, vibration sensors for around-the-clock, in-depth condition monitoring of critical assets, or something in between.

Many successful maintenance teams use condition monitoring to collect asset data in real time. Every machine

will require intervention at some point — usage and wear eventually cause failures — but condition monitoring can provide the insights you need to identify potential failures before they happen. The frequency and detail of the monitoring can be tailored to the criticality of the machine.

Using condition monitoring sensors and analysis software

Condition monitoring is a cost-effective way to track asset health in real time. Sensors and software make it possible to assess the condition of many machines, around the clock, without requiring someone on site taking measurements. When you and your team know the condition of your machines, you can reduce or avoid failures and downtime.

Trending machine condition over time, and using software to analyze the data, gives your team the insights and knowledge they need to plan and prioritize their actions most effectively. Vibration monitoring is an effective way to monitor assets, from the most critical to the most often overlooked.

With a full picture of asset health, you can more effectively determine which maintenance actions need to happen and when. Planning maintenance this way, rather than relying on a calendar or reacting to failures after the fact, increases uptime while reducing spending. Replacing parts before their true end of life uses labour and materials that could be used in other ways. Calendar-based maintenance doesn’t neatly or necessarily correspond to actual asset condition, and it doesn’t help teams spot quickly progressing problems. Significant failures can still happen even with regular preventive maintenance.

When maintenance teams are in a reactive mode and responding to failures, rather than keeping machinery in peak operating condition, reliability, efficiency, and production are all hampered. Using real-time knowledge of asset condition enables teams to use the full lifespan of machine components and plan repairs in advance. Repairs can be made before extensive damage occurs, meaning unplanned downtime occurs much less often.

Analysis software makes it possible for even small teams or novice technicians to interpret asset data. Some software even offers teams the ability to customize operational thresholds for assets, and to send notifications and alarms whenever an asset operates out-

side of those defined limits. From there, the team can intervene as necessary and diagnose the problem.

Taking a proactive maintenance approach

Aligning a machine is not a one-time event. To understand how the alignment of your machines change over time, you need to collect and analyze machine condition data. That real-time asset data makes it possible for teams to identify and resolve potential problems before they escalate. It also makes your team safer.

Not only does condition monitoring reduce the number of times technicians need to access hard-to-reach or hazardous areas as part of route-based maintenance, but planned repairs are much safer than emergency corrective repairs. With a combination of condition monitoring and software, your team can remotely monitor assets, accessing real-time measurements from a desktop computer or a smartphone. Having an overall facility view of asset health helps teams plan and prioritize. Labour hours are often a limited resource for maintenance teams, and using time and effort wisely drives productivity and safety.

Making data-driven decisions improves operations — but is only possible when teams have the right data and know what to do with it. Maintenance teams that don’t pay attention to machine alignment are operating with a blind spot.

Keeping your machinery properly aligned has numerous benefits. It reduces downtime, decreases your energy bills, extends the life of your equipment, and allows your maintenance team to optimize their time and effort. In today’s competitive landscape, the costs of wasted time, energy, parts, and materials add up quickly. Availability and reliability are key. Being proactive about alignment can mean more uptime with less spending. MRO

Eric Elder is Service Manager for the Americas region at Prüftechnik (www. pruftechnik.com), part of the Fluke Reliability family. He holds a Bachelor of Science Degree in aviation maintenance from the Pennsylvania College of Technology. Eric has more than 10 years of experience in industrial maintenance, including as an alignment specialist and is a Certified Reliability Leader (CRL) and Vibration Analyst, Category II (ISO 18436.2).

ASSET MANAGEMENT IN THE PUBLIC AND PRIVATE SECTORS

– IS THERE A DIFFERENCE?

The opportunity for North American companies to adopt asset management as their approach in doing business.

BY CLIFF WILLIAMS

Asset Management has not been embraced in North America as much as it was expected by those who saw the benefits realized in other countries through the use of PAS 55, which was the precursor to the development of ISO 55000 suite and how organizations found value and success in managing the organizations.

Recently, only 14 or 15 organizations were certified to ISO 55001 in North America, out of over 300 worldwide. Across the world, we see uptake from utilities, airports, transportation, facilities management, infrastructure, and engineering as well as a smattering of government type organizations.

Obviously, there is an opportunity for North American organizations to adopt asset management as their approach to doing business, but we haven’t seen it yet. This is not a new phenomenon, as those of us who were around for the outburst of lean manufacturing around the world in the 1990s and 2000s can testify; many North American organizations took parts of the lean process and used it in conjunction with their existing processes and called themselves lean, but very few adopted all of the facets that would have realized the benefits of the lean approach.

Some, in fact, thought it simply meant doing more with less, and reduced their workforce and claimed to be lean.

The interesting take on asset management in North America, especially in Canada, is the uptake of asset management by governments and municipalities. It is unlikely that municipalities will certify to ISO 55001, as there is no

perceived benefit other than, maybe, reputational, as opposed to the private sector that has always considered ISO certification as being a way to demonstrate their commitment to quality, environment, and value in their marketplace, and by inference, a company you’d like to do business with.

What has driven governments to suggest asset management has been the belief that money, such as grants, taxes, etc., has not been utilized to the fullest value?

The belief in asset management in Ontario was so strong that the government enacted Ontario Regulation 588/17 – Asset Management Planning for Municipal Infrastructure, which required municipalities to provide detailed asset management plans with justification, initially for their core assets, such as water, wastewater, roads, bridges, and culverts and expanding to all of their assets (COVID-19 has forced the due dates to be a little bit fluid).

This Ontario Regulation is detailed in what it requires from the municipalities, but, in a somewhat similar way to ISO 55000, it doesn’t prescribe how or what these details should result in; it presents itself more as a report card rather than a road map for continuous improvement.

So, let’s look at some of the differences that applying asset management in the municipal or government sector brings.

Of course, the focus of asset management is providing value for the stakeholders, so how do the municipalities demonstrate that?

The first challenges they face are; the number and different types of stakeholders; the government that provides grants and funds; the residents and businesses who pay taxes in one form or another; the employees at the municipality who are meant to oversee all of this; and the council. There is such a wide range in the stakeholder group of residents and businesses, which makes it very difficult to come up with a statement of what represents value.

What is of value to some, will be meaningless to others, so how do we determine value?

This usually ends up with strategic objectives as general as “deliver exceptional service” or “promote a high quality of life”, which mean many different things to different people. When the municipality then tries to cascade these objectives into meaningful measures so they can identify success, they find it difficult to do so, and this then cascades through the organization, with each level struggling to find those measures that really impact the strategic objectives.

When some departments find themselves in this situation, they become