APRIL 2021

Vol. 37, No. 2

Established 1985

www.mromagazine.com

Twitter: @mro_maintenance

Instagram: @mromagazine

Facebook: @MROMagazine

Linkedin.com/company/mro-magazine

Reader Service

Print and digital subscription inquiries or changes, please contact

Beata Olechnowicz, Audience Development Manager

Tel: 416-510-5182 Fax: 416-510-6875

email: bolechnowicz@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400 Toronto, ON M2H 3R1

Mario Cywinski, Editor 226-931-4194 mcywinski@annexbusinessmedia.com

Paul Burton, Senior Publisher 416-510-6756 pburton@annexbusinessmedia.com

Maryam Farag, Associate Editor 437-788-8830 mfarag@annexbusinessmedia.com

Ilana Fawcett, National Account Manager 416-829-1221 ifawcett@annexbusinessmedia.com

Graham Jeffrey, Media Designer Catherine Giles, Account Co-ordinator 416-510-5232 cgiles@annexbusinessmedia.com

Scott Jamieson, COO sjamieson@annexbusinessmedia.com

Machinery and Equipment MRO is published by Annex Business Media, 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1; Tel. 416-442-5600, Fax 416-510-5140. Toll-free: 1-800-268-7742 in Canada, 1-800-387-0273 in the USA.

Printed in Canada

ISSN 0831-8603 (print); ISSN 1923-3698 (digital)

PUBLICATION MAIL AGREEMENT #40065710

Subscription rates.

Canada: 1 year $65, 2 years $110. United States: 1 year $110. Elsewhere: 1 year $126. Single copies $10 (Canada), $16.50 (U.S.), $21.50 (other). Add applicable taxes to all rates.

On occasion, our subscription list is made available to organizations whose products or services may be of interest to our readers. If you would prefer not to receive such information, please contact our circulation department in any of the four ways listed above. Annex Privacy Officer

Privacy@annexbusinessmedia.com, 1-800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2021 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

Recently, we posted a poll on MRO’s LinkedIn page asking “Does your company have a safety program in place.” The results showed that a vast majority (82 per cent) voted yes, with 11 per cent voting no, four per cent voting they did not know, and four per cent voting sort of. On the surface, these are great numbers as more than four in five people say their company has a safety program. However, that means that one in five people said that either their company does not have a safety program, sort of has one, or they do not know if it does. While this was an unscientific poll on social media, it does show that while the majority of companies are serious about safety at their facilities, some are still lagging behind.

Speaking of safety, in our February 2021 issue, we used a stock photo that showed maintenance professionals using CMMS. However, one of them was not wearing proper footwear on what was a facility’s plant floor. We received feedback from our readers about it and as a result, this issue features an article about using the appropriate footwear for protection and comfort.

The footwear article, Tomorrow is your Reward for Working Safety Today (page 18) was wri en by our new Associate Editor, Maryam Farag. She is also working on MRO’s Food and Beverage magazine, as well as our sister publication, Plant magazine. You may have already seen the plethora of news and product articles that she has wri en for MRO’s website. Please help me to welcome her to the MRO team.

As this is our safety issue, we have covered a variety of areas of the safety world. The Canadian Centre for Occupational Health and Safety speaks about Keeping Your Employees Engaged in Safety (page 10), while Marie e Pacheco discusses how Employee Health and Safety Beyond COVID-19 (page 22) will look like. Finally, our Mr. O, The Practical Problem Solver segment, this time by Erika Mazza, looks at Planners: The Underestimated Safety Heroes

I would be remiss not to thank everyone who a ended the first-ever virtual MRO/DEX Expo recently. Over 300 maintenance, reliability, manufacturing, design and operations professionals a ended the event, which saw over 20 companies exhibiting. For more on the expo, read First Virtual Expo a Success (page 16). Also, do not forget to mark August 19 down on your calendar, as the next expo will be taking place then.

Stay healthy and stay safe.

Good Day,

Mario Cywinski Editor

Predicting rotating equipment issues is easy with SKF Pulse. This portable Bluetooth™ sensor and free mobile app allows you to quickly evaluate asset health on demand and prevent machine failure. Get expert advice without investing in complex technology.

• On-the-spot machine diagnostics with visual alarm indicators

• No need for training or diagnostic expertise

• Connect directly with SKF experts for analysis and diagnostic reports

• Pulse Check diagnostic reports include recommended corrective actions, if required

Keeping Your Employees Engaged in Safety / 10

Taking the time to keep employees engaged in program development, interested in ongoing training, and involved with continuous improvement.

First Virtual Expo a Success / 16

MRO teamed up with its sister publication, Design Engineering, to host a virtual expo focusing on maintenance, reliability, manufacturing, design and operations.

Employee Health and Safety Beyond COVID-19/ 22

A year ago, everything changed with the declaration of a global pandemic.

MRO Quiz / 12

Air compressors; lubrication, maintenance, condition monitoring and troubleshooting.

Tomorrow is Your Reward for Working Safely Today / 18

Stressing the importance of protective and comfortable shoes to employees.

What’s Up Doug / 24

A stich in time saves nine.

Editor’s Notebook / 3

Newswatch / 6 In Conversation with Mr. O / 30

New in Products / 28

Maintenance 101 / 20

Tradespeople and the new digital world of maintenance.

Asset Management - What is it and where did it come from? / 26

Over the last few years, a new term has become more popular in the world of maintenance and reliability.

SKF USA Inc. has hired Fal Dieso as Vice-President of Marketing, and promoted Amy Sliwinski to Vice-President of Human Resources.

Dieso will lead the SKF marketing initiatives in North America, including demand generation, product marketing, brand and corporate communications. She will also serve as the North America Executive Sponsor for Women of Influence; SKF’s employee resource group focused on mentoring and targeted professional development for women at all levels within the company.

Previously, Dieso served in marketing roles for RS Components and Allied Electronics and Automation. She also led digital marketing roles in senior positions at Ricoh USA, TE Connectivity, Princeton Power Systems and Nokia.

Sliwinski will lead human resources for SKF North America, where she will lead implementation of the company’s new organizational culture program. Most recently, she served as VP of recruiting and talent management for SKF USA.

Prior to joining SKF, Sliwinski was director of human resources at Santander. MRO

The Ontario government is developing a critical minerals strategy to help generate investment and increase the province’s competitiveness in the global market.

According to the government, the strategy will support Ontario’s transition to a low-carbon economy both at home and abroad.

New technologies and high-growth sectors that rely on critical minerals include information and communications technology, electronics, energy, aerospace and defence, health and life sciences and transportation MRO

Swagelok has launched a gas distribution program that offers subsystems designed to enhance safety and increase uptime of gas distribution systems in industrial facilities. The company’s gas distribution advisors provide an evaluation of existing gas distribution systems to identify any potential leak points. They then provide actionable recommendations to improve existing system designs or explain how standardized Swagelok gas distribution subsystems can be incorporated to overcome challenges.

By eliminating potential leak points in existing systems or integrating subsystems designed for easier use and maintenance, industrial companies can reduce the risks posed to their team members by underperforming gas distribution systems. MRO

Sullair announced that John Randall will be appointed as President and CEO, replacing Charlie Takeuchi, who will become President of Hitachi Industrial Equipment Systems (HIES), both are effective April 1.

Randall has been serving as President of Sullair Asia for over two years. Previously, Randall was VP of Global Engineering for Sullair, for nearly five years. Before joining Sullair, he held various leadership roles in his nearly 24 years with Navistar, including a three-year assignment in India, where he launched a new commercial vehicle platform and plant start-up.

Takeuchi joined Sullair in July 2017 as COO and was promoted to President and CEO on April 1, 2020. MRO

David Roberts, President and partner of Ontario-based internet so ware developer, Glacier Digital, has created an online tool that can help businesses open safely.

COVIDScreener.cais a web-based technology tool that automates and streamlines businesses’ COVID-19 health screening of employees and customers.

A business can set up their own account online, a er which employees and customers can begin using it; by answering the screening questions.

COVIDScreener.cacan be accessed from any internet-enabled device from anywhere. Businesses can pre-approve entry based on the respondent’s answers to the screener questions and download contact tracing information.

The key points of COVIDscreener.ca include a personalized account for each business with their own URL, and screening questions are current and updated to reflect public health regulations.

It offers two types of screening; passive screening, where the same people coming in regularly can self-screen, such as employees; active screening, where new people coming in every day can get screened and then checked-in by staff, such as in restaurants, dental offices or gyms.

All collected data can be downloaded and shared with public health for contact tracing, and it is auto-purged a er 30 days. MRO

Continental sharpens its profile as a provider of service and complete conveying solutions, unifying its portfolio. All products, technologies and services, know-how and expertise, are now combined under the Continental brand.

All products from company-owned brands PHOENIX, IMAS, Kolubara, Matador and National Belt Service will be integrated into the broad Continental product and

service portfolio. LEGG and BELTTRADE belt products will remain available to North American distributors. All LEGG agricultural products will be integrated into the Continental product portfolio and sold under the Continental brand. MRO

EcoGrid Technologies Inc. and Streamline Electrical’s 2018 partnership on Streamline Energy Inc. has removed over 4.5 megawa s of peak power and 2.8 million kilowa hour of consumption off the mainland BCHydro grid.

With lower power rates in British Columbia, the lack of financial incentive to switch to clean energy has resulted in a slower adoption in smart LED energy within the province’s industries.

With BCHydro’s power smart program, customers can receive up to 75 per cent return on investment. The advanced controls in the smart LEDs’ will bring unparalleled savings, resulting in a higher incentive payout, since it is a performance-based program. MRO

The Ontario government is providing an investment of up to $27 million for the operation, maintenance and capital needs of six major tourism and cultural institutions in the Greater Toronto Area. The government will provide financial support to Metro Toronto Convention Centre, which will receive up to $9.6 million in stabilization funding for operating costs. The Royal Ontario Museum will receive up to $9.5 million, the Ontario Science Centre will receive up to $4.35 million, the McMichael Canadian Art Collection will receive up to $1.2 million, the Art Gallery of Ontario will receive $705,000 and the Royal Botanical Gardens will receive $430,000. MRO

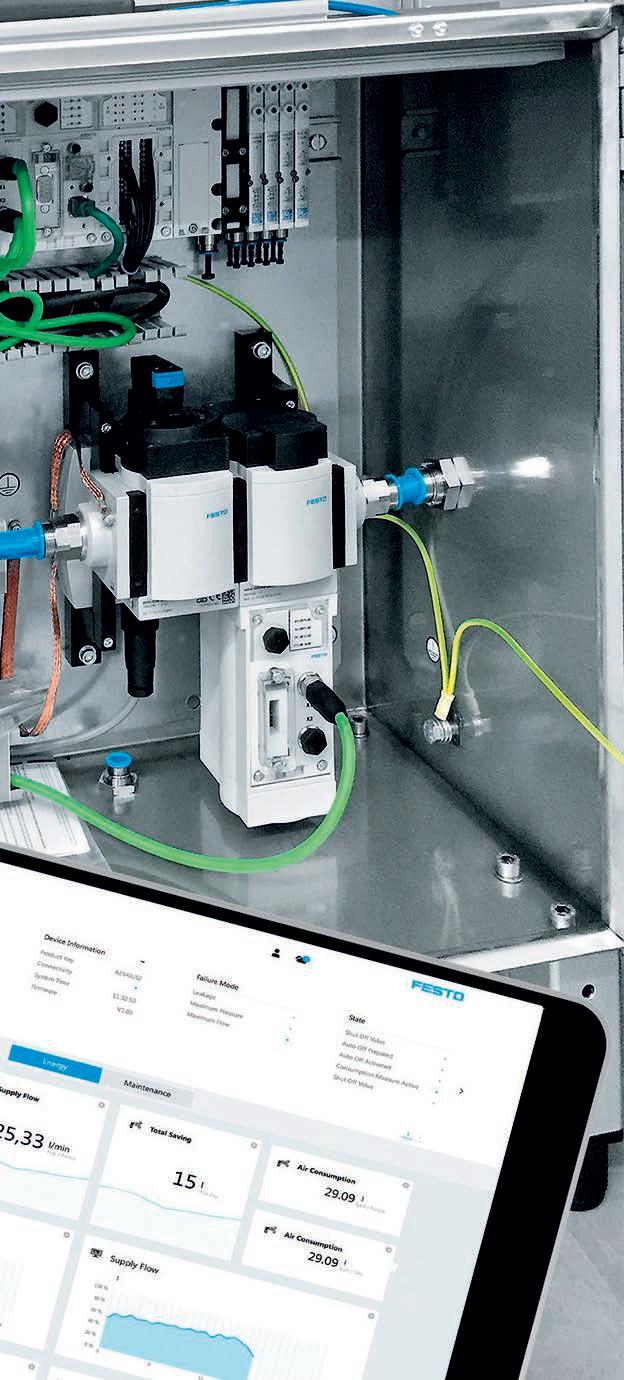

Saving energy is easier than ever before thanks to the Festo MSE6-E2M. Achieve your energy efficiency and sustainability targets while optimizing process equipment performance.

Intelligent assembly features include:

• Zero compressed air consumption in standby mode

• Monitors the system for leaks

• Ensures maintenance in the event of leaks

• Enables effective monitoring of relevant process data

ABB launches a new condition-based maintenance (CBM) service that enables robot users to create a preventive maintenance schedule for individual or robot fleets.

The new service, CBM, uses real-time data on robot operations to help identify any potential issues that could affect performance, such as speed, acceleration and gearbox wear.

The CBM tool can advise whether remedial action is required, involving either repair or replacement of affected parts. This is done by identifying when and which parts are likely to fail, so spare parts can be purchased and prepared without having to hold them in stock.

There is also a report provided for the robot to help customers decide which preventive measures to take, including its serial number, summary table, data analysis, individual maintenance recommendations, conclusions and rating of the system. MRO

PEMAC Asset Management Association of Canada’s GTA Chapter hosted a virtual Professional Development event recently on augmented reality and digital twins tools.

Ghaz Marinho, events coordinator, PEMAC, kicked off the event by introducing speakers, and announcing PEMAC’s next events.

Presenter Eric Bradnam, Interaptix Inc., took PEMAC members through a brief introduction of the subject ma er, an overview of the market forces, an orientation on the tools and technologies available today, and specific use cases with tangible results for organizations that have deployed these solutions.

Bradnam explained two terms: augmented reality and digital twins. He defined the characteristics of augmented reality; combining the real and virtual, where the real and the virtual can be seen at the same time; interactive in real-time, where the user can interact with virtual context; and registered

in 3D, where virtual objects appear as though they are fixed in space.

Bradnam mentioned, “Microso saw a 44-fold rise in remote-assistance usage of HoloLens 2 between January and December of last year, largely because of social-distancing and lockdown requirements amid the pandemic, the company said.”

Bradnam explained digital twins as, according to Forbes, “Quite simply, a digital twin is a virtual model of a process, product or service. This pairing of the virtual and physical worlds allows analysis of data and monitoring of systems to head off problems before they even occur, prevent new opportunities and even plan for the future by using simulations.”

“Augmented reality gets you to places you can’t get to,” said Bradnam. “Digital twins let you document and visualize your assets from anywhere.”

Bradnam also spoke about the benefits of these tools, including increased efficiency, improving training access,

VuWall has partnered with Samsung Electronics Canada to offer solution bundles, combining video wall control systems with a high-resolution display technology.

The solution bundles are created for 24/7 mission-critical control room and crisis room environments within security operation centres, traffic surveillance

facilities and network operation centres across various sectors from government, military and defence, public safety, transportation and security environments.

The solution enables customers to mix AV, IP and IT sources on a single controller, customize screen arrangements and sizes, and mix display technology (LED, LCD, etc.). MRO

reducing and eliminating travel, improving health and safety, and improving audit records.

“87 per cent of executives agree digital twins are becoming essential to their organization’s ability to collaborate in strategic ecosystem partnerships.” said Bradnam.

He also spoke about industry success stories: “GE Aviation incorporated Upskill’s Skylight platform into its preventative maintenance on Bnuts, a critical component in aircra engines, achieving an average of eight to 12 per cent increase in mechanical efficiency.”

Bradnam concluded his presentation by speaking about the tools’ application in asset management, and augmented reality in environmental, social and governance planning and practice.

For PEMAC members, PEMAC is seeking Canadian success stories, and there is a limited number of no-fee deployments for 2021. MRO

Taking the time to keep employees engaged in program development, interested in ongoing training and involved with continuous improvement will help everyone keep safety top of mind.

Health and safety are important in any situation, especially in the workplace. But how do you keep your employees engaged, interested and involved in keeping safe work practices top of mind?

A good practice to keep your employees safe at work is to have a comprehensive, integrated health and safety program for the organization. This program should include a series of strategies, policies and related activities and initiatives developed by the employer, with involvement from the employees, health and safety commi ee and the union. The program must be fully communicated to the employees, implemented throughout the or-

ganization, integrated into business practices and evaluated on an ongoing basis.

Ideally, the first step in increasing employee involvement in safety is to effectively train staff and promote a strong safety culture when new hires are onboarded.

Studies have shown that the level of employee engagement in training is a key factor in an organization’s safety program effectiveness. Training that uses spoken or wri en multimedia presentations, but requires li le or no active participation by the employee, has minimal impact on reducing workplace incidents. On the other hand, training that engages the employee and involves hands-on practice

in a realistic se ing resulted in the highest retention. Therefore, it only makes sense to ensure your training programs and courses include elements that actively involve the employee and include their participation.

Communicating safe work practices does not start and stop with a new hire. While it is a crucial element during the orientation process, it is equally important to provide ongoing safety and refresher trainings to existing employees. Implementing these strategies into training and re-training on an on-going basis will help everyone develop a safety-first a itude.

Here are some tips to ensure that your organization is adhering to health and safety guidelines:

•Always ensure that your comprehensive workplace health and safety program is o en referenced by your management team and that it is easily accessible to all employees. This can help set the tone that safety and the well-being of the employees are a top priority.

•Organize regular re-training sessions for managers and supervisors on conducting safety audits, workplace inspections and incident investigations. Wherever possible, involve them in the health and safety program, and have them participate in new-hire safety orientations and lead safety toolbox

While you may not be able to implement a change immediately, letting people know their voice is heard and stating the organization’s intentions to improve will continue to foster an environment of worker engagement and involvement.

talks. By taking the lead, management shows through its actions that they are supportive and commi ed to protecting their people and creating the safest workplace possible.

•It is important to routinely check-in with your employees and ask how the safety procedures are going and what is, or is not, working for them. See if there is anything you can do to make their work easier and less time consuming (without sacrificing safety or introducing new hazards).

•When developing new safety procedures, make sure to focus on safety practices as well as workplace culture. Include your employees in these discussions and efforts.

•Encourage staff to speak up when they see unsafe work or risky behaviour, and report any health and safety concerns. Get their feedback and use it to improve your safety practices. This reinforces the internal responsibility system, where everyone has a responsibility for health and safety as part of their job, and work together to prevent work-related injuries and illnesses.

•Communication and involvement are key to successful employee engagement. Focus groups, surveys and interviews can provide information on the most ideal ways to gather input and provide training that is most useful to your employees, and use the results to tailor your training program spe-

cifically to your workforce. You may also gain insights into which values guide and motivate employees on a day-to-day basis.

•Be sure to always follow-up and acknowledge their feedback. While you may not be able to implement a change immediately, le ing people know their voice is heard and stating the organization’s intentions to improve will continue to foster an environment of worker engagement and involvement.

Remember, there is no one-size-fits-all solution. Each workplace is unique in terms of tasks, needs, values and culture. Taking the time to keep employees engaged in program development, interested in ongoing training and involved with continuous improvement will help everyone keep safety top of mind. MRO

Article provided by theCanadian Centre for Occupational Health and Safety (CCOHS), which promotes the total well-being, physical, psychosocial and mental health of workers in Canada by providing information, training, education and management systems and solutions that support health and safety programs and the prevention of injury and illness.

BY 6 PM FOR

Air compressors provide pressurized air to operate tool or instrument systems. They are either “positive displacement,” providing intermittent flow or “dynamic”. Positive displacement compressors include reciprocating piston and rotary types, including helical screw, straight lobe, liquid piston or rotary. Positive displacement compressors confine volumes of air in an enclosed space reduced to accomplish compression.

BY L. (TEX) LEUGNER

Dynamic compressors convert energy from the prime mover into kinetic energy, providing continuous pressure and include centrifugal and axial flow types.

High pressures cause the temperature

of discharged air to increase, causing water to condense. Discharged air temperature and condensate must be controlled, and condensation also occurs during unloaded periods when the cylinders cool below the dew point of the air remaining in them. Water becomes acidic at 180°F (82.2°C) and control of condensate prevents corrosion and rust depos-

its. When very high discharge pressures are required, compression is o en carried out in two or more stages to cool the air and limit temperatures. (See table 1) A er coolers or heat exchangers are used to lower the temperature and precipitate out water in the compressed air, the cooled air enters a water separator and the dry air enters the reservoir.

Lubricants selected for compressor applications depend upon seven conditions; the type of compressor, discharge pressures and temperatures, lubricant oxidation, rust and foaming resistance, hydrolytic stability, carbon deposit reduction and compatibility with seal materials.

High quality mineral base oils are frequently used as compressor lubricants, but the trend is toward synthetic fluids. The reasons for their use are their extremely high viscosity indices and superb oxidation resistance. A synthetic lubricant with a high viscosity index can reduce power consumption by up to 12 per cent. A typical rotary air compressor will discharge air with an average temperature of 93°C (200°F). Without a proper lubricant, this air temperature could be as high as 370°C (700°F).

Even oxidation resistant mineral base oils tend to oxidize at about 70°C (160°F)

with the potential of forming carbon deposits and varnish. At air discharge temperatures of 93°C, lubricant life can exceed 8,000 hours of operation. If discharged air temperature is 110°C or higher, lubricant life can be reduced by 60–70 per cent, and when discharge temperatures are between 150°C–200°C (302°F–392°F), synthetic oil of equivalent viscosity grades is recommended. Synthetic fluids are generally compatible with the following seal materials.

The following compressor maintenance recommendations should be considered:

1. Determine and record normal full load electric motor current at a specific voltage. This can be referred to as a baseline when problems are experienced.

2. If the compressor has its own reservoir, allow the compressor to fill this reservoir from zero to the cutout pressure. Record the cutout pressure and the time it takes to fill the reservoir. This can be used to monitor compressor efficiency at any later date.

3. Determine the acceptable discharge temperature. Normally, the high air temperature switch on water cooled, dual stage reciprocating compressors is set at about 150–165°C (302–328°F). This temperature should be recorded and monitored as part of the condition-monitoring program. (The higher the discharge temperature, the greater the possibility of discharge

line explosions if hot spots develop).

4. In rotary compressors, the high air temperature switch is normally set at about 110°C (230°F) and will shut the compressor down if the temperature rises. (Discharge temperature should be about 38°C (100°F), higher than the temperature of the inlet air).

5. Determine oil operating temperature. Oil temperatures should be about 65°C (150°F). This will ensure that the oil temperature is about 15 to 20 degrees higher than the pressure dew point to reduce the formation of condensate, carbon and varnish deposits. (Pressure dew point is the lowest temperature to which compressed air can be exposed without causing condensation of entrained water vapor). For example, in a two-stage air compressor taking in air at atmospheric pressure and a relative humidity of 75 per cent, with a discharge pressure of 120 pounds per square inch (psi) (758 kilopascal), about 14 litres (3.75 gallon) of water per hour may be condensed for each 1000 cubic feet per minute (CFM) of free air compressed. Any unusual increase in the recorded oil temperature should be immediately investigated.

6. Determine the filter quality necessary to ensure that inlet air enters the compressor uncontaminated, and oil and bearing filters are capable of removing contaminants in the 10 micrometre range. In flooded rotary compressors, the oil separator is a critical component. It is a large

sub-micronic filter and its quality of operation is critical. It should be replaced or cleaned when differential pressure reaches about 10 psi.

7. Determine the normal, expected discharge pressure and record it for future reference and comparison if problems arise.

8. Due to the potential for corrosion, rust and varnish deposits, intercoolers, cylinder water jackets, a er coolers or heat exchangers should be inspected and cleaned annually, as part of the PM program.

9. Air reservoirs, drains, condensate traps and air line filters should be visually inspected and drained at least once each week to ensure clean, moisture free instrument or tool system control air. This is a frequently neglected PM activity.

10. Inspect and clean lubricators regularly. In most pneumatic systems the lubricant is carried in the air stream and the amount of oil metered is determined by adjusting the oil feed rate. This oil drip feed rate must be monitored regularly and effective feed rates recorded for maintenance reference.

11. Determine the cylinder lubrication feed rates for reciprocating compressors and record this information in the maintenance files. It is recommended that new or rebuilt compressor cylinders should be run in for 5–10 hours of operation at no load conditions, using double the oil-feed rate, to establish normal wear pa erns and eliminate the possibility of scoring components. The lubricator oil-

feed rate can be determined using the formula (shown in previous column). Once the proper rate has been established, it is recorded in the maintenance files. If the oil type or specifications are changed, this process is repeated. (An example is: A 12-inch (30.5 cm) compressor cylinder compressing air at a discharge pressure of 10 bar (145 psi) requires oil feed rate of 12 drops per minute).

12. Inspect piping to ensure that fittings and drain valves are not leaking and supports are in good condition. Leaking compressed air systems cost industrial plants hundreds of thousands of dollars annually. (A combination of leaks totaling a half inch diameter hole, escaping at 60 psi of leaking pressure, will cost approximately $30,000). When repairing or replacing piping, smooth bore aluminum or plastic pipe should be used. Interior corrosion, poor system configuration and contaminated air can cause inefficient energy use. (A 15-psi pressure drop uses about 10 per cent additional energy and over a long period, the cost of energy may exceed other maintenance costs).

a) Using spectroscopic oil analysis, monitor the rates of compressor component wear. pH, acid number and viscosity should be monitored. An excessive decrease in pH indicates the ingestion of acidic gases or other contaminants. An increase in acid number indicates oil is reaching the end of its useful life.

Water content should be measured using the Karl Fischer test. Particulate content should be monitored using particle-counting technology. If a component fails, analytical ferrography can be used to provide information on the cause. Compressor condensate analysis is recommended to detect corrosive or acidic gases that may be harmful. A low pH or high acid number resulting from conden-

sate analysis can reveal potentially serious corrosion conditions.

b) Vibration Analysis are programs available to detect common vibration problems unbalance, misalignment (of couplings), mechanical looseness, resonance or bearing failures. Stroboscopes can be used to confirm if a suspected vibration is present, after which analyzers determine the source. O en noise is mistaken for a vibration.

c)Ultrasonic analyzers can determine if noise levels are associated with a faulty component, such as early bearing failure or noise caused by an air leak in a control valve, and they are invaluable for locating leaks that are difficult to find. Resonant conditions may be the result of air leaks, so it is recommended that leaks be corrected before more advanced troubleshooting or repairs are wasted.

d) Thermographic analysis is used primarily for locating electrical system hot spots, but it has become extremely useful for locating hot spots caused by excessive discharge temperatures, partially plugged components, like intercoolers or heat exchangers, seal rubs, misaligned couplings or drive belts, overheated bearings and faulty lubricating oil pumps. For example, a slightly misaligned coupling can cause an increase in temperature without any apparent vibration. The temperature increase at the coupling may be high enough to cause premature failure of the bearings nearest to the coupling. MRO

L. (Tex) Leugner, the author of Practical Handbook of Machinery Lubrication, is a 15year veteran of the Royal Canadian Electrical Mechanical Engineers, where he served as a technical specialist. He was the founder and operations manager of Maintenance Technology International Inc. for 30 years. Tex holds an STLE lubricant specialist certification and is a millwright and heavy-duty mechanic. He can be reached at texleug@shaw.ca.

Symptom

Failure to deliver output

Insuf cient output or low pressure

Compressor overheats

-Excessive clearance between vanes, lobes or screws (rotary compressors).

-Restricted or dirty inlet lter.

-Excessive leakage (air system).

-Inadequate speed.

-Carbon deposits on discharge valves.

-Excessive discharge pressure.

-Worn or broken valves.

-Excessive speed.

Compressor running gear overheats-Inadequate lubrication.

-Excessive drive belt tension (where used).

-Excessive speed.

Compressor knocks

Compressor vibrates

-Inadequate lubrication.

-Insuf cient head clearance.

-Excessive crosshead clearance.

-Loose piston rod(s).

-Excessive bearing clearance.

-Piping improperly supported causing resonance.

-Misalignment at coupling.

-Loose ywheel or pulleys (where used).

-Defective unloader(s).

-Inadequate cylinder lubrication.

Excessive intercooler pressure

Low intercooler pressure

Excessive receiver pressure

High discharge temperature

Cooling water discharge temperature too high

Valves overheat

Drive motor overheats

High levels of condensate

-Worn or broken valves and/or defective unloader(s) (reciprocating compressors).

-Worn or damaged piston rings (vanes, lobes or screws on rotary systems).

-System demand exceeds capacity.

-Worn valves or defective unloader(s).

-Inadequate cooling.

-Dirty cylinder water jackets.

-Inadequate cylinder lubrication.

-Defective unloader(s).

-Excessive discharge pressure.

-Worn or damaged rotating components (rotary compressors).

-Excessive discharge pressure

-Loose or damaged piston(s) (reciprocating compressors).

-Loose ywheel or drive pulley (where used).

-Misalignment at coupling.

-Damaged foundation or grouting.

-Loose motor rotor or shaft.

-Loose base plate mounting bolts or soft foot.

-Incorrect speed.

-Damaged foundation or grouting.

-Excessive discharge pressure.

-Worn or damaged rotating components (rotary compressors).

-Unbalanced motor or defective motor bearings.

-Worn or broken valves, second stage.-Defective unloader, second stage.

-Worn or broken valves, rst stage.

-Defective unloader, rst stage.

-Dirty or restricted inlet lter or suction line.

-Defective unloader(s).

-Carbon deposits on discharge valves.

-Worn or broken valves.

-Defective unloader(s).

-Excessive discharge pressure.

-Low level of coolant.

-Dirty water jackets.

-Worn or broken valves.

-Defective unloader(s).

-Excessive discharge pressure.

-Long unloaded cycles (inlet valves).

-Inadequately sized motor.

-Excessive discharge pressure.

-Worn or broken valves.

-Abnormal intercooler pressure

-Excessive discharge pressure.

-Excessive discharge temperature.

Premature oil thickening or discoloration-Excessive lubricant operating temperature.

-Compressor operating temperature too high.

-Inadequate lubricant type (wrong oil for the application).

-Worn piston rings on low pressure ( rst stage) piston.

-Worn rotating components (rotary compressors).

-Excessive discharge pressure.

-Inadequate cooling.

-Dirty water jackets (or plugged or dirty ns on air cooled compressors).

-Dirty or plugged intercooler.

-Abnormal (high) intercooler pressure.

-Inadequate cylinder lubrication.

-Excessive discharge pressure.

-Dirty or corroded intercooler.

-Abnormal intercooler pressure.

-Damaged or carbonized valves.

-Defective unloader(s).

-Inadequate lubrication (compressor running gear or motor bearings).

-Misalignment at coupling.

-Excessive belt tension (where used).

-Low voltage.

-Inoperative intercooler.

-Plugged or inoperative heat exchanger or water separator.

-Worn or faulty piston rings.

-Excessive discharge temperature.

-Lubricant oxidation.

Compressor seals fail prematurely

High oil consumption

-Excessive operating temperatures.

-Lubricant incompatible with seal materials.

-Oil level too high.

-Scavenger tubes plugged.

-Misalignment at coupling.

-Excessive crank case pressure.

-Oil leaks at gaskets, seals or ttings.

-Excessive oil pumping (reciprocating compressors).

Note: This troubleshooting guide is general in nature. Depending upon the compressor type, its operating conditions or its application, some of these symptoms and their possible causes may not apply.

MRO teamed up with its sister publication, Design Engineering, to host a virtual expo focusing on maintenance, reliability, manufacturing, design and operations.

BY MARIO CYWINSKI

In year’s past and under normal circumstances, the MRO/ DEX Expo would be welcoming a endees live and in-person. With many exhibitors offering information in their booth as part of the table top show. As that is a no-go this year, we went virtual, and came up with an expo that is as close to an in-person event as possible.

The first-ever virtual expo a racted over 400 registrations, over 300 a endees, over 20 exhibitors, and many keynotes and sessions divided into MRO and Design Engineering streams.

The morning keynote was presented by Steve Lo us, President and Founding Partner, Innovative Automation, who spoke about “The Collection and Value of Machine Generated Data.”

“I would like to say thank you for the opportunity to present

at the MRO/DEX Expo. This was a great opportunity for me to convey my thoughts on the planning and executing of an Industry 4.0 program for factory equipment,” said Lo us. “Some of the key points are the true value in proper planning, including not just positives but shortcomings, so proper actions are put in place. We must always do an “honest assessment” prior to the start. Keeping in mind the success of a project will lead you to the next one. These ongoing improvements will result in lower overhead cost and drive the competitive advance into the future. One of the key features, sometimes overlooked, is using your data for everything including inventory control and automatic reordering of consumables.”

The first MRO stream session was on “Effective Asset Management Starts with Good Assets” by Leonard Middleton, Consultant, Asset Management Solutions.

“There seems to be a vast difference in perspective between

those who approve projects, those who execute projects, and those who need to operate and maintain those assets that projects deliver. The presentation was delivered by someone who has worked in each of those areas, and has direct knowledge of the linkage and implications of decisions made,” said Middleton.

“The presentation intended to provide a pragmatic high-level overview that provided insights on the issues and what changes can be made to improve the situation for the benefit of the organization and the individual groups,” said Middleton. “Virtual conferences are the new normal. There is no longer the immediate feedback from the body-language and a ention of the audience indicating whether they are engaged and following the presentation, and that takes some adjustment.”

The second MRO stream presentation was on the topic of scheduling and planning, led by Doc Palmer.

For those who attended the expo in February, thank you, and be sure to save the date for the next expo set to take place on August 19. If you missed this expo, be sure to join us for the next one.

“We had a great virtual conference with a lot of helpful, practical information. Thank you for le ing me be a part of the worldwide MRO Magazine maintenance family and sharing my thoughts. The question and answer time was enjoyable during my presentation on Examples of Great Results and Why Planning and Scheduling Work,” said Palmer.

“Typically, we get a bump in work order completion rate when we start doing proper planning and scheduling. All the extra work done is proactive because normally the reactive work is done anyway. During the presentation, I showed the increased productivity of nine companies around the world, and explained the simple, but unusual concepts that made it work,” said Palmer. “Companies that mandate higher schedule compliance, invariably under load the schedules and don’t get the productivity bump. Parkinson’s law says “the amount of work expands to fill the time available,” so it is critical to fully load the schedules. Therefore, allowing planners to make imperfect plans, and supervisors to break schedules, makes life easier than typical rigid programs. And in turn, more work is completed.”

The final MRO stream session was on-demand, and focused on “Bearing Lubrication and Health Insights Made Simple,” presented by Blair Fraser, Director of Global IIoT Solutions, UE Systems Inc.

The exhibit hall had a large cross section of exhibitors showing off their products in their virtual booth. Some also provided presentations during the networking breaks, to display new products and technologies.

“We are only scratching the surface of what is possible. Virtual trade shows will a ract more visitors due to the ease and

Effective Asset Management Starts with Good Assets was presented by

Steve Loftus spoke about The Collection and Value of Machine Generated Data, during his morning keynote.

time efficiency of participating,” said Lars Ruuth, A ermarket Sales and Marketing Manager, SKF Canada.“Exhibitors achieve higher engagement and sales results as they customize the visitor experience through digital tools combined with direct interaction.”

Networking for many was a big reason for a ending the event, and with the networking lounge at the expo, as well as chat features on every page of the expo platform, many took advantage of the chances to communicate.

For those who a ended the expo in February, be sure to save the date for the next expo set to take place on August 19. If you missed this expo, be sure to join us for the next one. MRO

BY MARYAM FARAG

oes footwear make a difference on the job? Not everyone thinks about the importance of wearing the right shoes to work. Lots of HR people have codified rules in dress code policies, but a good number of companies and employees could benefit from more awareness of why it is important to wear protective and supportive footwear.

Protection

Steel toed or protective work shoes play a vital role in protecting front-line workers in manufacturing, industrial, and various maintenance types of jobs. Also, they can be considered a category of personal protective equipment (PPE), and many labour departments have laws about the distribution of PPE to workers.

According to the Ontario Ministry of Labour, Training and Skills Development, in workplaces where regulations under theOHSArequire “foot protection appropriate in the circumstances” or “suitable footwear”, employers should conduct a risk assessment to determine the foot protection appropriate in the circumstances or suitable footwear to protect the worker.

“A supervisor has to make sure that workers are wearing appropriate foot protection, so not just foot protection, but foot protection appropriate to circumstance as required by the employer and by the act of regulations.” said Ron Landry, Senior Manager, Provincial Industrial Health and Safety, Ontario Ministry of Labour, Training and Skills Development.

Wearing the wrong shoes can result in numerous health conditions. According to the Canadian Centre for Occupational Health and Safety (CCOHS), some foot problems are so common that they can occur in any workplace and under any working conditions, such as: severely aching feet, blisters, calluses, corns, rheumatism, arthritis, malformations of toes, fallen arches (flat feet), bunions and sprains.

The common causes of these foot problems are long periods of standing, hard flooring, and poorly fitted footwear; pointed shoes, lack of arch support, and too loose or too tight footwear.

“You can even have hazards of injury to the foot without any machinery or equipment being present,” said Landry. “For example, if you’re in a warehouse stocking shelves and using power equipment to move things around, or even pump carts to move things around.”

In general, people tend to get sore and tired when wearing shoes that are uncomfortable and spending long hours standing or walking in a workspace. Therefore, promoting the use of comfortable footwear can help with productivity and general wellness.

Another area in which footwear is important is in supporting balance and mobility. Workers may decide to skimp on shoe costs and wear the wrong shoes, which can cause them to slip, trip, stub their toes or even sprain ankles because of a lack of friction.

“If the right footwear isn’t selected, or the safety footwear isn’t worn properly, there may be an increased risk of injury from impact repression, puncture, electricity and ankle injury,” said Riane Marrs, Occupational Health and Safety Specialist, CCOHS. “It is really important to conduct a hazard workplace assessment of the activities in the workplace and choose footwear that will provide protection.”

Marrs added that employers are required to make sure that any machinery provided in the workplace is safe and in good operating condition, which should include preventative maintenance that align with the manufacturer recommendations, and they are also required to train employees and instruct them on the safe-use of the machinery.

Finally, the right pair of safety shoes helps factory workers to stay on their feet. Not to mention that there are many resources for organizations who are looking to implement a protective footwear program in their workplace, and this includes referring to the Canadian Standards Association’s section about protective footwear. MRO

Maryam Farag is the Associate Editor for Machinery and Equipment MRO Magazine, Food and Beverage Magazine, and Plant Magazine, Annex Business Media. She is a freelance writer at The Windsor Local, Torstar Corporation.

BY PETER PHILLIPS

Working with CertainTeed Gypsum and implementing new digital technologies within the maintenance departments has made me realize how vitally important it is for tradespeople to adapt to the new technologies. It has also made me realize that a digital revolution is upon us.

Right now, and moving forward, tradespeople will need a range of digital skills to keep pace with the future of work. Experts say that improving digital skills will be the most important factor in adapting Canada’s skilled tradespeople to new innovative technologies. The question is, are maintenance departments ready for it?

When looking at the maintenance workforce, there is currently a generational difference between young and older workers. Younger tradespeople have the benefit of growing up in a society full of technology. In the past few years, advances in the digital world has made it easy for younger tradespeople to accept and use technologies in their daily maintenance routines. However, some of our more senior tradespeople have fallen behind as they struggle to understand and use new advanced digital tools.

In 10 to 20 years, the current older maintenance employees will retire and their new young replacements will already be adapted to technology, and trade schools will have them prepared for the digital world of maintenance. In the meantime, maintenance departments have the obligation to help the senior tradespeople use the new digital technology and programs.

As an example of how fast technology is moving for maintenance people, here are some of the maintenance technologies CertainTeed Gypsum has intro-

duced to the maintenance departments in North America. Below is a short list of the key applications that have rolled out in the past two years, and that directly affect tradespeople and their ability to function in the new digital world.

• A new CMMS system with completely changed work order processes.

• Work order mobility for trades to process their work orders using a tablet application. Paper work orders are now obsolete.

• Tablets integrated with HMI and other manufacturing processes and equipment controls.

• Complete digitization of equipment resources and documentation.

• Laser alignment and chain tension applications.

• Remote equipment sensor so ware for vibration and temperature.

The majority of the younger generation of tradespeople have devoured the new technology. The middle to older generation can and do struggle to adapt, and if they are not helped to overcome their skills, knowledge and a itudes towards the new tools they will o en revert back to the old way of doing things and ignore the new digital systems. However, there are ways we can help them.

Bob Purcell, recently retired from Rockwell Automation, a er being their Allen Bradley PLC and Control Logic Systems trainer for 30 years.

Purcell started out his career as industrial electrician and controls tradesperson, and before he went to work with Rockwell, he went back to college and received his teaching license. We o en get into discussions about how technology designers of maintenance applications need to look at the usability of the product from a maintenance perspective.

Instead of looking at a new technology from a management point of view about the report, KPIs and analysis that the new program can provide, people like him look at it from a tradesperson’s angle of what this new technological tool can do for me.

Secondly, his experience with training tradespeople indicates that the success of a new digital tool depends on the simplicity and ease of use. New maintenance tools can come from a variety of sources. Sometimes the product is purchased off the shelf and other times they are designed in-house by engineers. He firmly believes that the decision makers need to take every user’s perspective into consideration when deciding on a new purchase or design.

Purcell also noticed when Control Logic Systems were designed and programmed in a way that the maintenance person could understand and use it to troubleshoot equipment, the tradesperson becomes convinced that the program is useful and they depend upon it to help them solve problems. The program be-

Experts say that improving digital skills will be the most important factor in adapting Canada’s skilled tradespeople to new innovative technologies.

comes the engine to run the equipment or process as well as a tool to fix it. As an example, in early versions of PLC, the computer that the program was loaded on was very limited and there was no enough memory space to add the complete description of the inputs and outputs on the ladder logic design.

However, in advanced computers and Control Logic Systems there are massive amounts of memory, and descriptions of inputs and outputs can be given exact to what the tradesperson sees on the equipment. Instead of the input/output device being named -[ ]- X1 ,for example, it can now be named -[ ]- Le Conveyor Photocell. If the logics program takes the time to properly describe the elements of the program, it becomes a tremendous trou-

bleshooting tool for the tradesperson.

The changes in technology that Purcell and other people like us have witnessed tells us that any tool purchased or developed for people of maintenance needs to be simple and easy to use. Of course, it also needs to have the capability to deliver the analysis that management requires, but if the application is difficult to use, then tradespeople will not use it, and, at the end, the new technology will be useless for every level of the maintenance department.

Technology is here to stay and will advance faster than we think. We need to consider and involve all the stakeholders when planning new systems and the introduction of digital technology. If different levels of people are going to use the

technology, then it needs to be developed from the ground up and not the top down because the people who use it the most will be the same people who make it sink or swim.

If it helps the tradesperson do their job and it adds value to their role as a maintenance person, then it is highly likely they will use it.

If these key points are taken into consideration by the decision makers when technological tools are purchased or developed, then the end result will be the tradespeople buying into the new technology and they will want to learn how to use it in their everyday maintenance activities, and everyone wins. MRO

Peter Phillips is the owner of Trailwalk Holdings Ltd., a Nova Scotia-based maintenance consulting and training company. Peter has over 40 years of industrial maintenance experience. He travels throughout North America working with maintenance departments and speaking at conferences. Reach him at 902-798-3601 or peter@ trailwalk.ca.

A year ago, everything changed with the declaration of a global pandemic. Every industry has been impacted by a different magnitude from periodic shutdowns and closures to reduced capacities.

BY MARIETE F. PACHECO

The one element that has changed for every business regardless of industry has been employee health and safety. Keeping employees safe

during a health crisis such as COVID-19 has become paramount. Let’s look at what employee health and safety may look like in the future; post-pandemic.

Millions of dollars have been spent this past year in employee health and safety protocols; increased usage of personal protective equipment (PPE), such as masks and gloves, hand sanitizing stations, installing barriers and retrofi ing HVAC systems with enhanced filtration and ventilation systems.

Of all the changes, will any of the new protocols become part of the much anticipated “new normal”?

The efforts made to contain and reduce the spread of the coronavirus, such as rolling lockdowns, physical distancing, mask wearing, reduced travel and increased hand washing, has had a significant impact as well on controlling the spread of the seasonal flu and common cold seasons.

Many of the COVID-19 protocols for manufacturing, food processing plants, construction sites and others have been focused on increased PPE usage and

enhanced personal hygiene measures. These short-term operating procedures can be relatively quickly adapted or eliminated all together without much effort, based on local public health direction. The challenge remains to be seen as it relates to permanent and large-scale initiatives that organizations invested in to ensure compliance and protect employees during the early stages of the pandemic, when limited knowledge was available regarding virus transmission.

Employee health and safety will remain at the forefront for many industries and employers. Not only as a part of employee retention programs and demonstrating the organization’s social responsibility commitments, but also as a means of securing cost savings for sick days usages/productivity losses against future respiratory illnesses spreading. The longer-term focus on employee health and safety can be a ributed to larger investments many organizations had made into not only more costly solutions, but also into semi-permanent/permanent

The most visible long-term changes to supporting employee health and safety has been the addition of physical barriers in manufacturing and assembly plants. Similar to clear barriers/shields, now common place in retail stores, banks and restaurants.

remedies, such as physical barriers and improved HVAC systems.

The most visible long-term changes to supporting employee health and safety has been the addition of physical barriers in manufacturing and assembly plants. These are similar to the clear barriers/ shields that have become common place in retail stores, banks and restaurants.

This physical barrier has been vital to protecting employees in high-risk and close-quarters operations to aid in maintaining space between employees when the recommended six-feet distance is not possible. In those facilities whereby, employees must remain working on site.

There has been an increase in requests for installation of touch-free fixtures and touch-free appliances. Some of these touch-free items have been around for years, such as touch-free plumbing products like paper towel and soap dispensers, faucets, toilets and electric hand-dryers, which offer not only protection against cross contamination and transition between users, but also offer cost saving benefits through reduced usage.

The more recent addition to the touchfree industry has been voice/motion-activated smart lighting solutions, which offer a hands-free option for maintaining a safely lit work environment. Once either of these solutions are installed, it is highly unlikely of their removal and will remain to be used well beyond the duration of the pandemic.

Another tread in the hands-free movement has been use of foot-activated appliances or fixture, which, although not touchless, keeps a user’s hands from possibly transferring viruses from the appliance to their face. Commonly used in garbage cans, the shi to appliances such as foot-activated water coolers, coffee dispensers and door pulls have taken off due to the fears of transmission risk. Once staff return to working at facilities, these too will likely remain as a staple, given their higher cost compared to their traditional counterparts or to the semi-permanent installation of the door

pull systems.

A far less visible and much higher priced solution used in high occupant dense or dusty work environments are enhanced HVAC systems. This can be as simple as replacing existing air filters with the highest minimum efficiency reporting value available, or using HEPA filters, which can capture air-borne contaminant as it filters the air through the heating or cooling system.

As part of the many provinces and territories re-opening strategy, guidelines have been shared regarding HVAC systems, including increasing ventilation throughout a facility, either through mechanical methods, such as fans, or encouraging natural ventilation, such as opening doors or windows.

Finally, maintain pressurization in public areas compared to private areas, since these are centres for breeding infection due to their high traffic nature, such as hallways, elevators and corridors. The enhancements made to the HVAC systems are generally on the higher end due to their complexity and scope of possible physical changes made to the physical building, which lends itself to becoming a permanent improvement made to keeping employees healthy and safe.

Each organization is obligated to maintain a standard of employee health and safety, but never has it been so profound as now. During challenges, businesses evolve to adapt and overcome the current difficulties, and would revert to the previous methods of operating once the threat is no longer there. However, with the duration and global implications of COVID-19, impacts have become memorialized beyond the present and will change how businesses approach employee health and safety for years to come. MRO

Mariete F. Pacheco has over 15 years of procurement and supply chain management experience across a variety of industries including industrial, construction, retail and more.

Coming across three cases where pre-planning, the right tools, and the right processes, saves both time and money when undertaking the maintenance and rebuild of machinery.

BY DOUGLAS MARTIN

A user removed a large winch assembly and replaced it with their spare. The assembly that was removed was scheduled into the future for upgrade and rebuild. There was no timeline for the start of the rebuild and as it turns out, the assembly sat in the “as removed” condition for 18 months (about one and a half years) exposed to the elements.

When the job started, it had a strict deadline, so any delays were of concern. The assembly was delivered to the shop. For the rebuild, it was discovered that the bearings had suffered from moisture corrosion to the point that they needed to be replaced. Fortunately, there was stock available for the bearings so replacing the bearings did not delay the job, however, the $20,000-cost was an unnecessary dent in the project budget.

The expected bearing life for this machine was exceptionally long and the used life of the bearings was a small fraction of their design life. The loss of these bearings was wasteful. Had the bearings been cleaned and protected at the time of dis-assembly, they would have easily avoided the damage. The cost of paying for a full day of one millwright’s time to clean and refill with fresh grease and shrink wrap the housing is a fraction of the replacement cost of the bearings.

In this case there is a shop that routinely rebuilds large rolls with bearing journals of 480 millimetre (19”) diameter. The bearing is installed onto the sha with the use of a withdrawal sleeve. The way the withdrawal sleeve works is that it is a tapered sleeve that is pushed under the bearing using a hydraulic nut. In this arrangement, there are two sliding surfaces, one on the bore of the sleeve and one on the outer diameter (OD) of the sleeve, as the

sleeve is jammed under the bearing. To assist with the installation, the withdrawal sleeve has hydraulic channels machined into it such that a high-pressure oil film is injected into the sleeve bore/sha gap and the sleeve OD bearing interface. This reduces the friction and protects the sliding surfaces from metal-to-metal contact that could cause surface damage.

This does require the use of two high pressure oil injectors and the associated hardware to hook up to the sleeve and create the film. These injectors only cost about each, so they are an additional expense for the shop, but these tools last for a long time.

So, in this case, the installer is not using the hydraulic injectors, they are using the brute force of the hydraulic nut to push the sleeve into place. The result is that the sleeve is galling the sha as no separating film has been generated. As such, the shop is reporting that they must fix the bearing journal a er each install/removal cycle.

At this point, the cost to rework the bearing journal is unknown. However, the cost of this rework is being charged to the user instead of the shop, who is the cause of the problem.

In this case the application is a coupling using a tapered sleeve shrunk onto a sha . The first step is to heat the sleeve to fit it onto the sha , as there is an interference fit between the sleeve bore and the sha outer diameter. The second step is to mount the taper bored hub onto this mounted sleeve.

The method suggested for heating the sleeve is in an oil bath to ensure the sleeve is evenly heated. The contractor had suggested that they could heat the sleeve with a torch. This is a much simpler method, however, its downside is

that it first heats only the surface material. With this, any temperature measurements may indicate that the sleeve is the correct temperature, but this would reflect the surface temperature of the sleeve as opposed to the temperature of the bulk of the sleeve.

If an a empt is made to slide the sleeve onto the sha before it is properly heated (and expanded), then the likelihood is that the sleeve jamming on the sha is only halfway mounted. Once this happens, there is no way out without damaging the material, either by localized heating to get the sleeve to grow, or by galling if brute force is used to pull the sleeve back off.

Using a torch to directly heat a sleeve or

bearing is never recommended as there is a lack of control of even heating. Any “hotspot” created could cause a metallurgical change in the material and cause distortion or other damage. This may have been the case with the first a empt to install the sleeve, as the sleeve was found to be out of round. The probable cause would have been uneven heating.

The sleeve ge ing stuck is what happened in the first a empt, which resulted in a damaged sleeve and journal. The complete coupling was sent out for repair at the factory at a cost of $80,000. When returned, the installer was required to build a proper oil bath. When it came to the time to install, the wait for the oil bath added two days to construct the

oil bath and then one day to get the oil to temperature. However, the benefit was that the time it took the sleeve to be installed (tank to final position) was less than a minute and it was completed without a hitch.

The task of installing the sleeve was a critical step that if done wrong would have added a significant amount of time. When the first a empt to install the sleeve went wrong, it took eight weeks (about two months) until the replacement sleeve was ready to be installed. So, the extra three days to properly get the sleeve heated was a small cost, and, in fact, had the oil bath been constructed during the repair of the coupling, then the two-day wait would not have occurred.

It is o en the case that, in the scope of a job, preparation for the job takes longer than the job itself. The critical part of the job o en has associated risks both in terms of safety and success of the installation (without any damaged components or rework due to errors). Preparation that includes the right tools, the right preventative actions and the right work plans may be expensive, but in the scope of the potential for failure or damage, the costs of preparation are minimal. MRO

Douglas Martin is a heavy-duty machinery engineer based in Vancouver. He specializes in the design of rotating equipment, failure analysis, and lubrication. Reach him by email at mro. whats.up.doug@gmail.com.

Over the last few years, a new term has become more popular in the world of maintenance and reliability and its asset management.

BY CLIFF WILLIAMS

Oen, it is difficult to tell the difference between asset management and maintenance and reliability, as they o en seem interchangeable. This begs the questions, “are they the same things, what is asset management?”

To answer these questions we need to understand where the term “asset management” came from and what it entails. Asset management is not a new term, but its context has changed. An internet search 10 years ago would

show links to financial institutions or plans. Today, those still show up, but spread amongst them are links to organizations or articles about “effectively manage existing and new assets to deliver value.” When adding “holistic” or “physical” to the search, the number of financial links drop off dramatically. So why the change?

The events that prompted the change in context, started in the U.K. during the 1980s and 90s. It was when the U.K. government privatized industries (steel, utilities, infrastructure and railways) that had previously been government owned. By the late 1990s into the early 2000s, problems started to occur within the utilities and infrastructure in the U.K. These problems were related to the failure of assets. It was recognized that this could not continue, and there appeared to be a systemic problem related to how the assets were being managed. Asset related failures ultimately led to the issue of Publicly Accessible Specification for the optimal management of physical assets or PAS55 in 2004 – issued by the Institute for Asset Manage-

ment and the British Standard Institute, which was revised in 2008. Numerous other countries were involved in the 2008 revisions, which led to the realization that no real international standard for asset management existed.

Therefore, the idea of an ISO standard was formulated and a technical committee set up in 2010 to start the process of developing an ISO standard. It took until 2014 and over 30 countries as creators or observers for it to come to fruition. The standard, published in early 2014, was made up of three parts.

-ISO 55000 Asset management –Overview, principles and terminology

-ISO 55001 Asset management –Management System - Requirements

-ISO 55002 Asset management –Management systems - Guidelines on the application of ISO 55001

In 2018, there was a revision and version ISO 55002 – 2018 now exists.

It was the publication of the ISO Standard that prompted changing context, and the introduction of asset management into the world of maintenance and reliability. Many ISO development

commi ee members lived or had lived in the maintenance and reliability space. therefore, it was natural for them to introduce the new standard to their audience. The response varied around the world. In the U.K. and Australia, the countries that had adapted the PAS 55 philosophies the most, viewed it as the next logical step in the asset management process.

In North America, which had a limited uptake of PAS55 or its philosophies, there was confusion. Some organizations presented it as the next step in maintenance and reliability, some substituted maintenance and reliability with the term asset management, and some embraced the philosophies and approaches described in ISO 55000.

The situation in Canada has certainly swung towards the ISO 55000 end of the spectrum. Governments and bodies such as the Federation of Canadian Municipalities have identified this approach as being the desired philosophy for asset management. In 2017, the Government of Ontario enacted O REG 588/17 Asset Management Planning for Municipal Infrastructure, which follows many of the principles presented in ISO 55000 and requires municipalities to develop asset management plans (AMP).

Asset - something that has potential or actual value to an organization. (ISO 55000).

You can see this does not restrict the definition to tangible assets, such as equipment and tools, but includes intangible assets such as reputation, intellectual property, knowledge, systems, and even human assets. This is where we realize that maintenance and reliability is not synonymous with asset management. Maintenance and reliability are an important part of asset management, but there is more, as becomes apparent when we see the definition of asset management.

Asset management – the co-ordinated activity of an organization to realize value from assets (ISO 55000).

The key takeaway is that it implies all activities required to realize value (goal se ing, finance, personnel, procurement, design, marketing, administration hiring, systems), and maintenance and operations. Therefore, asset management is an organization’s operating philosophy.

To understand asset management better, we need to see it is built upon four fundamentals as per ISO 55000.

Value - The reason that assets exist is in order to provide the maximum value to the organization and its stakeholders.

This can only be achieved by ensuring that what you are trying to achieve, with your asset management goals and objectives, clearly support your organizational objectives. To do this there will need to be a clear definition of value in response to stakeholder needs, and the whole lifecycle management approach is used to derive value.

Alignment - This ensures consistency of purpose and direction from the organizational objectives, through the asset management policy to the activities, plans, and decision making, in enabling the achievement of the objectives.

This requires the integration of the various functions or departments of the organization into the decision-making processes that are driven by a risk-based, informed approach in support of the organizational goals.

Leadership - Leadership and workplace culture are determinants of the realization of value (ISO 55000).

This requires that the leadership create a culture where employees are educated, empowered, and engaged with the skills knowledge and information to carry out their clearly defined roles and responsibilities.

Assurance - This is how the organization can demonstrate effective governance by ensuring the assets are fit for purpose and will fulfill the required purpose.

This requires that processes exist to monitor the capability of the assets to meet purpose and measure that performance with a view to continual improvement. This is done in the context of demonstrating the capabilities of the asset management activities in delivering value as described in the organizational objectives. MRO

Cliff Williams is author of the bestselling maintenance novel ‘People – A Reliability Success Story.’ He is a maintenance and asset management educator, and a keynote speaker at conferences around the world, who believes success is achieved through people. Currently Cliff shares his knowledge and experience as an advisor on maintenance and reliability for people and processes, and asset management with TMS asset management and is a facilitator for PEMAC’s Asset Management Program.

Flir SV87-KIT is a new automated vibration and temperature condition monitoring device.

Flir SV87-KIT includes four wireless SV87 vibration and temperature remote sensors, anda wireless Flir GW65 Gatewayfor 24/7 continuous monitoring of asset vibration and temperature data.

The data can be transferred to any tablet, smartphone or computer via a Wi-Fi network, and allows the user to visualize trends and receive alerts via an app or email in the event of exceeding a threshold. Configuration of thresholds can be set manually for customized applications or based on common ISO standards.

www.flir.com

Ri al Systems Ltd. TS IT

Pro enclosures are designed for large scale deployments, and high-density cooling and cabling solutions.

TS IT Pro ships with a perforated single front door and split rear doors keyed alike, leveling feet, casters, roof with brush baffle cable access channels, and vertical cable walls with dual PDU mountings.

Features include shock pallet packaging for shipping, full height rear accessory channels, quick-release door handles, removable doors and increased cable openings.

www.ri al.us

EXAIR VariBlast precision safety air gun with nano super air nozzle has an engineered variable flow trigger to produce variable force upon a target.

Built in the 1/4 NPT gun is a full finger trigger and a hanger loop. It requires 8.3 SCFM and is made of type 316SS or PEEK thermoplastic.

Available with a standard 12-inch or 20" extension, which can also be outfi ed with an impact resistant polycarbonate chip shield. The air gun body is made of glass reinforced nylon and produces 75 dBA noise level.

www.exair.com

The Endress+Hauser iTEMP TMT142B new generation smart temperature transmitter, delivers measurements, wireless communication via Bluetooth, and user-friendly operation, packaged in a single-chamber field housing.

The transmi er features a secure Bluetooth interface that enables users to wirelessly visualize measured values, NAMUR NE 017 diagnostic information and perform configuration tasks.

The backlit display provides readability under all environmental conditions. Diagnostic messages are highlighted when the normally white background turns red.

The configurable single-channel device transmits converted signals from resistance sensors, thermocouples, resistances and voltage transmi ers via the four to 20 mA signal or the HART 7 communication. www.us.endress.com

Atkore has expanded its one-piece TECK cable connectors to provide protection in indoor and outdoor applications, and available in two versions.

The TECK cable connector is made from Type 304 stainless steel. Rated to IP65 and NEMA 4 protection, the they utilize a neoprene bushing that provides pull out and sealing protection. They form a watertight seal around the cable and at the enclosure entry, with no assembly or disassembly required.

The calbond PVC coated version is made from aluminum. Both TECK cable connectors are available in 1⁄2” to 4” hub sizes. www.calbrite.com

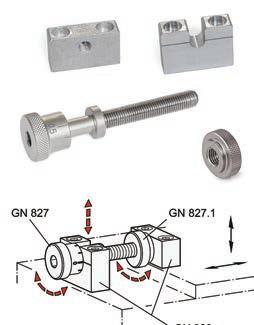

Winco GN 827 stainless-steel adjusting screw is intended for use with bearing blocks GN 828. The mechanisms are moved into or out of position using an adjusting screw with rotating knob and hexagon socket fi ed with a scale with 0.1 millimetre graduations.

The stainless-steel adjusting screws are available in a variety of thread diameters and lengths, and can be fastened to the production machine in combination with bearing blocks GN 828.

Once the right se ing has been found, the adjusting screw can be locked in place with a stainless-steel knurled nut GN 827.1.

They are available with a female thread matching the adjusting screw, or a receiving groove that provides axial support for the adjusting screw. Also, the receiving groove has a laser-engraved reference line for adjusting the device. www.jwwinco.com

JW Winco added antibacterial protection to a series of standard parts, grouped into the sanline product family. The handling elements: bu ons, hand levers, U-handles and wing nuts, make use of two different principles. In the case of plastics, special additives with silver ions are mixed in, while metal parts are given powder coatings based on zinc molybdate.

Both principles destroy the cell walls of the microorganisms, causing them to die. Zinc molybdate additives are of particular interest. With the help of moisture in the air, an acidic film with a pH of about 4.5 forms on the surfaces, similar to the one on human skin. The acid protons penetrate the cell membrane of the bacteria and destroys them.

www.jwwinco.com

Rinnai’s new building management system (BMS) gateway provides a so ware systemused to remotely control and monitor Rinnai commercial tankless water heaters.

BMS gateway allows businesses to remotely turn tankless water heaters on or off, adjust water temperature, monitor flow rates and operation hours. The touchscreen user interface allows up to 15 view-only parameters, such as water flow rates, combustion cycles, operation hours and error code history.